In many industries, welding is essential, and before high-quality results can be achieved, you have to know the materials involved. Among other things surrounding welding, selecting the right electrode or welding rod is an important aspect, with each of these having a specific numbering system. This article aims to expose the mysteries behind the numbers on welding electrodes, providing information about what these figures stand for and how they affect the welding process. By understanding different welding rod numbers, we can equip readers with the knowledge required to make informed choices leading to stronger welds and increased safety and efficiency in their projects.

What Do Welding Rod Numbers Mean?

welding rod number meaning

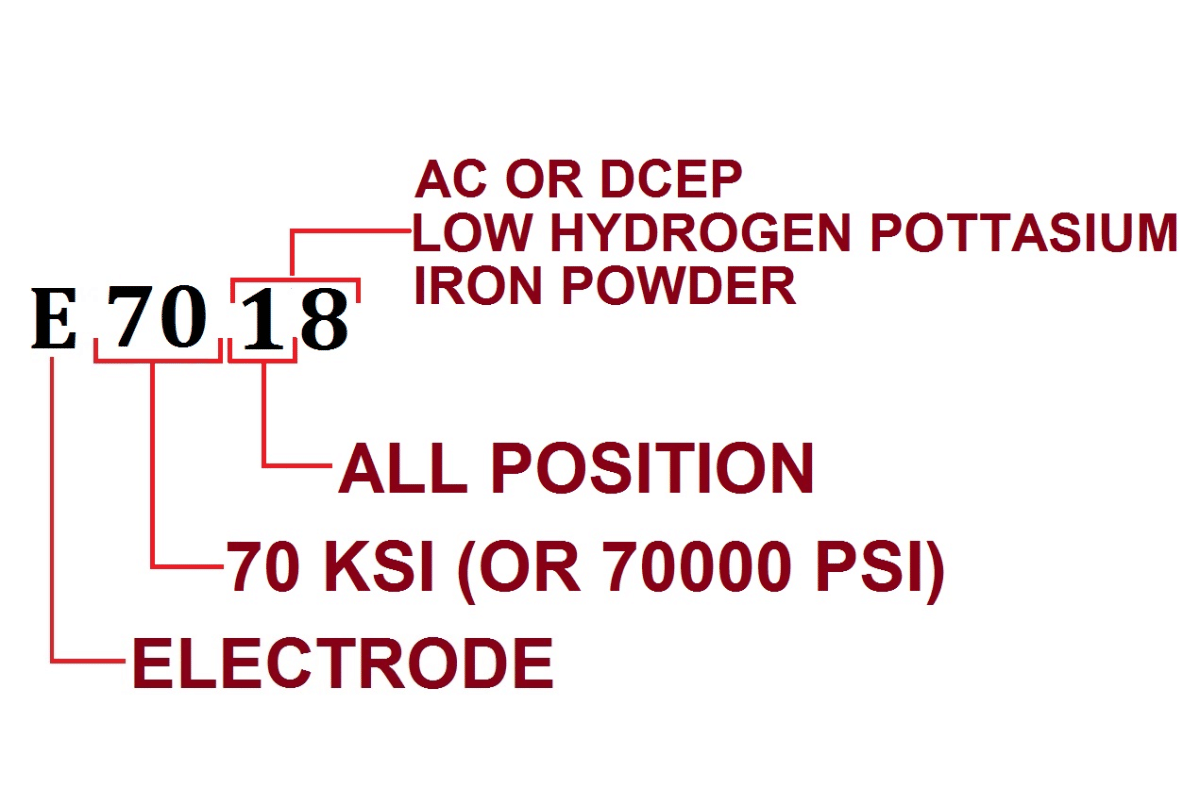

Welding rod numbers are intended to communicate key information regarding each electrode’s attributes and fitness for specific welding tasks. Usually, one would notice that the two first digits represent the tensile strength of a rod (e.g., 70 means 70,000 pounds per square inch). The third digit often tells us when and where this rod can be used such as ‘1’ being flat or horizontal while ‘2’ stands for all positions. In addition, the last figure may sometimes indicate the coating type and current for welding. I can select my appropriate electrode by interpreting these numbers to get optimum performance in my welding work.

Understanding the First Two Digits of Welding Rod Numbers

The first two digits are crucial in determining the strength of an electrode; this will determine its suitability for different types of tasks. Tensile strength refers to how much stress a material can take before it breaks apart when subjected to stretching or pulling forces.

- Tensile Strength: The first two digits reveal the PSI (Pounds per Square Inch) tensile strength value (psi) while specifying a specific location where the products are produced elsewhere, like E6010 at 60-kilo pounds psi, E7018 at 70-kilo pound psi, or E6013 at 60-kilo psi. Welders select rods that can handle the stresses they will experience in their specific projects.

- Importance of Selection: Proper choice based on tensile strength ensures the weld can withstand specified loads and environmental conditions. If an electrode with inadequate strength is used, a failure point could be created, leading to weak welds in the welded structure.

- Common Examples: The industry has many welding rods, such as E6010 (60,000 psi), E7018 (70,000 psi), and E6013 (60,000 psi). Each one has its own uses and attributes that stress why it is essential for welders to understand these numbers.

By comprehending what the first two digits stand for in terms of welding rod numbers, welders can make wise decisions that contribute to the success and safety of their entire welding project.

What Does the Last Digit Indicate in Welding Electrode Numbers?

The last digit of a welding electrode number usually indicates the position for which it was designed. This number ranges from 0 to 8, typically representing different positions or capabilities:

1. All-position welding—It is Suitable for all types of positions (flat, horizontal, vertical, and overhead).

- Flat and horizontal positions – These are useful for flat and horizontal welding applications.

- Horizontal position – Designed for horizontal welding.

- Overhead positions are advised that this is ideal for overhead welding.

2. Vertical down – Vertical downward welds.

- Overhead position – Ideal for overhead welding.

- Overhead position – Suitable for overhead welding.

- Rarely seen in practice – It is not usually used by welders

- This generally means a particular formulation or capability, often non-standard

Welders who understand these designations can choose the right electrode to improve their work’s quality and efficiency. Proper alignment of electrode type with its corresponding position is imperative, as wrong choices may result in insufficient penetration, poor bead appearance, and stress joint failure.

Decoding the Letters in Welding Rod Numbers

Most numbering systems for welding rods contain letters and numbers that give information about their characteristics and intended use. The letters sometimes denote what kind of electrode it is, including:

1. E stands for “electrode,” meaning that it has been manufactured exclusively as a welding tool

2. Classification Letters: After ‘E,’ you might find letters indicating the filler material type or process to be used during welding. Some common ones are:

- R refers to the rod instead being used in some structural applications primarily;

- L implies low hydrogen levels which, according to me, signifies less possibility of hydrogen cracking from an arc welded joint;

- S symbolizes stainless steel electrodes

3. Filler Metal Designation: Usually involves a numeric code after this stage representing minimum tensile strength deposited weld metal specified as thousands of pounds per square inch (psi). For instance, code 70 indicates a minimum tensile strength of at least 70k psi.

4. Additional Specifications: In other cases, the subsequent lettering may provide specific information regarding such parameters as chemical composition or mechanical properties associated with weld deposits. Such may include:

- H4 means that there are 4 ml Of hydrogen per hundred grams in this particular electrode.

- 1 or 2 indicates the welding position for which the electrode is suitable, coinciding with the last digit of the welding rod number.

Welders must know what such codes stand for to ensure that they choose electrodes right for their particular needs. This will adhere to technical requirements and optimize welds. Such knowledge is further reinforced by standards guidelines, including those from AWS (American Welding Society) specifications, which are crucial in maintaining safety and performance during welding activities.

How to Choose the Right Welding Electrode?

Choosing the right welding electrode starts with my understanding of what I want for my project. I look at the base materials and choose electrodes that go well with them considering the intended welding processes. I also look at the mechanical properties required, including minimum tensile strength as indicated by numeric codes given to electrodes. For example, if I need a tensile strength of 70,000 psi, I will look for a 70’ designation. In addition, hydrogen content in an electrode is also important; low hydrogen electrodes, denoted by “L,” prevent cracking in critical applications. To this end, by referring to industry standards and guidelines like those of the American Welding Society (AWS), I ensure informed decisions concerning weld quality optimization and safety maintenance during my undertakings.

Factors to Consider When Choosing a Stick Electrode

Several Key factors should be considered when picking out a stick electrode:

- Base Material Type: Distinguish the sort of metal you will join together (e.g., mild steel, stainless steel, aluminum) as it impacts your choice of an electrode—there are specific types for each material.

- Electrode type & Coating: What happens when you choose one coating over another on an electrode? It affects arc stability and slag type. Some alternative options include E6010 for deep penetration or E7018 for low hydrogen applications.

- Welding Position: Flow characteristics determine which weld positions specific electrodes are best suited for.

- Tensile Strength Requirements: Match up the electrode’s tensile strength with what it entails in your project specifications. For instance, E7018 electrodes are recommended for steels requiring a minimum tensile strength of 70,000 psi.

- Hydrogen Content: In cases where cracking becomes a problem, such as cracks in pipe welds, low-hydrogen ‘L’ designated rods were used to eliminate them.

- Current Type (AC or DC): This will depend on whether the power source for welding is AC or DC. For instance, E6013 electrodes can be used with either, while others are best suited for DC welding.

- Electrode Diameter: The diameter of the electrode influences weld bead size and penetration depth. Larger diameters may be preferred for thicker materials.

- Manufacturer Specifications: Review the manufacturer’s guidelines for electrodes, including usage recommendations, safety precautions, and compatibility with various welding machines.

- Application Environment: One must consider the environment where one will weld. In outdoor or windy conditions, a stronger electrode may be required to ensure that the weld holds together better.

- Cost and Availability: Finally, you should also assess the price and availability of electrodes because even when you select quality, material budgeting remains an important consideration.

By critically evaluating these factors, technical and safety standards can be met by selecting a suitable stick electrode for welding work.

Comprehending Varied Forms of Welding Electrodes

The correct welding rod is rather essential for a strong and dependable weld. Different welding rods exist for different materials and applications, each with unique characteristics. Some common types are discussed here, together with their technical specifications;

- E6010: This is excellent for pipework and structural welding root passes. Its deep penetration is best employed in direct current (DC) when one desires to travel faster.

- E6011: E6011 rods are known for their versatility. They can be used on AC and DC processes, making them perfect for welding at various positions. They can provide excellent arc stability even under dirty or rusty surfaces.

- E6013: These rods are typically used in mild steel applications. They offer a smooth arc that is easy to control and clean in appearance on the finished weld. They also work well in DC, often applied where thinner materials are involved.

- E7018: E7018 rods are a group of low-hydrogen electrodes suited for high-strength fields; their storage must be done correctly to perform efficiently. They can easily be used for thicker sections because they fit AC and DC.

- E7024: This is an example of the massive deposition rate type. It suits horizontal or flat positions better than others but remains ideal for extensive structure weldings, such as bridges or buildings.

When purchasing these types of electrodes, specific technical parameters include tensile strength rating, suitability for welding position, and type of current used. Understanding these details will assist you in choosing the right electrode for your project’s needs to maximize productivity without compromising safety during welding operations. Ensure you read more about its application and performance from the manufacturer’s technical data before using any electrode coating you buy.

Why Coating Welding Electrodes?

Coatings found in welding electrodes play crucial roles during the overall welding process. Their performance is affected by the weld’s quality and the electrode’s effectiveness. Below are highlighted some of the functions and importance of coatings.

- Stable Arc: A coat stabilizes the arc during welding, enhancing the controlled and consistent process. This is important for ensuring a strong joint with uniform strength.

- Shielding: The coverings also function as protective shields against atmospheric influences on molten weld pools like oxygen or nitrogen that may lead to defects such as porosity or oxidation in the final welds.

- Slag Formation: Slags are produced by coatings, which, when they harden, cover and protect welded joints, shielding them from possible contamination with improved surface finishing.

- Alloying Elements: Weld deposit mechanical properties, mainly its tensile strength and durability, can be enhanced through alloying elements in some electrode coatings for specific applications.

- Weld Appearance: Coating composition also affects how attractive an individual weld looks, giving better finishes crucial in visible structural situations.

Electrode Coatings Influence Several Technical Parameters Including:

- Tensile Strength – A measure of resistance to pulling forces when subjected to separate materials from one another

- Compatibility with Current Type – These coatings define whether an electrode can be utilized with AC or DC current, thereby influencing ease of use based on available equipment

- Position Suitability—Certain coatings have been designed to work effectively under different welding positions, such as flat, vertical, or overhead, assisting users in selecting electrodes for their projects.

In short, the covering on welding rods is important for solid and excellent welds. It must be thought about properly according to the welding process, meeting project requirements and safety standards. Always consult the manufacturer’s specifications for more detailed information on how electrode coatings affect things.

What Are The Different Types of Welding Rods?

I have discovered several significant types of welding rods as I delved into the world, and each is suitable for specific applications. These include:

- Mild Steel Electrodes: These are multipurpose rods recommended for general welding that involve steel structures.

- Stainless Steel Electrodes: These electrodes help resist corrosion when welding stainless steel, so they are used in food processing plants and marine environments.

- Cast Iron Electrodes: Explicitly designed for cast iron welds, these are mostly used to repair piping and machinery.

- Aluminum Electrodes: These welding sticks make a lightweight, strong bond as an alternative to many aluminum alloys, including those found in the automotive and aerospace industries.

- Flux-Cored Electrodes: This type of electrode is often used in semi-automatic or automatic applications with deep penetration required, usually with outdoor requirements, yet special equipment is needed.

Each variety of welding rod has distinctive characteristics, which should be selected based on the job specifications, including, but not limited to, particular materials to be welded and desired properties of the weld after completion.

Overview Of Commonly Used Welding Electrodes

When it comes to commonly used welding electrodes, it is important to understand their classifications and technical parameters to select the right one for a specific application. Here is a brief review according to various authoritative sources:

1.E6010 (Mild Steel Concrete):

- Characteristics: It can go deep into metal surfaces, making it perfect for vertical or overhead operations

- Application: Used mainly on pipelines with alternating or direct current as power sources

- Polarity: DC+ recommended

2.E6011 (Mild Steel):

- Characteristics: Arc stability is good even though the metal being joined may be unclean or rusty

- Application: For repair and maintenance work

- Polarity: Either AC or DC can be used.

3.E6013 (Mild Steel):

- Characteristics: Soft arc makes it easy to use and produces less spatter

- Application: Used for thin materials, as well as for auto body work

- Polarity : DC- preferred.

4.E7018 (Low Hydrogen):

- Characteristics: Welds are of high quality hence low moisture absorption.

- Application: Mostly used in structural welding activities.

- Polarity : DC+ is preferred, but it needs a dry storage place.

5.E308L (Stainless Steel):

- Characteristics: It is a low-carbon stainless steel electrode that does not allow carbide precipitation to happen.

- Application: This is commonly used in welding austenitic stainless steel.

- Polarity : DC+

6.E316L (Stainless Steel):

- Characteristics: Nith and molybdenum were added to it to enhance corrosion resistance.

- Application: Used for welding processes found in chemical manufacturing plants

- Polarity : DC+

7.E7010 (Low Hydrogen):

- Characteristics: Good strength properties are required here since it forms root passes during pipe welding

- Application: For joining high-strength steels together

- Polarity: DC+ recommended.

8.E4047 (Aluminum Alloy):

- Characteristics: It can be employed when joining aluminum alloys belonging to the 3000 or 6000 series categories

- Application: The electrodes are best suited for marine applications and the car industry

- Polarity: DC+

9.ECu (Copper-based electrodes):

- Characteristics: These are typically used in maintenance welding because they have good electrical conductivity.

- Applications: They assist in fixing copper-based components.

- Polarity: DC- recommended

10.E308L-17 (Stainless Steel):

- Selecting the appropriate electrode involves assessing your project’s specific materials and requirements, such as joint configuration, material thickness, and position. Always refer to manufacturer specifications for optimal technical parameters to ensure the best welding outcomes.

- Characteristics: Provides excellent weld quality and low carbon content.

- Application: Used in applications requiring good corrosion resistance at elevated temperatures.

- Polarity: DC+.

Differences Between Low Hydrogen And Mild Steel Electrodes

Low hydrogen and mild steel electrodes have different roles in welding processes, which vary depending on the types of materials and characteristics:

- Hydrogen Content: Low hydrogen electrodes such as E7010 are made to minimize hydrogen that can lead to cracking during welding high-strength steels. Mild steel electrodes usually contain relatively more hydrogen gas, which makes them unsuitable for critical applications.

- Mechanical Properties: In high-strength materials, low hydrogen electrodes create strong welded joints with high ductility. Mild steel rods might suffice for normal work, but they may not meet stringent requirements for heavy-duty areas.

- Welding Position: Unlike the other, a low hydrogen electrode, with its balanced penetration qualities, could give anyone an option among all techniques. Due to potential weld defects in vertical or overhead positions, mild steel electrodes are most effective when used flat or horizontally.

- Polarity: Despite this, both kinds of electrodes can have DC+ polarity; however, there is a common design feature that determines this kind of performance in arc stability and penetration.

- Applications: Shielded metal arc welding (SMAW) using a lo-hydrogen electrode is ideal for joining pressure vessels and pipelines, where their integrity must be assured. For example, the mildest form of steel rod can be used successfully in general fabrication and construction works requiring lesser specifications than those needing higher strengths.

When choosing an electrode, consider factors such as the properties of the base material being joined, the welding position, and the environmental conditions prevailing at the site to ensure compatibility and the best results. Always check technical data from the manufacturer before purchasing any electrode.

Understanding the Aws Classification System

The American Welding Society classification system primarily helps classify welding electrodes based on their specifications, such as alloy composition, mechanical properties, and usability. Each electrode’s code is distinct and generally starts with “E” followed by a series of digits that give an insight into its nature.

- Electrode Type: The first digit identifies the type of electrode. For instance, an “E” would suggest it’s an electrode while an “F” signifies flux-cored electrode application.

- Yield Strength: The second and third digits represent the minimum tensile strength in thousands of pounds per square inch (psi) for the weld metal. Thus, 7018 indicates its yield strength to be 70,000 psi.

- Core Substance or Alloy: The fourth digit describes its chemical composition or any special features that it might possess. In this case, 7018 refers to a low-hydrogen rod containing elements such as nickel or molybdenum, which make it suitable for heavy-duty applications.

- Polarity: Finally, if available, the last letter suggests the recommended polarity. For example, H means using Direct Current Electrode Negative (DCEN) polarity to meet specific requirements.

Without understanding these parameters, selecting the right electrode for any job will be difficult, and you may not achieve the best results and structural integrity. AWS’ detailed specifications and guidelines provide a lot more technical information.

How Does Welding Current Affect Electrode Performance?

The electrode’s performance is significantly affected by welding current. I have noticed that the amperage impacts both the rate of melting of electrodes and heat input into the weld pool. This can cause too much heat to be created by higher currents, which can promote better fusion but also risk burn-through, particularly with thinner materials. However, lower current may fail to melt well enough, leading to poor penetration and weak joints. Moreover, different types of electrodes and their coatings will react differently at various currents; for example, low hydrogen electrodes such as ‘7018’ require a range specific for optimal performance to avoid defects like hydrogen-induced cracking. Therefore it would be important that we strike a balance based on the specifications of the electrode and nature of materials being welded.

Choosing the Right Welding Current for Different Electrode Types

Considering each electrode’s specifications/characteristics is vital when choosing suitable welding current for different electrode types. The following are key categories for some common electrodes:

1.E6010 (Cellulosic):

- Recommended Current: 70-130 A

- Justification: Because this arc has deep penetration and fast freezing characteristics, it needs a higher current to prevent it from stubbing or flickering out.

2.E6011 (All-Purpose):

- Recommended Current: 60-140 A

- Justification: It is possible to work with this electrode under AC or DC because every direction you choose gives its own advantage providing more flexibility in use cases; moderate current span allows best penetration without overheating.

3.E6013 (General Purpose):

- Recommended Current: 40-125 A

- Justification: This rod is meant for light-duty welding jobs where lower amperages help maintain a smooth stable arc with minimal spatter.

4.E7018 (Low Hydrogen):

- Recommended Current: 70-180 A

- Justification: This rod requires a higher amperage to prevent hydrogen cracks while still ensuring adequate penetration in thicker materials.

5.E7024 (Flat Position):

- Recommended Current: 150-300 A

- Justification: This electrode is well-suited for flat position welding, which works best at high currents because of its high deposition rate and filler metal distribution efficiency.

6.E308L (Stainless Steel):

- Recommended Current: 75-175 A

- Justification: With stainless steel being one of the materials that can distort easily when welding, it is necessary to strike a correct balance between both sides by maintaining an appropriate amount of current to get enough penetration and fusion.

7.E313 (Flux-Cored Wire):

- Recommended Current: 100-250 A

- Justification: Higher values have to be considered for flux-cored electrodes. These types are aimed at increased deposition rates, meaning more heat should be controlled to eliminate slag inclusion before adding any other product to your pipeline or project.

8.E71T-1 (Self-Shielded Flux-Cored Wire):

- Recommended Current: 75-300 A

- Justification: The broader current range needed to achieve optimal arc stability and penetration makes it better suited for thicker materials or outside applications.

9.E6014 (Medium Penetration):

- Recommended Current: 70-130 A

- Justification: This universal rod performs well with moderate ampere levels, thereby enabling us to reduce spatters and improve appearance concerning joint formation characteristics during joining operations such as these.

10.E308-16 (Stainless Steel):

- In conclusion, the selection of welding current should be dictated by the electrode type, material thickness, welding position, and specific project requirements. Always refer to technical datasheets and manufacturer’s guidelines for precise specifications to achieve the best welding results.

- Recommended Current: 80-200 A

- Justification: Tailored for welding stainless steel, a range of current ensures enough heat to fuse with underlying metal without causing overheating.

Effects of AC Power on Stick Electrodes

When using Stick Electrodes with AC (Alternating Current) power, various key factors come into play and affect the welding process. For some applications, some alternatives are better than others. It is especially true when you are practicing welding on materials that might require the balance between penetrating deep and having an even bead shape. A review of these impacts is given as follows;

1. Improved Arc Stability:

- The alternating nature of the current through AC powers helps to stabilize arc stability, which is hence essential in controlling overabundance spattering electrodes or steady hands for similar welds.

2. Enhanced Penetration:

- In particular, electrodes like E6010 and E7018 do very well on AC due to better arc characteristics allowing them to go deeper into the base metal. For example, E6010 needs a current range of about 70-125A when used with AC, ensuring the joint has properly fused joints.

3. Distortion Reduction:

- AC reduces thermal distortion by alternating current flow, which is an important benefit when working with thin material. This is particularly important in processes where maintaining the integrity of the base metal is essential.

4. Electrode Performance:

- Some of these, such as E6011 and E7018, can be used under DC or AC supplies, illustrating their versatility in performance areas. By way of illustration, a good range for use with E7018 in AC welding that balances speed against quality would be between 120 and 180a.

5. Compatibility with Various Materials:

- Oxygen has to be removed from the aluminum oxide layer during the welding process, so using alternative currents effectively but without overheating provides a means of doing this. In fact, this demonstrates how AC can maintain effective heat input without causing overheating.

To summarize it all in brief, there is no doubt that the use of AC power for stick electrodes influences the following things; improved stability and penetration arcs while reducing distortion coupled with reinforcement of the performance of certain electrodes. In other words, these technical parameters highlight the need for appropriate current ranges based on an electrode’s specific type and purpose for optimal welding outcomes. If you are not certain, always refer to the manufacturer’s specifications and guidelines for various welding scenarios.

Welding Position and Its Effect on Electrode Selection

The selection of an electrode is also influenced by its position relative to welding, as different positions cause different pool behavior, penetration, and arc stability. A brief summary of the effects of welding at different positions on some key technical matters follows;

1. Flat:

- Electrode Type: E6010, E6011, E7018

- Justification: This allows greater control over the weld pool to achieve consistent bead appearance and penetration levels. The flat position has high heat input strength, ideal when using low hydrogen electrodes like E7018, usually set at 120-180A.

2. Horizontal:

- Electrode Type: E6013, E7016

- Justification: Horizontal welding involves careful management of the molten pool, making it ideal for electrodes with good flow properties. Setting up at 90-150A works well with E6013 since it promotes smooth arcs and less spattering.

3. Vertical:

- Electrode Type: E7018, E6010

- Justification: Vertical welding creates complications such as gravity-induced dripping of molten metal. Low hydrogen electrodes such as those above can give better control so that there is no excessive droplet transfer. The recommended range for this kind would be between 100 and 150a.

4. Overhead Position (4G/4F):

- Electrode Type: E6013, E7018

- Purpose: Electrodes for overhead welding must possess good arc stability and the ability to handle slag. This type of electrode is often used with 90-130 A to effectively control the molten pool and prevent excessive drooping or defects.

5. Pipe Welding Position:

- Electrode Type: E6010, E7018

- Rationale: It is very important to keep a uniform angle during pipe welding. E6010’s deeply penetrating nature makes it suitable for current settings, usually about 100-140 A, while E7018 ensures a clean weld profile.

By understanding the specific requirements of each welding position, welders can select the most appropriate electrodes and settings, ensuring optimal performance and quality in their work. Always check out the manufacturer’s guidelines on electrode matching concerning intended welding positions.

What Are the Common Applications for Welding Electrodes?

My experience with welding rods has been that they are used in various industries and applications, each with specific rod types for the best results. For example, E6010 and E7018 rods are often utilized for structural steel fabrication in construction due to their strength and penetrating ability. In shipbuilding, these rods are used to join metal parts together to make them strong enough to resist harsh environmental conditions too. Welding rods in the automotive industry perform repairs and help assemble parts to ensure reliability and safety. Other areas where welding rods find common applications include pipeline maintenance, which requires materials that can withstand high pressure. Manufacturing also involves machinery fabrication using welding rods, among other activities. Each application above points out why selecting the right welding rod is paramount in meeting the project’s requirements.

How To Use Welding Rods On Sheet Metal Projects

In sheet metal projects, it is important to choose an appropriate welding rod for producing strong and good-looking welds. The most commonly used ones include E6013, E7018, and E308L, which offer different services according to material type and thickness.

1.E6013:

- Application: Ideal for mild steel and thin materials.

Technical Parameters:

- Current settings: 100-150 A

- Electrode diameter: often 1/8″ to 3/16″.

- Justification: It is well known for its smooth arc stability and low hydrogen content, which reduce cracking in welds and make it suitable for structural applications.

- Application: Used for welding stainless steel.

2.E7018:

3.E308L:

Using proper filler material can enhance the quality of a weld, but choosing the right one helps maintain integrity and durability in the finished project. Material compatibility should always be considered alongside consulting individual manufacturer’s guidelines aimed at achieving optimum results regarding sheet metal applications of welding rod use.

- Current settings: 70-130 A

- Electrode diameter: typically 1/16″ to 1/8″.

- Reasoning: Its versatility and ease of use make it ideal for projects requiring a clean finish (such as automotive repair or light construction).

- Application: Best for low-alloy high-strength steels.

Technical Parameters:

- Current settings: 90-130 A

- Electrode diameter: usually 1/16″ to 1/8″.

- Justification: This rod is used when working with corrosive-resistant projects to ensure thorough weld with great corrosion resistance.

Applications of E6010 and E6011 Electrodes

1.E6010:

- Application: Primarily used for vertical and overhead welding on medium to thick materials.

Technical Parameters:

- Current settings: 70-120 A

- Electrode diameter: typically 1/16″ to 5/32″.

- Reasoning: It has excellent penetration and freezes fast. This rod works particularly well in fieldwork, making it the most common choice for pipe welding and agricultural machinery repairs. The deep strong bead produced helps cope with difficult positions in which welding may be needed.

- Application: It is suitable for all positions and can be used on AC and DC power sources, making it versatile for various projects.

2.E6011:

- Whether to use either E6010 or E6011 electrodes will depend mainly on specific application needs like position, material conditions, and weld properties required to achieve top-notch results that one can rely upon.

Technical Parameters:

- Current settings: 80-150 A

- Electrode diameter: generally 1/16″ to 3/16″.

- Justification:E6011 gives a more stable arc and is less affected by oil or dirt, so it’s best when welding rusted or greasy metal surfaces.It’s mainly used during maintenance operations and repair works, which means that it’s also beneficial in adverse working conditions.

Best Practices for Welding with E7018 Electrodes

1. Preparation:

- Surface Cleanliness: Before welding, ensure the weld surface is clean and free of dirt, rust, and oil. A clean surface results in stronger bonds and better-quality welds.

- Electrode Handling: Keep your E7018 electrodes within a dedicated oven to maintain their low hydrogen content so as to ensure they do not absorb any moisture that might lead to hydrogen-induced cracking.

2. Electrode Specifications:

- Current Settings: The recommended range is from 70-180 A, depending on electrode diameter.

- Electrode Diameter: Common sizes include 1/8”, 5/32”, and 3/16”.

- Justification: Optimal heat input allows good arc stability and minimizes weld distortion because of these parameters.

3. Welding Technique:

- Travel Speed: Proper bead appearance and penetration are ensured by maintaining appropriate speed during travel. Slow speed will result in overheating, leading to burn-through, while fast speed will cause poor fusion.

- Angle and Arc Length: To gain better control, keep the working angle at about 15-20° and the arc length short for higher penetration levels.

4. Post-Welding Practices:

- Cooling: Let this weld cool gradually to minimize residual stresses, which can induce cracking after rapid cooling.

- Inspection: Check visually and carry out non-destructive testing when necessary to ascertain the integrity of welds, especially in critical applications.

Following these best practices when working with E7018 electrodes can achieve solid and high-quality welds appropriate for many structural and pipefitting applications.

Weld Quality: What Factors Determine It?

The quality of a weld depends on various factors. The type of electrode used is crucial; for example, using E7018 electrodes results in good mechanical properties due to their low hydrogen content. Further contributions include slow cooling after welding and thorough inspection, all of which lead to stronger welds with high reliability. Finally, post-welding techniques such as slow cooling and thorough examination add to the overall strength and dependability of the joint.

Understanding Penetration and Deposition Rates

Welding penetration and deposition rate are key parameters influencing a weld’s general quality and strength. It represents the depth that a welding bead attains into the parent material, while deposition rate refers to how much filler material is deposited within a given period.

1. Penetration: The typical desired penetration depth ranges between 1/8th to ¼th the thickness of base materials depending on specific applications and types of materials. Some important parameters that affect penetration include:

- Voltage: Higher voltages may increase penetration, but it may cause an unstable arc when too high.

- Speed: Decreased travel speed usually increases penetration as more heat might be absorbed.

2. Deposition Rate: While deposition rate can be expressed in weight (lb/hr) or mass (kg/hr), it generally means how much filler metal is melted in one hour. Deposition rates are influenced by:

- Current levels: If current levels are higher, melted filler materials will be more abundant, increasing deposition rates.

- Wire thickness: Larger diameters result in high deposition rates but can require some technique adjustment to balance heat input against penetration control purposes.

- Material type: Different electrodes use different amounts per unit of time, but mostly solid wire has a lower deposition rate than flux-cored wires.

If welders understand these parameters well enough and optimize them, they can better control quality, resulting in improved performance value in structural applications with long service lives.

Impact of Electrode Coating on Weld Quality

The coating on an electrode is one determining factor of the quality of a weld. Here are vital aspects to consider, along with corresponding technical parameters:

1. Shielding Gas Formation: The coating generates gases during welding to protect the molten weld pool from atmospheric contamination. Proper shielding minimizes chances for defects like porosity. For example:

- Coating type: Basic or rutile coatings provide different levels of protection.

- Gas composition: The generated gas must effectively shield against oxygen and nitrogen levels in the environment.

2. Slag Formation: The properties of a slag that helps protect the weld as it hardens are influenced by the electrode coating. A suitable slag can provide better mechanical properties to the weld. Relevant parameters include:

- Viscosity and fluidity: Coatings that produce low-viscosity slags produce smoother weld bead appearances.

- Solidification rate: Affecting joint cooling speed, this is useful in deciding how fast slag will solidify.

3. Electrode Stability: Coated electrodes must maintain arc stability throughout welding. Factors to consider are:

- Electrode diameter: Arc stability is more manageable with larger diameters but may also affect heat input magnitude.

- Current settings: To avoid excessive spatter on different coated electrodes, optimizing amperage is crucial to maintaining a stable arc.

4. Deposition Efficiency: The ability of the filler material to be deposited into the weld joint is affected by its coating. Important parameters include:

- Deposition rate: This factor depends on the type of coating; for instance, high cellulosic content may lead to faster deposition.

- Absorption of Moisture: Coatings that can absorb moisture can initiate hydrogen-induced cracking in a completed weld.

5. Weld Appearance and Finish: The quality of the coating contributes to the overall aesthetics and finish of the weld. It can be measured using:

- Bead Shape and Size: A suitable coat electrode gives uniform weld beads.

- Surface Defects: When adequately evaluated, coating quality will directly correlate with defects such as undercutting or slag inclusions, among others.

By understanding these parameters and their impacts, welders can select the appropriate electrode coating to enhance weld quality, ultimately leading to stronger and more reliable joints in structural applications

Common Issues in Stick Welding and How to Avoid Them

Despite its effectiveness, stick welding has many problems that can cause low-quality welding. Some common issues are discussed below, along with how they can be avoided:

- Inconsistent Arc Length: Maintaining a steady arc length is crucial for producing high-quality welds. An inconsistent arc could result in excessive spatters or insufficient penetration. Solution: Leave a 3/16 inch gap between an electrode and the workpiece.

- Contaminated Electrodes: Different contaminants, such as oil, rust, dirt, etc., can harm your welds by contaminating your electrodes, which might cause porosity or, even worse, defects in your wires when you use them. What you need to do here is clean the basic metal properly before striking an arc. Clean off any impurities from electrode surfaces before welding by wiping down these parts using solvents such as lacquer thinner, acetone, or alcohol.

- Incorrect Amperage Settings: Undercutting may occur if the wrong amperage settings are used. Solution: Ensure to check the diameter of the electrode and review the manufacturer’s recommended amperages in order to set up a weld correctly; approximately 70-120 amps for 1/8 inch electrodes

- Poor Travel Speed: Traveling too fast or slow can lead to inconsistent bead width and penetration. Solution: Maintaining a consistent speed of around 4-6 inches per minute imparts uniformity.

- Slag Inclusion: Weaknesses in the weld joint may be due to insufficient slag removal from previous passes. Solution: Slag between passes should be removed; use a chipping hammer as needed.

- Lack of Penetration: Insufficient heat can lead to weak welds and inadequate base material bonding. Therefore, you must verify the heat settings and work on travel speeds and electrode angles to increase penetration depth.

- Cracking: Rapid cooling or poor choice of electrodes cause cracking. To control the rapid cooling rate, adjust the welding speed properly and choose appropriate electrodes based on the base metal.

- Porosity: The existence of gas bubbles within the weld means that there could be potential weaknesses. Thus, don’t forget about shielding during the welding process. Also, avoid welding in windy environments where foreign substances might enter your job.

- Poor Bead Appearance: A poorly formed bead could mean an incorrectly executed technique or Incorrect settings used in achieving such appearances. Solution – Consistently apply similar techniques while modifying parameters depending on which types of electrodes you have employed to attain better-finishing touches

- Moisture in Coated Electrodes: Moisture can lead to hydrogen-induced cracking within welds. This is why it is important to store them under dry conditions or even bake these consumables once they’ve absorbed some water content

Fixing these issues is important for welders as it ensures the quality of the welds, which makes them more durable.

Conclusion

To get an electrode suitable in a specific application, knowing what you should look for when looking at the numbering on welding rods is essential. These numbers give composition, welding position, and type of electric current used by each electrode. For example, in the American Welding Society (AWS) system, the first two digits usually indicate the minimum tensile strength of the rod in thousands of pounds per square inch (ksi). In contrast, the third digit signifies a character suitable only for specific types of weld positions. The last two numbers most often cover characteristics and their nature affecting usability, arc stability, and depth into a substance. By understanding these numbers, a welder can choose better and optimize his or her welding technique, making it possible to achieve successful results on any project.

Reference sources

- American Welding Society (AWS) – The AWS provides comprehensive guidelines and standards for various welding processes, including detailed descriptions of electrode classifications and their properties..

- Welding Handbook by the American Welding Society – This publication is a definitive resource packed with technical information on welding processes, materials, and electrode specifications. It can be accessed through academic libraries or purchased at reputable book retailers.

- “Welding: Principles and Applications” by Larry Jeffus – This textbook covers a wide range of welding techniques, including the significance of welding rod numbers, types, and usage. It is widely used in academic institutions and found in libraries or online bookstores.

Frequently Asked Questions (FAQs)

What do the numbers on a welding rod indicate?

The numbers on a welding rod provide essential information regarding its specifications, such as minimum tensile strength, suitable welding position, and coating type. These numbers help welders select the appropriate rod for their specific applications.

How do I interpret the AWS classification system for welding rods?

In the AWS classification system, the first two digits indicate the minimum tensile strength in thousands of psi (ksi), the third digit represents the welding position for which the electrode is suitable, and the last two digits detail the type and characteristics of the coating.

Why is it important to choose the right welding rod?

Choosing the correct welding rod is critical for achieving optimal performance, ensuring strong welds, and preventing issues such as poor arc stability or inadequate penetration. The right rod enhances the quality and durability of the final weld.

Can I use a welding rod with a higher tensile strength than needed?

While it is possible to use a welding rod with a higher tensile strength, it may not always be necessary and could lead to welding challenges such as increased spatter or difficulty controlling the weld pool. It’s best to select a rod that meets your project’s specific requirements.