ESD is a vital factor for the survival and durability of delicate electronic components in the rapid electronics world. The importance of incorporating ESD safe materials into 3D printed items as 3D printing technology integrates with other manufacturing processes continues to increase. This guide, thus, aims at providing an in-depth analysis of all aspects related to 3D printing with ESD safe plastics such as their advantages, applications, material options and best practices. For that reason, whether you are a professional engineer or interested in experimenting, this article will enlighten you about how you can successfully incorporate ESD safe plastics into your 3D printing projects without compromising electrostatic damage on your electronics.

What is ESD Safe Material for 3D Printing?

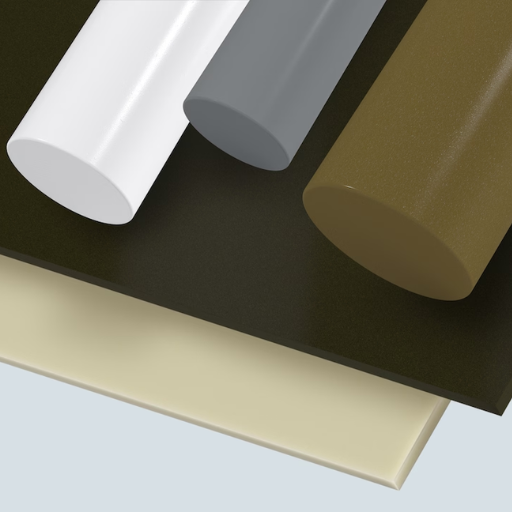

Image source: https://www.esdgoods.com/

Materials that can be used for 3D printing are called ESD safe materials and are plastic compounds that have been modified to prevent the build-up and discharge of static electricity. These materials contain additives like carbon fibers, carbon nanotubes or other conductive elements which disperse electrical charges and thus protect electronic components from electrostatic damage. Printing with ESD safe materials ensures that the finished printed parts possess required electrical conductivity properties in order to reduce risks related to electro-static discharge and make them acceptable in electronics manufacturing and assembly applications.

Understanding ESD Safety

Electrostatic Discharge (ESD) protection is used for safeguarding components against abrupt electrical surges. Grounding helps divert static electricity from vulnerable equipment. Conductive materials such as ESD safe plastics spread around any collected charges making sure they do not escape suddenly. In controlled environments such as cleanrooms and ESD safe workstations, humidity is regulated and everything surfaces and tools on the ground to avoid any chances of static building up. All this forms a strong framework for ensuring an ESD safety protocol that keeps delicate electronic devices protected while being assembled or manufactured in different ways.

Types of ESD Safe Materials Available

Various applications require different kinds of ESD safe materials:

- Conductive Plastics: These are used widely and contain conductive additives like carbon fibers or carbon nanotubes, they are critical in dissipating static charges and thus commonly employed in 3D printing as well as electronic component housings.

- ESD Flooring: These can be vinyl tiles, rubber mats, and epoxy coatings that are meant to discharge static electricity making them indispensable for ESD safe workstations along with cleanrooms.

- Anti-Static Coatings and Sprays: They are applied on surfaces and objects to reduce build-up of charge hence shielding electronic gadgets in addition to sensitive components.

- Conductive Foam and Packaging: These prevent static discharge that may ruin delicate parts while holding and shipping electronic components.

These materials play an important role in the establishment of complete ESD safety protocols in areas where electrostatic discharge is a major concern.

Importance of ESD Safe 3D Printing for Electronics

The importance of ESD safe 3D printing to the electronics industry lies in its ability to avoid electrostatic discharge which can harm sensitive electronic components. In 3D printing, if ESD safe materials are employed, manufacturers can produce custom parts and housings that protect against static electricity damage. These substances help ensure that charge is safely dissipated which maintain the quality and functionality of electronics. Moreover, ESD safe 3D printing facilitates better design flexibility and faster prototyping leading to quicker development cycles under strict ESD safety requirements. It is this confluence of protection and innovation that must be maintained for progress in electronic manufacturing and assembly methods.

Which ESD Safe Filaments are Best for 3D Printing?

Here are some of the best ESD-safe filaments for 3D printing:

- PETG ESD Filament: This is a famous kind of filament in this field because it is tough and user-friendly, which makes it the best choice when creating protective housings and fixtures for electronic components.

- ABS ESD Filament: This type of filament is good for strong parts that need to be resistant to impact as well as static charge.

- PLA ESD Filament: PLA ESD filament has less enduring property unlike PETG or ABS but easier to print and thus great for prototypes and light-weight parts.

- Nylon ESD Filament: These are very good mechanical properties including safety from electrostatic discharges and therefore ideal for industrial applications requiring both strength and static dissipation.

The choice of what kind of filament is right will depend on various factors like durability, flexibility, as well as how much they protect against electrostatic discharge.

Top ESD Safe Filament Choices

Below are some of highly recommended ESD safe filaments for 3D printing:

- 3DXTech ESD PETG: 3DXTech’s ESD PETG is known for being strong, flexible, printable and durable amongst other things. It can be used in making reliable protective cases for sensitive electronic parts because it has been designed with the highest level of electrostatic discharge safety in mind.

- Proto-pasta ESD PLA: This filament is popularly known for its ability to be printed directly without any hassle especially for prototype work and lightweight applications. Proto-pasta’s ESD PLA has a moderate degree of strength and yet dissipates static effectively which makes it suitable for 3D printing projects that require complexity and detail.

- Taulman3D ESD Safe Nylon: Taulman3D’s nylon is also famous due to its superior mechanical properties and exceptional strength as compared to other brands. Its excellent resistance to ESD added with high tensile strength makes this filament highly adaptable in tough environments requiring both robustness and static control.

Selection of the right filament will depends on your particular project requirements such as material toughness, printability as well as how much static electricity protection you wish.

Properties of the Best ESD Safe Filaments

When considering the best ESD safe filaments, some important properties differentiate these advanced materials from ordinary 3D printing filaments.

- Static Dissipation: The main purpose of ESD safe filaments is to dissipate static charges that prevent the buildup of electrical charge which can damage sensitive electronic components. For instance, 3DXTech ESD PETG, Proto-pasta ESD PLA, and Taulman3D ESD Safe Nylon are among the engineered filament types with reliable static dissipation for shielding against potential electrostatic discharges.

- Durability and Mechanical Strength: Besides static discharge, such ESD materials have been designed to be highly durable and mechanically strong. For example, Taulman3D ESD Safe Nylon is known for having high tensile strength making it suitable for use in industrial applications needing robustness. Also, 3DXTech ESD PETG combines strength and flexibility thereby being useful in protective housing.

- Ease of Printing: When evaluating any filament ease of printing must not be left out as an important aspect. Proto-pasta is particularly popular due to its friendly nature while printing because prototyping and detailing process should be easy without complications.

- Thermal Stability: These filaments must also retain their structure under different temperatures. Typically, many materials classified as ESD safe exhibit excellent thermal stability hence allowing them to function consistently under various environmental circumstances.

- Compatibility: This implies that the ideal materials should support multiple printers as well as applications that may come with it. In this manner they can be used across varying projects without much ado starting from basic prototypes to very complex elements found within manufacturing units thus promoting efficient operations within such industries.

In combination, these vital qualities result in effective solutions for 3D printing demands involving electrostatic discharge protection when using certain brands of ESD safe filaments like those by 3DXtech, Proto-pasta, and Taulman3D.

Comparing ESD Filaments for Different Applications

When ESD filaments are compared on the basis of their material characteristics, ease of use and specific advantages it brings about for different applications, there will be a need to focus on this. This is what some top writers have said:

- Material Characteristics: The different varieties of ESD safe filaments like PETG, PLA and Nylon offer unique benefits with each having its own special uses. PETG filament is famous for strength and flexibility that make it suitable for durable applications. On the other hand, PLA filaments are user-friendly and appropriate to detailed tasks while Nylon filaments have an edge in terms of tensile strength and durability that makes them best suited in industrial applications.

- Ease of Use: In general, PLA is considered the easiest to print with as it gives smoother printing experience and calls for lower temperature settings. Next comes PETG which has medium level difficulty and requires higher temperatures. Lastly, nylon is more challenging due to its high temperature requirements coupled with its moisture sensitivity; hence proper handling and storage should be observed.

- Application Advantages:

- PLA: Best suited for prototyping, educational purposes, or fine prints whose friendliness matters most.

- PETG: Perfectly fits into areas requiring both strength as well as flexibility like protective housings and mechanical parts.

- Nylon: For heavy-duty industrial application where they possess high tensile strength and durability qualities.

By considering such factors when choosing a right filament users can optimize their 3D printing projects for both effectiveness during operation and protection against electrostatic discharges (ESD).

How to Choose the Right ESD Safe Resin for 3D Printing?

There are several factors that you need to consider when choosing the right ESD safe resin for 3D printing, such as your particular project needs and material properties. Here they are:

- Electrical Properties: ESD protection should be guaranteed by the resin, especially in electronic applications.

- Mechanical Strength: A durable and a tensile strength of the resin should be chosen based on purpose.

- Surface Finish: Assess whether the resin gives models the desired smoothness and precision details.

- Compatibility: The compatibility of the resin with your 3D printer model and its operational temperature ranges should be confirmed.

- Environmental Resistance: Resin has to withstand moisture, chemicals, and heat; this is even more important in industrial setting where conditions might become very demanding.

Therefore, through these requirements one can determine what kind of an ESD-safe resin would best suit their purposes.

Characteristics of ESD Safe Resins

To assess ESD safe resins’ qualities, a combination of electrical and physical attributes should be looked at that improve their performance in electronic and industrial applications:

- ESD Protection: These kinds of resins are specifically designed to dissipate static charges. They possess surface resistivity values usually ranging from 10^5 to 10^11 ohms/square which ensures effective ESD control.

- Mechanical Properties: Excellent mechanical strength is provided by these resins including high tensile and impact strengths, which makes them suitable for robust components. They also offer good resistance to wear and abrasion.

- Thermal Stability: The main purpose of designing ESD safe resins is to allow them function optimally under various temperatures. They have high heat deflection temperatures and can sustain long-term exposure to elevated temperatures without deteriorating.

- Chemical Resistance: In many cases, these resins hold up against broad spectrum of chemicals such as solvents, oils, acids etc., meaning that they can function well even in the harshest industrial environments.

- Dimensional Stability: Resisting stress during use or over time, ESD safe resins retain their shape and size ensuring dependable precision performance every time.

- Printability: This means that they behave well on multiple 3D printing techniques with good flow characteristics guaranteeing smooth dependable printing processes.

By understanding these key characteristics users are able to select the most appropriate ESD safe resins for their specific requirements hence improving the performance and reliability of their FFF printed parts.

Best Practices for Using ESD Safe Resins

While using ESD safe resins, here are recommended practices that guarantee best performance and long life of your components:

- Proper Storage: Keep ESD safe resins in a place that is cool, dry, and out of direct sunlight. Good storage conditions help to maintain material stability and its shelf life.

- Control Environmental Conditions: Make sure the working environment maintains consistent temperature and humidity levels because fluctuations can affect the properties of the material as well as the quality of printouts.

- Thorough Mixing: Before use, mix all resin completely so that there is uniform dispersion of conductive additives which is essential for good ESD protection.

- Use Appropriate Equipment: Use equipment that is compatible with ESD safe materials. For instance, employ 3D printers with enclosed chambers for stable printout environments.

- Regular Maintenance: Ensure that printing machines are cleaned and maintained regularly in order to avoid contamination and ensure uniform results. This involves cleaning the printer nozzles as well as platforms or replacing worn parts.

- Protective Gear: While handling ESD safe resins, wear protective clothing like gloves and goggles so as to prevent skin contact by them thus guaranteeing safety precautions.

- Post-processing Care: After printing, it is important to follow recommended post-processing techniques including curing or washing parts using appropriate solvents or solutions for desired mechanical or ESD properties.

The above practices will enhance performance efficiency as well as safety levels in electronic ad industrial applications where these materials are used.

Top ESD Safe Resin Brands

AS far as ESD safe resins are concerned, the following brands are consistently highlighted for their high-quality products and reliability:

- MakerJuice Labs: Its premium ESD safe resins are famous for great mechanical properties and static dissipation. Because they do not require frequent adjustments of viscosity in use, these resins are best-suited to a diverse range of industrial applications.

- Formlabs: Known as one of the leading names in 3D printing industry, Formlabs makes various types of ESD safe resins that have been engineered for durability and precision. They maintain uniform electrical conductivity on all occasions, thus making them suitable for use in making intricate electronic components.

- Elegoo: The affordability and quality aspect is what is associated with a line of ESD safe resins provided by Elegoo. These materials offer efficient protection against electrostatic discharge (ESD) which makes them popular among professional users and hobbyists due to their balance between price and performance.

What are the Key Considerations for ESD Safe 3D Printing?

While working on ESD safe 3D printing, some essential issues must be considered to achieve the best results.

- Material Selection: Select the resin that is of ESD protect and has also been formulated so as to match your specific requirements. It should exhibit consistent electrical conductivity and appropriate mechanical properties.

- Printer Compatibility: Make sure that your printer is compatible with resins that are ESD-safe. For efficient handling of these materials, some machines may require special configurations or adjustments.

- Environmental Control: Keep the environment constant for preventing contamination as well as maintaining consistency in ESD properties which might be influenced by humidity levels and temperature fluctuations.

- Safety Precautions: Put on necessary personal protective clothes such as gloves, goggles etc., if you want to keep your skin from coming into contact with this type of material. Moreover, reduce vapor exposure by working in properly ventilated places.

- Post-Processing: Follow all the recommended post-printing measures including washing and curing processes for completing printouts. Essentiality of right post-printing practices holds responsibility for reaching aimed at ESD & mechanical performances.

- Quality Assurance: Frequently check up on printed parts so they can meet required ESD specifications; after tests have been run, modify process where needed.

Understanding Electrostatic Discharge (ESD)

Electrostatic discharge (ESD) refers to a sudden flow of electricity from one electrically charged object to another resulting from contact, electrical short or dielectric failure. ESD can destroy electronic components and lead to product failure, hence making it important for many industries.

Why is ESD Important in 3D Printing?

In additive manufacturing, ESD is very significant in that it has the capacity of destroying any sensitive electronic parts present during production process. To prevent this, use ESD safe materials and maintain a controlled environment. Proper handling, environmental control and quality assurance measures are taken to ensure the integrity of the printed parts as well as meeting industry standards. In fact, including practices such as using ESD-safe resins and following recommended procedures not only preserves the components but also increases overall quality and reliability of final products.

Minimizing Static Charge in 3D Printing

A number of key practices must be followed in order to minimize static charge in 3D printing so that both the printed parts and equipment remain safe while printing is going on. To start with, controlling humidity levels at the place where printing will take place is important because high humidity hides static charges. Additionally, all equipment which comes into contact with printed materials should be grounded so that static does not accumulate rapidly. Grounding mats, wrist straps or grounding the printer itself can be used for this purpose. Moreover, ionizers can be introduced which produce ions to neutralize electric charges thus reducing static charge further. Static charge build-up can also be curtailed by regularly cleaning and maintaining printers as well as their components so that dust and debris do not pile up on them. Thus through these efforts you would achieve minimum static charge during 3D printing hence your printed parts would be both secure and meet required quality standards.

How to Ensure ESD Safety in 3D Printed Parts?

In order to observe ESD safety with respect to 3D printed parts, one must start by selecting ESD safe resins which are specifically manufactured for preventing static electricity buildup and charging. A controlled environment should be maintained during printing process with appropriate humidity levels and grounded equipment. The use of ionizers will help in neutralizing any static charges in the air. After printing, treat all parts particularly if an electrostatic discharge is unlikely to be introduced using ESD-safe gloves and tools. Keep these printed components stored in anti-static bags or containers until they are ready for use. These practices will ensure that your 3D printed parts maintain ESD safety.

Design Tips for ESD Safe Printed Parts

- Material Selection: Pick materials that possess natural ESD safe traits. Conductive and static-dissipative filaments are used to decrease static charge building up. Common materials include ESD-safe PLA and ABS, which are made specifically for handling electronic components.

- Layer Thickness and Print Speed: Set up your 3D printer with thinner layers and lower its print speed. Thinner layers assist in achieving greater surface uniformity, a prerequisite of ESD safety measures. Slow print speeds ensure adequate bonding between the layers thereby reducing any gaps that may form into pockets of static charges.

- Part Geometry: The design elements that you should be using must reduce sharp edges or corners where there is a higher possibility of accumulating static charge. Smooth rounded surfaces are preferred. Constructing parts with equal thickness also helps in distributing potential static charges uniformly.

- Surface Finishing: The application of post-print treatments such as sanding as well as the use of ESD-safe coatings has the effect of further reducing accumulation of electrostatic charge on these surfaces. These finishes improve surface conductivity while minimizing chances for electrostatic discharges.

- Infill Density and Pattern: Higher infill density can make the part stronger, thus reducing the likelihood of damage which leads to creation of static charges. Proper choice of infill patterns which are specifically meant for ESD safety would also enhance good electric resistance properties.

By following these design tips, 3D printed parts can be made suitable for environments sensitive to static electricity hence protecting both equipment and electronic components themselves.

Testing ESD Safety in 3D Printed Parts

Before you print your 3D objects, it is important to test the resistance of their surfaces with a megohmmeter or an ESD resistance meter. The surface resistance should be measured in different areas of the part and checked to see if it falls within the range suitable for ESD-safe materials (normally between 10^5-10^9Ohms). Also, perform charge decay tests by connecting a certain voltage on the parts and then measure time that can take for such charges to reduce to safe levels. Finally, employ a field meter to determine the electrostatic field around the piece and find high charge concentrations.

Applications of ESD Safe 3D Printed Parts

When dealing with sensitive electronic components, many industries have embraced ESD safe 3D printed parts. Such parts are used in manufacturing electrical gadgets’ custom jigs, fixtures and assembly tools without which static current could be discharged during production process hence causing damage that may cost huge sums of money since delicate circuitry or components would be destroyed. These include brackets, enclosures and housings in aerospace and automotive industries where mechanical strength is needed along with electrostatic protection. Additionally, medical field employs ESD safe 3D printing in creating equipment or spares that operate in environments where static discharge could interfere with sensitivemedical devices. This will make industries safer while reducing their costs as well as making all other kinds of products more durable through incorporating appropriate materials for preventing ESD cases into 3D printing technology.

Can ESD Safe Plastics Be Used in 3D Printing?

3D printers can use plastics that are ESD safe. They have been designed to dissipate static charges and hence are suitable for manufacturing components required for protecting electronics from static discharges. Recent advances in 3D printing technology have made it possible to obtain ESD safe filaments and resins making it easy to fabricate custom functional parts that can be used across various industries.

Types of ESD Safe Plastics for 3D Printing

In 3D printing with ESD safe plastics, we have some major materials known for their electrostatic dissipative properties:

- ABS-ESD: One often opts for ABS-ESD due to its strength, flexibility and ability of electrostatic dissipation. These reasons make it a popular choice of material when making tool holders, conveyor parts and work surfaces in the electronics manufacturing industry.

- PC-ESD: PC is an extremely strong yet lightweight material with high impact resistance and temperature tolerance. As such, PC-ESD is ideal for applications where robust mechanical performance is necessary along with electrostatic discharge protection such as housing or structural components.

- PETG-ESD: PETG has excellent toughness, moderate stiffness and is very easy to print. This filament is often used for manufacturing casings of electronic gadgets as well as free from static components which help them function continuously.

These materials allow industries to combine the need for proper functionality with protection against electrostatic discharge (ESD) risks on 3d printed parts they produce.

Advantages of Using ESD Safe Plastics

There are several key benefits to using ESD safe plastics in 3D printing:

- Protection of Sensitive Electronics: One of the most important advantages of using electrostatic discharge (ESD) safe plastics in a 3D printer is that it protects fragile electronic components from static discharges. In an environment where even the smallest amounts of electricity can disrupt operations and cause data loss, this kind of protection is indispensable.

- Increased Safety in Manufacturing Environments: Incorporating ESD safe materials into production workflows lowers the risk of electrical shock or fire incidents. This also ensures that employees have a safer workplace and that they do not expose their valued tools to possible damage by static electricity.

- Enhanced Durability and Longevity: Mechanical stresses and environmental factors are some of the conditions that many ESD safe plastics should be designed for, so as to improve upon the longevity and reliability associated with resulting components. This durability is particularly important for parts subjected to repetitive handling or harsh operating conditions.

- Cost-Effectiveness: While the cost might be more initially, when compared to common plastics, there will be long-term benefits such reduced equipment downtime, minimized product failures, and prolonged component life which cumulatively lead to overall savings.

- Compliance with Industry Standards: The use of electronic static discharge (ESD) safe materials helps manufacturers observe industry rules/regulations concerning electro-static discharge prevention. This compliance is essential for maintaining quality and reliability in critical applications across sectors such as electronics, aerospace, and medical devices.

Case Studies of ESD Safe Plastic Usage

1. Electronics Manufacturing

One leading electronics manufacturer managed to incorporate ESD safe plastics into their production line to shield the vulnerable components at manufacturing stage. In addition to that, by using ESD-safe trays and containers, the enterprise reduced electrostatic discharge cases significantly hence leading to a decline in product failures and return rate. As a result, product quality improved while operational efficiency and cost savings were enhanced.

2. Aerospace Applications

In the aerospace industry, one renowned aircraft manufacturer deployed ESD safe plastics for avionics system enclosures. Because of high-level stakes involved in aviation where there is no room for mistakes made by sensitive electronic systems installed on board any aircraft, this material was used. The overall robustness of these ESD safe items as well as reliability contributed towards safety and performance of aircraft thus providing a solution that could withstand electrostatic charges.

3. Medical Devices

A major medical devices company introduced ESD safe plastics to its advanced diagnostic equipment’s production procedures. To maintain precision and accuracy required for delicate medical tests, the devices had to be protected from ESD impacts. By changing over to ESD safe materials, stringent industry standards were met along with guarantees for integrity and durability of products that eventually resulted in better patient outcomes.

Frequently Asked Questions (FAQs)

Q: What is ESD material and why is it important in 3D printing for electronics?

A: ESD material, or Electrostatic Discharge material, is used to prevent static electricity, which can damage electronic components. In 3D printing, using ESD-safe 3D printing materials is crucial for creating components that protect sensitive electronics from ESD events.

Q: How do I ensure the properties of the material meet ESD surface resistance requirements?

A: To ensure the properties of the material meet ESD surface resistance requirements, it’s essential to choose the right ESD-safe 3D printing materials. These materials are specifically designed with dissipative properties to prevent static charge buildup that can harm electronic parts.

Q: Can I 3D print ESD safe parts and fixtures?

A: Yes, you can 3D print ESD safe parts and fixtures using ESD-safe 3D printing materials. These materials are designed to produce parts that protect electronic devices from electrostatic discharge.

Q: What common materials can be used for ESD-safe 3D printing?

A: Common materials for ESD-safe 3D printing include ESD ABS, ESD resin, and other specially formulated 3D printing materials that exhibit dissipative properties to mitigate static charge.

Q: Where can ESD-safe plastics be used in electronics?

A: ESD-safe plastics can be used in a variety of applications within electronics, including housings, jigs, fixtures to be 3d printed, and any component that might be exposed to electrostatic discharge. It is crucial to understand where ESD-safe plastics have been used effectively to ensure proper ESD protection.

Q: What are the benefits of using ESD resin in 3D printing?

A: ESD resin is beneficial in 3D printing because it combines the advantages of high precision and the necessary ESD-safe properties. This makes it ideal for creating intricate parts that meet ESD surface resistance requirements, reducing the risk of ESD events.

Q: How does 3D printing help in reducing the number of parts in an assembly?

A: 3D printing allows for complex designs to be combined and reduced into a single 3D printed part, simplifying the assembly and reducing potential failure points where static could cause issues.

Q: Who should I consult for advice on ESD-safe 3D printing materials?

A: Consulting with a head of R&D for materials or a co-founder involved in R&D for materials can provide expert advice on the most suitable ESD-safe 3D printing materials for your specific application.

Q: Can 3D printable ESD materials be used in rapid prototyping for electronics?

A: Yes, 3D printable ESD materials are ideal for rapid prototyping in the electronics industry. These materials allow for the fast creation of ESD-safe parts, enabling quicker testing and development cycles while ensuring ESD protection.