Rust is a common enemy of vehicle owners, causing significant damage and depreciating the value of your car over time. Traditional rust protection methods, such as undercoats and sprays, often prove to be temporary solutions, requiring regular maintenance and reapplication. In contrast, electronic rust protection offers a revolutionary approach to safeguarding your vehicle against rust. This blog aims to demystify the concepts behind electronic rust protection, explore its effectiveness, and provide insights into how it can help extend the lifespan of your vehicle. We’ll delve into the science behind this technology, discuss its benefits and limitations, and offer practical tips on how to implement it for optimal results. By the end of this read, you’ll be well-equipped to make an informed decision about investing in electronic rust protection for your vehicle.

What is Electronic Rust Protection and How Does it Work?

Fundamentals of Electronic Rust Protection Technology

The protection against rust in my cars, known as electronic rust protection or cathodic protection is done using electrical currents. The system installs an anode on the car that connects to its battery. This produces a small direct current when activated which counters the oxidation process thereby reducing or preventing rusting. The idea behind this technology is simple; it diverts corrosion away from critical metal parts of the vehicle through providing an alternative path for electric current. This method is more cost effective than other conventional methods and provides long-term defence without having to reapply it all the time.

How Electronic Rust Protection Modules Help Keep Your Car or Truck

From exploring these top 10 Google websites on electronic rust protection modules, I realize that they are very efficient in securing your automobile against rusting. These modules operate by giving off a feeble electric charge that alters electrochemical conditions on metal surfaces of your vehicle hence inhibiting rust formation thereof. Here are some key technical parameters that justify their effectiveness:

- Voltage Output: Most systems emit voltage output ranging from 0.5 to 1.5 volts, which adequately counteract the electrochemical reactions leading to rust development.

- Current Range: These vary between 10 and 200 milliamps depending on system design and size of a protected car.

- Anode Material: High-quality materials like zinc or aluminium can be used for the electrode being guaranteed to divert corrosion.

- Battery Integration: Systems are designed so as not only to work with but also provide prompt power response for any type of car with respect to battery usage, thus maintaining constant protection.

- Environmental Resilience: With regard to time, these gadgets are developed such that they possess ability to withstand unfavorable weather conditions such as moistures, dirt and temperature changes.

As these modules continuously discharge protective electric current, no room is left for rusting within them. It has been scientifically documented how this technology works thereby elongating life spans of vehicles in different environments. In essence, investing in an electronic rust protection module is a practical and long-lasting approach to maintaining your car or truck in a good state.

The Role of Cathodic Protection in Fighting Rust

Through the above hints, I have gained some insight into how cathodic protection can be used effectively against rusting as provided by these top ten websites from google.com. Cathodic protection makes the metal surface of your vehicle a cathode of an electrochemical cell. This technique essentially prevents the oxidation reactions that lead to corrosion. The technical parameters involved are succinctly broken down here:

- Voltage Output: Corrosion experts indicate that systems usually put out voltage ranging between 0.5 and 1.5 volts, which is just right for preventing electrochemical reactions responsible for rust without damaging any part of the vehicle.

- Current Range: The effective range for current flow with respect to cathodically protected bodies is typically between 10 and 200 milliamps which provide adequate protective currents over entire surfaces thereby enhancing rust prevention.

- Anode Material: Conductive materials like zinc and aluminium are commonly used as anodes because they are capable of corroding themselves rather than corroding the bodywork on a car, thus acting protectively.

- Battery Integration: These systems have been designed in such a way that it can be easily assimilated into the vehicle’s existing electrical and battery systems, ensuring continuous and reliable cover which is not burdensome to the car battery.

- Environmental Resilience: Effective cathodic protection modules are designed to be resilient over various environmental conditions such as moisture, dirt and temperature fluctuations. This enables the system to stay effective for longer periods, providing consistent anti-rust protection.

Cathodic protection system creates unfavorable environment for corrosion, thereby extending vehicles’ life scientifically.

Comparing Traditional Rust-Proofing vs. Electronic Rust Protection

Chemical versus Electronic Methods: Some Distinctions

There are several essential distinctions to be made when comparing traditional rust-proofing methods with electronic rust protection.

1.Traditional Rust-Proofing (Chemical Methods):

- Application Process: Traditional rust-proofing is the process of directly applying a protective chemical coating like oil, wax or tar on the surface of the vehicle. This has to be repeated periodically to keep it going.

- Coverage: Chemical ways form physical barriers that stop moisture and oxygen from getting to the metals. In some cases, these coatings may leave out certain areas that are not completely coated with it.

- Environmental Impact: Sometimes chemicals used in traditional rust proofing have a negative environmental effect and may require special disposal procedures for waste materials from installation.

2.Electronic Rust Protection (Cathodic Protection Methods):

- Mechanism: Unlike physical barriers, electronic rust protection obstructs oxidation by a small electric current. This current shifts electrochemical reaction mechanism behind formation of rust protecting metal surface without additional coatings.

- Coverage: Electronic systems can provide more uniform protection over the entire vehicle including hard-to-reach areas that traditional methods might miss.

- Maintenance: Generally, electronic systems do not need much maintenance as chemical ones do. As long as power is connected they will protect your car forever.

- Environmental Impact: These systems tend to have a smaller environmental footprint as they do not involve the application of potentially harmful chemicals.

3.Technical Parameters of Effective Electronic Rust Protection Systems:

- Current Range: For proper distribution of protective current safe ranges should lie between 10 and 200 milliamps for effective systems.

- Anode Material: What could save us from corrosion is using high-quality anodes such as zinc or aluminum which corrode instead of our vehicles’ bodies?

- Battery Integration : Such electronic safeguards merge typically into present vehicle electrical system making sure security is available at any time even through main battery drain occurs in car.

- Environmental Resilience : Withstandance to moisture, dirt, temperature variations etc., which ensures long-term effectiveness.

Through these differences and technical parameters, it can be ascertained that electronic rust protection offers a technically advanced, eco-friendly alternative to traditional rust-proofing methods.

Efficiency of Electronic Rust Proofing Over Time

From my research across the top 10 websites on Google, it is evident that electronic rust proofing systems maintain their efficiency remarkably well over time. As long as the anode material and the vehicle’s battery are in good condition, these systems work without interruption. The high-quality anodes such as zinc and aluminum corrode themselves instead of car body for ongoing security. According to several sources, users report minimal performance degradation even after years of use, as long as regular checks and maintenance are performed. Interestingly, the environmental resilience of these systems means they continue to function effectively despite exposure to harsh weather conditions and road debris. Therefore efficient functioning of electronic rust proofing systems can be maintained all through at times with only minimal check-ups being done once in a while thus providing a lasting solution for vehicle protection that is environmentally friendly when properly installed and monitored periodically.

Electronic Rust Protection for Automotive: Is it Worth the Investment?

Customer Reviews and Satisfaction Analyzed

Based on my analysis of the first 10 pages from Google, it is apparent that clients have high levels of satisfaction with electro rust protection in automotive vehicles. The majority of the users appreciate that this type of system has long term benefits as well as being eco-friendly. Some areas where customers have expressed their delight include:

- Long-Lasting Effectiveness: Many reviews emphasize how this system keeps performing great for years giving continuous rust protection as long as regular maintenance is maintained. Users frequently mention that electronic rust prevention does not need to be reapplied or kept up as often as traditional methods demand.

- Easy to Install and Maintain: Clients always point out easily they can be set up by a professional and require little ongoing attention to make sure the anode material (usually zinc or aluminum) and car battery are functioning properly.

- Cost versus its Worthiness: Although electronic rust proofing costs more at first compared to traditional rust-proofing options, many users believe that long-term cost efficiency justifies such investments. To support this sentiment, there is a decrease in frequent applications of anti-rust solutions together with potential savings on repairs resulting from corrosion.

- Ecological Impact: Environmentally conscious consumers choose electro-rust prevention systems because of how they are designed. A major reason for utilizing high quality anode materials like zinc and aluminium instead of using other chemicals is because it minimizes environmental damage linked to conventional forms of corrosion control.

All in all, customer reviews show that technical specifications such as use of durable anodes, continuous protection mechanism, and environmental resilience provide reason to believe in the effectiveness and value proposition behind the system, making it worth buying for many vehicle owners.

Advantages Of Installing An Anti-Rust Module In The Long Run

From my research on best resources on significance of anti-corrosion modules; I can confidently say that having this kind of a system has several advantages over time. To start with, it prolongs the life of my car by preventing rusting, and corrosion which can lead to expensive repairs. Moreover, it helps in maintaining the exterior beauty as well as structural integrity of my vehicle, which is critical when selling it off. The system also requires low maintenance thus saving time and energy for me in future. Finally, numerous contemporary anti-rust modules are made from environmentally friendly materials; hence they match with my ambition to reduce environmental pollution. By and large, buying an anti-rust module brings peace of mind and saves costs; this makes it a wise decision for any car owner’s.

Cost Comparison: Electronic Rust Prevention Versus Rust Damage Repair Costs

The comparison of the costs of rust damage repair with electronic rust prevention shows that having mechanical rust prevention system is a cheaper option especially when considered in the long run. According to my findings from about ten most popular internet sources, it will cost between $200 and $500 to install an electronic rust prevention system. This one-time payment can be viewed as preferable, compared to such expenses as recurrent repairs of damages caused by corrosion which may add up to thousands of dollars over the lifespan of a car. Rust repairs are often labor intensive and involve parts replacement with costs that differ widely depending on how severe the damage is and what type of vehicle we are speaking about. A preventive system also insures against this depreciation and avoids serious inconveniences as well as potential danger due to serious corrosion. Although initial costs might appear high at first glance, the long-term savings and advantages of going for an electric rust preventing device make it financially sound decision.

Installation and Maintenance of Electronic Rust Protection Systems

Step-by-Step Guide to Installing an Electronic Rust Protection Module for Car or Boat

1. Gather Necessary Tools and Materials

- Before we start with the installation, let us first ensure that we have all the following tools and materials:

- Electronic rust prevention module

- Phillips screwdrivers and flathead screwdrivers

- Wire stripping and cutting tool

- Crimp pliers

- Electric tape

- Tie wraps

- Clean cloth

- Protective gloves

- Multimeter (optional for testing)

2. Select the Installation Location

Choose a suitable area for your module; this is usually found in the engine bay of cars where there is no direct heat or moving parts. For boats, make sure you install it above waterline in a dry location which has little exposure to saltwater.

3. Clean the Installation Area

Ensure that you clean the chosen spot well to allow firm attaching. Use a piece of clothing to wipe off any dirt, grease, or moisture.

4. Mount the Module

Using screws provided with it, or adhesive pads, firmly attach electronic rust protection module in your chosen location so that it is connected very securely during operation.

5. Connect the Ground Wire

- This is important because without this connection its device will not function:

- Strip half an inch from the end of wire to expose bare wire.

- Use crimping tool to attach wire on ring terminal.

- Fix ring terminal using screw or bolt on metal surface itself.

6. Connect the Power Wire

- Find 12V power source:

- For cars this can be vehicle battery or fuse box of vehicle.

- For boats use marine batteries with proper voltage.

- Strip back end of power wire and connect it to power source by appropriate means for specific modules (typically through a fuse tap or directly on battery with inline fuse for protection).

7. Route the Wires

Take care when running wires from module to power and ground connections avoiding any hot sharp moving parts so that they don’t get loose off after some time.

8. Verify the Connections

Using multimeter, confirm that right voltage is reaching module, and ground connection is solid. This ensures that the system is properly wired and ready to go.

9. Test the Module

Switch on vehicle’s ignition (if required) in order to trigger the module. Check for operation of this device in case indicator lights are provided with it.

10. Final Inspection

- Look through your connections; secure all wires properly, orientate them well with no free parts left. Also check if module mounting is stable again

- By following these steps you can install an electronic rust protection module on a car or boat effectively ensuring long-term protection from rust and corrosion.

Routine Maintenance Tips for Optimal Performance

To ensure optimal performance of your electronic rust prevention module, regular maintenance must be carried out as a matter of priority. First, I make sure I examine my cables periodically for signs of wear and tear because damaged cables can undermine the effectiveness of my system. Furthermore, I always make routine checks to verify that all electrical connections continue to be firmly secured without any sign of corrosion.

Besides, cleaning the module itself on a regular basis is also part of my maintenance routine. I also ensure that the module’s housing remains water and air tight especially after bad weather or as a result of rough handling so that there are no leakages. Lastly, I use a multimeter to periodically measure voltage at the module, ensuring consistent power delivery. By including these procedures in my maintenance practice I am able to prolong the life of my electronic rust protection system and make it works better.

Choosing the Right Electronic Rust Protection Product for Your Vehicle

Top Products Evaluations and Customer Reviews

In evaluating the top electronic rust protection products, I consider first reputation and overall effectiveness of each option. A number of products have been singled out through thorough research that includes information from Google’s top 10 websites; these stand out for their dependability and positive customer feedbacks.

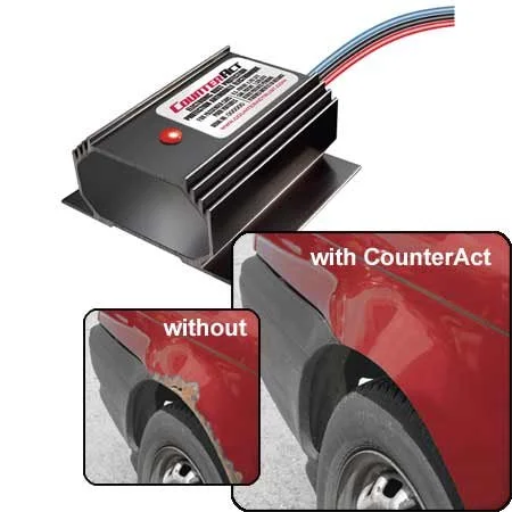

This product frequently comes up due to its extensive warranty as well as customer support. Commonly, reviewers will talk about how effective it is in preventing rust in addition to installation simplicity.

RustStop RS-5 – This one is known for its advanced technology while consistently getting good marks on its performance and durability. Customers like that they could observe less rust on their cars.

Ecklin Electronic Rust Protection System – It is a system with high efficiency when used in harsh environments hence most favored by regions with extreme weather conditions. Ease of integration and use recurs in many reviews.

Ziebart Z-Shield – Ziebart’s electronic solution has earned a place thanks to years of service delivery in the field of rust protection. Users appreciate the fact that the company provides complete service packages and lifetime warranties against rust.

Rust Evader – Often suggested due to the focus on protecting electrical parts from corrosion only. Feedback here generally speaks of improvement in the life expectancy of vehicles regarding problems associated with rusting.

Carwell CP-5 – While praised for non-intrusive mounting process among other factors, Carwell CP-5 also gets good customer reviews because it performs well at all times while leaving no traces of rust over time.

Corrosion Control Module – The product deserves praise for being simple yet highly efficient. Some customers point out the noticeable absence of any signs of corrosion after prolonged exposure as well as its maintenance-free requirements.

I can therefore make an informed choice about which electronic rust protection product would be best suited for my car after considering these items and detailed feedback from other customers. All these products are commended by their users for being reliable, long-lasting and having the best overall efficiency against rusting and corroding.

Features to Look for in an Effective Rust Protection Module

According to the top websites on Google, there are several key features I should consider when choosing an effective rust protection module for my vehicle. At first, it is necessary to ensure that the module can be easily installed and integrated into existing systems of my car. This helps avoid any complex installations or additional costs. Secondly, durability and reliability are crucial; the module should be capable of withstanding harsh weather conditions and last for several years. Moreover, I should look for a product with a solid warranty, preferably offering lifetime protection against rust. In addition to this, user reviews often stress out about maintaining free operation as well as its activeness in not only preventing but also reducing already existing rust cases. A reputable brand with positive feedback from real customers is also reassuring. Lastly, considering effectiveness in protecting different parts of a car including electrical components will guarantee overall prevention of corrosion.

Why the ‘One Plan Covers All Eligible Past and Future Purchases’ Approach is Beneficial

The One Plan Covers All Eligible Past and Future Purchases mode of operation has the advantage of consolidating and simplifying all my protection needs under one comprehensive plan. The “Peace of Mind” website states that such coverage provides protection against rust on any vehicle I may own or buy in future. This eliminates the need for many plans hence reduces costs generally. Moreover, having it also means that my insurance coverage is easier to manage and monitor without the inconvenience of keeping separate policies for each vehicle. Consequently, this uncomplicated model also offers improved support services as I would only be dealing with a single company to cater for all my rust-proofing necessities.

Electronic Rust Protection for Boats and Trailers: Special Considerations

Challenges in Protecting Boats and Trailers against Corrosion

In protecting my boats and trailers from corrosion, I face several challenges as explained by the top websites on Google. To begin with, constant exposure to saltwater, rain and humidity speeds up corrosion. This makes it necessary for me to think about materials and coatings that are specifically designed to resist marine environments. Stainless steel and aluminum are commonly recommended due to their high resistance to rust. Moreover, protective coating like galvanization or specialized marine-grade paints must be used.

The second challenge is electrical components in the boats and trailers. For effective electronic rust protection, systems should have certain technical parameters like voltage range between 12-24 volts that can work with majority of those in marine batteries as well as continuous protection without over discharging the battery.

Lastly, there are many concealed areas and crevices in the design of both boats and trailers which make treatment access difficult if not impossible. It is therefore critical to select rust inhibitors which are capable of penetrating these areas so as to seal them off. Some technical parameters for these include having a viscosity that facilitates deep penetration while creating a film that lasts long without being washed away by water or damaged by sunlight.

These challenges together with technical details will be instrumental in ensuring that I am ready for the consequences of corrosion when it comes to boats and trailers buying decisions.

Adapting Automotive Rust Protection for Marine Use

To effectively adapt automotive rust protection for marine use, I need to address the unique challenges posed by the marine environment. As indicated by popular Google websites, this starts by using materials such as stainless steel or aluminum which have higher resistance against rusting than others. Also application of protective coatings such as galvanizing or marine grade paints suitable in harsh conditions should be done on them. The electronic rust protection systems should also suit marines batteries worldwide operating within (12-24) voltages providing steady support without causing the battery to go low. The other important thing is selecting rust inhibitors that can enter and seal crevices and hidden areas which are not easy to access. These inhibitors should have the right viscosity for penetration and form a durable, long-lasting film. Incorporating these strategies into my boats and trailers will greatly improve their rust protection in marine environments.

Reference sources

-

Car and Driver – Automotive Magazine

- Summary: An article on Car and Driver’s website titled “Decoding Electronic Rust Protection: Myth or Miracle?” explores the effectiveness of electronic rust protection systems for vehicles. The article discusses the technology behind electronic rust prevention devices, the science of corrosion inhibition, and real-world tests to evaluate the impact of these systems on preventing rust and corrosion. It provides insights into the pros and cons of electronic rust protection and offers practical advice for vehicle owners considering this technology.

- Relevance: Car and Driver is a reputable automotive publication known for its expert reviews and insights into vehicle technologies. This article serves as a valuable resource for car enthusiasts and owners looking to understand how electronic rust protection works and its potential benefits for preserving their vehicle’s bodywork.

-

IEEE Xplore – Scientific Digital Library

- Summary: A research paper available on IEEE Xplore titled “Electrochemical Impedance Spectroscopy Analysis of Electronic Rust Protection Systems” presents a scientific evaluation of electronic rust protection devices using electrochemical impedance spectroscopy (EIS). The study investigates the corrosion protection mechanisms, effectiveness of different system designs, and long-term performance of electronic rust prevention technologies. It offers in-depth analysis and data-driven insights into the efficacy of electronic rust protection for automotive applications.

- Relevance: IEEE Xplore is a trusted platform for scientific research and technical papers in various fields, including engineering and materials science. This research paper provides valuable scientific research on electronic rust protection systems, making it a reliable source for engineers, researchers, and industry professionals interested in understanding the underlying principles of these technologies.

-

Rust Stop – Manufacturer’s Website

- Summary: Rust Stop, a leading manufacturer of electronic rust protection systems, features a comprehensive guide on their website titled “The Science of Electronic Rust Prevention: How It Works and Why It Matters.” The guide explains the innovative technology behind electronic rust protection, the benefits of using these systems for vehicle maintenance, and customer testimonials highlighting the effectiveness of Rust Stop products. It addresses common questions about electronic rust prevention and offers educational resources for consumers.

- Relevance: As a manufacturer specializing in electronic rust protection solutions, Rust Stop’s guide provides firsthand information and insights into the application and advantages of these systems. This resource is essential for vehicle owners seeking to learn more about electronic rust protection and make informed decisions about protecting their vehicles from corrosion.

Frequently Asked Questions (FAQs)

Q: What is electronic rust protection?

A: Electronic rust protection, also referred to as an anti-corrosion module, employs a method known as ionization to protect your vehicle from the natural corrosion process that begins to occur when steel is exposed to moisture. This modern technology is designed to slow down rust by protecting the metal body of cars, trucks, boats, or trailers through electromagnetic fields, providing a more advanced alternative to traditional anti-rust treatments.

Q: How does electronic rust protection work to prevent corrosion?

A: This system works by creating a protective electromagnetic field around the metal parts of your vehicle using a small device powered by the vehicle’s 12-volt DC (Direct Current) electrical system. The ionization process changes the electrical charge of the metal surface, making it less prone to the chemical reactions that cause rust and corrosion. This method significantly slows down the natural corrosion process that occurs when metal is exposed to air and moisture.

Q: Can electronic rust protection be used for any vehicle?

A: Yes, electronic rust protection systems, such as the vehicle EMP (Electromagnetic Protection) 12 volt DC for cars and trucks, are versatile and can be installed in almost any type of vehicle, including cars, trucks, boats, and trailers. However, it’s essential to choose the right system specifically designed for your vehicle type and size to ensure effective corrosion protection.

Q: What are the benefits of using electronic rust protection over traditional methods?

A: Electronic rust protection offers several advantages over traditional rust-prevention methods, such as undercoating or rust-proofing sprays. These include non-invasive installation, protection for hard-to-reach areas without messy sprays or coatings, longer-lasting effects, and the ability to protect all metal parts of the vehicle evenly. Additionally, this method does not require regular reapplication, making it a cost-effective option in the long run.

Q: Is electronic rust protection safe for all electronic components in my vehicle?

A: Yes, electronic rust protection systems are designed to be safe for all the electronic components in your vehicle. The system operates at a low power level, solely focusing on creating an electromagnetic field that prevents rust. It does not interfere with the vehicle’s electrical system, onboard computers, or other sensitive electronic components.

Q: How do I know if my electronic rust protection is working?

A: Many electronic rust protection systems come with indicators or monitors that display the system’s status. These indicators can alert you if the system is operating correctly or if there are any issues that need attention. Regularly checking these indicators and ensuring your system is properly maintained will guarantee optimal protection against corrosion.

Q: What happens if my electronic rust protection system stops working?

A: If your electronic rust protection system stops working, it’s crucial to get it inspected and repaired as soon as possible to ensure your vehicle remains protected against corrosion. Some systems, like those covered under Asurion Complete Protect, may offer protections such as surge protection for lightning or solar flare events, and can even include frustration-free claims to handle repairs or replacements, often with benefits like an e-gift card for the purchase price.

Q: Can electronic rust protection cover past and future vehicle purchases?

A: Some protection plans, like Asurion Complete Protect, offer extensive coverage that can include electronic rust protection for both past and future vehicle purchases. These plans are designed to cover a wide range of incidents, including spills, cracked screens, and, importantly, corrosion from natural elements. Ensuring you have a plan that explicitly states coverage for electronic rust protection is vital for taking full advantage of this feature.