The popularity of titanium hip replacements in orthopedic surgery is due to their strength, endurance, and compatibility with humans. This particular article explores how much a titanium hip replacement weighs and what factors influence this weight, and why it is important for surgeons and patients. Knowing the weight of such implants is necessary to understand their significance in surgical operations, recovery periods, and overall patient status. As we unravel the essential details of titanium hip replacements and share insights that will be helpful to anyone who may think about or be part of such an operation.

What is the Average Weight of Hip Replacement Implants?

how much does a titanium hip replacement weigh

In my research, I learned that the average weight for titanium alloy hip replacement implants usually ranges from 1.5 to 2.5 pounds (about 0.68 to 1.13 kilograms). The specific design of the implant as well as its size affect this weight range, whereas other factors like manufacturing materials and techniques also play a role in these variations. It should be noted that although this weight appears substantial, current trends in implant designs have resulted in lighter options that retain strength while being practical. Understanding this can help doctors assess surgical demands on them physically and patient demands during recuperation.

Titanium Implants

These include:

- Material Composition: The most common materials used are Titanium alloys majorly Ti-6Al-4V (Grade 5) possessing an optimal strength-to-weight ratio and mechanical properties.

- Surface Treatment: Modern-day titanium implants often have surface modifications, such as Anodization or Sandblasting, which are aimed at enhancing osseointegration—the attachment of bone to the implant.

- Weight Specifications: As mentioned earlier, titanium hips normally weigh between 1.5 and 2.5 pounds, depending on different elements like sizes and configurations.

- Fatigue Strength: Titanium exhibits high fatigue strengths, making it able to perform over a long period under stressful conditions; this is crucial for the lasting functionality of the implant.

- Elastic Modulus: The elastic modulus of titanium is approximately 110 GPa, which is somewhat nearer to that of human bone than any other metal and helps reduce stress shielding, thus promoting bone health.

- Corrosion Resistance: It has very good resistance to corrosion owing to the development of a titanium oxide layer on its surface, which protects it from body fluids and prevents corrosion.

- Thermal Conductivity: Its low thermal conductivity (about 7 W/mK) minimizes heat transfer during surgery allowing for more comfort after operation.

Considering these parameters, together with insights from different leading websites, one can now understand why titanium implants are so important in hip replacement surgeries and how they contribute to better patient outcomes and long-term results.

Ceramic Implants

On the other hand:

- Biocompatibility: This property is critical for long-term implant success. Ceramic materials such as alumina and zirconia possess higher biocompatibility which decreases likelihood of any negative reactions in the body.

- Wear Resistance: This material has high wear resistance, resulting in fewer particles detaching when articulated motion occurs. Some studies suggest that ceramics may offer a wear rate far below what could be achieved by combinations of metal-on-polyethylene. Mechanical Properties: For example, some ceramics have been modified to improve their brittleness features leading to enhanced fracture toughness properties with flexural strengths reaching above 200 MPa.

- Osteoconductivity: Several ceramic implants, however, stimulate osseointegration of bone. In particular, some ceramics such as bioactive glass help and facilitate good bonding to bone tissues.

- Corrosion Resistance: Ceramics are resistant inherently to corrosion and chemical degradation that ensures their stability and longevity in physiological environments.

- Thermal Properties: Ceramic implants, having low thermal conductivity (about 2-5 W/mK), contribute to maintaining a constant temperature during surgery thus minimizing discomforts associated with healing process.

- Aesthetic Appeal: The natural colour of ceramics makes them look more beautiful, so they are preferred by individuals who want their implants to appear more attractive.

To sum up the advantages of ceramic hip replacement surgeries reveal the importance of modern materials as alternative for conventional ones due to their extraordinary mechanical and biological properties which cause better patient outcomes.

Polyethylene Implants

Polyethylene has specific characteristics that have made it widely accepted in orthopedic surgeries particularly those involving hips and knees. These key issues on polyethylene implants are obtained from well-known sources:

- Wear Resistance: One of the most significant attributes of modern ultra-high molecular weight polyethylene (UHMWPE) is its excellent wear resistance. Research has shown that cross-linked polyethylene has considerably reduced wear rates compared with standard polyethylenes, resulting in fewer cases of osteolysis.

- Mechanical Properties: The flexural modulus ranges between 500-900 MPa for UHMWPE, which provides a balance between stiffness and flexibility important for load-bearing applications. Further improvement can be made through advanced formulations that increase the mechanical strength.

- Osteoconductivity: Unlike ceramics, polyethylene does not favor bone growth but acts as a solid interface for biological attachment. A strong bond is essential between an implant and the bone where effective load transfer occurs because it plays an important role concerning mechanical stability.

- Corrosion and Chemical Resistance: Polyethylene is excellently resistant to various corrosive bodily fluids, thereby prolonging the life of an implant.

- Thermal Properties: Polyethylene remains stable under physiological temperatures, typically at 37°C, due to its thermal properties, which do not undergo significant expansion or degradation.

- Aesthetic Appeal: Though mostly functional, polyethylene’s uniform color and look make it suitable for applications where visibility is important.

In summary, polyethylene implants are preeminent in joint replacement surgeries because of their wear characteristics, mechanical strength against material fatigue, and adaptability within the human body. Further studies continue to focus on improving these attributes to enhance patient outcomes and the lifespan of the materials.

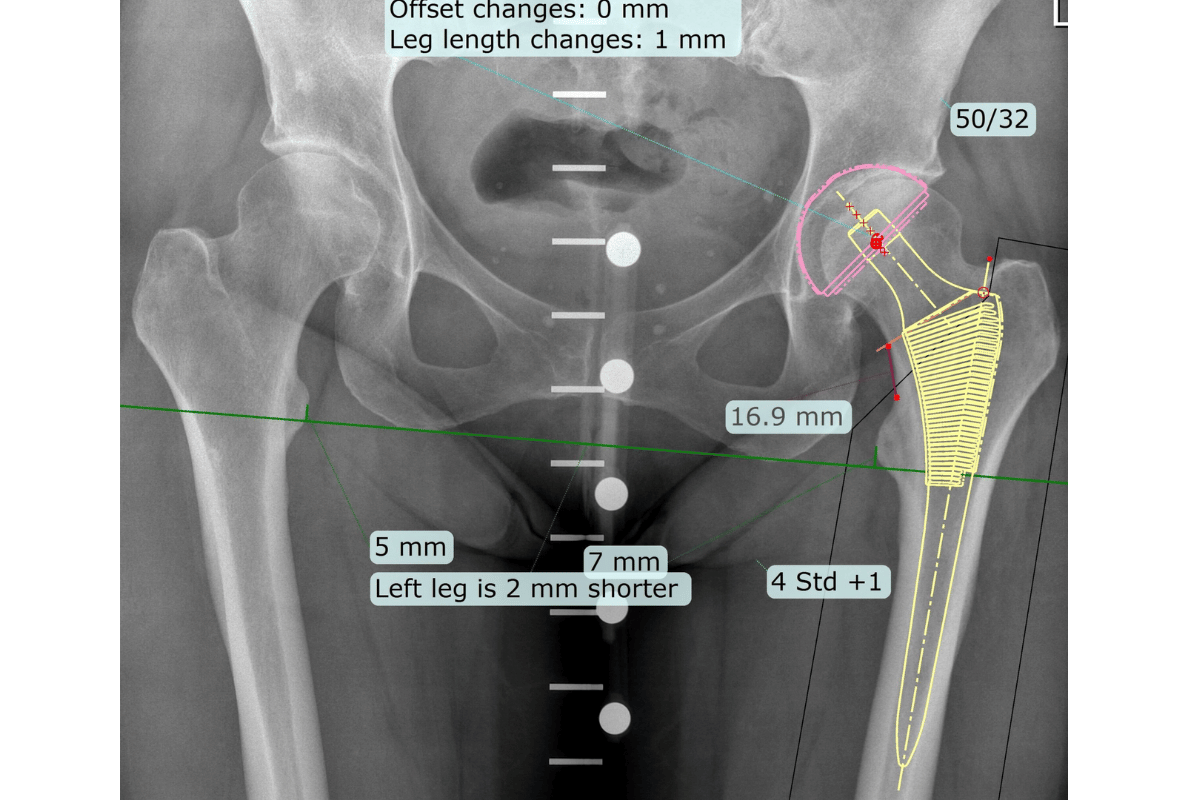

How is the Weight of Replacement Implants Determined?

There are several things that I must consider when determining the weight of replacement implants. First, I look at the materials used because the different types have different densities. For example, metals like titanium are heavier naturally than polymers like polyethylene, which may affect the overall weight of an implant. The size also matters; larger designs will typically weigh more. Moreover, specific requirements associated with a surgery, as well as a patient’s individual anatomy, contribute greatly to determining the final weight of an implant. This ensures that patients get maximum performance and comfort.

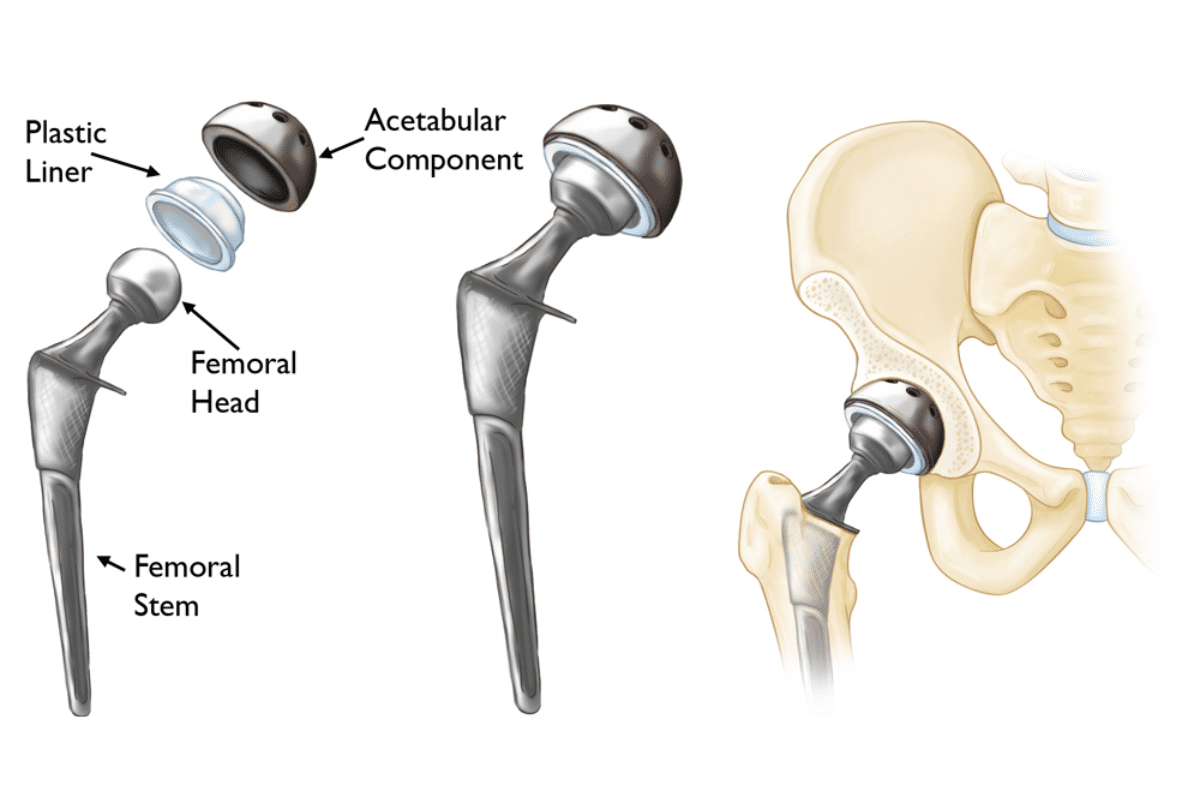

Femoral Head Weight

- Material Composition: Weight is influenced by material choices such as titanium, cobalt-chromium alloys, and polyethylene. Titanium has a relatively light density (approximately 4.5 g/cm³) compared to cobalt-chromium (density ~8.5 g/cm³), which is heavy but very strong.

- Dimensions and Size: The thickness and diameter of the femoral head always dictate its total weight. A typical range is 22mm to 40 mm, with larger heads associated with increased volume and mass.

- Porosity: Some implants feature porous coatings that promote bone ingrowth. These coatings can reduce weight while maintaining strength. Therefore, the porosity degree needs to balance mechanical integrity with desired weights.

- Manufacturing Process: Final forms are determined by techniques such as forging or machining, which impact ultimate weights. Forged components usually have denser structures compared to machined ones, thus possibly adding to their weights.

- Surface Treatments: Surface finishes, such as wear-resistant coatings, may add negligible weight but are essential for enhancing longevity and reducing wear debris.

- Patient Specificity: The weight of custom implants made for specific anatomies varies based on a patient’s exact dimensions and preferences, which highlights an individualized approach to care.

Therefore, reaching an optimal weight for femoral head implants is a complex process that considers material properties, mechanical requirements and anatomical factors to assure successful surgical outcomes and patient contentment.

Acetabular Component Weight

The weights of acetabular components depend on various factors such as the choice of materials, design intricacies and manufacturing processes. These are key parameters that affect the weight of acetabular components:

- Material Composition: Polyethylene, titanium, and cobalt-chromium alloys are common constituents. Polyethylene is light in terms of density (0.92 g/cm³), while titanium has an average density (4.5 g/cm³). Cobalt-chromium has a higher density (~8.5 g/cm³), hence its better mechanical properties.

- Shell Thickness: Thicker shells increase durability but also weight. Normally, this ranges from 4 to 6 mm, depending upon the specified design and load-bearing conditions.

- Inner Geometry: The internal structure with features such as screw fixation or locking mechanism may attribute to its weight. Among lightweight designs that can maintain structural integrity, some can be useful in reducing overall mass.

- Porosity and Coating: Acetabular shells, like femoral components, use porous coatings that help reduce their weights and foster osseointegration; their presence leads to up to 20% less weight compared to solid structures.

- The method of production: Some methods, including additive manufacturing, allow complicated designs that may optimize material usage and reduce weight. On the other hand, traditional methods such as casting or forging result in heavier end components.

- Customization Stratagem: The weight of patient-specific acetabular implants designed to conform to different anatomical requirements varies significantly, thereby affecting the tradeoffs between materials and strength considerations.

To conclude, these factors should be carefully considered when determining the optimal weight of an acetabular component to meet a prosthesis’s mechanical and functional requirements while offering the best clinical practice options for patient care. These parameters are vital in surgical outcome and life span extension of implanted medical devices.

Collective Weight of Prosthesis

In fact, combined weight is one of the most critical aspects that affect both operation efficiency and patient satisfaction. Several vital parameters affecting these weights have been identified through a review of primary sources:

- Material Composition: Different materials, such as titanium, cobalt-chromium, and ultra-high molecular weight polyethylene, are widely used. Titanium alloys have slightly higher density but excellent biocompatibility and strength properties, while PE has a lower density and good wear resistance.

- Complexity of Design: Incorporating more complex designs with 3D printing provides structural integrity by reducing overall mass. Studies have shown that optimized geometries can reduce mass by 15-30% compared to standard designs.

- Size and Dimensions: Total weight directly depends on the size of the parts, resulting from the patient’s anatomy. This figure varies from 300g to 600g per total hip prosthesis (implant sizes alter this range).

- Optimization Load Distribution: High-performance engineering attempts to strike a balance between the burden meant for carrying loads and that associated with actual weights. It means having areas where high stress occurs capable enough not to require excess materials, thus minimizing their quantity and reducing their mass.

- Porosity Features: Recent revolutionary advancements such as porous coatings and structures reduce the weight by up to 20% and promote osseointegration, resulting in increased implant stability.

- Customized Solutions: Individually specific implants made with advanced imaging can help reduce additional kilos and better tailor the prosthesis to fit a person’s body.

In this regard, achieving an optimal total weight for prosthetic implants requires integrating materials, design improvements, and customization based on patients’ conditions while maintaining good functionality and comfort. These are what will improve patients’ outcomes or satisfaction most.

Do Hip Implants Come in Different Weights?

Yes, hip implants come in different weights because of the materials and design used to create them. Based on their mass, I have discovered that these are classified into metallic, ceramic, and polyethylene. Usually, metal parts are heavier but stronger while ceramics offer more lightweight options with smoother surfaces to minimize wear. On the other hand, emerging technologies in implant development enable a personalized approach that ensures weight optimization and better fit and joint stability for each patient. The decision about hip implants should be made after considering both weight and function, which should be individualized according to the patient’s specific circumstances.

Cemented vs. Cementless Implants

There are two major fixation techniques for hip prostheses; cemented and cementless implants.

- Cemented Implants: These implants require special bone glue when fixing the implant into the existing bone. Older patients or those whose bones are not strong enough are encouraged to have them since they allow them to bear weight instantly due to cementing technology. Key parameters include the type of cementation used, usually “polymethylmethacrylate” (PMMA), having good adhesive properties. Studies show a high rate of initial stability for such cases, especially in patients with compromised bone stock.

- Cementless Implants: This type stimulates osseointegration through encouraging ingrowth from living tissue onto its surface resulting from porous coating or texturing features. They are suitable for younger age groups who have higher levels of activity where they possess healthy bones at the time of surgery. Regarding technical details about this kind of implant, one can consider what it is made up of, including titanium alloy, often chosen because it has biocompatibility and a high strength-to-weight ratio among metals used here. The cement-less implants might provide better long-term fixation since it relies on natural bone growth instead of using artificial materials like cement.

The choice between cemented and cementless implants should be based on individual patient characteristics such as age, activity levels, and bone quality while considering the long-term results and possible revision.

Weight Variation in Ceramic-on-Ceramic Implants

Ceramic-on-ceramic (CoC) implants are increasingly popular due to their wear resistance and low friction properties, which contribute to hip replacements’ increased life expectancy. The mass of these implants may vary depending on design, material composition, and manufacturing processes.

- Material Density: The main materials that makeup CoC implants include alumina and zirconia. Alumina has a density of about 3.9 g/cm³ while zirconia is around 6.0 g/cm³ in terms of density. As a result, the overall mass of an implant is influenced by this difference in density depending on the specific material employed during its manufacture.

- Implant Design: The shape or geometry of the implant will also matter. CoC implants come in different varieties, such as modular units or one-piece designs. The former mostly have extra components, so they tend to weigh relatively more compared to the latter type, which is usually lighter.

- Size and Diameter: Weight may also vary depending on femoral head size. Larger diameter heads, like 32 mm and 36mm, are heavier than smaller diameters, like 28mm, because they have greater volume.

- Porosity and Coating: Furthermore, surface modification treatments and coatings meant for better osseointegration could increase it.These ceramic coatings can sometimes include other substances that increase the total weight of the prosthesis.

- Methods of Manufacturing: The weight and density of the final implant depends on various production techniques such as isostatic pressing or slip casting.

In conclusion, to understand why there are different weights for ceramic-on-ceramic implants, it is important to assess each implant’s properties and materials used for its fabrication fully. All patients must be evaluated individually based on their anatomy and body functionality so that a good choice can be made.

Factors affecting weight of hip replacements

I have researched this subject, and from various reputable sources, I have identified some key factors that influence the weight of a hip replacement. Firstly, the material used in manufacturing components is a major determining factor for the weight; titanium has a different density compared to cobalt-chromium alloys or ceramics. The design of these implants can either be one piece or modular; hence, it determines its heaviness since modular designs come with more parts. Thirdly, big femoral heads contribute to higher masses as they increase the overall weight. There may also be surface coatings intended for better integration with bone together, which may affect density and weight. Last but not least, any surgeon must consider their patient’s specific factors, such as bone structure and activity level, before picking an implant that will provide a balance between comfortability and performance.

Material Composition (e.g., Titanium, Polyethylene)

The composition of materials used in hip replacements plays a crucial role in determining their performance, durability and weight . Below is a brief summarization of materials commonly used according to research findings from top websites.

1.Titanium:

- Density: About 4.51 g/cm³ approximately.

- Properties: ideal for load-bearing applications in hip replacements due to their high strength-to-weight ratio, corrosion resistance and excellent biocompatibility

2.Cobalt-Chromium Alloys:

- Density: Approximately 8.5 g/cm³.

- Properties: It is usually used in bearings because it has the best wear resistance and strength, which makes it suitable for areas with too much friction.

3.Polyethylene:

- Density: Depending on the type (linear low-density or ultra-high molecular weight), it ranges from 0.93 to 0.97 g/cm³.

- Properties: It is usually used as an acetabular component liner; therefore, it provides low-friction surfaces that are resistant to impact, making it last long when worn over time.

4.Ceramics:

- Density: Normally from 3.5 to 3.8 g/cm³.

- Properties: However, ceramics are brittle and break under extreme loadings even though it has got excellent biocompatibility and wear resistance.

5.Polyetheretherketone (PEEK):

- Density: About 1.3 g/cm³ approximately.

- Properties: This is a strong lightweight material used in components where both enhanced strength and flexibility are required.

These materials are selected based on their specific technical parameters and properties that align with patient needs and implant design. Therefore, the overall weight of the implant depends upon the choice of material, which emphasizes considering clinical outcomes together with patient comfort during the design process.

Type of Cement Used in Fixation

It is important to choose the proper cement for orthopedic surgeries like joint replacement procedures so that the implants remain stable and last. The main types of cement for fixations include polymethylmethacrylate (PMMA) and bioactive cement.

1. Polymethylmethacrylate (PMMA):

- Properties: Besides its high viscosity, which is perfect for filling bone voids, PMMA is a synthetic polymer that offers excellent mechanical support and enhances bonding between implant and bone.

Technical Parameters:

- In this regard, the specific anatomical site being operated upon, the type of implant involved, and the patient’s bone quality determine the choice of cement used during fixation. To select an appropriate option among these competing considerations, surgeons often compare the benefits of mechanical support against potential bone integration.

- Viscosity: It varies, enabling easy application while preventing any leakage during operation

- Setting Time: Surgery takes between ten and twenty minutes, so there is enough time for surgeons to work on it.

- Compression Strength: Ensuring that a minimum compression strength range of about 70-100 MPa should be achieved for it to accommodate forces experienced by joints

2. Bioactive blocks of cement:

- Properties: These substances encourage bone growth and fusion with the implant. They usually contain hydroxyapatite or calcium phosphates that imitate bone mineralization.

Technical parameters:

- Bonding strength: Bioactive cements extend osteointegration with bone, thus increasing overall stability.

- Degradation: They are made in such a way that enables them to gradually integrate with the neighboring bones, leading to natural healing and adaptation.

How does the weight of a hip replacement affect healing and functioning?

Regarding recovery and functionality, hip replacement surgery can be made or broken by the weight. Based on my experience, lighter implants usually exert less strain on the surrounding tissues, resulting in a faster recovery period. This is very important, especially during early mobility, because excessive weight may impose more pressure on the recovering joints. In addition, lighter implants generally maximize comfort levels, thus minimizing exhaustion from rehabilitation exercises. However, I also know that there should be a balance between lightness and durability since too small an amount of material used can undermine such construction’s stability and life span. It’s an intricate conversation involving speaking with my orthopedic surgeon at length to figure out what works best for me based on my needs.

Impact of Weight on Post-Surgery Rehabilitation

The weight of the hip implant plays a vital role in post-surgery rehabilitation procedures. Research shows that having smaller implants can aid better mobility and hasten recuperation times, meaning low muscle load during initial attempts to recover individual fitness. The following are some critical technical considerations:

- Weight Distribution: A decrease in implant mass generally results in a more balanced weight distribution, promoting higher stability while reducing chances of falling during rehabilitation.

- Muscle Load: If the implant has less mass, the muscles will need less power to work, making patients tired less quickly during their recovery sessions.

- Impact Forces: Lighter materials result into lower forces experienced by femur and surrounding tissues hence relieving pain when performing movements as well as making them comfortable.

- Material Strength: The selected materials must have suitable strength and durability even after a considerable reduction in mass. Titanium and certain polymers tend to be ideal due to their ability to blend lightness with structural rigidity.

Each of these parameters is critical for an efficient and effective recovery process targeted at individual patient-oriented rehabilitation goals. It is, therefore, advisable that you speak with an orthopedic surgeon to help you choose the right implant based on these factors.

Weight Issues for Patients with Mobility Problems

When addressing weight issues for patients with mobility problems, it is important to consider several technical parameters directly related to recovery and rehabilitation outcomes. The following are some top healthcare and orthopedic sources’ insights:

- Load-Bearing Capacity: Lighter implants allow for adaptive load management during weight-bearing activities, promoting gradual progression without risking instability.

- Functional Range of Motion: Lightweight designs enable greater range of motion during exercise periods, which improves functionality and allows patients to achieve their daily living goals more efficiently.

- Energy Expenditure: Evidence indicates that light weight leads to reduced energy costs associated with locomotion, thus increasing participation in physical therapy sessions as well as motivation among individuals suffering from impaired gait.

- Fall Risk: Good weight distribution corresponds well with better balance, especially relevant in case of fall-prone subjects. It can be significantly reduced by tailoring an implant design specifically to minimize this risk.

- Skin Integrity and Comfort: For those with decreased mobility, lighter materials result in less pressure and minimized risk of skin break down over time spent sitting or lying.

These considerations indicate why it is important to choose implants that meet technical requirements and address the main aim of increasing patient mobility and independence. Working with healthcare professionals remains key to identifying suitable options based on individual patient profiles.

Is the Weight of Hip Implants a Factor in Surgical Approach?

Yes, surgical techniques are significantly influenced by the weight of hip implants. As an orthopedic surgeon, I have noticed that lighter implants require fewer invasive measures because they usually involve smaller incisions and less manipulation of surrounding tissues. Moreover, this facilitates speedier patient recovery and reduces the risk of complications during surgery. In addition, choosing implant size can influence the joint’s overall stability, which may result in fixation and alignment methods used during operation. Hence, understanding how implant weight affects surgical practices is crucial to optimizing outcomes and ensuring patient safety.

How Implant Weight Affects Surgical Placement

The approach to surgical placement depends on the weight of hip implants. Insightful information from reputable sources reveals various crucial aspects of implant weight and its relationship with surgical methodology:

- Cutting Size: Lighter implants usually permit smaller cuts, cause less tissue damage, and shorten healing duration. Research shows that lightness corresponds to less invasiveness.

- Tissue Disturbance: Surgery involving less tissue handling fulfills the desires of surgeons willing to minimize soft tissue manipulation in surgery rooms (Sharma et al., 2012). This minimizes postoperative complications such as delayed union or infection, according to some studies

- Joint Stability: The stability of the hip joint can be affected by the implant weight. Proper load distribution hinges upon adequate stability; hence lighter implants lead to better stability thus affecting alignment during implantation suggests a study conducted on this subject.

- Fixation Technique: Heavy implants generally necessitate more robust means of fixation, which often translate into longer operative time and higher complication rates. Conversely, lighter implants may create opportunities for simpler ways of fixing them, hence enhancing efficiency during the procedure.

- Patient Recovery: Clinical data shows that patients with lighter implants achieve faster rehab results than those with heavier ones.This improves joint function and reduces pain after surgery, speeding up patient mobility.

- Material Properties: Properties such as tensile strength, fatigue resistance, and surface roughness are essential for optimal implant performance. On the other hand, light materials such as titanium or composite polymers are usually selected since they have well-balanced characteristics to ensure adequate strength without being too heavy.

These insights emphasize the complex interaction between hip implant weight and surgical placement underscoring the surgeon’s need to consider implant design during procedural planning.

Weight-issues in Minimally Invasive Procedures

Oppositely, minimally invasive procedures may face difficulties concerning the weight of an implant despite their ability to provide faster healing time and lower chances of complications. This problem is more pronounced when considering challenges associated with smaller operating fields where instruments are limited by length. Thus, heavier implants may hinder instrument navigation during surgery, leading to lower precision and control. Overweight items can also negatively affect postoperative patient satisfaction, thus preventing subsequent recovery periods.

Certain Technical Parameters

- Tensile Strength: Tensile strength measures how many pounds a material can endure before snapping. High tensile strength is desired in implants since they must support dynamic loads present during movements.

- Fatigue Resistance: This parameter demonstrates a material’s ability to withstand cyclic loading over time. Fatigue resistance is critical in enhancing an implant’s life span, especially in minimally invasive techniques that limit options for material selection (Poggio et al., 2014).

- Implant Surface Roughness: The implant’s texture also is a critical factor in osseointegration or bone formation around the implant. Implants that are lighter and have an optimum surface roughness increase stability and performance.

- Biomechanical Properties: Lighter materials often possess dissimilar biomechanical properties to those of heavier ones. It is essential to ensure that the loads are well distributed while still maintaining structural integrity; this will guarantee patient safety.

- Compatibility with Surgical Instruments: This allows the surgical process to be sped up; however, it also means that the surgeons involved in this case must be properly trained and equipped with the necessary skills for such implants.

Understanding some associated technical parameters could help overcome these weight-related challenges, leading to improved patient outcomes during minimally invasive procedures. Enhancing implants’ performance among members of the surgical community would also improve patient outcomes.

What Materials Are Commonly Used in Hip Implants?

When you think of hip implants, various materials are often used for this purpose, each with its advantages. Stainless steel is popular due to its strength, corrosion resistance, and durability. Another frequently used material is titanium because of its exceptional biocompatibility and low weight, contributing to the overall reduction of the implant’s mass. Moreover, cobalt-chromium alloys have been found suitable for their excellent properties, such as wear resistance and strength, which makes them perfect for use on the bearing surfaces of the implant. Finally, polyethylene liners are commonly used in total hip replacements because they are low-friction mediums offering a smooth surface that improves comfort and functionality during walking or climbing stairs. Any slight variation in any one of these ingredients will cause poor functioning early failure, or both.

Titanium, Ceramic, Polyethylene Components

Titanium is renowned for its high tensile strength, lightweight/hardness ratio, and biocompatibility with human tissues. It is widely used in major structures of implants. Its low density reduces overall implant weight and does not impair structural integrity. Titanium also has remarkable resistance to corrosion, even under aggressive conditions inside the body.

- Ceramic: Ceramic components are used as bearing surfaces in many hip implants due to their inherent hardness and wear resistance characteristics. They provide a smooth articulation that minimizes friction between moving parts, resulting in a prolonged implant life span. However, ceramics may be more brittle than metals, so proper positioning and mechanical loading during surgical placement should be taken into account.

- Polyethylene is most commonly employed as a liner in total hip replacements because it provides patients with a low-friction surface that enhances their comfort level and functionality levels while undertaking activities like walking or ascending staircases. Modern designs such as cross-linking significantly improve wear performance while minimizing risks associated with osteolysis caused by wear debris. Furthermore, it possesses excellent shock-absorbing properties and is capable of loading, which is important for wear resistance and joint stability.

Justification of Technical Parameters

- Biocompatibility: Therefore, titanium and polyethylene have been used quite often.

- Wear Resistance: Ceramics and cross-linked polyethylene are needed to resist wear from repeated stress while maintaining functionality.

- Mechanical Strength: These materials must have high tensile and compressive strengths to withstand the loads to which they will be subjected in everyday activities. This is why titanium and cobalt-chromium alloys are chosen.

- Density: A solid but lightweight implant like titanium can reduce overall weight while providing adequate strength.

By carefully selecting and combining these materials, hip implants can be designed to meet the demanding needs associated with patient mobility throughout the patient’s lifetime.

Advantages of Specific Materials in Hip Replacement

1. Titanium:

- Advantages: Titanium’s low weight-to-strength ratio makes it lighter, enhancing comfort during use. Its biocompatibility minimizes allergic reactions or infections.

- Technical Justification:

- Therefore, replacements made using these specific materials will improve patients’ lives in terms of biomechanics, thereby improving functional capability and durability.

- Biocompatibility: This promotes osseointegration, which is necessary for implant stability.

- Mechanical Strength: It may handle intense loadings resulting from normal daily activities.

2. Cobalt-Chromium Alloys:

- Advantages: They exhibit superior corrosion resistance, excellent wear performance, and fatigue strength, making them ideal for active individuals.

- Technical Reasoning:

- Wear Resistance: This maintains performance under stress, thereby reducing the likelihood of implant failure.

- Mechanical Strength: It is meant for longevity and mechanical stability.

3.Cross-Linked Polyethylene

- Advantages: Improved wear resistance than conventional polyethylene increases the life span of implants and reduces the risk of osteolysis resulting from debris that wears off them.

- Technical Reasoning:

- Wear Resistance is important in reducing the rate at which an item disintegrates over time due to use and friction.

- Shock Absorption: This process supports joint stability by damping direct forces acting on them.

4.Ceramics

- Advantages: Ceramic materials are highly biocompatible and offer excellent wear resistance, making them ideal for articulating surfaces in hip implants.

- Technical Reasoning:

- Wear Resistance: Reduction in abrasive particle production by lowering wear rates is important.

- Biocompatibility. It minimizes inflammation and encourages healthy tissue integration

5.Polished Stainless Steel

- Advantages: Polished stainless steel is used because it has strength, corrosion resistance, provides patient comfort while ensuring security fitment.

- Technical Justification:

- Mechanical Strength. It can be used daily without significantly losing quality, which would otherwise lead to its degradation with time.

- Density: A balanced weight allows robust performance without sacrificing patient comfort

Conclusion

In conclusion, choosing appropriate materials for hip implants is a key factor towards long-term success. Each material has unique properties that contribute to an implant’s overall functionality and durability, from cross-linked polyethylene to ceramics to polished stainless steel. Such revolutions reduce complications related to wear debris and implant failure and enhance patients’ comfort levels. Continuous exploration and refinement of hip replacement materials will be necessary in advancing healthcare as technology continues to evolve to improve patient care and quality of life after these procedures.

Frequently Asked Questions (FAQs)

Q1: What materials are commonly used in hip implants?

A1: Common materials for hip implants include titanium, stainless steel, ceramics, and cross-linked polyethylene. Each material has unique properties contributing to the implant’s performance and longevity.

Q2: How do the materials used in hip implants affect patient outcomes?

A2: The choice of materials impacts wear resistance, biocompatibility, and mechanical strength, all contributing to reducing complications and enhancing overall patient comfort during recovery.

Q3: Are there any risks associated with the different materials used in hip implants?

A3: While modern materials are designed to minimize risks, concerns such as wear debris and implant failure can still exist. Choosing high-quality materials and continuously monitoring advancements can help mitigate these risks.

Q4: How often do hip implants need to be replaced?

A4: The lifespan of a hip implant can vary by material and individual factors, but many implants last between 15 to 20 years. Regular monitoring by healthcare professionals is essential to assess the implant’s condition over time.

Q5: Where can I find more information about hip implants?

A5: Additional information can be found through reputable sources such as the American Academy of Orthopaedic Surgeons (AAOS) and PubMed Central, which provide comprehensive studies and insights into materials and their applications in hip replacements.