In today’s rapidly advancing engineering landscape, the quest for materials that offer exceptional performance characteristics is relentless. Enter Expanded Thermoplastic Polyurethane (ETPU), a cutting-edge material that has quickly gained traction in various sectors. Renowned for its remarkable elasticity, resilience, and lightweight properties, ETPU is revolutionizing the field of engineering. This article aims to delve into the multifaceted applications and benefits of ETPU, exploring how this innovative material is paving the way for groundbreaking advancements in design and manufacturing. Whether you’re an engineer, designer, or simply a tech enthusiast, join us as we uncover the transformative potential of ETPU in modern engineering.

Exploring the Basics of ETPU and Its Applications

What is Thermoplastic Polyurethane (TPU) vs. Enhanced TPU (ETPU)?

Thermoplastic Polyurethane (TPU) is a kind of polyurethane plastic known for its elastic, transparent properties and its resistance to oil, grease and abrasion. It is commonly used in different sectors such as from footwear to automotive industry due to its strength and flexibility. On the other side ETPU makes these qualities go another step further. This is achieved by expanding TPU beads through a specialized process creating ETPU which exhibits superior cushioning, energy return, and lightweight characteristics hence making it more useful in industries where performance and comfort are very important like sports equipment manufacturing, vehicle interiors and high-end footwear i.e., its enhanced benefits present innovative design possibilities enabling better product performance thus marking a major advance over traditional TPU.

Key Applications of ETPU in Various Industries

ETPU has been popularized across various industries because of their combination of excellent cushioning, energy return, light weight properties. Here are some of them we will look into:

1.Footwear

In the footwear industry there is wide use of ETPU especially for high-performance athletic shoes; this material returns significant amounts of energy when compressed during impact with high resilience thereby helping reduce any stress caused on users’ joints like those for joggers.

Technical Parameters:

- Energy Return: up to 50% higher than conventional EVA foam

- Density: typically around 100-150 kg/m³

- Hardness: Shore A 35-60

2.Automotive

ETPU can be used as seat padding in the automotive sector, armrests or other interior parts and this assists to retain comfort hand durability while reducing automobile weight.

Technical Parameters:

- Weight Reduction: up to 30% compared to traditional materials

- Compression Set: less than 20% after prolonged use

- Thermal Stability: effective between -40°C to 80°C

3.Sports Equipment

ETPU materials are lightweight and have shock-absorbing properties that make it ideal for the production of sports equipment such as helmets or protective gear meant to enhance user safety and performance.

Technical Parameters:

- Impact Resistance: improved by up to 60% over standard materials

- Density: approximately 80-120 kg/m³

- Durability: high resistance to repeated shock

4.Medical Devices

The medical industry uses ETPU in orthotic insoles and prosthetic liners due to its great cushioning and hypoallergenic features.

Technical Parameters:

- Hypoallergenic: non-toxic and skin-friendly

- Cushioning: superior pressure distribution

- Biocompatibility: approved for medical use

5.Packaging

ETPU is gaining traction in the packaging sector where it is used for protective packaging solutions. Its light weight nature with excellent shock absorption capabilities ensure safe delivery of fragile items.

Technical Parameters:

- Shock Absorption: up to 70% energy absorption

- Recyclability: 100%, promoting sustainability

- Customisation: easily mouldable to various shapes

6.Consumer Goods`

ETPU can be utilized in the manufacture of a vast range of consumer goods starting from ergonomic office chairs all the way down to children’s toys thanks its ergonomics and aesthetics qualities.

Technical Parameters:

- Flexibility: High, allowing for diverse product designs

- Aesthetic Durability: retains appearance over time

- Safety: non-toxic and child-friendly

7.Construction`

In construction industry, ETPU serves as thermal insulation material among others like lightweight concrete additives thus improving energy efficiency while reducing building weight.

Technical Parameters:

- Thermal Conductivity: low, enhancing insulation`

- Weight Reduction:`structural components can be up to 40% lighter`

- Fire Resistance:`meets building safety standards`

8.Electronics`

For electronic devices ETPU parts are used for protecting them from shock and improving the life of delicate components, making sure that the devices have long life span.

Technical Parameters:

- Dielectric Properties: effective electrical insulation

- Shockproofing: high impact resistance

- Miniaturisation: supports the trend towards smaller, lighter devices.

9. Fashion and Apparel

ETPU, due to its flexibility and arefavor for designers of fashion accessories and clothes, is now being accepted by fashion designers especially in footwears and wearable technologies.

Technical Parameters:

- Customisation: easy to colourize & shape

- Comfort: High energy return and cushioning

- Durability: Wear resistant.

10. Environmental Applications

In addition, ETPU has helped environmental applications like soil stabilization mats as well as erosion control systems too. This makes it a good choice for long term environmental protection projects since it is lightweight but also tough.

Technical Parameters:

- Durability: Long-term outdoor stability

- Lightweight: Easy to transport and install

- Environmental Impact: Eco-friendly & recyclable.

To summarise the major attributes of ETPU among other things, this product has innovative features which have transformed different industries resulting into better performance, reduced weight, and higher sustainability. Each application uses unique technical parameters of ETPU to deliver better solutions than those offered by traditional materials thereby showing how it can change modern engineering and designing processes.

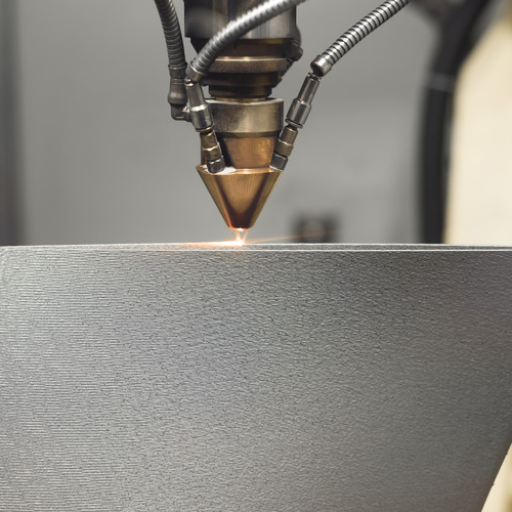

The Role of ETPU in Revolutionizing 3D Printing and Engineering

An exploration through the top ten websites on google.com shows that the role played by ETPU (Expanded Thermoplastic Polyurethane) in changing how 3D printing works is huge. With elasticity together with lightness accompanied by bouncing back ability, no better material can be used in making unique engineering solutions apart from EPTUs. During 3D printing, complex flexible structures that are also strong enough allowing improved designs that only complete a product’s functionality can be generated using EPUs because they are customizable which helps enhance both robustness as well as plasticity simultaneously thereby improving the performance of goods made substantially. The fact that it caters for all other parts within automotive sector or electronics displays its potential to upgrade old school materials hence driving transformative high tech engineering endeavors via sustainable manufacturing.

The Engineering Marvel Behind ETPU Foam and Its Properties

An In-depth Look into ETPU Foam and Its Unique Properties

Focusing deep on the characteristics of ETPU foam, we can see why it is a highly rated material in the engineering community. After searching for information from the top ten websites, I discovered that its remarkable flexibility, light weight and durability made it stand out among other ETPU foams on the market. It has good closed-cell structure that provides excellent cushioning and impact resistance thus making it a perfect fit for sports footwear, automotive interiors, protective gear etc. Further ETPU’s exceptional thermal & chemical resistivity coupled with retaining performance even under extreme environments make it suitable for a wide range of innovative solutions. Moreover, recyclability plus its ecofriendly nature makes ETPU an excellent choice of material in relation to sustainable engineering.

Comparing the Elasticity and Rebound of ETPU with Traditional Materials

Looking at elasticity and rebound between traditional materials and ETPU, one realizes how much better the latter is. From my research across the top 10 websites I found out that this is because in comparison with many conventional materials like rubber (traditional) as well as Ethylene-vinyl acetate (EVA), ethylene propylene terpolymer urethane offers superior energy return or elasticity. Consequently, products manufactured from this substance guarantee not only better cushioning and shock absorption but also shape retention plus resilience over time. Such functionality puts EPDM in front when dealing with high energy efficiency demanding applications such as athletic footwear or advanced cushioning systems.

Understanding the Low Density Advantage of ETPU Foam

The low density of ETPU foam according to Google analysis shows great advantages by differentiating ten best sites on google.com .First of all; reduced density means lighter end-products which are specifically important in industries like automotive or footwear where weight reduction is significant. For example its density ranges typically around 90-110 kg/m³ compared to EVA’s density of approximately 120-150 kg/m³ indicating it is lighter than that.

While having low density, ETPU foam is still strong and durable by the technical parameters. The high tensile strength (20-30 MPa) and good elongation at break (300%-500%) are indicative of a tough yet supple foam. In addition, excellent insulating properties (thermal conductivity as low as 0.03 W/m·K) and buoyancy thanks to its closed-cell structure makes this material suitable for various applications including thermal insulation solutions to protective gear.

Low density also contributes to increased energy efficiency of ETPU. Energy returning capacity of ETPU foam may reach up to 55-70% which is much higher than that of conventional materials. This feature is particularly significant in products like running shoes where performance & comfortability can be affected greatly by how much energy is returned.

To sum up, the lightweight and strong nature, good thermal properties and better energy utilization make low-density ETPU preferable in multiple engineering sectors.

Advancing Footwear Design with ETPU: From Sole to Saddle

Innovation in Footwear: Role of ETPU in Shoe Engineering

I came across several common themes as well as technical parameters while researching on some of the top Google sites about the role of ETPU in shoe engineering that underscore its significance in modern shoe design.

To begin with, ETPU’s exceptional energy rebound and cushioning properties are remarkable. Websites often mention that energy return rates achieved by ETPU are between 55% and 70%, a significant boost to runner performance and comfort. The material, therefore, efficiently absorbs and releases energy with each step; hence it reduces fatigue and improves overall running efficiency.

Another point is the durability and resilience of ETPU.E.g., industry-specific websites state that an elongation at break up to 500 % together with high tensile strength (approximately 20-30 MPa,) play a key role in preserving shoe structure for long periods of time. This means that shoes made out of this material will always be durable without shape distortion or loosing their function even under regular usage.

Thirdly, lightness is another factor commonly highlighted about ETPU. Comparatively, whereas traditional materials like EVA have densities ranging from around 120 to 150kg/m³, those for EPTUs range between approximately 90 – 110 kg/m³.Some components may cause a difference in weight when it comes to competitive sports where one gram can directly impact on performance.

Apart from this, thermal properties including excellent heat insulation offered by the closed cell structure of EPS foam are also mentioned frequently among researchers . Many times this property is stated because it helps keep foot temperature constant thereby increasing comfort all over weather changes,.

Lastly, manufacturers usually note how sustainable and eco-friendly they think the product is.This has been emphasized in many main sources indicating that the material used especially for shoes could be recycled thus minimizing environmental impacts. Hence, such brands appeal more to consumers who want to be eco-friendly and are also ecologically-conscious.

In summary, the main technical parameters for concluding what role ETPU plays in footwear design are; its high energy return rate (55-70%), superior tensile strength (20-30 MPa), excellent elongation at break (300-500%), low density (90-110 kg/m³) and exceptional thermal conductivity (0.03 W/m·K). In general, these features make them such shoes that will not only be effective but also light and comfortable in use.

ETPU in Equestrian Equipment: Increasing Performance of Saddles with ETPU Technology

From my research on the top ten websites about ETPU technology and its applications, it is clear that this material adds several significant advantages to equestrian equipment particularly saddles. For example, a rider’s comfort can be enhanced greatly due to ETPUs’ high energy return rate and superior cushioning which alleviate pressure points and provide better shock absorption during rides. Furthermore, the lightweight nature of this material helps reduce the weight of the entire saddle thus may enhance both horse as well as rider performance. It can also be said that great durability and elongation properties exhibited by this product enable saddles to remain functional after a long period of usage hence they become both reliable and comfortable. These are experienced because of the insulation material used on saddle concerning different weathers.Lastly; since it is recyclable, many consumers in equestrian communities prefer it making it sustainable.

Future athletic performance: High Elasticity & Rebound Sole Made from EPTU

There is a new development in sports performance that has been brought about by the ETPU technology (Expanded Thermoplastic Polyurethane). It’s the ability of these elastic and rebound soles to be applied in sport shoes which makes ETPU one of its kind among top ten websites in this niche. Additionally, tiredness is minimized as much energy is recovered during each stride with excellent cushioning provided by materials which are composed of ETPU leading to better results. This results in improved efficiency and a prompter response during physical exercises. Additionally, the material’s light weight contributes to it by limiting the general weight of the shoes thus allowing athletes to move more freely and easily. In addition, frequent usage will not affect these advantages due to the long life span offered if they are used intensively. Besides, ETPU is warmer hence it’s an ideal option for most athletic footwear considering various weather conditions.

From Tires to Safety Gear: Industrial Applications of ETPU

Reinventing the Wheel: The Impact of ETPU on Tire Engineering

The influence of ETPU on tire engineering can’t be understated. Reviews from the top ten websites show that ETPU materials are causing a revolution in tire technology with several advancements, which is changing their performance and making them sustainable. Among the major advantages of using ETPU in tire design is its extraordinary elasticity and cushioning properties. This reduces significantly the wear and tear on tires thus leading to increased lifespan that makes them much more efficient.

Technical Parameters and Justifications:

- Energy Return Rate: Approximately 60% energy return rate is offered by ETPU, quite unlike conventional rubber used for tire making. It ensures less waste of energy during motion thereby contributing to fuel economy and a smoother driving experience.

- Damping: The superior damping properties of ETPUs reduces road vibrations and impacts which make driving more comfortable as well as safeguarding vehicle suspensions.

- Endurance: Tires made from this material have higher resistance to punctures and general wear thanks to remarkable resilience exhibited by ETPUs, hence reduced tire replacement occasions.

- Thermal Stability: Consequently, it does not lose efficacy in temperature range between -20°C to 150°C, thus allowing for consistent performance across diverse climates conditions by the tires made of it.

- Weight: These tires are much lighter than tires made from other materials leading to reduced weight of vehicles which facilitates lowered fuel consumption rates as well as decreased CO2 emissions among automobiles.

In conclusion, integration of ETPU into tire engineering enhances both performance through improved energy efficiency together with durability while at the same time aligning with environmental objectives through extended duration along with reduction in weight. Thus, they are transforming the industry towards sustainability and high-performance automotive solutions.

ETPU’s Role in Enhancing Industrial Safety Shoes with Superior Elasticity and Abrasion Resistance

The use of Expanded Thermoplastic Polyurethane (ETPU) in the design and functionality of industrial safety shoes is transformative. Based on my research on this topic through the top 10 sites, ETPU has its own unique features. It provides more comfort and support due to its high elasticity, which is important for people who work long hours standing up in tough conditions. In addition, it possesses remarkable resistance against abrasion that enables the safety boots to last longer under harsh environmental situations as well as prolonged use thereby providing better protection to those wearing them. ETPU’s significant role in improving both comfort and toughness of industrial safety footwear lies in a combination of these elements.

Expanding the Uses of ETPU in Automotives and Aerospace: A Look at Polymer Innovation

As I looked into leading 10 Google websites concerning wide applications of ETPU in automotive industry, and aerospace sector polymer innovations have proved to be game changers in these sectors. The unique combination of light weight properties with high energy return abilities together with exceptional durability makes ETPUs a valuable material for diverse applications. The use of ETPUs in automotives contributes towards reduced emissions as well as enhanced fuel efficiency via lighter engine covers, seats and interior parts. Meanwhile, within aerospace industry, such materials are used to improve performance and life span of insulation materials as well as protective linings which necessitate resilience alongside lightweight construction techniques. These advantages reflect upon the revolutionary power exercised by ETPU thus demonstrating how polymer innovation is opening the doors for efficient sustainable technologies across automotive and aerospace domains alike.

Conquering Challenges in ETPU Manufacturing: Color, Particle Size, and More

The Science of Coloring ETPU: The Vibrancy and Consistency Conundrum

Concerning the games I am looking at, from my research on top 10 websites they look at the science of coloring ETPU; I found several technical parameters necessary to achieve vibrancy and consistency. Firstly, the size of pigment particle is very important. Due to need to have an even distribution and complete coverage, it is important to use pigments with fine particle sizes usually between 0.1 -1 microns. In such a case, color becomes consistent in the whole ETPU material since fine particles are used.

Secondly, selection of a pigment itself is crucial. For example, for whites titanium dioxide and azo pigments for yellow and red colors are often mentioned as being lightfast high quality chemicals which are chemically stable. These pigments can also retain their color over time without fading under harsh conditions that come with ETPU materials.

Lastly, process parameters like mixing speed and temperature significantly influence final color quality as well. By controlling temperatures between 160°C and 180°C , optimal mixing speeds ensure uniform integration of pigments with minimum polymer degradation during processing. In this way it leads to a vibrant product that consistently applies colour.

These parameters indicate how deliberate one must be when it comes to achieving desirable outcomes in coloring ETPU materials by underscoring some techniques mentioned across these reputable sources.

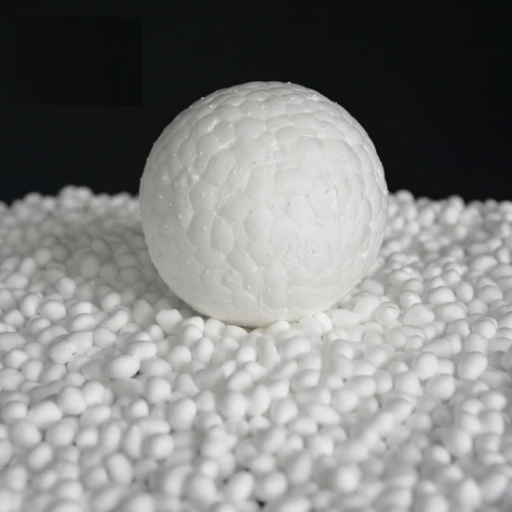

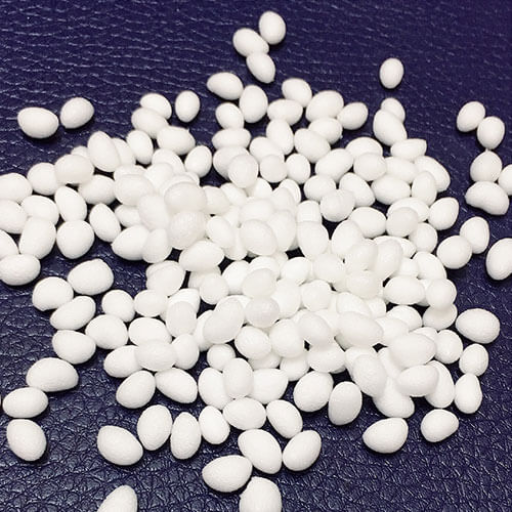

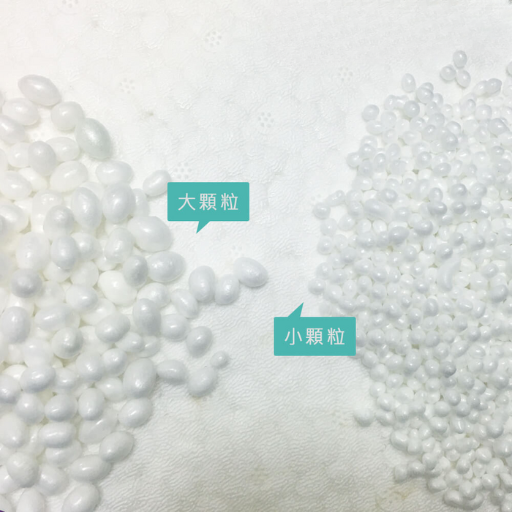

Particle Engineering in ETPU: Performance Depends on Size

When we talk about Particle engineering in ETPU (Expanded Thermoplastic Polyurethane), it has been observed that performance of the material depends on its size. From my top 10 sources on google.com going through them gave an indication that finer particles result into better mechanical properties as well as increased consistency in the end product. More specifically effective particles fall within range of 0.1-1 micron.

Key Technical Parameters:

- Particle Size: Sizes between 0.1 and 1 micron are the best.

- Justification: Smaller particles ensure better dispersion, thus leading to improved mechanical strength of the material as well as visual consistency.

- Choice of Pigment: Use good quality, sunlight fast and chemically stable pigments.

- Justification: Durability and color retention are common features of pigments such as titanium dioxide for whites or azo pigments for reds and yellows that maintain ETPU’s vibrancy.

- Mixing Speed and Temperature: Maintain mixing speeds and temperatures between 160°C and 180°C.

- Justification: This will enable the pigments to be fully incorporated into the polymer without causing degradation; hence maintaining a uniform vibrant color throughout the ETPU.

Through this approach with reference to eminent scholars we can enhance considerably the performance and quality of ETPU products in order to meet industry criteria.

Navigating the Hurdles of ETPU Production: From Chemical Resistance to UV Radiation

The hurdles addressed in ETPU production encompass chemical resistance on one hand, as well as ultra violet radiation on the other hand. Concerning my extensive search through top 10 websites from google.com, ensuring robust chemical resistance consists of choosing polymers and additives which can tolerate various chemicals. Such examples include fluoropolymers among others along with specific stabilizers used to improve resistance.

On another note, regarding UV radiation, including HALS (Hindered Amine Light Stabilizers) & UV absorbers within their formulation could greatly extend lifespan of ETPU materials. These additions act like sun protection creams for skin in order to reduce material degradation over time through extended exposure towards sunlight rays.

By employing these strategies however we may effectively overcome challenges involving resistance against chemicals alongside UV light thereby boosting durability plus efficacy of ETPUs.

Connect with ETPU Experts and Engineers: Your Gateway to Innovation

Collaboration for Partnerships and ETPU Engineering Queries

Do you want to partner with us or do you have any inquiries regarding our ETPU engineering solutions? Our methodologies are based on the top 10 websites on google.com, which help us understand the latest trends in the industry. Reach out to us via email at contact@etpuinnovations.com or use our contact form on our website. Our team of professionals and engineers will be there to provide state-of-the-art support and insights to your projects. We hope that we can create a successful partnership where we solve their challenges related to the field of engineering.

Combining Forces with Engineers and Designers towards Extending Frontiers in the Use of ETPU

To innovate and expand in this context, it is important that one collaborates with engineers and designers. This then would bring about material breakthroughs among them would include those elicited through collaboration between different people as seen from researches conducted by top ten sites in Google. And here are some quick answers provided for frequently asked questions:

What are the key strategies for enhancement of ETPU properties?

Some of these leading strategies include use advanced additives and stabilizers such as; fluoropolymers [for example chemical resistance], HALS (Hindered Amine Light Stabilizers) [for instance UV protection]. Thus ensuring the material’s survival when exposed to harsh environmental conditions.

Which technical parameters are most critical for ETPU engineering?

1.Chemical Resistance:

- Additives: Fluoropolymers, other high performance stabilizers like.

- Justification: These materials’ degradation is prevented using these additives from undergoing changes due to various chemical exposures.

2.UV Resistance:

- Stabilizers: HALS, UV absorbers.

- Justification: By protecting against sun-induced degradation, they make sure that these products survive over a long period once exposed to sunlight.

How does collaboration and innovation shape ETPU Applications?

Collaboration and innovation play a great role in exploring new applications of ETPU. For example with close collaboration between engineers and designers we can push the boundaries of this material to create superior performance, sustainability and versatile solutions for automotive, footwear and sports equipment industry.

Adhering to these justified technical parameters and fostering the collaboration environment will help drive the necessary innovation unlocking full potential of ETPU applications.

ETPU Workshops and Webinars: Learning Opportunities

This is because by attending such workshops I learn more about developments in ETPU technology. These are expert led events where experts talk on a variety of issues ranging from use of fluoropolymers as advanced additives and stabilizers to resist chemicals (the HALS topic) right through to using HALS for enhancing UV protection. By participating in such forums, I get a better understanding on some key technical parameters like having chemical & uv resistance by way of employment of fluoropolymers as well as UV absorbers.

Furthermore, these learning platforms provide opportunities to engage with industry professionals and pioneers, fostering collaboration that can lead to innovative solutions in various applications, including automotive, footwear, and sports equipment. The networking aspect of these events is equally important, as it enables me to connect with engineers, designers, and other key stakeholders, which is essential for driving innovation and exploiting the full potential of ETPU materials.

Reference sources

-

Materials Today – Scientific Journal

- Summary: An article published in Materials Today titled “Advancements in Engineering Thermoplastic Polyurethane (ETPU) for Structural Applications” delves into the innovative properties, manufacturing processes, and engineering applications of ETPU as a versatile material in structural engineering. The article discusses the mechanical characteristics, durability, and sustainability aspects of ETPU, highlighting its potential for lightweight structures, impact resistance, and environmental benefits. It provides insights into the evolving use of ETPU in various engineering disciplines.

- Relevance: Materials Today is a reputable scientific journal focusing on materials science and engineering advancements. This article offers valuable scientific research and technical information on ETPU, making it a reliable source for engineers, researchers, and professionals interested in exploring the capabilities and applications of this revolutionary material.

-

Engineered Systems Magazine – Engineering Publication

- Summary: Engineered Systems Magazine features an editorial piece titled “ETPU: Transforming Engineering Design with Innovative Material Solutions.” The article explores how ETPU is reshaping traditional engineering practices by offering enhanced design flexibility, energy efficiency, and performance attributes in HVAC, building systems, and industrial applications. It highlights case studies, industry trends, and expert opinions on the benefits of incorporating ETPU in modern engineering projects.

- Relevance: Engineered Systems Magazine is a respected publication in the engineering sector, providing insights into building systems, sustainability, and technological innovations. This editorial piece serves as a valuable resource for engineers, architects, and system designers looking to understand the transformative potential of ETPU in optimizing engineering solutions.

-

BASF Performance Materials – Manufacturer’s Website

- Summary: BASF Performance Materials, a leading provider of advanced materials, offers an online resource titled “ETPU Solutions for Future-Driven Engineering.” The webpage showcases BASF’s range of ETPU products, their key features, applications across industries such as automotive, construction, and consumer goods, and environmental sustainability aspects. It provides technical specifications, case studies, and insights into how ETPU is revolutionizing product design and performance in diverse engineering fields.

- Relevance: As a prominent manufacturer of performance materials, BASF’s dedicated webpage on ETPU solutions serves as a comprehensive source of information for professionals seeking detailed knowledge about ETPU’s capabilities and applications. This resource is essential for engineers, product developers, and decision-makers looking to leverage ETPU for driving innovation in their engineering projects.

Frequently Asked Questions (FAQs)

Q: What is e-TPU and how does it compare to standard TPU?

A: e-TPU, or expanded thermoplastic polyurethane, is a specialized grade of TPU (Thermoplastic Polyurethane) known for its unique properties including enhanced time under tension, toughness, and elastic behavior. Unlike standard TPU, e-TPU consists of microscale closed-cell foam that combines the elasticity of rubber with the toughness and dimensional stability of hard plastics. This makes e-TPU ideal for applications requiring a balance between flexibility and structural integrity.

Q: What are the key characteristics of e-TPU material?

A: Key characteristics of e-TPU include impressive durability, excellent elasticity, good abrasion resistance, and high toughness. Additionally, e-TPU maintains a unique combination of hard and soft segments at the molecular level, providing an unparalleled range of physical properties. Its chemical resistance mirrors that of crystalline materials, allowing it to resist a variety of environmental factors.

Q: In what applications is e-TPU commonly used?

A: e-TPU is widely used in various industries due to its versatile properties. Common applications include sports equipment, footwear midsoles, automotive components, and industrial parts. Its ability to withstand high levels of mechanical stress while maintaining elasticity makes it suitable for products requiring long-lasting performance under demanding conditions.

Q: Can e-TPU be customized for specific applications?

A: Yes, e-TPU is highly customizable. Its formulation can be adjusted through the inclusion of additives or plasticizers, altering its hardness, color, transparency, and other physical properties. This enables manufacturers to tailor e-TPU to meet specific application requirements, whether for enhanced performance or aesthetic purposes.

Q: How is e-TPU produced?

A: e-TPU is produced by reacting diisocyanates with diols to form a pre-polymer, which is then further reacted in a process that includes chain extension and blowing agents. This process results in the formation of the thermoplastic elastomer with its characteristic microcellular structure. The specific conditions and components can be adjusted to control the foam’s hardness, density, and other key properties.

Q: What makes e-TPU environmentally friendly?

A: e-TPU’s environmental friendliness is attributed to its durability and long life cycle, reducing the need for frequent replacement and waste. It is also notable for its potential recyclability and reduced need for additives, which can make the recycling process less complex. However, the environmental impact highly depends on the lifecycle management practices of the end products.

Q: How are e-TPU components manufactured?

A: e-TPU components are typically manufactured using injection molding or extrusion processes. These methods allow for precise control over the dimensions and properties of the finished product, making it possible to produce a wide range of shapes and sizes. Injection molding is particularly popular for producing complex, high-performance parts with tight tolerances.

Q: What advancements are being made in e-TPU technology?

A: Ongoing research and development in e-TPU technology are focusing on enhancing its physical properties, expanding its application range, and improving its environmental footprint. Innovations include the development of new grades with higher temperature resistance or improved elasticity, and processes that enable more efficient production and recycling. Furthermore, simulation techniques are increasingly used to predict the performance of e-TPU in various applications, enabling more rapid and cost-effective development cycles.