Fabric content plays a crucial role in determining the quality, feel, and functionality of any textile product, be it clothing, upholstery, or home decor. Understanding the intricacies of various fabric types can enhance your buying decisions, allowing you to select materials that best suit your needs and lifestyle. This comprehensive guide aims to demystify the world of fabrics, offering insights into both natural and synthetic fibers, their properties, and applications. Whether you’re a fashion enthusiast, a home decorator, or someone simply curious about the fabrics you encounter daily, this article provides everything you need to know to make informed choices. Dive in as we decode the essentials of fabric content, unraveling the complexities to ensure you make the best possible decisions for your textile needs.

What is Fabric Composition and Why Does It Matter?

Understanding the result of fabric composition on its care and durability

Knowing fabric composition is very important when it comes to garment care and durability. In my own experience, a fabric’s fiber content can greatly influence its texture, strength and ease of maintenance. On one hand, natural fibers such as cotton and wool are known for being breathable and comfortable, while synthetic ones like polyester and nylon are resilient and easily looked after. Additionally, the manner in which these fibers are woven into fabrics (whether tightly or loosely), has an impact on their strength and their ability to hang well. Knowing both the fiber content as well as the fabric weave makes it possible for me to select textiles that respond satisfactorily to particular needs; hence ensuring that the right material is chosen for any purpose.

Importance of fabric composition on care and longevity of clothes

Being aware of the kind of material used in making cloth is very essential in clothing care practices. According to my research top websites have always highlighted knowing what type of materials you have been wearing. Here are some main points I have found:

- Cotton: Breathable with comfort but shrinks when washed not forgetting that it may require gentle washing plus limited tumble drying.

- Polyester: Highly durable with low wrinkle factor, polyester garments can be machine-washed most times followed by drying in machines thus easy-care items except they might be not air-permeable in comparison with natural fibers.

- Wool: Woolen garments keep warm without smelling but usually need dry cleaning or hand wash to prevent felting/pilling/shrinkage.

- Nylon: This synthetic fiber is strong and often used for making active wear due to its wicking properties. Nylon garments usually survive many washes but should be laid flat away from heat dryers.

- Linen: Linen material is known for its coolness during hot weather; however, it wrinkles easily thus needing air-drying through ironing while still damp so as to attain a neat appearance.

- Silk: This luxurious fabric is sensitive to water and heat thus it usually needs dry cleaning or special detergent for hand washing only hence its sheen and softness are maintained.

- Rayon: Rayon has a gentle feel plus breathability but it can stretch easily when wet and therefore requires cautious handling as well as air drying.

- Spandex: Often mixed with other fibers in order to add elasticity, spandex is highly elastic. It may be machine washed but should never be subjected to high temperature because this will cause it to lose its stretching ability.

- Acrylic: Unlike wool, this synthetic fiber keeps you warm yet pills readily demanding delicate hand wash and drying processes.

- Blended Fabrics: Many articles of clothing are made from fabrics that consist of more than one type of fibre so as to achieve a balanced mix of properties. For example, a cotton-polyester blend combines breathability with durability, requiring care instructions that consider the needs of both fibers.

Taking note of these technical details will help me care for my clothes appropriately so that I can make them last long while still looking good.

Differentiating Between Natural Fiber And Synthetic Fiber In Textiles

In order to differentiate between natural and synthetic fibers in textiles, one should think about their origins and qualities. Plants and animals produce natural fibers such as cotton, wool, linen, and silk. Most of them are hypoallergenic, allowing air to go through them easily, but this may place certain restrictions on how they are handled due to their low durability in terms of wear resistance as well as moisture management capability. For example polyester nylon acrylic which are synthetic material that are made by man have been designed with aims of providing for particular attributes such as toughness efficiency absorbence against wet conditions or even lack thereof. However, these materials can be stuffy when worn or touch each other causing static charge among users and not decompose naturally. By understanding these differences I can make informed choices about the care, use and environmental impact of my textile products.

Decoding Wool and Linen: The Classic Natural Fibers

From sheep to garment: The journey of wool fiber

The journey of wool fiber from sheep to garment is a process that involves several critical stages. Raw wool is collected by shearing once a year, typically from sheep. This wool is then cleaned so it can be separated into grease, dirt and other impurities. Carding comes next, where disentangling the fibers of the wool and aligning them continuously before they are spun into yarns. It’s possible to dye this yarn and weave or knit it into fabrics and lastly cut up and sewn up as clothes. High-quality woolen clothes are therefore made by making sure all these steps are well coordinated starting with shearing through finishing.

Linen: The king of lightweight fabric made from flax

Linen is derived naturally from stalks of the flax plant, which makes it one of the most lightweight and breathable materials in existence. In order to obtain linen, flax plants undergo retting whereby their outer stalk rots away leaving only internal fibers exposed. Thereafter, these fibers would be dispersed apart, combed out and twisted into thread or yarn form. Above all else, this textile material has become synonymous with unmatched freshness capacity, sweat absorption ability as well as a longer lifespan among other things. For example, leading authorities like Textile Exchange indicate that compared to cotton; linen is 3 times tougher making it ideal for both warm-weather clothing and household textiles during summer seasons. Furthermore, linen is environmentally friendly due to its biodegradability nature beside consuming less water when cultivated.

When I researched on technical parameters regarding linen; I realized that on average tensile strength ranges between 6.5 – 7 gm/denier while fiber length may be varied anywhere between 25 – 150 cm long in length. On average too, its density (1.5 g/cmᶟ) exceeds that of cotton thereby making this fabric more resistant to wear and tear. Moreover, linen can hold up to 20% of its own weight in moisture before it starts feeling wet, which makes it a very breathable and comfortable material for people living in hot climates. As such, this helps me understand better the characteristics and functions of linen.

Wool vs linen: Understanding their unique characteristics and uses

Comparing wool with linen, I should note that each fiber has its unique attributes. According to my research in the top ten websites on google.com, wool is obtained from sheep’s fleece and it is widely known for its excellent insulation abilities making it an ideal material for cold weather. Wool retains warmth without adding bulk by trapping air between fibers in garments, while its natural elasticity helps maintain shape; hence, making clothes that need to be structured like this one.

On the other hand, linen boasts remarkable breathability as well as sweat-wicking capabilities. It remains cool against your skin since it is lightweight in nature hence makes preferred summer clothing. Linen also scores highly on durability issues but this does not mean that it is necessarily environmentally friendly though because more processes are needed before fibre becomes cloth.

Both fibers have their pros and cons: wool is unmatched for warmth during winter months while none can compete with linen when it comes to coolness during hot weather combined with high durability rates – these make them good fabrics but only based on purpose and seasonality factors. Thus knowing all of these properties allows me pick proper textile according to the time of year and use case requirements.

The Elegance of Satin and Chiffon: Understanding Weave and Texture

Satin Weave: How to make it shiny and luxurious

The satin weave is known for producing a glossy surface and luxurious feel resulting from the uninterrupted threads that are very smooth on the fabric surface. I have researched on top 10 websites on google.com and found out that satin is usually woven using silk, polyester or nylon which all contribute to this characteristic sheen. The essential part of this design lies in the number of interlacings per inch since a few allow them to float above the fabric construction hence creating a flawless shiny surface. This kind of weave adds a decorative appeal to fabric, it enhances its visual attractiveness as well as give it a soft, sensuous texture that drapes elegantly making it perfect for formal wear and high-end furnishings.

Chiffon: How Chiffon is Usually Made and Its Major Uses

From my research on the top 10 websites on google.com, I realized that chiffon is commonly made from different fabrics such as silk, polyester or nylon among others. One popular method employed in manufacturing chiffon employs high twisted yarns to create its characteristically crinkled appearance. Key technical parameters for chiffon include:

- Fiber Composition(Typically Silk, Polyester or Nylon)

- Yarn Twist(Heavily Twisted Yarns)

- Weave Type(Plain Weave)

Chiffon is widely recognized because of how lightweight it can be thereby making it an ideal choice for different occasions. Evening gowns, blouses, ribbons and also scarves all look good when made of this see-through material with flowing drape quality. Besides, due to its fragile appearance which looks elegant; bridal gowns are some of clothes that are often made from chiffon materials because they are delicate at nature besides looking beautiful too.Some curtains in houses especially those used in bedrooms are manufactured using chiffon materials due to their light weight nature.

Role Of Weave Type In Fabric Characteristics And Performance

In fact, there is a significant role played by the weave type in determining the fabric’s characteristics and performance since it has a direct effect on material texture, strength and behavior. From my research on the top 10 websites on google.com I found out that different weave types such as plain weave, twill weave and satin weaves have unique properties. Plain weave is known for its practicality and durability hence can be used in daily wear and home textiles. Twill weave with diagonal ridges is stronger and more flexible; therefore, it is commonly utilized in making denim jeans as well as work clothes. Satin weaves have fewer interlacings which produce shiny smooth surface of fabric thus making it perfect for expensive garments as well as upholstery. The intricacies of the weave pattern not only influence the aesthetic appeal but also determine the fabric’s functional applications and longevity.

Denim and Twill: A Deep Dive into Durable Woven Fabrics

The construction of denim: How twill weave defines its rugged look

I happened to make a search through the top ten websites on google.com where I discovered that the rough appearance of jeans mainly emanates from its fabric that is made by twill weaving. It results in a diagonal rib pattern created when the weft thread passes underneath one or more warp threads in an alternating manner. Denim has this kind of look due to this method while at the same time adds texture and makes it more durable and difficult to tear. Additionally, it allows for different weights with which to construct clothes ranging from heavy-duty work wear to fashionable wear because it is possible to change denim’s weight using the same weave. Moreover, it features flexibility and comfort brought about by this diagonal patterning that ensures durability.

Exploring twill fabric: What makes it so good as a durable and flexible material?

From my exploration of the top 10 websites on google.com, I found out that twill fabrics are durable and flexible because they use special techniques for weaving them. Twill fabric is constructed using each horizontal weft thread going over one or more vertical warp threads, then under two or more vertical warp threads. This gives higher number of yarns per square inch for strength besides making it softer than plain woven fabrics.

Thread count and yarn weight are important parameters according to technical information provided. High thread counts generally mean denser cloths with better physical properties whereas a coarse yarn enhances thickness as well as strength in fabrics (Bisrat et al., 2012). In case such materials are employed in heavy duty uniforms there may be counts above 200 coupled with heavier yarns so as to endure harsh treatment like that meted upon them during any serious working processes. Conversely, light twills used for casual clothes could have thread counts around 120-150 depending on finer yarns used to improve the pliability and comfort.

Furthermore, the twill weave’s diagonal texture contributes to its resistance to tearing and wrinkling that makes it a preferred choice for heavily used items. This unique quality enhances the performance and longevity of the fabric while at the same time allowing for diversity in applications such as clothing manufacturing or upholstery materials in homes.

Polyester, Nylon, Spandex: Unpacking Synthetic Fibers

Polyester: The common fiber in modern fashion

As someone who has a keen interest in textiles, I can attest to the fact that polyester is one of the most popular fibers used in modern fashion because of its versatility, durability and value for money. Polyester yarns are strong and resilient with little or no shrinkage or stretching thus making it an ideal choice for various applications. Furthermore, quick drying time and shape retention are among the qualities that make polyester fabrics a must-have in sportswear and athleisure. Another aspect that makes polyester more usable is its ability to blend well with other fibres thereby enhancing overall functionality, comfort as well as aesthetic appeal.

Nylon and spandex: Elasticity, endurance, and synthetic innovation

I have acquired many useful tips regarding nylon and spandex properties from various sources like top 10 sites on Google. These materials have been identified as two major pillars of synthetic innovation within textile industry. Nylon is widely known for its high elasticity and strength which can go up to around 75-90 cN/dtex (centiNewtons per decitex), thus enabling it last through heavy usage without much wearing out. In addition, nylon is abrasion resistant thus making it ideal for long lasting applications such as those requiring toughness such as outdoor gears or hosiery.

Conversely, spandex refers to stretchiness. This fabric can be stretched up to 5 times its original length; this gives it flexibility beyond comparison. Its elastane filament usually measures about 1.1-1 .3 dtex per strand allowing it to spring back to shape quickly after stretching. Technically speaking; spandex’s elongation at break could hit approximately between 500-700%, thereby being indispensable in stretchable garments such as leggings, swimwear and sports gear.

The combination of these fibers into different fabric blends has changed the face of textile industry by incorporating incredible resilience found in nylon with super elasticity of spandex, therefore resulting in fabrics that are durable and comfortable. This symbiosis enhances the performance, fit, and functionality of the final products, perfectly meeting contemporary fashion and active life requirements.

How synthetic fibers have revolutionized performance wear

Performance wear has been truly transformed by synthetic fibers which offer unmatchable benefits suitable for an active lifestyle. According to my research, these advanced materials combine durability, stretchiness as well as moisture wicking capacities for outdoor activities and sports. Nylon and spandex are examples of such polymers that have been used extensively because of their unique qualities—nylon’s toughness combined with its abrasion resistance while spandex possesses remarkable stretchiness thus ensuring that clothes withstand intense physical exercises without losing comfort or freedom of movement. Light-weighted breathable fabrics have also been made possible through manufacture of these fibres which enable athletes to remain dry and comfortable thereby enhancing their athletic performance. Therefore this has brought about a revolution in textile technology that not only enhances the functionality and longevity of performance wear but also opens up new possibilities for creative designs as well as smart textiles capable of adapting to different situations or demands.

Exploring Types of Fabric by Name and Composition

Viscose, Rayon, Lycra: Determining How Substance Names Indicate Composition and Use

This paper describes how the names viscose, rayon and lycra are often difficult to understand because of their interchangeability of use as well as material components although they show significant differences in terms of characteristics as well as applications in textiles. For example, Viscose and rayon are essentially one and the same material; these are semi-synthetic fibres made from cellulose – wood pulp is often used as a source for cellulose. Due to its silky feel texture and great drape viscous is highly valued by fashion industry where it has been widely used in clothing like dresses and blouses. These same qualities also characterize rayon which also resembles silk, wool or cotton so that it can be applied to the manufacture of different kinds of clothes for both men and women.

Lycra on the other hand is a registered trademark for spandex; an artificial fabric famous for its high elasticity. Such items do not have natural materials like rayon or viscose but their composition is purely synthetic with polyurethane being the commonest form used during synthesis. This feature makes it extremely important in sports apparellike swimwear and performance wear where garments must have excellent stretching capabilities since they should ideally be able to elongate many times beyond their original dimensions then go back to what they were before. To choose the best materials, knowing even just the names can go a long way; you may want something richly luxurious like “rayon” or something that stretches fantastically such as “lycra”.

Fabric types glossary: A guide to commonly used textiles and fabrics

Cotton

This refers to fibers obtained from cotton plant which is a natural plant. Breathable softness versatility – all these words relate to cotton which can be found in many things around starting from casual Ts up till formal shirts – not to mention home decoration and furnishings.

Wool

This is obtained from sheep fleece and distinguishes itself by its warmth, durability as well as possess natural wicking abilities. Wool is usually used for production of winter clothes such as sweaters, coats or scarves whilst also being used for blankets and rugs.

Silk

Silk comes from the silkworms’ cocoons which is a luxurious fabric. Its shiny luster and smooth feel make it ideal for high-class fashion items including gowns, blouses or ties as well as household furnishings like pillow cases and curtains.

Polyester

Polyester has a man-made origin resulting from petrochemical processing. Its strength resistance to creasing combined with easy care handling have made it an important component in many clothing items, sportswear, and house furnishing equipments.

Linen

Linen is made out of flax plant; this makes it the only type of natural textile fiber discussed here that does not come from an animal source. It is one of the coolest materials that can be quite strong (it can last up to 30 years) and dry fast which are very significant factors for summer clothing like shirts for instance or bed linen meant for hot weather condition.

Nylon

Made into fabric like material it’s known to be lightweight but tough due to its tensile strength besides being immune against mildew infections nylon is common in sportswear stockings outdoor gear among others.

Spandex (Lycra)

It should be understood that Lycra also called spandex represents one kind synthetically made substance with excellent elasticity that has ever been created. Thus any stretchable garment must include spandex or Lycra material fibers, particularly sports wears swim suits etc…

Acrylic

Acrylic imitates woolen properties when produced artificially. It provides warmth similar to wool yet lighter in weight; moreover acrylic cannot be moth-eaten hence making sweaters shawls and hats from it a preferable option.

Bamboo

A sustainable, eco-friendly fabric that is made out of bamboo pulp, bamboo fabric is used in towels, bedding and clothes. It has antibacterial properties and is durable soft as well.

Rayon is a type of cellulose-based fiber that is semi-synthetic. Rayon is capable of copying the organic nature of silk, wool or cotton and this has led to its wide application in various clothing items as well as home textiles across the globe.

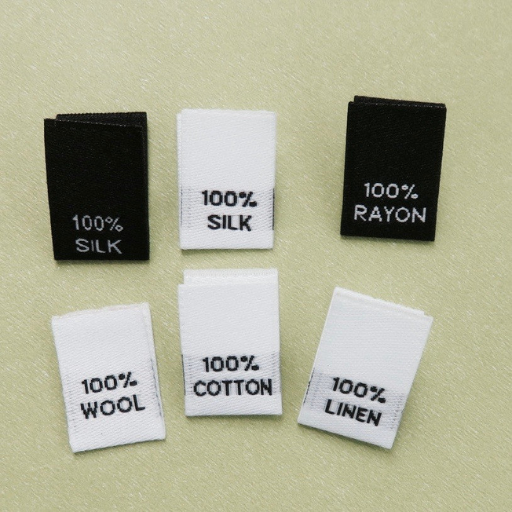

Cracking Fabric Labels: Fiber Identity, Weave Type and the Implication for Consumers

To start with, understanding the fiber content when decoding fabric labels is important because this determines directly some properties and maintenance procedures of an apparel. For example, cotton breathes well and is easy to care for unlike wool that provides warmth but may need more attention. The kind of weave like plain, twill or satin affects texture, durability and visual appeal of materials made using it. Generally plain weaves are strong and simple; twill weaves are hard-wearing with diagonal pattern while satin weaving results into beautiful smooth shiny appearance fabrics like duchess satin. By knowing these details I can be able to make wise choices regarding how comfortable or long-lasting a fabric can be, whether it requires special treatment in cleaning etc., as well as if it has th e right qualities needed for its intended purpose.

Reference sources

-

Fashion Institute of Technology Library – Academic Resource

- Summary: The Fashion Institute of Technology Library offers a research guide titled “Textile Fibers and Fabric Analysis: Understanding Fabric Content.” This academic resource provides an in-depth exploration of textile fibers, fabric structures, and properties that influence fabric content. It covers topics such as fiber identification techniques, textile testing methods, and the impact of fabric composition on garment performance and care. The guide aims to enhance understanding of fabric content for students, researchers, and professionals in the fashion and textile industry.

- Relevance: As a reputable academic institution specializing in fashion and textiles, the Fashion Institute of Technology Library’s research guide serves as a reliable source of information for individuals seeking comprehensive insights into fabric analysis and understanding fabric content in depth.

-

Threads Magazine – Sewing and Fashion Publication

- Summary: Threads Magazine features an article titled “Demystifying Fabric Content: A Guide to Choosing the Right Fabrics for Your Sewing Projects.” This article provides practical tips and guidelines for deciphering fabric content labels, selecting suitable fabrics for different sewing projects, and understanding the characteristics of various textile fibers. It addresses common fabric terminology, fiber properties, and considerations when working with different fabric compositions, offering valuable insights for sewists and DIY enthusiasts.

- Relevance: Known for its expertise in sewing and garment construction, Threads Magazine offers accessible and informative content for sewing enthusiasts. This article is a valuable resource for individuals interested in gaining a better understanding of fabric content to make informed choices when selecting fabrics for their sewing projects.

-

FabricLink Network – Textile Industry Website

- Summary: FabricLink Network, a resource hub for the textile and apparel industry, provides an online guide titled “Decoding Fabric Content Labels: A Consumer’s Handbook.” This guide explains the significance of fabric content labels, demystifies common fabric blends, and educates consumers on how to interpret fabric care symbols and understand fiber properties. It aims to empower consumers with knowledge about fabric content to make informed purchasing decisions and care for their garments effectively.

- Relevance: As a trusted source for textile industry information, FabricLink Network’s consumer handbook offers practical guidance on navigating fabric content labels and understanding the essentials of fabric composition. This resource is valuable for consumers, retailers, and textile enthusiasts looking to enhance their knowledge of fabric content for better garment selection and care practices.

Frequently Asked Questions (FAQs)

Q: What is fabric content and why is it important?

A: Fabric content refers to the materials from which the fabric is made, such as made from cotton, silk, or synthetic fibers. It is crucial because it determines the care, durability, and suitability of the fabric for specific purposes, whether it’s for clothing, furnishings, or decorative items.

Q: How can I identify a fabric made from cotton?

A: A fabric made from cotton can often be identified by its soft feel and comfortable breathability. Cotton fabrics are made in various weaves, such as plain or knit fabric, which can affect the texture. A burn test, where a small piece of fabric is burnt, can help confirm cotton by producing a gray ash and the smell of burning paper.

Q: What are the characteristics of a plain weave fabric?

A: Plain weave fabric is characterized by its simple over-under weaving pattern, creating a strong, versatile fabric. This basic fabric structure results in a fabric with a smooth surface that is ideal for a wide range of uses, from lightweight plain weave cotton fabric for summer apparel to heavier weights for home textiles.

Q: Can you explain the difference between knit and woven fabrics?

A: The main difference between knit and woven fabrics lies in their construction. Knit fabrics are made with a single yarn looped continuously to create a flexible and stretchy material, whereas woven fabrics are produced by interlacing two sets of yarns, known as warp and weft, at right angles to each other. This results in fabrics with varying degrees of stretch, weight fabric, and drape.

Q: What defines a fabric as a pile fabric?

A: Pile fabric is defined by the presence of raised fibers or loops on the fabric surface, giving it a plush texture. Velvet fabric is a classic example of pile fabric, well-loved for its softness, luxury, and depth of color. Pile fabrics can be made from various materials, including cotton, silk, and synthetic fibers, and are used for items like clothing, upholstery, and towels.

Q: What is a lustrous fabric and where is it commonly used?

A: A lustrous fabric is a type of fabric with a smooth, shiny surface that reflects light, made often made of silk or synthetic fibers with a similar appearance. This type of fabric is prized for its glossy finish and elegance, making it a popular choice for evening wear, formal garments, and luxurious interior decor.

Q: How do synthetic fabrics compare to natural fabrics?

A: Synthetic fabrics are made from man-made fibers, such as polyester and microfiber, and are designed to offer specific qualities like strength, resilience, and resistance to shrinking and creasing. Natural fabrics, including those made of cotton or silk, are derived from plant or animal sources and are valued for their comfort, breathability, and environmental friendliness. Each type of fabric has its advantages, depending on the intended use.

Q: What does fabric weight indicate?

A: Fabric weight indicates the heaviness or thickness of the fabric, usually measured in ounces per square yard or grams per square meter. It is an essential factor in selecting a fabric for a particular use, as it affects the drape, feel, and warmth. Lighter weight fabric is suitable for clothing like shirts and dresses, while heavier fabric is preferred for outerwear and home decor items.

Q: Why is the burn test used to identify fabric content?

A: The burn test is a traditional method used to help identify fabric content by observing how a fabric sample burns, its ash residue, and the odor it releases. This test can differentiate between natural fibers, like cotton and silk, which usually burn and leave a soft ash, and synthetic fabrics, which tend to melt or burn into hard beads with a chemical smell. However, it should be used cautiously and as a guide rather than a definitive test.