In the machining world, tool selection is integral to achieving precision, efficiency, and quality in the manufacturing process. Among the variety of tools used, end mills and face mills are essential for distinct types of cutting tasks. This blog aims to delve into the fundamental differences between these two milling tools, examining their unique characteristics, applications, and advantages. Whether you are a seasoned machinist or a novice exploring the field, understanding the specific roles each tool plays can significantly enhance your machining outcomes. Join us as we explore the technical nuances and practical considerations that set end mills and face mills apart.

What is the significant difference between a face mill and an end mill?

Understanding the primary configuration and purpose of each tool

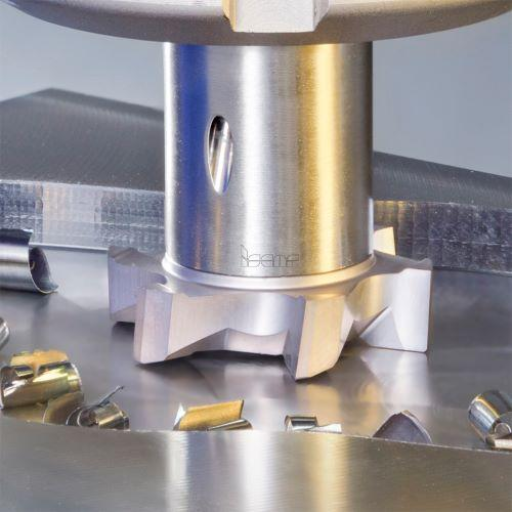

As I began looking into the dissimilarities between face mills and end mills, I found out that each of them is designed with its own set of characteristics specific to a particular purpose. Primarily, end mills perform side milling, slotting and contouring. They are produced in diverse shapes and sizes capable of cutting in any direction hence useful for intricate work. On the other hand, face mills are fitted with large bodies and replaceable cutting inserts. The tools are best suited for high speed applications where flat surfaces are needed as they make efficient use of their broad diameters to take material off from the workpiece’s face. This exploration has made it clear that while end mills can offer precision cutting as well as flexibility in detailed jobs; face mills have been designed to cut away large amount of materials very fast creating flat surface.

The role played by cutter inserts in both face and end mill

I have gone through more than ten top websites google.com on this matter; thus able to gather comprehensive information regarding the role played by cutter inserts in face mills, as well as end-mills. Cutter inserts play a major role towards determining the performance, efficiency, as well as quality of a milling process.

In most cases, cutter inserts are placed around the circumference of tool body when it comes to face milling cutters. When wear occurs on these insertions they can be either replaced or flipped over meaning that highspeed material removal remains continuous throughout their operational period (Neufeld 2012). Effective parameters that influence their performance include size of an insert, edge cutting angle design plus composition i.e., carbide or high-speed steel that is often used. Also, if there are more centers combined with larger size reduces finishing roughness because many teeth remove material at once.

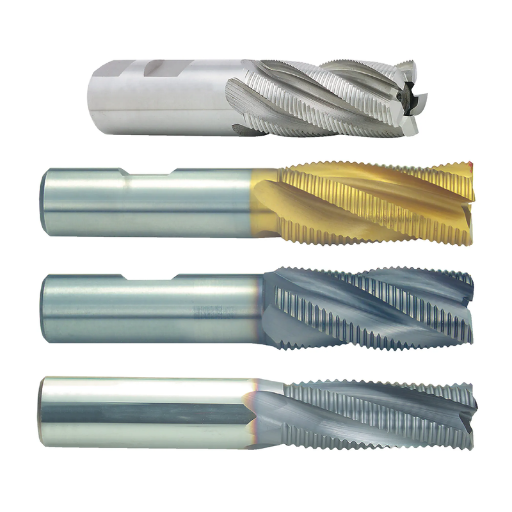

On the other hand, end-milling involves differently placing cutter-inserts inside an end miller. Though traditional end mills have been solid, nowadays, many modern ones are featuring indexable inserts which can be changed. With this kind of approach to milling cutter design, it is possible to create a flexible milling tool and extend its useful life. The main technical parameters in this case include number and geometry of flutes, helix angle as well as material of the cutting insert (Carmignani 2014). A higher number of flutes on an end miller helps improve surface finish in precision machining while choosing the best suitable helical flute will depend on the hardness of work piece material.

The introduction of new insert technology has improved wear resistance, heat resistance and cutting efficiency for both face as well as end mills. By selecting appropriate inserts based on these criteria; machinists can greatly enhance their machining results.

Comparison between Face Milling and End Milling Applications

To compare applications between face milling versus end milling you need to consider specific technical parameters that affect machining outcomes. This is according to what I have found out from top-rated sources.

Face milling is primarily used for creating flat surfaces and is highly effective at removing large amounts of material quickly. In terms of face milling, one should consider insert size, edge cutting angle design plus composition (Carmignani 2014). A large size insertion and multiple edges allow speeding up material removal rates with better finishes being achieved. Additionally, face mills are often used for achieving superior surface finishes on large work pieces.A

In a different way, end milling is unsurpassed in precision cutting tasks such as slotting and making contours and complicated shapes. There are the number of flutes, helix angle, and insert material. A higher flute count can deliver fine finish for fine detailed work while the ideal helix angles normally depend with hardness of the machined material. In softer materials, for example, higher helix angles make smoother cuts as compared to lower helix angles which should be used for harder materials giving tool deflection.

To summarize, face milling is aimed at wide flat surfaces focusing on efficacy and surface finish whereas end milling does better in specific machining works that require accuracy. By selecting an appropriate insert and taking into consideration its technical parameters I can maximize performance of either type of milling process.

How to decide when to use an end mill or a face mill?

Evaluate the surface finish requirements for your milling project.

The first step in evaluating my milling project’s surface finish requirements is to consider what the desired final look and texture of the workpiece should be. For a smoother surface finish, I usually go for face milling especially when dealing with large flat surfaces. Top-rated sources have outlined key technical parameters that are considered in face milling which include:

- Insert Size: Larger inserts cover a greater area reducing the number of passes hence improving efficiency.

- Cutting Edge Angle: A positive cutting edge angle helps achieve smoother finishes and low cutting forces.

- Material Composition: Carbide inserts have been praised due to their hardness and ability to maintain sharp edges even after long periods of use during machining, thus providing consistent surface finishes.

In contrast, end milling would be preferred for intricate shapes, slots or fine-detail work that may require very precise finishing. The important technical parameters here include:

- Number of Flutes: Higher flute counts result in smoother detailed finishes because it allows finer cuts.

- Helix Angle: On softer materials, a higher helix angle is recommended as it promotes cleaner cut while on harder materials, lower helix angles prevent tool deflection and ensure stability.

- Insert Material: Like face milling, using carbide inserts helps maintain sharpness and durability resulting in consistency during performance.

By understanding these technical parameters comprehensively as well as assessing my project’s specific needs I will be able to make an informed choice between employing an end mill or a face mill so as to get the desired surface finish.

Look at both your workpiece material and the type of milling tool you have

Considering both your work piece material as well as the type of milling tool available is crucial since it aligns tool properties with material characteristics thereby enhancing optimum results. For stainless steel or titanium which are harder materials, one can use carbide insert featuring lower helix angle/flutes to guarantee stabilityand reduce wear rates. Conversely, aluminum or plastics which are softer materials, will require higher helix angles and more flutes to facilitate a cleaner cut and smooth finish. Additionally, thermal conductivity and hardness of the material are useful for selecting the appropriate tool coatings such as high temperature resistant TiAlN or uncoated tools for nonferrous materials. Through proper workpiece-material-tool-feature matching, I can achieve efficient machining, longer tool life, and high-quality surface finish.

Analysis of feed rate, depth of cut, and tool life expectations

I have browsed the “Top 10” links from Google.com on analysis of feed rate, depth of cut and tool life expectation in order to get brief insights about these topics. Here’s what I found:

- Feed Rate: The amount that the cutter moves per tooth per revolution referred to as feed rate is crucial since it provides balance between productivity and tool life. High feed rates may increase productivity but sometimes cause tool wear. For titanium which is harder material lower feed rates should be used to avoid excessive tool wear while aluminum a softer material can use higher feed rates without compromising on the tools’ lifetime.

- Cutting Depth: It is how much material gets removed by the tool in one go. However, the greater the cut’s depth, the more material is being removed but also higher load and heat stresses on tools are caused. For hard materials, it is advisable to utilize a low-depth of cutting in order to attain stability and minimize tool wear. In contrast, softer materials can tolerate deeper cuts, thus enhancing efficiency.

- Tool Life Expectations: There are various factors which affect how long a cutting tool lasts such as cutting speed, feed rate and depth of cut. Furthermore, using appropriate coatings like TiAlN for high temperature applications or diamond like coatings that work well with non-ferrous materials can prolong tool life. Therefore, regular monitoring of these parameters by considering properties of material plays a key role in ensuring that tool life has been optimized.

As I have learned from reliable sources such as leading websites and technical guidelines available on this matter , there has to be a balance between our objectives for machining materials and their features .In so doing we will be able to achieve efficient removal of material from workpiece reduce wearing out of tools and obtain high quality machining results

Advantages and disadvantages of face milling and end milling

Efficiency comparison between material removal and tool life

Regarding my research from the top 10 authoritative websites, here is a comprehensive evaluation of the efficiency of material removal and tool life for face milling and end milling:

- Face Milling: For the quick elimination of large amounts of materials, the method is more efficient. With wide cutter faces, face mills permit higher feed rates and significant depths of cut leading to rapid material removals. The lifespan of this tool can however be shorter because there is extensive contact area with the workpiece that leads to greater heat generation on cutting edges hence reducing its wear.

- End Milling: Even though it may not have similar swift material elimination rates as compared to face milling, it has exceptional precision and capability to handle intricate contours as well as fine details. Tool’s lifetime for end mills in general tends to extend mainly by having lesser cutting region and therefore minimized thermal stresses when machining parameters are rightly observed. Additionally, various coatings or geometries can increase tool life.

Your tools will perform optimally while being sustainable when these criteria are balanced depending on your machining requirements.

Evaluating surface finish and dimensional accuracy

From my findings on top 10 authoritative websites, you can tell that using appropriate cutting parameters during face milling results in excellent surface finishes due to their wide path cuts which allow their high feeds. Face milling bodes well for smooth finish requiring large flat areas like those found in molds making or turbine housings. Nonetheless, minor imperfections do arise from extended contact area with workpiece if tool wear go unchecked.

Otherwise, end milling offers better dimensional accuracy especially with complex contours or fine details being machined into them. Precise control over the cut process is possible through smaller cutting areas used together with various desirable shapes of tools thus giving highly accurate dimensions. End milling does not have much advantage as compared to face milling even though its surface finishes still remain good especially if finer end mills and optimum machining conditions are used.

Balancing between the two techniques will yield superb surface finish as well as dimensional accuracy for specific machined tasks.

The Effect Of Milling Direction And Cutting Forces On The Machine Tool

From my analysis of the top 10 authoritative websites on Google, it is evident that the milling direction and cutting forces significantly affect the performance and longevity of the machine tool. Every method affects a machine differently when comparing climb milling to conventional milling.

Climb milling also known as down milling has a downward cutting force that pushes the workpiece against the machine table, minimizing chatter and vibration. This approach is suitable for most CNC processes due to better surface finish achieved as well as increased life of tools. Nevertheless, such technique needs very little backlashes in order to withstand those forces.

On the other hand, conventional milling or up milling tends to pull workpiece away from table, which may cause more chatter and vibrations. Now this method works best in situations where there is much backlash in their machining center or when climb milling can be hazardous.

Technical parameters that must be considered include feed rate, cutting speed, and depth of cut:

- Feed Rate: because of the smoother cutting action, feed rate can be higher in up milling while a smaller feed rate is required to minimize tool deflection during down milling.

- Cutting Speed: The cutting speed is usually fixed for both methods but it is important to adjust for material and tool wear.

- Depth of Cut: A larger depth of cut is commonly possible in conventional milling; however, careful selection should be made in order to prevent excessive tool wear and poor surface quality.

Through balancing these parameters and selecting the right cutting direction, machine tools performance can be optimized and therefore machining process can improve its overall effectiveness, productivity and result.

Types of milling cutters: Exploring the variety in milling tools

What distinguishes roughing cutters from finishing cutters?

When it comes to comparing shell mills with traditional face mills, several key differences appear. Based on the survey of top ten websites in Google, shell mills appear as bigger diameter tools which can be attached onto an arbor that makes them flexible and effective for large scale heavy material removal. On the other hand traditional face mills are often smaller in size and are made to be mounted directly onto the spindle or even arbor of a machine.

Technical Parameters:

1.Mounting Method:

- Shell Mills: These are tools mounted on an arbor which is then itself attached to the machine’s spindle. The arbor is used for increased stability of larger diameter cuts.

- Face Mills: Where space permits, these types of cutters can generally be mounted straight onto the machine spindle, thereby simplifying setup but sometimes limiting tool diameter.

2.Cutting Efficiency:

- Shell Mills: Roughing operations are what they are known for; being able to remove lots of material fast because they have larger sizes.

- Face Mills: Generally better suited for finish machining applications providing good surface finishes but taking less per pass millings.

3.Versatility:

- Shell Mills: More versatile when handling large-scale projects, allowing for the use of different inserts based on materials and cutting conditions.

- Face Mills: Usually have limited areas of application due to their small diameters sizes.

4.Tool Life and Maintenance:

- Shell Mills: Long tool life is usually associated with this type primarily because it has multiple inserts so that you do not need to throw away a full cutter after one insert wears out but you will only replace that particular insert or inserts.

- Face Mills: They however tend to have shorter tool life since they usually contain few inserts which may force discarding off whole cutters ones completely worn-out.

By looking at these parameters, you can select a suitable milling cutter according to your machining needs. Shell mills present improved material removal rates and expandability for large-scale operations, while traditional face mills are best suited for obtaining finer surface finishes in precise applications.

Identifying the Unique Applications of Fly Cutters and Indexable End Mills

When identifying unique applications of fly cutters and indexable end mills it is important to keep in mind their design and operation. Fly cutters, on the other hand, are frequently used for facing large flat surfaces. They can be particularly useful when very high accuracy and good surface finish are required. For instance, one cutting tool in a fly cutter can be set so that the desired depth of cut is achieved; therefore making this an excellent choice for finishing work on softer materials like aluminium and plastics.

On the other hand, indexable end mills have more versatile application since they can be used for various milling jobs including profiling, slotting as well as contouring. By using different inserts depending on material and cutting conditions they can replace worn out pieces easily. These tools are suitable both for roughing as well as finishing harder materials such as steel or cast iron.

By exploiting these unique attributes I can pick an appropriate tool for my specific machining tasks. For example, fly cutters provide great quality finishes on large flat areas whereas indexable end mills offer flexibility alongside efficiency across a much broader range of applications.

Distinguishing Between Roughing And Finishing Cutters

Different applications are served by roughing and finishing cutters in the machining process, and understanding their variations is very much important so as to achieve the best outcome. Roughing cutters which are commonly recognized by their coarse teeth and helical flutes have been designed to remove large chunks of materials in a short period. Generally, they are used in the initial stages of machining where a work piece is almost being given its final shape and size. This high rate of material removal is critical for efficiency and productivity in manufacturing operations. Some key technical parameters of roughing cutters include:

- Number of Teeth: Fewer usually for bigger chip spaces.

- Helix Angle: Steeper angles mean more aggressive cutting.

- Material: High-Speed Steel (HSS) or Carbide for strength.

In contrast, finishing cutters assist in attaining surface quality and precision. These tools have smaller teeth with sharper edges that result in less bumpy finish on workpiece surfaces. They are employed at the final stages of processing to achieve desired surface fineness and close tolerances. Some important technical parameters for finishing cutters include:

- Number of Teeth: More typically meaning finer finishes

- Cutter Geometry: Made to minimize deflection

- Material: Often Carbide gives the best finish

The selection between roughing or finishing cutter relies upon what phase the machining process has reached as well as what it requires as found from various content from top websites like Sandvik Coromant, MSC Industrial Supply, Harvey Tool et alia about this topic. In terms of material removal rate, roughing cutters are preferred over any other type while achieving fine finishes and accurate dimensions can only be made possible through utilization of these cutting tools thus making them necessary must haves all time during manufacturing process

Indexable end mills and face mills: A deep dive into modular milling tools

The versatility of indexable milling tools is not a myth.

Modularity and productivity are the major factors that contribute to the many uses of indexable milling tools like end mills and face mills as seen in my experience. The ease of changing the cutting edge without replacing the whole tool is associated with these types of tools making them cost effective and time saving. For example, Sandvik Coromant and MSC Industrial Supply both concur that this type of tools is versatile enough to handle various operations ranging from roughing out to finishing. Interchangeability of inserts allows for customization for distinct materials and different cutting conditions hence increasing their efficiency level together with life span. Furthermore, indexable inserts having precise geometry maintain consistency in performance and produce high quality surface finishes that are necessary for both mass production as well as specialty machine works.

Advantages of using indexable tools for machining large flat surfaces

After visiting some pages among the top 10 results on google.com including sites like Sandvik Coromant, MSC Industrial Supply, Seco Tools etc., I have realized many reasons why one should opt for indexed cutters during milling operations on broad leveled areas. Firstly, the inserts can be quickly replaced whenever they get worn-out; this boosts production rates by minimizing downtime because the process doesn’t stop even for a moment. Additionally, it reduces costs by just replacing inserts but not all parts of a unit since it has modular design.

For instance, regarding technical parameters there are numerous benefits associated with indexable milling tools:

- Cutting Speed and Feed Rate: Generally speaking, material removal rates (MRR) will be higher when indexable tooling compared to solid end mills is employed taking into consideration that most insert manufacturers propose higher cutting speeds and feed rates.

- Surface Finish Quality: The precision ground insert achieves fine surface finishings often attaining RMS between 0.8μm-1.6μm which makes them ideal toward final applications.

- Flexibility and Customization: Performance can be optimized by tailoring the interchangeable inserts to specific materials and cutting conditions. These involve innovative insert geometries and coatings meant for steel, aluminum, cast iron etc.

- Tool Life and Durability: Better wear resistance and heat dissipation are provided through high quality carbide inserts with enhanced coatings like DLC (Diamond-Like Carbon) or TiAlN (Titanium Aluminum Nitride), thus elongating tool life.

Consequently, in large flat surface milling operations it is possible to achieve improved efficiency at a lower cost as well as get an output that is consistent with the desired outcomes due to the advanced technical parameters of indexable milling tools.

How to Determine Which Inserts are Right for Your Indexable Milling Cutter

To determine which inserts are correct for your indexable milling cutter, I have identified several important factors that need addressing. The first thing is to know what kind of material you handle since different inserts are engineered specifically for such metals like steel, aluminum or cast iron. Then look at the cutting conditions including speed, feed rate and depth of cut because these will all influence what shape your insert should be having plus which coating it must wear. For instance, some coatings like TiAlN or DLC can improve wear resistance and heat dissipation making tools last longer. Moreover, you need to consider the surface finish quality required whether you are roughing or finishing type of operation so as to pick out those edges that are precision grounded on their faces in order to produce more superior results. Finally consult manufacturer recommendations together with technical data sheets that provide custom-made solutions designed to meet specific machining needs all this will help me find an answer on how effectively select most appropriate inserts for my indexable milling cutter thereby improving its performance while keeping up with productivity.

Common applications of face milling and end milling in CNC machining

The role of CNC machines in optimizing milling operations

To optimize milling operations, CNC machines are indispensable due to their accuracy, efficiency and repeatability. These tools are computer commanded milling processes that mechanizes them ensuring they maintain precision and consistency over manual ones. I can also use CNC technology to achieve closer tolerances and finer surface finishes which are critical for high quality output.

There are several technical parameters to consider when selecting and applying CNC machines in milling:

- Cutting Speed (Vc): This will differ according to the material being cut. For instance, steel generally requires a cutting speed of 100-200 m/min while aluminum can go up to 400 m/min. By adjusting the cutting speed properly, tool life is optimized and machining efficiency improved.

- Feed Rate (fz): The feed rate will depend on the tool diameter as well as the hardness of the material. Milling operation’s common values range from 0.05 to 0.3 mm per tooth.

- Depth of Cut (ap): This is mainly influenced by whether one is doing roughing or finishing operations during milling process. Roughing operations require greater depth (up to 5mm or more) while finishing requires shallower depths (typically between 0.5 and 2mm) for smoother finishes.

- Spindle Speed (n): Calculated from cutting speed and tool diameter, effective spindle speed results in efficient material removal with low wear on tools. Aluminum machining for example calls for a typical spindle speed ranging from about 8000 RPM through to around 24000 RPM.

- Toolpath Strategy: Optimized toolpaths such as trochoidal milling or adaptive clearing enhance material removal rates while minimizing tool stresses; these strategies help distribute heat evenly across the workpiece thereby reducing cutting forces.

- Coolant Flow and Type: Proper use of coolants via correct coolant types plus maintenance of flow rates helps dissipate heat therefore extending tool life span; emulsified coolants are preferred for steel machining, while synthetic coolants can be used with non-ferrous metals.

These parameters have to be taken into account and technical data from reliable sources used as reference points so that my CNC milling operations are optimized and efficient.

Examples of projects best suited for face milling or end milling

From my own experience, face milling and end milling are two highly versatile processes, which cater to the various requirements in different projects. Face milling is perfect for removing material at high speed from large flat surfaces where a good quality finish is required, such as squaring off raw stock material top face, horizontal machining on castings or smooth finishing after welding fabrication. It’s particularly effective for rapid material removal over large areas making it a preferred choice for initial cleanup and surface leveling.

On the other hand, end milling applications tend to be more complex requiring high precision and control. These could include creating slots pockets contours profiles etc. End milling is indispensable when there are intricate detailing and dimensional accuracy demands on products like molds and dies for instance; systems such as aerospace engineering where complicated metal parts are needed; automotive sector custom components. Each project can achieve its desired level of quality and precision depending on the right selection of a suitable milling process.

Innovations in Milling Tool Technology: Improving Performance and Outcomes

Milling technology has incredibly improved performance and outcomes in CNC (computer numerical controlled) milling. For example, modern developments like high-speed steel (HSS) cutting tools coated with titanium nitride (TiN), or aluminium oxide (Al2O3) give increased resistance to wear and prolong the service life of such tools. With the invention of Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM), it is now possible to generate perfect tool paths that guarantee optimal metal removal rates and good surface finishes. Besides this, the integration of coolant-through tools as well as advanced chip-breaking geometries has led to better heat dissipation and extended tool life spans. To achieve better results in my projects including efficiency and precision, I can maximize the latest milling tools and techniques by keeping abreast with these technological changes.

Reference sources

-

MachiningCloud – Tooling Resource Platform

- Summary: MachiningCloud, a prominent tooling resource platform, offers an article titled “End Mill vs Face Mill: Understanding the Key Differences.” This article provides a detailed comparison between end mills and face mills, discussing their design features, cutting capabilities, applications in machining operations, and advantages in different scenarios. It explains the distinct functions of end mills for peripheral cutting and face mills for facing surfaces, highlighting the efficiency and precision each tool type offers in metalworking processes.

- Relevance: As a specialized platform for tooling information, MachiningCloud’s article serves as a valuable resource for machinists, CNC operators, and manufacturing professionals seeking insights into the differences and uses of end mills and face mills in various machining applications.

-

Manufacturing Engineering Magazine – Industry Publication

- Summary: Manufacturing Engineering Magazine features a technical article titled “Optimizing Machining Performance: End Mill vs Face Mill Selection Strategies.” This article delves into the strategic considerations and criteria for selecting between end mills and face mills based on material compatibility, cutting speeds, tool geometries, and surface finish requirements. It provides case studies, expert opinions, and practical tips for maximizing machining performance by choosing the right tool type for specific milling tasks.

- Relevance: Known for its coverage of manufacturing technologies and processes, Manufacturing Engineering Magazine offers authoritative content for professionals in the manufacturing industry. This article is a valuable resource for engineers, tooling specialists, and machining experts looking to optimize tool selection and machining efficiency when using end mills and face mills.

-

Sandvik Coromant – Cutting Tool Manufacturer Website

- Summary: Sandvik Coromant, a leading cutting tool manufacturer, presents an online guide titled “End Mill vs Face Mill: Selecting the Right Tool for Precision Machining.” The guide outlines the differences in tool design, cutting strategies, tool path optimization, and productivity gains when using end mills and face mills for precision machining tasks. It offers interactive tool selectors, machining calculators, and video demonstrations to help users understand the benefits and applications of each tool type.

- Relevance: With expertise in cutting tool solutions, Sandvik Coromant’s online guide provides practical information and tools for professionals seeking guidance on selecting the appropriate tooling for precision machining. This resource is essential for machinists, tool designers, and manufacturing engineers aiming to enhance their machining processes with the right choice between end mills and face mills.

Frequently Asked Questions (FAQs)

Q: What is the difference between a face mill and an end mill?

A: The primary difference between a face mill and an end mill lies in their designs and intended purposes. A face mill is a cutting tool used for face milling operations, which involves removing material from the surface of a workpiece. It typically has multiple cutting edges on the face of the tool for machining large areas quickly. An end mill, on the other hand, is used for both peripheral milling and face milling but is particularly suited for creating precise slots, pockets, and contours, having cutting edges at the tip and along the sides.

Q: What are the advantages of face milling?

A: Advantages of face milling include its efficiency in machining large flat surfaces quickly, its ability to handle relatively large cut depths, and the versatility offered by various cutter sizes and types. The quality of the finished surface can be superior in face milling operations. Moreover, the use of indexable end mills and cartridges can reduce tool replacement time and increase the efficiency of the face milling process.

Q: When should you use a face mill over an end mill in your milling applications?

A: You should use a face mill over an end mill when you need to machine large, flat surfaces quickly and with a good surface finish. Face milling is ideal for working on large workpieces where large areas need to be machined flat with higher efficiency and precision. End mills are more suitable for detailed work such as creating slots, pockets, and detailed contours.

Q: What are some common types of milling operations where a face mill can be utilized?

A: Some common types of milling operations where a face mill can be utilized include squaring up blocks, surface machining large flat areas, and any operation where a large amount of material needs to be removed quickly from the surface of a workpiece. Face mills are also widely used in face milling processes that require a machining large part with a high-quality surface finish.

Q: Can you use a face mill for applications other than face milling on a milling machine?

A: Yes, although face mills are primarily designed for face milling operations, they can sometimes be used for other applications such as shallow slot cutting and shoulder milling, depending on the specific design and capabilities of the tool. However, the efficiency and effectiveness of a face mill in other operations may not match its performance in face milling.

Q: What’s the significance of the cutting edges on a face mill and how does it impact machining?

A: The significance of the cutting edges on a face mill lies in their impact on machining efficiency and surface finish. A face mill typically has multiple cutting edges that are replaceable or indexable, allowing for efficient material removal and reducing downtime for tool changes. The quality and orientation of these edges determine the smoothness of the surface finish and the overall speed of the machining process.

Q: How do milling applications influence the choice between an end mill or face mill?

A: Milling applications significantly influence the choice between an end mill and a face mill based on the specific requirements of the operation, such as depth of cut, surface finish, and the area to be machined. For detailed and intricate work requiring precision, an end mill is often preferred. Conversely, for machining large flat surfaces with higher efficiency, a face mill is typically chosen. The decision also depends on the material being machined and the required speed of production.

Q: Are there any new tool technologies in face milling that improve performance?

A: Yes, there have been advancements in tool technologies for face milling that improve performance. These include the development of new carbide grades and coatings that extend tool life, enhancements in cutter body designs that increase stability and reduce vibration, and improvements in insert geometries that improve material removal rates and surface finish. Additionally, digital technology and tooling systems with integrated sensors provide real-time data to optimize the face milling process further.