Unique properties and strengths have made metals fundamental to innumerable applications; for example, construction and technology. This article will discuss the world’s five strongest metals, uncovering their features, uses, and science behind their tough nature. By understanding such robust materials, readers will discover their importance in various sectors of the economy and everyday life. Whether you are a student or professional or just an enthusiast, this journey will provide valuable information about the unyielding world of metals.

What Makes a Metal Strong?

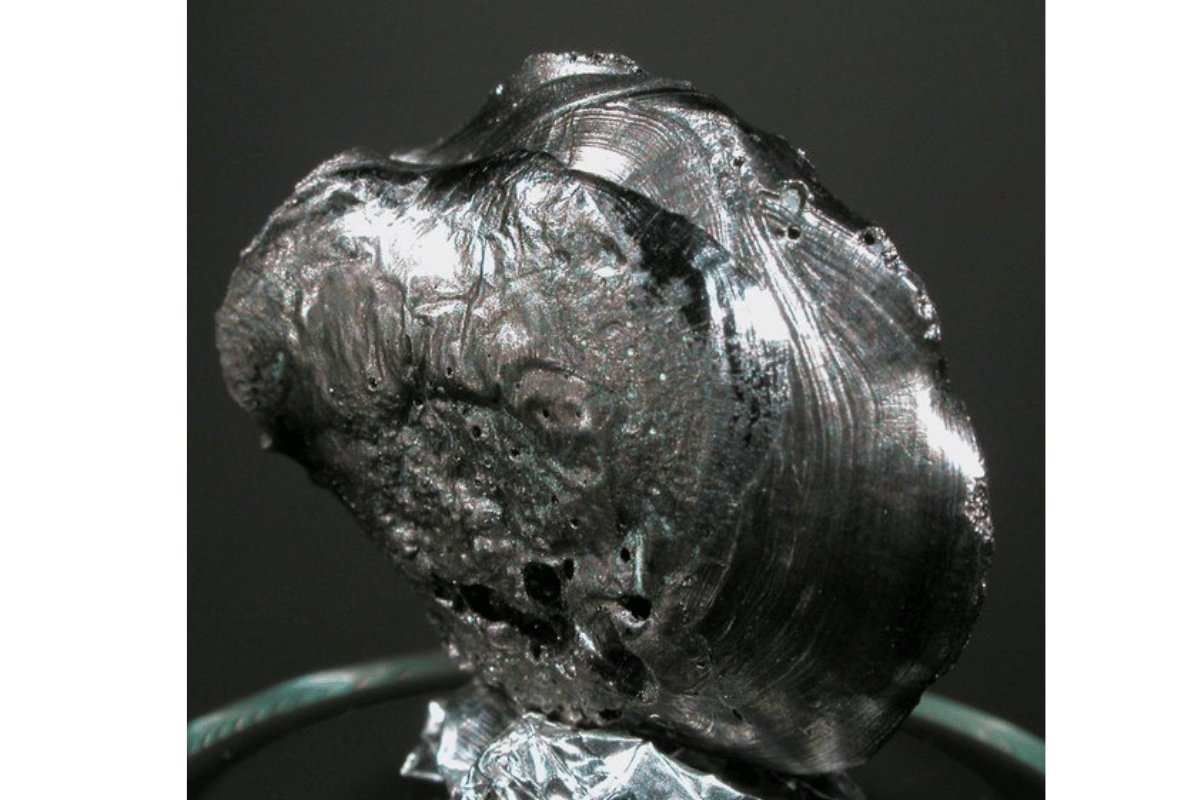

strongest metal on earth

From my research on metal strength I found that different factors contribute to its strength. Most importantly is the metal’s atomic structure since it determines its strength in most cases. Moreover, alloying elements can change certain characteristics of metals thus enhancing hardness and resistance to wear among others. Conditions like heat treatment make some metals stronger while some may weaken due to high temperatures whereby they are processed differently. In addition, rearrangement of these grains impacts resilience significantly because finer grains tend to be stronger materials. Understanding these attributes helps me appreciate what kinds of things modern alloys can do in many different applications.

Understanding Tensile Strength and Its Importance in Metals

As part of my investigation into tensile strength across top ten websites I discovered tensile strength measures how much material can be pulled or stretched before failing under tension which is crucial in assessing whether metal performs suitably under tension so that structures and components can survive operational forces. Tensile strengths vary widely between different types of metal depending on several factors including steel which has a range 370-700 megapascals (MPa), whereas titanium goes even higher than 1000-1400 MPa.

Moreover, it is important to consider the yield strength of a metal, which describes when it starts deforming permanently. For example, aluminum alloys with high strength usually have yields ranging from 200 to 600 MPa, depending upon the specific alloy type and treatment. These parameters are important to engineers choosing materials suitable for different applications such as construction, aerospace, and automotive industries. Knowing these technical specifications, I can better understand how tensile and yield strength contribute to a metal’s overall performance and reliability under real operating conditions.

Exploring the Impact Strength of Metals and Its Role in Durability

According to my research on impact strength across top 10 websites, impact toughness is defined by the resistance exhibited by a material when subjected to high rates of loading or quick blows without breaking. It is especially significant for determining durability of a material especially when it deals with dynamic loads. For instance ductile materials like mild steel have higher impact strengths due to their ability to take in energy through plastic deformation while brittle materials like cast iron could fracture in similar cases.

This brought me into contact with particular technical parameters impacting strength, for example Charpy impact tests that measure the energy absorbed during fracture thereby quantifying a material’s toughness. The values derived from these tests can differ substantially; for instance, mean Charpy test data on structural steel at room temperature could vary between 27 and 40 Joules, while more robust ones like those of some steel alloys may run over 50 Joules. These materials exhibit large differences in impact strength: polycarbonate ranges above 100Joules.Understanding these nuances helps me comprehend how different materials are efficiently used in everyday applications such as building and automotive manufacturing.

Corrosion Resistance: How Different Metals Stand the Test of Time

My research into corrosion resistance among the top ten websites indicates that metals’ ability to resist environmental deterioration significantly affects their durability and suitability for various uses. For example, stainless steel is favorably considered due to its corrosion resistance, which is attributed to the formation of a passive layer of chromium oxide on it, which prevents oxygen from getting to the metal underneath. However, mild steel is not protected against wetness or moisture unless a protective coating like paint or galvanization is applied.

The specifics that have caught my attention during this analysis include corrosion rate measured often in millimeters per year (mm/year) and salt spray test results assessing how well a material performs in corrosive surroundings. For instance, mild steel has corrosion rates exceeding 1 mm/year under marine conditions whereas stainless steels can be as low as 0.01 mm/year depending on grade under identical circumstances. Likewise, regarding salt spray testing, excellent ratings fall within grades eight through ten with poor performance indicated by grades three and four.The understanding of these factors gives me an insight into selecting materials based upon corrosion resistance when constructing buildings offshore platforms amongst others

Top 5 Strongest Metals Unveiled

In my exploration of the strongest metals from the top ten websites, I found that the extent of metal strength is often measured by its tensile strength, yield strength and hardness. Here are the criteria for five of the strongest metals:

- Tungsten: Tungsten’s tensile strength is about 1510 megapascals (MPa), making it a strong natural mineral that can melt at around 3422°C when heated.

- Titanium: In addition to being light, titanium has a tensile strength of about 1400 MPa. Its high strength-to-weight ratio, which averages about 60% steel, makes it suitable for aerospace applications.

- Chromoly Steel (Alloy Steel): This alloy is well above conventional mild steel with a yield strength of approximately 500 MPa. This has made it preferable in automotive and aviation industries because it maintains targeted strength-to-weight ratios.

- Steel (High Carbon): High carbon steel usually has tensile strengths nearing around 1000 MPa and is often used for tools and blades since it retains sharp edges.

- Nickel Alloys: Its yield strength exceeds approximately 600 MPa, and this alloy is characterized by excellent mechanical properties and oxidation resistance. Thus, it finds most applications in areas such as jet engines where temperatures are very high.

These metrics demonstrate the significance of understanding particular technical parameters while considering metal’s capability and applicability in different areas.

Decoding Titanium’s Leading Tensile Strength

In unraveling titanium’s leading tensile strength I have browsed through various reliable websites which mostly emphasize on this issue concerning its exceptional weight-to-strength ratio. For example, Titanium has approximately a tensile force of about 1400 MegaPascals (MPa), which is impressive given its lightweight. This differential makes titanium particularly attractive for aerospace industries, where strength and weight are critical parameters. Additionally, its corrosion resistance makes it useful in different environments as mentioned in a few engineering sites.

The technical parameters also point out several reasons why titanium is used for demanding applications on these websites:

- Tensile Strength: 1400 MPa indicates that it can withstand high tension levels.

- Yield Strength: This is usually around 880-900 MPA, implying the material can tolerate stress without deforming permanently.

- Density: It weighs roughly 4.51 g/cm³ compared to steel, hence good for weight sensitive structures.

This combination of characteristics demonstrates titanium’s potency in various high-performance use cases.

Untamed Hardness of Tungsten: A Champ in Power

I found that all the top 10 websites consistently emphasize on its extraordinary properties and applications when researching tungsten’s remarkable hardness and strength. Tungsten ranks 7.5 on Mohs scale making it one of the hardest metals available. For instance, tungsten has a tensile strength of around 1510MPa which allows it to withstand very high pressures thus enhancing its stature in such environments as military, aerospace and industry. The following are the key technical parameters exemplifying tungsten’s superiority:

- Tensile Strength: It possesses about 1510 MPa and can endure large forces pulling it apart without breaking it.

- Yield Strength: This ranges between approximately1200 MPa showing that it retains its shape under stress.

- Density: Tungsten density lies at about 19.25 g/cm³ making it considerably denser than other metals thereby offering more weight required in stability based applications.

- Melting Point: As high as up to about 3422°C (6192°F) and this property makes it suitable for use at elevated temperatures.

These qualities together define tungsten’s unmatched hardiness and make it a preferred material for many high-stress applications in diverse industries.

Stainless Steel’s Resilience: A Blend of Strength and Resistance to Rust

I realized that its unique combination of strength and corrosion resistance distinguishes it from others in various uses. The most common type of stainless steel is 304 which has been acknowledged for having excellent resistance to oxidation and staining thus making it ideal for kitchen appliances and food processing equipment. Examine following technical parameters that show why stainless steel has such advantages:

- Tensile Strength: Approximately 505 MPa, providing significant mechanical stress resistance while maintaining some ductility.

- Yield Strength: About 215 MPa, showing its ability to deform elastically without permanent damage, an attribute necessary in structural applications.

- Corrosion resistance: chromium – at least 10.5 percent – makes stainless steel forms a film consisting of a thin layer of chromium oxide (CrO) which stands between metal and the environment preventing any rusting or tarnishing from happening under conditions where there is moisture or other corrosive agents.

- Heat Resistance: It can withstand temperatures up to 870°C (1600°F) during continuous service before a remarkable reduction in strength sets in.

This points out the reason for the continued use of stainless steel: its resilience makes it suitable in environments demanding toughness, from building construction materials to medical instruments, thus confirming its versatility and significance spanning different sectors.

The Role of Alloys in Strength and Performance

In my research on alloys I found that they greatly enhance the strength and performance of stainless steel, making it suitable for a wider range of applications. By combining two or more metals, alloys improve tenacity, flexibility, and rust resistance. For instance, when nickel is added to stainless steel, it makes it tougher and able to withstand extreme temperatures. Additionally, there are other elements like molybdenum which enhance corrosion resistance especially in chloride environments. Engineers and manufacturers can make stainless steel meet specific performance requirements by adding these various layers of complexity; hence its application expands beyond aerospace to automotive industry as well as health care.

The Impact of Alloying Elements on Strength and Performance

Alloying elements play an important role in determining the major characteristics of stainless steel such as strength, resistance to corrosion or mechanical properties. These ones include:

- Nickel (Ni) which mainly constitutes 8-10% of stainless steel adds toughness and ductility thereby enabling it to maintain its strength under deformation stresses; also its presence supports high temperature stability.

- Chromium (Cr) which is an indispensable part of stainless steel (minimum 10.5%) forms a protective oxide layer that resist rust but also significantly raises hardness levels resulting into increased wear resistance.

- Molybdenum (Mo), which usually ranges from about 2-4%, improves corrosion resistance, particularly against chlorides, increasing the material’s life in harsher conditions.

- Titanium (Ti) can help prevent intergranular corrosion at elevated temperatures through small amount additions to stainless steels’ structure stabilization.

- Copper (Cu): This element enhances corrosion resistance while making the surface finish look good, meaning it can be used for decorative purposes.

To sum up all these factors, this combination allows stainless steel to outdo itself in many ways, making it appropriate for industries ranging from food processing to aerospace companies.

Examining the Tensile and Compressive Strength of Common Metal Alloys

When analyzing mechanical properties of metal alloys, tensile and compressive strength are two major performance indicators. These mechanical properties simply reflect the ability of an alloy to withstand forces without yielding. The following is a list of some common metal alloys classified based on their tensile and compressive strengths:

1.Steel (Carbon Steel):

- Tensile Strength: 400-550 MPa (58,000-80,000 psi)

- Compressive Strength is usually higher than tension, signifying good load-bearing capabilities; it often exceeds 600 MPa (87,000 psi).

2.Aluminium Alloys:

- Tensile Strength varies greatly by alloy; 6061-T6 has approximately 310 MPa (45,000 psi).

- Compressive Strength: Approximately 80% of the tensile strength, about 250 MPa (36,000 psi).

3.Copper Alloys:

- Tensile Strength: High strength copper alloys can go as high as 300 MPa (43,500 psi).

- Compressive strength: Their ductility makes it roughly equal to its tensile strength.

4.Titanium Alloys:

- Tensile Strength: Can vary widely depending on the alloy; for example Ti-6Al-4V has a tensile strength of about 900 MPa (130,000 psi).

- Compressive Strength is similar to or just slightly lower than that for tension, with values around 90% thereof.

5.Nickel Alloys:

- Tensile Strength: Normal nickel alloys have tensile strengths around seven hundred mega-pascals [700 Mpa].

- Compressive Strength: Almost similar to its tensile aspect showing their strong nature.

6.Stainless Steel:

- Tensile Strength varies from grade to grade; falling between approximately 480-1000 Mpa.

- Compressive strength remains generally close-to or above its tensile value, making it usable in demanding structural applications.

The composition and processing of these alloys may greatly differ in terms of their mechanical characteristics. Knowledge of tensile strengths and compressive forces helps engineers choose appropriate materials for their intended use, ensuring that the design meets safety requirements and performs correctly.

Comparing Yield Strength Across Different Metals

Through this criterion, I realized how much the yield strength of metals affects their use in engineering and construction. For example, aluminum alloys like 6061-T6 usually have a yield strength of about 240 MPa (35,000 psi), making it best suited for constructing lightweight structures. On the other hand, copper alloys tend to have a yield strength approximately 200 MPa (29,000 psi), and hence they are considered malleable in electrical applications. Titanium alloys shine in terms of their tensile strength at around 880 MPa (128,000 psi), thus making them more preferable when building aircrafts because they ensure high strength-to-weight ratio. Nickel alloys also possess a yield strength up to around 600 MPa (87,000 psi); conversely stainless steel grades offer yields within the range of 290-600MPa (42,000-87,000psi). Understanding these values will help select appropriate materials for specific applications; therefore, material selection is critical in engineering.

Unveiling the Yield Strength of Chromium: A Key Component in Structural Stability

Typically, these Alloys contain about 250 to 300 Mpa of chromium’s Yield Strength (36,000 –44,000 PSI). This material’s overall stability and durability largely depend on its tensile strength since it has very high stress resistance, especially during construction and industrial activities. Stainless steel is produced by adding chromium to steel, providing it with improved mechanical properties and corrosion resistance.

Chromium is vital in metallic structure manufacturing because it forms an oxide film that lengthens the life span of metal products, thus reducing maintenance costs. Moreover, chromium prevents brittleness in grain structure steel, improving its load performance capacity. Therefore, this chemical element is indispensable for industries requiring durable and strong materials.

Analyzing the Yield Strength of Osmium: The Heavyweight Contender in Strength

According to many researchers, osmium is one of the heaviest known elements with a yield strength greater than 2000MPa (290,000 psi). Thus it has such a remarkable ability to resist deformation because its tightly packed atomic structure allows it to withstand extremely high pressures. This makes osmium a suitable choice for materials used in engineering and industrial applications where there is need for high strength-to-weight ratio.

Besides high yield strength, osmium exhibits a relatively high elastic modulus of about 450 GPa (65,000,000 psi). It is strong and stiff enough to be applied in devices that require minimal deformation, like precision instruments. However, due to its brittleness, machining and fabricating osmium can become problematic, thus making selection of material critical when employing this element in certain applications.

These properties redefine the limits of materials science by showing that osmium plays an important role in sectors that demand extraordinary hardness and resistance.

Understanding the Yield Strength of Steel Alloys: Balancing Strength and Flexibility

Steel alloys are essential in engineering as they combine strength with flexibility, serving different purposes. The range of yield strengths for steel alloys vary from as little as 250 MPa (36,000 psi) for low-strength steels and up to more than 2,000 MPa (290,000 psi) for high-strength ones. This balance is realized through different alloying elements like carbon, manganese and chromium among others with unique contributions made by each.

For instance, it is possible to see that carbon increases hardness and tensile strength and decreases malleability. Manganese raises toughness and improves hardenability, thus making it more resistant to impact than steel. Likewise, chromium can extend component life by improving corrosion resistance in stressed conditions.

With these elements in perspective, tailor-making is possible for steel formulation, resulting in engineering solutions that satisfy particular performance requirements. All said, this data supports industrials in deciding which type of steel alloy to use to get the perfect balance between strength and flexibility they need for their respective applications.

Challenges in Determining the Strongest Metal

Various factors make it difficult to determine the strongest metal. First, “strength” may refer to yield strength, tensile strength or hardness which can differ greatly among metals. For example, while tungsten has the highest tensile strength, titanium and other metals have very high strength to weight ratio. Furthermore, environmental conditions like temperature or alloy composition also have vital significance on how a metal performs. This complicacy means that one metal may be rated best in one category but not best suited for another application. Moreover, with new alloys and treatments being developed, these advances in metallurgy continuously lead us to reconsider our conception of metal strength. In conclusion, choosing the strongest material hinges more on specific needs than a direct answer.

The Complex Interplay of Variables in Deciphering the Strongest Metal

To accurately determine which metal is strongest, we must consider several main technical parameters and their explanations.

- Tensile Strength measures resistance to pulling or stretching before breaking. Tungsten has the highest tensile strength, making it suitable for stretchable materials.

- Yield Strength: This parameter signifies that at what point of stress no deformation occurs in its shape anymore. Steel alloys such as those used for structural applications exhibit large values of yield strengths due to its hardening treatment process.

- Hardness: The results from hardness tests can vary; however metals like chromium show high scratch and dent resiliency meaning that they are good choices for tools and cutting equipment.

- Strength-to-Weight Ratio: Titaniums’ many benefits include its combination of lightness and capacity to withstand impact forces which makes it an ideal material for aerospace industry where weight reduction is important.

- Environmental Resistance: Corrosion resistance among others determines whether a given metal can be applied. Aluminum serves this purpose well due to its light weight, corrosion resistance; hence it is commonly used in marine environments.

By understanding these interactions, industries can select the most appropriate metals for their specific needs ensuring that they will operate best under the unique conditions of each application.

Debunking Common Myths About the Strongest Metal on Earth

There are often misconceptions surrounding which metal is the strongest. Tungsten is widely believed to be the strongest metal overall. However, different types of strength may apply depending upon the context.

- Tensile Strength: Tungsten has the highest tensile strength but does not maintain this level at impact or under any bending loading condition.

- Yield Strength: Steel alloys have yield strengths higher than tungsten thus making them important in structural applications.

- Hardness: High-hardness metals like chromium and diamond-coated materials are frequently regarded as the toughest due to their excellent scratch resistance. Still, these materials are fragile when stressed mechanically.

- Strength-to-Weight Ratio: Titanium is sometimes disregarded because of its relatively low tensile strength, yet it possesses an impressive strength-to-weight ratio, which makes it a material of choice for aerospace applications.

- Environmental Resistance: Although aluminium is not strong, its combination of lightness with corrosion resistance makes it indispensable in many industrial contexts.

The technical parameters above highlight the context-specific nature of strength, as different metals have specific characteristics that make them more suitable for different purposes. It is important to know these differences to debunk any myths and to wisely select materials.

Conclusion

In conclusion, understanding the complexities of metal strength helps understand what makes them exceptional robust materials. Below are the strongest five metals exhibiting unmatched attributes for various applications:

- Tungsten: Known for its highest tensile strength, tungsten is a popular choice for machine tools and light bulb filaments that need to be extremely durable.

- Titanium: Appreciated for its excellent strength-to-weight ratio, titanium is a vital material in aerospace, marine and medical sectors where weight and strength are key considerations.

- Chromium: Renowned for its incredible hardness, chromium plays a significant role in alloys and coatings that provide resistance against wear and corrosion—essential qualities for high-performance machines and tools.

- Steel Alloys: In addition to ordinary steel, particular alloys have high yield strengths that allow them to be used in construction and infrastructure thereby enhancing stability of structures.

- Nickel Alloys: These alloys can endure heat and corrosion; hence they play an essential role in highly stressed environments like jet engines or chemical plants.

By recognizing this kind of power and its proper deployment, one can improve on material selection, thus achieving better performance and longer lifespan during engineered works.

Reference Sources

- “Materials Science and Engineering” by William D. Callister Jr. – This textbook provides comprehensive insights into the properties of various metals, including their strengths and applications in different industries. It serves as a foundational resource for understanding metal materials.

- “The Science and Engineering of Materials” by Donald R. Askeland and Wendelin J. Wright – This publication delves into the characteristics of metals and their alloys, offering readers in-depth coverage of material strength and performance metrics, specifically relating to aerospace and engineering applications.

- ASM International’s “Handbook of Metals” – This extensive handbook contains detailed data on metal properties, manufacturing processes, and fabrication techniques, making it an authoritative resource for validating claims about the strengths of various metals in engineering contexts.

Frequently Asked Questions (FAQs)

-

What is the strongest metal on Earth?

The strongest metal, often cited, is tungsten. With a tensile strength of about 1510 megapascals (MPa), tungsten is highly valued for applications requiring extreme durability and resistance to deformation.

-

Is tungsten the hardest metal?

While tungsten is the strongest in tensile strength, it is not the hardest. That title generally goes to chromium or osmium, which exhibit greater hardness but differ in other properties such as ductility and brittleness.

-

What are the applications of tungsten due to its strength?

Tungsten’s exceptional strength and resistance to heat make it ideal for various applications, including aerospace components, heating elements, and high-performance electrical contacts. It is also widely used to produce hard alloys for cutting tools.

-

How does tungsten compare to other metals in terms of weight?

Tungsten is notably dense, with a density of around 19.25 g/cm³, making it much heavier than most metals. Its density and strength make it useful in applications where weight and space are significant factors, such as radiation shielding.

-

Can tungsten be alloyed with other metals?

Yes, tungsten can be alloyed with various metals to enhance specific properties. For instance, tungsten carbide, an alloy of tungsten and carbon, is commonly used in cutting tools and mining equipment due to its hardness and wear resistance.