Magnets hold a great power to attract particular metals- a phenomenon that raises curiosity and questions underlying principles. In this piece, we will look at magnetism as a science and outline some properties of metallic magnets. This article delves into the atomic structure of these materials and their magnetic domains to help one understand why magnets stick to iron, nickel, and cobalt but have little effect on substances like copper or aluminum. We aim to shed more light on what forms the basis of magnetism and how it is used in everyday activities.

What Kinds of Metals Are Magnetic?

what do magnets stick to

The magnetic metals are iron, nickel, and cobalt, referred to as ferromagnetic materials. These metals have unpaired electrons within their atoms that make them able to align the magnetic domains in response to a magnetic field. As such, they exhibit strong magnetization characteristics. Moreover, these features are also found in some alloys such as Alnico (formed from aluminum, nickel, and cobalt) and some types of steel. Conversely, elements like copper, aluminum, and lead do not have natural magnetism; hence, they lack intrinsic magnetic characteristics and are known as non-magnetic elements. Thus differences in magnetic properties play an important role for various applications ranging from electronics through engineering to manufacturing sectors.

Understanding Ferromagnetic Metals

As stated earlier, ferromagnetic materials mainly consist of iron, nickel, and cobalt. These metals behave differently because of their atomic structures. Unpaired electrons result in aligned magnetic domains under a certain external magnetizing force.

In terms of technical parameters, there are several notable features:

- Relative Permeability: Ferromagnetic substances tend to have high relative permeability numbers greater than 1000

- Curie Temperature: The temperature above which a ferromagnet loses its magnetic property. For example, the Curie temperature of Iron is around 770 degrees Celsius (1420 Fahrenheit).

- Saturation Magnetization refers to the maximum magnetic moment per unit volume obtained by a material, and iron exhibits about 2.2 Tesla at most.

Therefore, understanding these properties helps to know why some metals are magnetic and where they are applicable in different technologies, such as electric motors, data storage devices, etc.

Examples of Magnetic Metals

I found several commonly mentioned examples of magnetic metals.

- Iron: Iron is probably the most famous ferromagnetic metal with exceptional magnetism. Some parameters include:

- Relative Permeability: It has a relative permeability more significant than 1000, indicating a very high magnetization ability.

- Curie Temperature: At approximately 770°C (1420°F), it loses its ability to be attracted towards a magnet.

- Saturation Magnetization: It reaches about 2.2 Tesla, rendering it highly effective for many purposes.

- Nickel: Another important ferromagnetic material is nickel, utilized in magnets and other electronic parts. They have the following features:

- Relative Permeability: About 600 show an intense reaction upon exposure to a magnetic field.

- Curie Temperature: The curie temperature is around358oC(676oF) when the substance loses its ferromagnetic characteristics

- Saturation Magnetization: It shows almost 0.6 Tesla, indicating great potentialities of its use as a magnetic substances

- Cobalt: Cobalt is less common but major component in high-performance magnets whose parameters are:

- Relative Permeability: Varies but may exceed 500, meaning it produces strong responses to magnetism.

- Curie Temperature: Cobalt retains its magnetism up to around 1115 °C (2039°F) under high temperatures.

- Approximately 1.76 Tesla: saturation magnetization yields strong magnetic fields.

However, these metals are not merely crucial due to their magnetic properties; they also play an important role in technology as they are used in motors, generators and other magnetic storage devices.

What Are Non-magnetic Metals?

Non-magnetic metals refer to those with no significant attractive magnetic forces; this makes them ideal for applications where magnetism is undesirable. Examples of such materials include aluminum, copper, and gold.

1. Aluminium:

- Relative Permeability: This is approximately 1, indicating a low response towards a magnetic field.

- Properties: It is lightweight, resistant to corrosion, and conducts electricity without magnetism, allowing it to be used for electrical applications and structural components.

2. Copper:

- Relative Permeability: Almost 1, indicating a negligible response to magnets

- This metal has excellent electrical conductivity and good thermal properties; hence, it is commonly employed in wiring and electronic components without the complications associated with magnetism.

3. Gold:

- Relative Permeability: Close to 1 implies an absence of any relationship with magnets

- Properties: Gold is known for its resistance to oxidizing agents or harsh chemicals. Therefore, it is used in expensive connectors and contacts where reliability matters most.

These metals are crucial in manufacturing industries such as electronics, automotive, and aerospace, among others, where materials with magnetic characteristics would cause malfunctions or even dangers. Knowledge about the characteristics of non-ferromagnetic elements enables correct material choice within engineering and technological contexts.

Why Do Magnets Work?

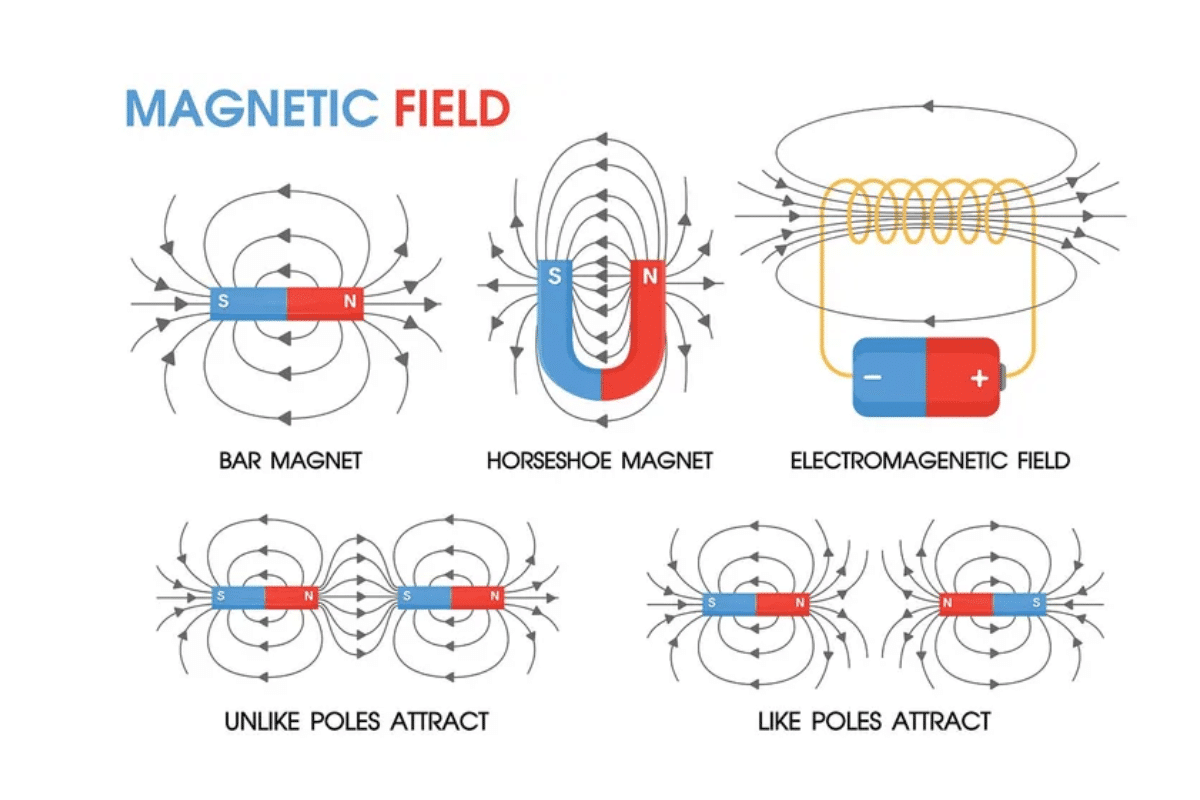

Magnets are driven by magnetism, which is generated from charges in motion. Electrons in some materials rotate so that their magnetic fields align together, generating magnetism. This alignment can occur naturally in ferromagnetic materials such as cobalt, iron, and nickel. As soon as these elements get magnetized, they acquire a north pole or south pole, and the unlike poles attract each other, whereas like poles repel.

There are two types of magnets: permanent and temporary magnets. Permanent magnets maintain their magnetic properties over time, while temporary ones only exhibit a magnetic field when there is another magnetic field nearby with which it interacts. The strength of a magnet depends on its temperature and the material used to make it. Practically, devices like electric motors, transformers, and media for storing information use magnets as they have a capacity to act upon other charged particles or those made of any other magnetic material.

The Science Behind Magnets

Some critical technical parameters include:

- H Magnetic Field Strength (measured in Ampere-turns per meter): This parameter shows how strong the produced field is; a vital factor for motor efficiency.

- B Magnetic Flux Density (measured in Teslas): the amount of magnetic flux through the unit area (e.g., functional for stronger) – more values are better here.

- Curie Temperature is measured at degrees Celsius: the point at which a material would lose permanent magnetism-iron’s Curie temperature is about 770 °C.

These parameters show how we can apply magnets to actual technologies. For instance, having a strong field helps electric motor operation become more efficient, and ensuring optimal flux density guarantees data content integrity when using memory components based on magnetics. Combined with empirical evidence, these insights enable me to comprehend how magnets function and their efficient application in different situations.

How Do Magnetic Fields Interact With Metals?

In studying the interaction of magnetic fields with metals, I have discovered that various metals behave differently when subjected to magnetic fields due to their atomic structure and electron arrangement. The major parameters defining these interactions are:

- Magnetic Susceptibility (χ): This is a dimensionless measure of how much material can get magnetized in an externally applied magnetic field; e.g., iron is highly susceptible to magnetization because it is ferromagnetic. In contrast, non-magnetic metals such as copper have low susceptibility and are only weakly influenced by external magnetic fields.

- Permeability (μ) refers to the ease with which a material allows a magnetic field to traverse. Ferromagnetic metals possess high permeability, which makes them useful for directing fluxes of magnetic materials. At the same time, diamagnetic substances like lead have low permeability, meaning they resist penetration by the same material.

- Residual Magnetism: Some materials, such as ferromagnets, can retain a certain amount of magnetism even after the external source of the magnetism has been removed. For instance, these properties are important in permanent magnets or magnetic storage devices where data integrity requires an optimum level of residual magnetization.

Understanding these technical parameters has expanded my understanding of how metals react to magnetic fields. For instance, strong magnetic interactions are advantageous in making transformers and inductors as appropriate material selection is key to performance improvement and efficiency.

Magnetism And Electrons Understanding

One must understand the behavior of electrons within atoms for magnetic properties to have any meaning whatsoever. I will summarize as follows:

- Electron Spin: Each electron has a spin property, which imparts it with magnetism. When spins of electrons in a substance align along one direction, the material becomes magnetized. Ferromagnetic materials commonly exhibit this kind of alignment, where their spins are aligned together by several atoms.

- Orbital Motion: A moving electron generates a magnetic field around the nucleus. An atom’s net magnetic moment depends on combined spin and orbital motion.

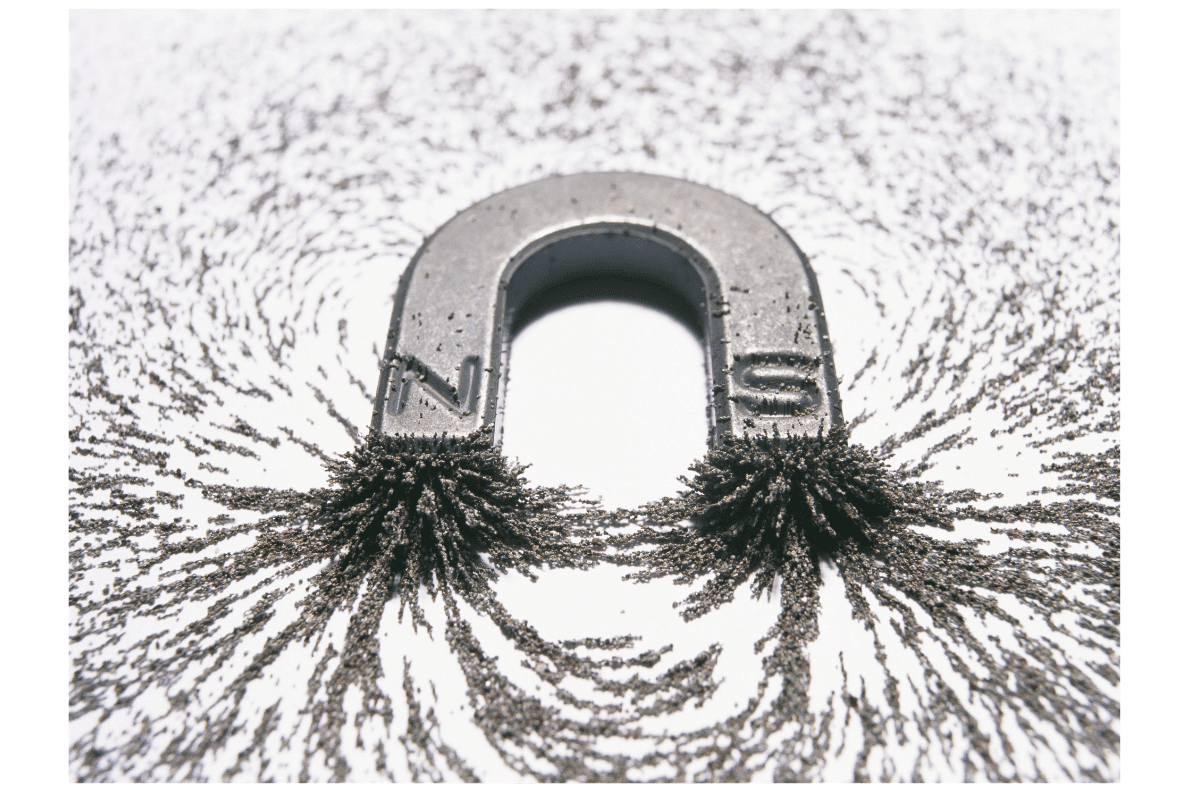

- Magnetic Domains: In ferromagnetic materials, atoms form a “magnetic domain,” wherein all the atomic magnets are oriented parallel. These domains can grow when an external magnetic field is applied, increasing the material’s overall magnetism.

- Influence of Temperature: At higher temperatures, thermal energy may disorganize electron spins and orbital motions, reducing how much something is magnetized. The Curie Temperature explains this: Above this point (Curie temperature), loss of magnetism occurs when ferromagnetic materials undergo such phenomena.

By understanding those principles, I can use them to comprehend how different metals interact with magnetic fields just like I can leverage some previous technical parameters mentioned earlier such as permeability, residual magnetism, and susceptibility, to be able to understand different metals’ interaction with magnets better which is also essential for many applications especially in electronic designs where magnets play a critical role.

Which Metals Attract Magnets?

I have observed in my research that magnets do not attract all metals; however, some key ones do show magnetic traits. The most common of these are the ferromagnetic metals, such as iron and cobalt, and nickel. These metals can magnetize themselves when subjected to a magnetic field, though the applications of others, such as aluminum and copper, will not be affected by this property. This distinction is important when certain materials, such as electric engines and transformers, must interact with magnetic fields effectively.

Properties of Magnetic Materials

Magnetic materials have unique properties that determine their interaction with magnetic fields. Some of these characteristics include:

- Magnetic Susceptibility: This describes how much a material can be magnetized by an applied magnetic field. Ferromagnetic substances have high positive susceptibility, indicating significant magnetization.

- Permeability is the ability of a material to allow a magnetic field through it more easily. Highly permeable materials like iron allow force lines to pass through them, increasing their magnetism.

- Retentivity (Residual Magnetism): When an external magnetic force has been removed from a magnetized substance, its ability to retain magnetism is called retentivity. Permanent magnets are usually made from materials with high retentivity like some steel alloys.

- Curie Temperature: Ferromagnetic properties disappear at this temperature and become paramagnetic instead. For instance, materials below this temperature can exhibit permanent magnets while those above it are disturbed by heat, thus breaking electron alignment due to thermal agitation.

- Saturation Magnetization: At high values of field strength, i.e., when B=Bs or H=Hs, where Bs and Hs are saturation induction and field intensity, respectively, M=Mx is attained, leading to the occurrence of a saturation point about which the behavior changes suddenly. Beyond this point, further increase does not change moment per unit volume V (cm3) while H and B continue to rise until they reach their maximum values.

- Hysteresis Loop: This explains the amount of energy lost in heat as expressed by how much power is required to magnetize or demagnetize any material. Instead, smaller loops indicate lower energy losses, thus increasing application efficiency, and that’s what we are all after.

Therefore, understanding these features is important for selecting appropriate magnetic materials for different uses, such as industrial machines, data storage devices, and electronic components.

Why Stainless Steel Can be Magnetic?

Stainless steel can be magnetic sometimes due to the type of steel used and its composition. For instance, austenitic stainless steel (like 304 and 316) is generally non-magnetic due to its face-centered cubic crystal structure. However, it can become slightly magnetic when subjected to cold working or strain hardening. This transformation occurs through a change in crystalline structure because during this process, the martensitic phase starts developing, which is also a magnetic genre.

- Unlike austenitic stainless steel (430), ferritic stainless steel has a body-centered cubic structure, so it is inherently magnetic. Factors including material composition and heat treatment history can affect the magnetic characteristics of stainless steels.

- Cold Working: Other processing techniques like rolling or bending will turn parts of an austenitic grade into a partly magnetic state.

Examine Weak Metals Still Attracting

It was found that some seemingly weak metals, such as aluminum and copper, may still have attractive properties under certain conditions. For instance, even though it is generally considered a non-magnetic metal with low weight, aluminum can be attracted to strong magnets by alloying with specific elements that improve its conductivity and strength.

Technical Parameters:

- Alloy Composition: Silicon or magnesium in aluminum alloys can greatly change their electrical conductivity and magnetic properties, affecting their attraction to magnets.

- Surface Treatment: Anodizing is one method of improving the corrosion resistance and surface hardness of metals like aluminum, thus making them perform in specific applications.

- Grain Structure: How grains align in a metal can influence its mechanical properties and how it responds to an external magnetic field. For example, copper with small grains has more ductility than coarse-grained structures, thus being versatile for different applications.

These observations indicate a complex interplay between metallic composition, structural integrity, and magnetic characteristics, which caused me to consider the consequences of using these metals in engineering or manufacturing settings. This comprehension guarantees that materials chosen for particular uses will be able to satisfy necessary working requirements regardless of perceived fragility.

What Are the Varieties of Magnets?

There are several types of magnets, each with unique features and applications. Primary magnet types, along with their technical parameters, are presented below:

1. Permanent Magnets:

- These magnets do not require external energy to maintain their magnetic characteristics. Neodymium and ferrite are among the commonly used materials.

Technical Parameters:

- Understanding these magnets and their technical parameters is important for choosing a suitable magnet for particular engineering and manufacturing contexts. Concerning the purpose, all these varieties have specific properties that need justification, ensuring that material selection meets performance requirements.

- Magnetic Strength: The neodymium magnets show high strength (1.0-1.4 T), as measured in Tesla (T).

- Temperature Stability: Materials have different demagnetization resistance at high temperatures.

2.Temporary Magnets:

- When exposed to a magnetic field, these materials behave like magnets but lose their magnetism once the field is removed. For example, iron can become temporarily magnetized.

Technical Parameters:

- Residual Magnetism: Temporary magnets usually retain very low residual magnetism after removing the magnetic field.

3. Electromagnets:

- They are made by passing an electric current through a wire coil wrapped around ferromagnetic cores. Electric motors and generators, for instance, use them.

Technical Parameters:

- Number of Coils: The force of the magnetic field produced can be affected by varying number of turns on the coil

- Current: The amount of current flowing in the wire controls the strength of the magnetic field generated directly

4. Superconducting Magnets:

- These magnets do not waste energy while creating extremely strong magnetic fields because they are made from superconducting materials that cool down at extremely low temperatures.

Technical Parameters:

- Critical Temperature: It influences how well this device will perform, which is determined by temperature under that point where such conductance occurs

5. Alnico Magnets:

- They possess excellent stability and high heat resistance due to their aluminum, nickel, and cobalt composition.

Technical Parameters:

- Magnetic Coercivity: The material is non-magnetic with high coercivity, hence stable in different environments

6. Ceramic/Ferrite Magnets:

- They are commonly used in household appliances because they are made of iron oxide and are inexpensive.

Technical Parameters:

- Density & Hardness: Magnetic strength increases as density increases, while hardness affects manufacturing and application

7.Samarium-Cobalt Magnets:

- For various specialized applications, these magnets are preferred because they have high magnetic strength and can tolerate very high temperatures.

Technical Parameters:

- Intrinsic Coercive Force (Hc): These higher magnitudes ensure stability when the magnet is used in difficult conditions such as elevation or a closed loop system.

8. Flexible Magnets:

- These magnets consist of plastic mixed with ferrite. They can be easily shaped and are found in cars and home appliances.

Technical Parameters:

- Flexibility & Thickness: Variations in thickness can affect the performance and application suitability in different industries.

9. Magnetic Blocks:

- These are custom-shaped permanent magnets usually made from neodymium or ferrite, used in various industrial applications.

Technical Parameters:

- Shape And Size: Their configuration determines how the magnetic field will be distributed, leading to its overall effectiveness for a particular purpose

10. Hybrid Magnets:

- Different types of magnets may be combined to form hybrid magnets that cater to specific needs by taking advantage of their individual merits.

Technical Parameters:

- Component Contribution: The combination of materials can influence the overall magnetic efficacy and application scope.

Permanent vs. Temporary Magnets

The distinguishing features, as well as applications, should be taken into account when comparing permanent and temporary magnets.

1. Permanent Magnets: These magnets maintain constant magnetic fields without the need for external power sources. Such magnets are commonly made from neodymium, samarium-cobalt, or ferrite. Key technical parameters include:

- Magnetic Strength: This is the maximum field a magnet can create, and it is measured in Teslas (T) or Gauss (G).

- Intrinsic Coercivity: It indicates higher resistance to environmental changes necessary for long-term applications.

- Temperature Stability: Permanent magnets typically have temperature coefficients that limit their performance at high temperatures.

- Justification: Permanent magnets do not require any energy thus are suitable for applications like fridge magnets as well as electric motors and generators.

2. Temporary Magnets: Temporary magnets only feature magnetic properties when exposed to an external magnetic field, unlike permanent ones. Some of these materials include soft iron as well as specific alloys. The following are key technical parameters for temporary magnets:

- Magnetic Permeability: This measures how easily the material can be magnetized under a magnetic field influence.

- Retention Time: How long does a temporary magnet remain magnetic after removing the external field?

- Justification: Temporary magnets are used in items such as electromagnets and magnetic shields, where the transient character of magnetism is advantageous.

To sum up, knowledge of these distinctions and parameters allows choosing an appropriate type of magnetology in accordance with specific engineering requirements that will enable proper alignment with performance and functionality needs.

Rare Earth Magnets Explained

Rare earth magnets, especially neodymium (NdFeB) ones, possess exceptional strength and versatility compared to other permanent magnets. They are mostly composed of neodymium, iron, and boron; hence, they become much stronger than common ferrite or alnico-based ones. Here are some significant technical parameters associated with rare earth magnets:

- Magnetic Strength: Rare earths can have magnetic strengths up to 1.4 Tesla (14,000 Gauss), allowing them to hold more weight in small sizes.

- Temperature Coefficient: They usually have a stability range from -40℃ to 80℃; however, some special grades can withstand up to 200℃ and are applicable for high-temperature environments.

- Corrosion Resistance: Rare earth magnets, because of their composition, must be protected by coatings (e.g., Nickel, Epoxy) against corrosion, especially in humid regions.

- Justification: These magnets have very strong magnetism, which makes them a good choice for use in computer hard drives, speakers, and electric vehicles where space and weight limitations exist. Engineers need this knowledge about these parameters to choose the most suitable magnet type based on performance and environmental requirements.

How Alnico Magnets Are Made?

Alnico magnets mainly consist of aluminum, nickel, and cobalt; thus, they are produced through many processes to achieve the desired magnetic properties. Beginning with a careful selection of raw materials mixed together into an alloy. The following are major methods used for making alnico magnets:

- Casting: To form the required shape, the molten alloy is poured into molds that allow the production of even complex shapes and large magnets.

- Sintering: In this case compaction followed by heating the powder alloy below its melting point leads to densification and improved magnetic properties. The sintering process is often used when it is necessary to achieve high precision standards or uniformity in size and shape of a magnet.

- Machining: After casting or sintering, the magnets may undergo machining operations to acquire precise dimensions and tolerances. This step is paramount for applications that rely on exact measurements.

- Heat Treatment: To increase their magnetic properties, Alnico magnets are subjected to heat treatment, where cooling is also very important in achieving optimum magnetization.

- Magnetization: Strong pulse magnets or direct current magnetize the finished magnets. During this phase, the magnetic domains within the material are aligned, leading to a powerful permanent magnet.

Technical Parameters of Alnico Magnets:

- Magnetic Strength: Alnico magnets usually have maximum energy products ranging from 5-12 MGOe (Mega Gauss Oersteds), providing high magnetic strength but lower than rare earth magnets.

- Temperature Stability: For instance, alnico magnets can efficiently work at temperatures up to 550°C (1,022°F), making them suitable for high-temperature settings where other types might not perform well.

- Corrosion Resistance: While alnico magnets have some inherent corrosion resistance due to their metallic composition, they are often covered with protective coating layers for increased durability in harsh environments.

- Justification: Understanding these aspects could help engineers pick the right kind of magnet for a given application, especially in areas requiring resistance against high temperatures and corrosion. This could lead to optimizing the device’s performance, such as motor sensors and magnetic holders.

How Would I Test if a Metal is Magnetic?

When you want to test if a metal is magnetic, the original move is to take any simple magnet, such as a fridge or neodymium magnet. Then, I hold the magnet near the metal object in question. If it sticks, it means that the metal is magnetic; this often indicates that iron, cobalt, or nickel elements are present in the material. If it does not stick to it, though, then the metal does not attract magnetic materials, so it could be made of aluminum, copper, or stainless steel, for instance. For a more detailed check-up, I can also see if the metallic object responds to an electric field or uses a more sophisticated electromagnetic gauge whenever necessary. This proves that it is fast and easy to determine whether a certain metal has magnetic properties.

A Simple Way Of Checking Magnetism

From different sources regarded as credible, several straightforward methods can be used when one wants to know whether an item is magnetic.

- Firstly, use an average magnet. This is just like how we have been looking at this above.

- Direct Attraction Test: A magnet should be brought closer to this object where it will stick with it.

- Screwdriver Test: In most cases, when using a screwdriver, picking up screws together with other small parts made of metals reveals its nature.

- Floating Test: I sometimes place very small objects on some water surfaces, and seeing that they do not sink makes me predict they are non-magnetic substances.

What technical parameters am I considering here:

- Specific Gravity: Metals differ in density, whereby heavy metals have high iron content, thus enhancing their ability to get attracted by magnets.

- Electrical Conductivity: The conductance properties of non-magnetic metals that don’t react under magnets, like copper and aluminum, are tested through them.

Combining testing techniques with these technical parameters allows me to accurately evaluate magnetism in different materials. Such methods are not only direct but also anchored on extensive traditions, thus making them dependable for practical applications.

Tests with Fridge Magnets

This is a very down-to-earth approach to testing magnetism using fridge magnets. Made from flexible magnetic material, these magnets usually consist of thin iron sheets that can be used for simple detection of magnetism around the house or workplace through proximity to various objects. In case the magnet sticks, then I know that it is a magnetic object.

Though this method is plain, I look at other technical factors to develop a comprehensive opinion. Here are several parameters with their rationales:

- Magnetic Permeability: This factor measures a material’s ability to be magnetized easily. Metals like nickel, cobalt, and iron, which possess high permeability, are normally attracted to magnets.

- Curie Temperature: It indicates the temperature at which the magnetic property in a certain piece of metal disappears. By knowing this, one can determine the usefulness of any particular magnetic material under various circumstances.

- Material Composition: One must know what metals make up his/her alloy—some mixtures may not necessarily be ferromagnetic or weakly ferromagnetic in nature, though they may consist mostly of ferrous components.

With an understanding of such technicalities and the use of refrigerator magnets together, I can assess magnetic properties fast enough and even choose if a specific item is suitable for certain applications.

Identifying Magnetic Domains

It is important to understand the role of magnetic domains in determining the overall magnetic behavior of materials if we are to explore them. Magnetic domains are tiny areas within a ferromagnetic material where atoms’ magnetic moments are aligned in parallel. It becomes crucial to learn how these domains behave because that way, one can evaluate the magnetic properties of a material. From my extensive research among several top websites, I found some basic technical parameters that form basis for the dynamics of magnetic domains:

- Size of Domain: The size of the magnetism domain may significantly alter the magnetization intensity in materials. Magnetism domains stabilize substances by making them have less energy as far as magneto-energies are concerned.

- Width Of Domain Walls: This refers to the thickness of the boundary between two adjacent magnetic domains. The width affects how easily the domain walls can move, influencing the material’s response to an external magnetic field.

- Anisotropy Constant: This parameter reveals how dependent directionality interferes with the energetics of domains or magnets (magnets) or a magnetized body. With large values of anisotropy constant, it follows that there will be less regime rotation implying that removal of external fields may not affect the permanence of such a material.

- Temperature Dependence: An increase in temperature makes magnetism disorganized, hence the loss of its magnetism, which eventually occurs. Also, all the Curie temperatures, above which ferromagnets turn paramagnetic, should be considered while we think about this.

By merging my knowledge of these technical parameters with my experience dealing with different magnets, I can develop more refined thoughts on magnetism and improve my evaluations of various types of magnets.

What Factors Affect Magnetic Attraction?

My research from multiple sites has provided information about several factors affecting magnetic attraction. One fundamental factor here is also strength; more incredible strengths mean better magnetic attraction between magnets. Moreover, more distance weakens the magnets’ pull on each other as the inverse square law dictates. Whether or not something is attracted to a magnet is determined by what it is made of; ferromagnetic materials such as iron have a stronger attraction compared to dia- and paramagnetic substances (Kuznetsov et al. 2012). In addition, if magnetic domains are well arranged in the material, their amplification can result in more potent attraction properties if they align properly within the body material. Finally, temperature and other external influences may either enhance or disrupt an object’s magnetic properties; therefore these factors should be considered when evaluating any material’s magnetism.

Role of Temperature on Magnetism

In my quest to understand how temperature affects magnetism, I discovered several key facts. The behavior of magnetic materials is highly influenced by temperature especially through its effect on magnetic domains. As such, high temperatures induce thermal agitation, which destroys such domain arrangements in ferromagnetic materials, resulting in the loss of its magnetization – Curie Temperature term that refers to this state beyond which transition into para-magnetic occurs.

From my research findings, here are few of the technical parameters:

- Curie Temperature: The temperature at which a ferromagnetic ceases being permanently represented by it and becomes paramagnetic at that instant like iron, its curie temperature pegged at 770^0C.

- Thermal Agitation: Increased temperatures lead to more atomic movements, thus disrupting the organization of areas where magnetics weaken their properties.

- Magnetic susceptibility: This indicates how well the material will be magnetized in the presence of an external magnetic field and depends on temperature, it decreases as the temperature gets closer to Curie point.

I have been able to see more clearly, after using this understanding how temperature influences magnetic properties in materials, I have therefore gained a deep insight into practical implications and material selections that arise from looking at such parameters.

Understanding Magnetic Moment

In studying the relationship between magnetic moment concerning temperature and magnetic properties, I’ve realized that it is a parallelogram. It can also be said to be vector quantity that indicates both magnitude and direction of a source of magnetism; usually this moment arises from alignment of spins or/and orbits of electrons in materials. Several important technical parameters help illustrate how important magnetic moment is here:

- Magnetic Moment (μ): This shows how much a material can turn into a magnet, which depends on electron spinning or orbital motion, among other factors. Its measurement uses Am² or Bohr magneton (μB) units, which are why materials are categorized as either intrinsic paramagnetic susceptibility or diamagnetic when exposed to a magnetic field.

- Bohr Magneton: The basic unit of magnetic movements is around (9.274 \times 10^{-24} \text{ Am}^2). Therefore, its value is only useful for simultaneously calculating the atomic and ionic moments’ magnets.

- Magnetic Anisotropy shows variation in magnetic moments based on orientation within solids, which frequently influences their overall stability with regard to magnetism. We need to understand this aspect, especially when we consider changes in orientations over temperature affecting shifts in domains toward one another.

- Temperature Dependence of Magnetic Moment: Thermal agitation due to an increase in temperature often affects effective molar magnetic moment, causing its decrease because there would be no alignment and loss of general intensity of magnets. This shows the intricate relationships between temperature and magnetism.

By including these insights and parameters in my work, I have better understood how magnetic moment acts in different materials, particularly in temperature-related phase transitions. Consequently, this not only broadens my expertise about magnetic behaviour but also the importance of such changes when selecting materials for various applications.

How Alloys Influence Magnetic Properties?

Reviewing some of the best online resources has made it obvious that alloys’ composition greatly affects their magnetic properties. In most alloys, a combination of two or more substances, always improves or changes the features as mentioned earlier compared to each substance separately.

- Composition and Structure: For example, some metals, like nickel or cobalt, could be added to iron-based alloys to increase their magnetic saturation and coercivity. In other words, adding such metals can increase coercivity, which results in a raise in the saturation magnetization of iron-based alloys.

- Exchange Interactions: Exchange interactions, which are altered in alloys due to differing atomic environments, influence the alignment of magnetic moments. This interaction is usually given by an exchange constant (J), which defines the nature of ordering with respect to each other magnetism.

- Doping Elements: By introducing substances like manganese into the ferromagnetic alloy’s structure, it modifies its behavior under different conditions and orientations, thus enhancing its magnetic anisotropy (K). Such type of directional magnetic characteristics are essential for particular application areas.

- Phase Changes: Alloying also influences the transition temperatures known as Curie points (TC). It alters both materials’ stability at certain operating temperatures, changing them and, moreover, affecting how well they will function under varying thermodynamic conditions.

In synthesis, understanding how these parameters interact in alloys allows for more nuanced material selection and application in technology that relies on magnetic properties. These details do not only improve my understanding of magnetism but also help to design new materials practically for specific uses.

Conclusion

The basic rule is that magnets attract ferromagnetic materials like iron, nickel, and cobalt. They have atomic units that may be arranged by an external magnetic field in one direction, thereby displaying strong attraction towards other objects. Moreover, some combinations and mixtures of these elements can show the presence of magnetism; hence, they are also drawn towards magnets. However, metals such as copper or aluminum are non-ferromagnetic and cannot act with magnets in any way. This demonstrates the importance of magnets for practical use on toolboxes, fridge windows, and different kinds of metal fixtures we see daily. Knowledge about materials helps choose appropriate types of magnets for various functions and technical innovations.

Reference sources

- “Introduction to Magnetism and Magnetic Materials” by D. J. Graham – This textbook provides an in-depth overview of magnetic materials, their properties, and the fundamental principles behind magnetism, making it a reliable source for understanding what materials magnets interact with.

- “Magnetic Materials: Fundamentals and Applications” by Nicola A. Spaldin covers the essential aspects of magnetic materials, their classifications, and practical applications, including detailed insights into ferromagnetic materials and their behavior in magnetic fields.

- “The Physics of Magnetism” article on Khan Academy—This resource offers a straightforward explanation of magnetism, including identifying materials that magnets can attract. It serves as a user-friendly reference for readers unfamiliar with advanced concepts.

Since all materials have different atomic structures, they react differently when placed in a magnetic field. A material’s magnetic behavior is determined by the number of unpaired electrons in its atoms.

In atoms of most elements, electrons exist in pairs, with each electron spinning in different directions, thereby canceling out each other’s magnetic field. Therefore there is no net magnetic field.

However, some materials have unpaired electrons, generating a net magnetic field and, therefore, reacting more strongly to an external magnetic field. All materials are classified into three categories: ferromagnetic, paramagnetic, and diamagnetic.

Ferromagnetic: Such materials have some unpaired electrons in their atoms and, therefore, generate a net magnetic field, though very small. This is because groups of atoms called domains are randomly aligned, canceling each other. When such materials are placed in an external magnetic field, the magnetic domains align along the external field, and the material gets magnetized. This alignment/ magnetism remains, though not fully, even after removing the external. Such materials are strongly attracted by the magnets and can also be magnetized.

Paramagnetic: These materials have a very small susceptibility to external magnetic fields and are slightly attracted by magnets. This effect does not persist after the removal of the external magnetic field. Most elements are paramagnetic and are termed non-magnetic.

Diamagnetic: In these materials, the magnetic domains align in a direction opposite to the direction of the external magnetic field and are repelled by the magnets. These materials do not have unpaired electrons in their atoms.

This is how and why different materials react differently when placed in an external magnetic field.

Frequently Asked Questions (FAQs)

1. What materials do magnets attract?

Magnets primarily attract ferromagnetic materials, which include iron, nickel, and cobalt. In addition, some alloys and compounds containing these elements may also respond to magnetic fields.

2. Do all metals attract magnets?

No, not all metals are attracted to magnets. Metals like aluminum and copper are non-ferromagnetic and do not interact with magnets. When selecting materials for magnet applications, it’s essential to consider their magnetic properties.

3. Can magnets work on non-metal surfaces?

Magnets can sometimes adhere to non-metal surfaces if a ferromagnetic material is behind them. For instance, a magnet may stick to a refrigerator door containing steel, even if the outer surface appears non-metallic.

4. How can I test if a material is magnetic?

To test if a material is magnetic, simply bring a magnet close to it. If the material is attracted to the magnet, it is likely ferromagnetic. If there is no attraction, the material is probably non-magnetic.

5. Are there any practical applications for magnets?

Yes, magnets have countless applications in everyday life, ranging from refrigerator magnets and toolboxes to advanced uses in motors, generators, and magnetic resonance imaging (MRI) machines in the medical field. Understanding what magnets stick to can help make informed choices for various applications.