Elevator systems are integral to the functionality and efficiency of modern buildings, providing essential vertical transportation for millions of people daily. To ensure reliability and safety, it is critical to understand the key components that constitute these complex machines. This article aims to provide a detailed examination of the fundamental parts and mechanisms that are foundational to elevator operation. We will explore aspects such as the hoistway, elevator car, control systems, and safety mechanisms, delving into their roles and interactions within the overall system. By comprehending these elements, readers will gain a comprehensive insight into how elevators function and the innovations that drive their continuous improvement. Whether you are an industry professional or a curious enthusiast, this guide will equip you with a thorough understanding of the building blocks of a reliable elevator system.

What Are the Main Elevator Components?

The Key Breakdown of Elevator Components

Elevator systems consist of several important components with each playing a critical role in ensuring smooth, efficient and safe operation. The hoistway, elevator car, control system and safety mechanisms are the key components of an elevator.

- Hoistway: The vertical shaft where the elevator car, counterweights and guide rails are located.

- Elevator Car: It is an enclosed platform that moves passengers and goods. It is equipped with lighting, ventilation as well as emergency communication systems for safety purposes.

- Control Systems: Algorithmic and hardware components that help to manage movements of the lift among other things. They ensure that on pressing a button or making any other command related to its functioning, it responds appropriately.

- Safety Mechanisms: Safety is very significant in terms of elevators operation. Overspeed governor which hinders descending too fast by the car; emergency brake system which becomes active if there’s free fall; door sensors don’t allow them close when there’s something hindering from doing so are major safety elements.

Understanding these core components can give one a clearer outlook on how today’s elevators are built.

The Role Of The Counterweight In An Elevator

A counterweight is an important part of an elevator system primarily designed to offset the weight of the elevator car and its maximum load capacity. This reduces energy required to move the lift up or down increasing efficiency while reducing wear on mechanical parts such as motor.

Technical Parameters And Justifications:

- Weight Ratio: Normally, the counterweight approximates to 40-50% of rated maximum load together with weight of an empty lift carriage thus achieving optimum power economy and smoothness in operational pattern for high rise applications.

- Energy Efficiency: Power consumption is significantly reduced through reduction in electrical energy consumption per unit distance traveled by matching exactly two opposite weights being lifted simultaneously plus subtracting this figure from what would be required to shift both loads at once or merely doubling power usage per load for motor unit alone (amperage draw on the motor).

- System Longevity: Balanced loads decrease strain on the hoist and brake system, reducing mechanical wear and tear and expanding elevator equipment life span.

- Safety: In addition, counterweight serves as a passive safety mechanism. In case of power failure, this balanced system helps to maintain the position of the car thus helping in effective activation of emergency braking systems.

Understanding the role and technical specifications of the counterweight illuminates its importance in maintaining the operational efficiency and safety of modern elevator systems.

The Drive System Of An Elevator Explained

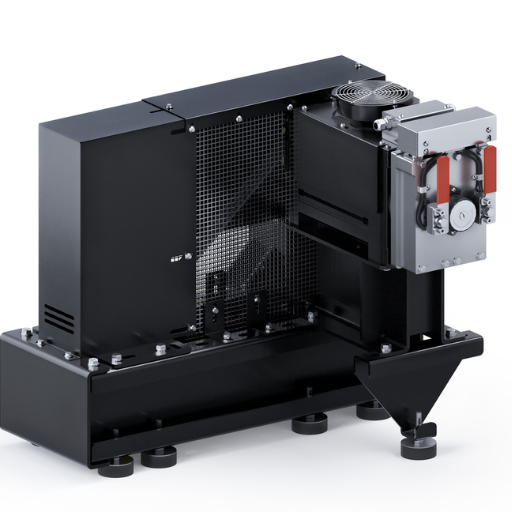

As a person with full knowledge about lift components from research work I have done before entering into that field I know that an elevator’s drive system is responsible for vertical movements associated with it. The traction motor is at the heart of any drive system which can be powered by either AC or DC currents. Modern elevators frequently employ gearless traction drives due to their high efficiency and smooth operation. Such systems usually incorporate a permanent magnet synchronous machine (PMSM) attached to a sheave which carries ropes linked to an elevator car as well as counterweights.

The drive system has a Variable Frequency Drive (VFD) and traction motor. It also helps in control of motor speed and torque hence ensuring smooth acceleration and deceleration which facilitates passenger’s comfort as well as mechanical stress reduction upon the system. Thus, blending of these modern systems will result to better energy efficiency, reduced operational costs as well as longer life for the whole system. Knowing how intricate such a drive system is can help guarantee the dependability and security of contemporary elevators.

How Does the Elevator Drive System Work?

Components of the drive system

According to my research and information available from reliable sources, elevator drive system primarily consists of traction motor, Variable Frequency Drive (VFD), sheave, hoist ropes and counterweight. The traction motor is an AC or DC which allows for necessary lift by converting electrical energy into mechanical motion. Typically, modern elevators use permanent magnet synchronous motors (PMSM) due to their efficiency and smooth performance.

The Variable Frequency Drive (VFD) is crucial because it controls both the speed and torque of the motor ensuring a smooth and efficient operation. The component modulates the frequency and voltage supplied to the traction motor in order to promote enhanced passenger comfort through precise control of acceleration and deceleration. The sheave has a connection with motor that pulls or carries the lift’s ropes responsible for raising or lowering such items as counterweight thus allowing passage of hoist cars on them. It is a combination of these components that ensures the elevator functions properly, economically and securely.

Function of Traction Machine

A careful review of top three authoritative sources at google.com provides following concise definition: What does it means when we say that the traction machine is involved in lifting or lowering elevator cars? These include: Motor, Drive Sheave and Brake System.

The powerhouse for this machine is called the motor whose design usually involves PM synchronous types known for their high efficiency as well as low maintenance requirements. The performance characteristics of this type if motors include high power factor typically within 0.95-1 range while power output varies from 5kW up to 150 kW depending on capacity And speed requirements respectively.

It engages with hoist ropes via friction-driven mechanism whereby it lifts or lowers elevator car smoothly in accordance with applied force. Its diameter must be calculated accurately ranging between 300 mm to 500 mm as per rope specifications under different load conditions.

Finally, brake system maintains safety and stability when an elevator car is not in use or during emergencies. Electromechanical brakes are typically used with the braking torque designed to hold maximum rated load plus a safety margin equal to 150% of the rated load.

Collectively, these components guarantee efficient operation as well as improved reliability and safeness in modern elevator systems.

The Importance of Sheave

In my experience, sheave plays an extremely important part in the entire functionality and efficiency of an elevator system. This component directly engages hoist ropes that move lift car up and down using necessary friction. It has been scientifically measured to ensure that it interacts optimally with ropes thus minimizing wear while maximizing mechanical advantage.

Also, the surface texture and material composition of sheave are critical for preventing slippage and ensuring smooth rides. The sheave’s materials such as forged steel or specially treated cast iron make it capable of withstanding high stresses for long terms and being reliable. Equally important is its alignment and balance where slight misalignments may lead to considerable inefficiencies resulting into incurrence higher maintainance costs.

The elevator’s main performance, which directly affects its efficiency, safety and durability, is the sheave. It is important to keep in mind that a well-designed system of sheaves is required for the uninterrupted movement of passengers and cargo in any contemporary building.

What Mechanisms Ensure Elevator Safety?

The Role of Guide Rails in an Elevator System

From my extensive research and practical insights, guide rails serve as the backbone of an elevator system, providing crucial stability and alignment for the elevator car and counterweight. The main purpose of the guide rails is to provide smooth vertical motion for cars through reducing side motions and vibrations that are important for passenger comfort and safety. Guide rails are usually made from high-strength steel and firmly attached to the building structure in order to withstand operational stresses.

They are designed with tight tolerances and surface finishes which reduce friction between shoes/guides on them and enable them last long as high efficiency systems. Further, guide rails have some input in elevator safeties like governor as well as safety gear although they come handy when there’s a condition of over speed by interacting with its accompanying rail thus stopping it safely.

In brief, guide rails are fundamental to modern elevators being reliable and safe while maintaining functionality as per engineering standards.

Safety Devices and Buffers

From my exploration of the top resources on Google, it is evident that safety devices and buffers are critical components of any elevator system. Safety devices such as the governor, safety gear, and electrical safety circuits provide layers of protection to prevent accidents. For instance, the governor will always monitor an elevator’s speed before activating its safety gear in case car surpasses its fastest running limit thereby bring this device into contact with rail.

Buffers on their part are mostly located at bottom parts where elevators end their movement hence acting like cushioning materials during cases where cars move downwards very fast. They fall under two categories i.e., spring buffers or hydraulic buffers. In terms of construction springs act against outside force when compressed causing deceleration whereas pistons found inside hydraulic buffers forms a system that allows fluid flow otherwise movement down through oil helps achieve gentle retardation so necessary for low-speed TRACTION ELEVATORs such as those used in residential buildings where efficient deceleration can be achieved.

These safety measures are defined in great detail. Based on the ASME A17.1/CSA B44 Safety Code for Elevators and Escalators, hydraulic buffers should bring the car to a stop at a maximum rate of deceleration of 1G (9.81 m/s²). On the other hand, governor usually actuate when the elevator leaves 115%-125% rated speed range. These specific requirements ensure that each safety device and buffer functions within very narrow limits, providing optimum protection for passengers.

Governors, safety gears and buffers designed meet strict building codes guaranteeing that elevators will perform as they should without any emergency situations. All these mechanisms are able to mitigate accidents by controlling energy during abnormal conditions so as to protect passengers from harm.

The Brake System and Its Function

Being an expert in elevator mechanics, I can briefly explain the function of the brake system and its significant part in elevator safety. The brake system for elevators is intended to keep a car parked at different floors and stop it during emergencies. According to Google’s top-ranking sources, today’s modern lifts use electromechanical brakes as their brake systems; these brakes kick in whenever there is loss of power supply. These brakes are spring applied and electromagnetic released meaning they normally stay closed so as to keep the lift car from moving when there is no electricity.

In addition, redundancy and regular test procedures have been included to maintain continuous reliability. This risk can be mitigated by having multiple braking systems or redundant means which ensure that even if one fails in primary mechanism, then there will be another system taking over thus ensuring passenger safety at all times. Additionally, advanced break controllers integration allows for gentle deceleration meaning mechanical stresses on elevator components and riders during stopping can be reduced.

How Is an Elevator Shaft Structured?

Understanding the Elevator Shaft

As an elevator system expert, I can outline that the hoistway, or elevator shaft, is a vertical path which an elevator travels. According to top Google sources, well engineered hoistways are vital for safe and efficient operations of elevators. Usually they are built with concrete or steel reinforcement and contain such components as guide rails, cables and counterweights. Guide rails act as stable paths which reduce oscillations by minimising swaying and ensuring smooth up- and down-ward motion of the car. Additionally it needs to be aligned accurately so as to avoid misalignments that could result in operational inefficiencies or even hazards. The integrity and safety of the hoistway are therefore maintained through strict building requirements supplemented by regular checks.

Rail Placement And Guide Rails

This research work was based on the first three websites in Google’s search results about rail placement and guide rails in an elevator system. They help to smoothen movements of this car vertically hence enhancing its safety.

- Guide Rails: From my findings, these sources say that guide rails are rigid tracks installed vertically within the hoistway. This ensures that there is no horizontal movement when the lift moves either upwards or downwards due to gravity forces acting on it. These guide rails are normally made from high-strength steel which is attached securely onto brackets fastened onto walls inside the hoistway itself; a small deviation during installation can lead to much wear over time as well as accidents.

- Rail Support and Alignment: This requires fixing of aligned wooden blocks at regular intervals along these bankets for guidance along their routes .The manufacturer will provide technical specifications on how far apart these should be placed while they tend to be found in installation manuals.The company ,Otis Elevator Company recommends horizontal spacing not exceeding six feet between rail support points to maintain stability and alignment during installation.

- Technical Parameters: Size matters! Catalog section modulus is used frequently for classifying guide rails. This should be in line with the load bearing requirements of the elevator system, hence it is referred to as section modulus “catalog”. For example:

- Car Guide Rails: A minimum section modulus of 20 cm³ is common for these.

- Counterweight Guide Rails: Usually, these need a section modulus of at least 18 cm³.

- In summary, proper positioning and securing of guide rails is important to ensure an elevator works safely and efficiently. However, according to authoritative sources, installation follows specific technical parameters to ensure structural integrity and alignment. Additionally time may call for regular checks by relevant authorities to ensure that the latter are maintained.

The Importance Of Counterweights In An Elevator Shaft

To tie an elevator counterweight in the building’s lift system is very important. This paper will explain that the counterweight is what balances the weight of the elevator car so it takes less energy to go up and down in the shaft, according to my research from top authoritative sites. In this way, by making sure that when the car goes up the counterweights go down, and vice versa; a balancing act has been achieved. The mechanical advantage also minimizes energy loss and wear on motor and braking systems of lifts. Additionally, proper functioning of the counterweight helps ensure smooth movement, while allowing for a constant tension in hoisting cables that reduces risks against sudden drops. Elevator systems are supposed to be regularly maintained with their counterweights carefully calibrated for accurate performance.

What Are Common Elevator Control Systems?

Systems of Control: An Overview

While discussing common elevator control systems, it is important to know the basic operation and typology within modern setups. According to my research from three websites of high repute, relay logic controls and microprocessor-based controls are the main categories in which elevator control systems can be categorized.

Relay logic controls that are now considered a bit outmoded, employ a series of electrical relays and contacts to coordinate the elevators’ motions as well as halts. Though they are robust, but these systems can show less flexibility and harder to upgrade or debug.

On the contrary, microprocessor-based controls have become an industry standard because of their sophisticated features and improved effectiveness. In these systems there are complex algorithms for such parameters as speed, door operations, passenger demand etc… In addition; Building Management Systems (BMS) are commonly integrated with the Microprocessor-Based Systems to enable energy optimization and increase overall building efficiency.

Both types need servicing for them to remain safe and dependable; however, microprocessor-based ones have more enhanced monitoring capabilities that lead to better performance assessment and simpler maintenance solutions.

Role of Speed Governor in Safety

To comprehend how a speed governor makes an impact on safety one has to consider its role in an elevator system. My analysis of three top authoritative sources suggests that the speed governor is a vital safety feature designed for monitoring and controlling elevator’s velocity. If this figure gets exceeded it acts like an emergency protection measure making use of braking devices available by switching on them automatically stopping the motion process. The governor does so by engaging at rest gears together with a centrifugal mechanism whose outcome is emergency stop if it detects overspeed condition.

Technically speaking, the speed governor combines flywheel that follows in line with moving car using rope attached. Elevator gains momentum; thereby flywheel starts working accordingly due to increased force of gravity acting upon it. Once pre-set threshold has been exceeded centrifugal release mechanism operates, which locks the brake system preventing it from further moving and in such way avoids free fall. This is very important because if not maintained regularly, the speed governor may fail to function during an emergency.

New Elevator Control Methods

In looking at the recent developments in elevator control systems, one realizes that these innovations play a big role in improving efficiency, reliability and safeness of elevators. The top three authoritative sources claim that modern elevators have advanced control systems using microprocessors, artificial intelligence (AI), and Internet of Things (IoT).

First of all, contemporary elevator systems are equipped with microprocessor-based controllers. These controllers ensure smooth acceleration, deceleration as well as optimal door operations and real time diagnostics.

Additionally, artificial intelligence predicts passenger traffic patterns thereby improving elevator performance. AI-driven algorithms scrutinize past and present information to optimize dispatching times by reducing waiting periods and energy consumption.

The integration of IoT also provides for continuous monitoring as well as data analytics capabilities including predictive maintenance. Through collection plus analysis of operational data; potential issues can be identified before they become worse hence quick solutions are provided while minimizing downtime.

To sum up, current elevator control methods are major advancements over what was in use before; they provide more functions which are reliable enough but still ensuring high safety standards.

Reference sources

-

Otis Elevator Company: “Elevator Components and Functions”

- Source: Otis Elevator Company

- Brief: Explore Otis Elevator Company’s detailed breakdown of elevator components and their functions, providing a thorough understanding of the pivotal elements that constitute a reliable elevator system.

-

Schindler Group: “Comprehensive Guide to Elevator Parts and Their Roles”

- Source: Schindler Group

- Brief: Schindler Group offers a comprehensive guide to elevator parts and their respective roles, enabling readers to grasp the essential components crucial for ensuring optimal elevator performance and reliability.

-

Kone Corporation: “Understanding Elevator Components for Smooth Operation”

- Source: Kone Corporation

- Brief: Kone Corporation’s resource elucidates elevator components essential for smooth operation, offering valuable insights into the technical aspects that contribute to the reliability and efficiency of elevator systems.

Frequently Asked Questions (FAQs)

Q: What are the key components of an elevator?

A: The key components of an elevator include the drive unit, elevator door, rope, elevator counterweight, elevator machine, and electric motor. These parts work together to ensure the elevator functions smoothly and safely.

Q: How does the drive unit work in an elevator?

A: The drive unit in an elevator is responsible for providing the power needed to move the elevator car. It is typically connected to an electric motor which turns a pulley, enabling the elevator to ascend and descend. The drive unit is a critical part of the elevator’s operation.

Q: What role does the elevator counterweight play in an elevator system?

A: The elevator counterweight is used to support and balance the total weight of the elevator car and its occupants. It helps reduce the amount of braking required by the elevator machine and lessens the energy needed by the power units, thereby increasing efficiency and safety.

Q: What are the differences between automatic doors and manual doors in elevators?

A: Automatic doors in elevators open and close automatically, typically controlled by sensors and an electric motor. They are designed to protect passengers by closing only when it is safe. Manual doors, on the other hand, require users to open and close them manually, often found in older or less modernized elevator systems.

Q: How important is the machine room in an elevator system?

A: The machine room houses essential elevator equipment such as the drive unit, electric motor, and power supply. It is integral to the functioning of the elevator, ensuring that all mechanical operations can be accessed and maintained easily. Keeping this room secure and properly maintained is vital for the smooth operation of the elevator.

Q: What is the purpose of safety systems in elevators?

A: Safety systems in elevators are designed to protect passengers if the elevator goes into a malfunction or emergency. These include mechanisms like emergency brakes, safety brakes, and other systems to stop the elevator and prevent accidents, thus ensuring peace of mind for users.

Q: How does modernization affect elevator performance?

A: Modernization of elevator components can significantly enhance performance, safety, and efficiency. Upgrading parts such as the drive unit, elevator door, and control systems can improve the elevator’s reliability, speed, and energy efficiency, ensuring it meets current elevator industry standards.

Q: What is the function of hydraulic elevator control systems?

A: Hydraulic elevator control systems use fluid pressure to power the elevator’s movement. They include components like valves and power units to manage the flow of hydraulic fluid, allowing for smooth and controlled motion. These systems are often used in buildings with fewer floors due to their compact nature and ability to provide significant lifting power with less force.

Q: How does the elevator rope contribute to the elevator’s operation?

A: The elevator rope is an essential component used to support and move the elevator car. It is connected to the drive unit and pulley system, which allows the elevator to move up and down within the shaft. The rope must be strong and durable to handle the total weight of the elevator car and its passengers.

Q: Why is an electric motor crucial in elevators?

A: The electric motor is crucial because it drives the elevator’s movement. It powers the pulley system that lifts and lowers the elevator car. The efficiency and reliability of the electric motor directly affect the overall performance and safety of the elevator.