The ECT is an important packaging industry assessment, especially for corrugated containers. This test assesses the strength of a stack of corrugated cardboard, telling us how well it can hold up to external forces during shipping and handling. This guide will offer an in-depth look at ECT, its significance and impacts on performance and reliability of corrugated packaging. With this comprehensive guide, you will find valuable information and practical insights about ECT whether you are a packaging professional working in the field or simply interested in how corrugated boxes work. Understanding this test will ensure that you choose the right kind of corrugated box for your need as well as ensuring the safety and preservation of items during transportation.

What is the Edge Crush Test (ECT)?

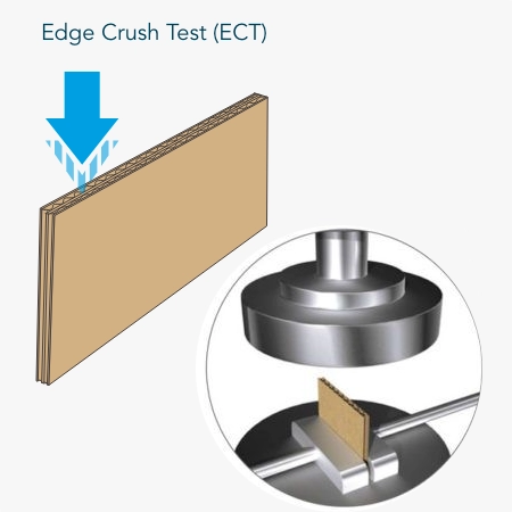

Image source: https://advancedpckg.com/

This is a standardized test called Edge Crush Test (ECT) which determines the strength of corrugated cardboard. It measures how much pressure it takes to crush a flat piece of the board when placed between two plates with one edge protruding out. The results from these tests give an approximation of pound force per linear inch (lb/in) or kilonewtons per meter (kN/m), which represent the ability of boxes to bear weight during stacking as well as resist collapse due to crushing forces coming from all directions. Thus, it is crucially important for determining whether corrugated boxes can be used for long-term storage purposes or if they should only be used temporarily until some sort of permanent solution becomes available in terms durability and functionality is reached with shipping products safely over long distances by air freight or else road transport means like trucks trains etcetera also including sea vessels cruiseships sailing ships across oceans etcetera.

Defining the Edge Crush Test

Defining the Edge Crush Test (ECT) as a vertical compressive strength measure of corrugated board is one way to interpret it. The strength of the corrugated material against forces applied at its edges towards crushing is shown in this experiment. Usually, the board sample is laid on its edge between two immovable platens and force applied to cause it to buckle progressively. It records the highest amount of force required to result in this collapse as ECT value. Higher ECT values imply more robust corrugated materials that enhance stacking power and protect packaged commodities in transit from damage. Manufacturers use these results to optimize the performance properties of their corrugated boxes, so that they conform with given specifications and can survive real world logistics.

Importance of ECT in Packaging

Packaging relies on Edge Crush Test (ECT) because it measures how strong and long-lasting a box made from corrugated material will be. A higher ECT implies that a box can withstand greater vertical compression meaning that it may withstand being stacked during storage and transportation better than other boxes can. This prevents goods from being crushed while still keeping them intact throughout their journey along the supply chain. Additionally, ECT figures help manufacturers meet industry requirements and conformity through optimizing material use for durable yet cost-effective packaging solutions. As such, ECT is an essential benchmark for evaluating packages’ functionality.

History and Evolution of the Edge Crush Test

To suit packaging needs that were evolving, initially measuring the strength of packing was accomplished by using Bursting Strength Test primarily assessing materials resistance against rupture under pressure however as logistics sector grew there was need for more inclusive measure of boxes’ ability to resist compression forces during stacking.

By 1970s, it had been developed in recognition of these requirements and presented a more accurate representation of how edgewise compressed corrugates would behave like when compressed edgewise. In other words this innovation allowed manufactures to design package forms which could adapt well with shipping systems since they were stronger therein (Paine & Teets 1992). The ECT has changed over time in relation to the progress made in material science and testing methods, taking on more complex equipment as well as standardization of procedures. Even today, it is a key principle in packaging tests used to ensure that corrugated materials can withstand modern logistic demands and regulatory standards.

How Does the Edge Crush Test Differ from the Mullen Burst Test?

Although both the Mullen Burst Test and the Edge Crush Test, which are of great significance in gauging the strength of corrugated materials, they do not measure the same properties. The ECT determines a material’s resistance to edge or edgewise compression, which is vital in determining how well boxes can endure stacking and shipping pressures. However, on contrast, the Mullen Burst Test concentrates on evaluating whether a material can be burst by measuring how much force must be applied to destroy it under pressure. Generally, ECT focuses more on structural integrity and stacking strength while Mullen Burst Tests checks for puncture resistance as well as general durability.

Understanding the Mullen Burst Test

Mullen Burst Test is used to measure how strong corrugated fiberboard is and how much pressure it can withstand before breaking up. This test involves using a specialized machine that applies hydraulic pressure onto a rubber diaphragm; this force gets transferred to the specimen being tested. These results give an indication of tensile strength of the material as well as its ability to resist such external forces that would lead to punctures or tears. Ultimately, Mullen Burst Test shows the toughness and puncture resistance in them generally indicating how good a box is at fending off impacts or sharp objects during transportations purposes.

Differentiating Between ECT and Mullen

Both ECT and Mullen Burst Test are essential in examining the strength and durability of corrugated materials; however, they concentrate on different aspects. The ECT ascertains the ability of corrugated boxes to resist edge-wise compressive forces and stacks compressive strength. This is important because it helps determine how well the boxes will perform under other boxes when stacked during storage or transportation.

On the other hand, Mullen Burst Test measures a box’s toughness overall and puncture resistance by hydraulic pressure rupture force. It considers how well the box will protect its contents from any outside forces that may be encountered during handling or transport.

To summarize, ECT mainly deals with the material’s stacking strength and compressive strength ensuring structural integrity under vertical loading. On the contrary, Mullen Burst Test concentrates on puncture resistance, evaluating whether or not a box can safeguard its contents from sudden impacts and punctures. Both tests taken together give an all-round picture of how corrugation performs under various conditions.

Practical Applications of Both Tests

To select the right corrugated materials for specific packaging needs, it is essential to comprehend the practical applications of both Edge Crush Test (ECT) and Mullen Burst Test. ECT is particularly important in industries that need efficient stacking and storing solutions. Often manufacturers use this test while designing packages for products transported or stored in layers, thereby minimizing their collapse chances and ensuring safe delivery.

On the other hand, Mullen Burst Test is indispensable where there is rough or sharp object handling of the package. For instance, this test assists industries such as e-commerce which frequently handle packages with various external forces to select materials that offer better protection against punctures and impacts. It can therefore be inferred that businesses can enhance their packaging protective characteristics by focusing on burst strength to keep contents inside undamaged.

Balancing between compressive strength and puncture resistance so as to meet different challenges in shipping and handling requires companies to build their packaging strategies based on insights from both tests. By taking a holistic approach, these packaged products are well-protected while probability of damage occurring is reduced resulting into higher customer satisfaction.

How to Perform an Edge Crush Test

The following steps are performed in doing an Edge Crush Test (ECT):

- Sample Preparation: Cut out a sample of corrugated board with a specific measurement, usually 25mm wide. Make sure the edges are neat and free from any damages or faults.

- Setting Up the Equipment: Use a machine specifically designed for Edge Crush Test system that has a load cell and two platens. Arrange the specimen thus prepared between the platens in vertical position.

- Applying the Load: Gradually compressing of the sample is done by bringing together at a controlled rate, usually at 13 mm per minute closer platen.

- Recording the Results: Continue to apply force until failure occurs on the test piece. Note down maximum force exerted in Newtons (N) or pounds-force (lbf) during failure.

- Calculating ECT Value: The recorded stress can be divided by width of sample in meters (or inches) to change into ECT value. This quantity is often expressed in N/m or lb/in.

Through these steps, it will be possible to determine edge-wise compressive strength of corrugated materials which assists one to judge their suitability for particular packaging requirements.

Required Equipment and Setup

An Edge Crush Test (ECT) is conducted using the following setup and equipment:

- Edge Crush Tester (ECT Machine): This machine must have a load cell that is accurate and two plate flat.

- Micrometer or Precision Cutter: For obtaining the correct sizes of the corrugated board samples with clean edges for accuracy.

- Conditioning Chamber: Whereby, at a uniform temperature level of 23°C and relative humidity of 50% RH, the samples are conditioned for not less than 24 hours before testing.

- Recording Device: The ECT machine includes an integrated recording device to automatically register the topmost pressure used during test and compute edge crush strength.

- Calibration Weights: These weights are necessary for frequent calibration of the ECT machine so as to ensure precision on measurements made.

With proper arrangement and servicing of these instruments, precise outcomes can be attained which effectively measure the strength and endurance levels in corrugated board used in packaging purposes.

Test Method and Procedure

- Preparation of Samples: Take samples from the corrugated board using a precision cutter or micrometer to achieve accurate dimensions (normally 25mm wide). Place all samples in a conditioning chamber set at 23°C and 50% RH for not less than 24 hours.

- Setting Up the ECT Machine: Use standard calibration weights to calibrate the Edge Crush Tester (ECT machine) for precise measurement. Vertical placement of a single sample can be done between two flat platens on the ECT machine.

- Performing the Test: Use standard calibration weights to calibrate the Edge Crush Tester (ECT machine) for precise measurement. Vertical placement of a single sample can be done between two flat platens on the ECT machine.

- Recording Results: Note down peak force at failure point. It is important that all measurements are taken with accuracy so as to reflect true edge crush strength of the sample.

- Calculation of ECT Value: Divide peak force by sample width in order to calculate edge crush resistance. This gives an ECT value expressed in N/m or lb/in, which depicts material’s capacity for edgeways crush.

- Repeating Tests: Carry out several tests (at least ten) so that data consistency and reliability are guaranteed. Average ECT value from these tests better represents material’s strength.

In this way, one can find out edgewise compressive strength of corrugated materials, thus assuring their suitability for different packaging applications.

Analyzing Test Results

When analyzing test results, it is important to analyze the reliability and consistency of ECT data. For instance, one can start by comparing average ECT values from multiple tests with industry standards or minimum requirements for packaging applications. Also, consider standard deviation of the test results which provides a measure of variability that should be within acceptable limits.

Data analysis must also include investigations into any implications suggested by trends or patterns. In addition, we need to evaluate external factors such as humidity or temperature fluctuations during testing which may have influenced the outcomes.

Finally, compile and interpret them in a comprehensive report containing graphs charts and statistical analysis. This report should provide insights that can be acted upon and suggestions to improve material quality/ alter manufacturing processes so as to increase the edgewise compressive strength of corrugated materials. In this way you will ensure that packaging materials are reliable and effective for their specific purpose through careful analyses of the test results.

Why is Edge Crush Test Important for Corrugated Cardboard Packaging?

The Edge Crush Test (ECT) is an essential test for corrugated cardboard packaging because it measures the ability of the material to stand up to compressive forces applied along its edges. This is particularly important since corrugated boxes are usually piled on one another while in storage or during transit. High ECT values show that boxes can maintain their integrity and protect what they carry when subjected to pressure. Besides, knowing and optimizing ECT allows manufacturers to choose suitable materials and designs so as to ensure durability and minimize product losses resulting from damage. In general, ECT tests assist in ensuring reliability of corrugated packages under real-life conditions.

Impact on Packaging Durability

The Edge Crush Test (ECT), however, has a major impact on the durability of the packaging by directly correlating with how well it would withstand getting crushed. For instance, research on packaging indicates that higher ECT ratings provide more stacking strength required in resisting box collapse during heavy loading applications. These protective functions lead not only to intact boxes, but also safeguarded contents throughout shipping or while still stored before being sold. Furthermore, according to experts on packaging, enhancing ECT using material choices and design modifications leads to efficient utilization of raw inputs hence lowering production costs without compromising performance levels. As such; therefore, ECT is a critical parameter for developing strong and robust corrugated cardboard packaging which minimizes damage risks at every stage in the supply chain process.

Correlation with Stacking Strength

The Edge Crush Test (ECT) is a good measure of stacking strength and is an important indicator of the performance of corrugated board boxes in general. ECT value predicts the maximum load a box can bear before collapsing under stacked condition, as supported by top industry sources. Higher ECT ratings imply stronger materials, which can withstand more weight, allowing the lower-most boxes to support those above without breaking. The relationship between stacking strength and ECT thus necessitates proper selection of material(s) with sufficient ECT values to avoid packaging failure, protect contents and optimize storage space. Thus, it is important to balance efficiently between ECT and stacking strength for cost effective and reliable packaging solutions.

Assessing the Compressive Strength of Corrugated Fiberboard

The compression strength of corrugated fibreboard is also significant when considering how well it will protect its content during distribution or storage; this property can be evaluated using tests such as Box Compression Test (BCT) and Edge Crush Test (ECT). Industry leaders suggest that main things that determine compressive strength are; the type of flute used, grade of paper involved together with adhesive properties.

Flute Type: Different types of flutes in corrugated fiberboards (e.g., A-flute, B-flute) endow them structural rigidity and cushioning having different levels of strength or compactness deemed fit for diverse applications.

Paper Grade: Indeed, the quality of paper utilized for making this kind of cardboard includes kraft or recycled paper has a great impact on overall board’s strength.

Adhesive Quality: Additionally, bonding between sheets should not be overlooked since high-quality adhesives maintain the stability of corrugations even after being subjected to loads in compression process.

In conclusion, evaluating compressive strengths through methods like BCTs and ECTs provides invaluable inputs on performance capabilities guiding design choices towards durability optimized corrugated fiberboards in packaging solutions.

What are Common ECT Ratings and Their Significance?

These tests are used to determine the resistance of corrugated fiberboard against vertical pressure and hence its ability to resist being crushed. These estimates, which reflect upon the maximum weight that a box can withstand in transit or storage, depict ECT values. This results in higher levels of protection for goods through greater ECT rates such as 44 or 55 psi, which are mostly found in heavy packaging. To illustrate, lighter applications would demand lower ECT ratings like 23 or 32 psi; conversely they mean little to heavy applications. Manufacturers and users need to understand these ECT ratings so that they will be able to choose the correct type of corrugated board that matches their specific needs regarding packaging materials thus achieving cost effective product safety outcomes.

Understanding 32 ECT and 44 ECT Ratings

32 ECT and 44 ECT are two of the commonest ratings when evaluating corrugated fiberboard that indicate different levels of durability. A 32 ECT rating is used to mean a board that can withstand up to 32 pounds per inch edge crush resistance, which makes it ideal for lightweight to medium weight packages. It is usually employed in making normal shipping boxes and perfect for items that do not call for heavy-duty protection.

Contrarily, a 44 ECT rating implies an edge crush resistance of 44 pounds per inch, which fits well with heavy-duty packaging needs. This rating is normally used in manufacturing boxes made to carry heavy loads and need strengthened construction like industrial goods, bulk goods or stackable items among others. The right ECT rating has to be selected so as to enhance the package’s stability during transit and storage consequently ensuring effective safeguarding of contents within it.

How ECT Ratings Influence Packaging Choices

Packaging choices are greatly determined by ECT ratings, which specify the level of protective strength needed for diverse shipping and storage situations. Some packaging needs such as heavy or high value items require boxes with higher ECT ratings like 44 ECT. These have excellent stacking strength necessary to avoid box crush while on transit or in storage; thus, they are commonly used for industrial products, bulk shipments, or packages that can be stacked in several layers.

On the contrary, some packaging needs for lightweight objects and less strenuous shipments require lower ECT rated materials like 32 ECT. These boxes offer enough protection for light-to-medium-weight items and are usually used when making ordinary deliveries. They are economical since they provide enough toughness without having to resort to expensive types of corrugated materials.

This enables companies to make informed decisions balancing their need for protection, efficiency and budget in producing more reliable and cost effective packing solutions. Most importantly, these ratings when well understood enable businesses choose correctly among the options available so as not to over- or under-pack resulting in a more efficient use of resources and costs with proper protection of goods during transportation.

Interpreting Test Results and ECT Values

The interpretation of ECT figures and their relationship with the strength and endurance of corrugated packaging materials is very important. It is done by collapsing a part of the edge of the corrugated material until it breaks down. This figure ordinarily appears in terms of pounds per inch (lb/in) and is an indication of how much strength it has when it comes to resisting compression.

To effectively interpret these testing results, you should:

- Identify the ECT Value: Look for the ECT value, usually specified in packaging standards or supplier documentation. This number will be used to determine the strength of a box.

- Understand the Units: The greatest representation for ECT values is lb/in (pounds per inch). High numbers indicate stronger materials that will take more pressure during shipping and storage.

- Relate ECT to Box Strength: Higher ratings on ECT generally mean better stacking strength and durability. For example,

- 32 ECT: Standard shipping for light weight to medium weight items.

- 44 ECT: Heavier products requiring enhanced protection and greater stacking strength.

- Consider the Application: Determine whether or not it matches your application’s needs. In heavy duty applications, high ratings in this area reduce damage risk during transit.

By applying these lessons from ETC test results, enterprises can make informed decisions on proper packing options that adequately safeguard their consignments while minimizing total costs as well as optimizing efficiency across board.

What are the Common Issues Encountered During Edge Crush Testing?

Edge Crush Testing (ECT) can have a number of common problems which may affect the accuracy and reliability of results. These are:

- Improper Sample Preparation: Using wrong sized or badly cut samples can influence test outcomes and thereby, leading to incorrect values for ECT.

- Misalignment of Samples: Perfect alignment of corrugated board while testing is very important; any slight deflection will affect the outcome.

- Equipment Calibration: Use of equipment that has not been calibrated or is not accurate may produce false data making the test invalid.

- Environmental Factors: Variations in humidity as well as temperature can lead to differences in performance and strength thus affecting ECT findings.

- Human Error: Inconsistencies when it comes to application of pressure or timing during the test process could also bring about variability in the results.

These issues should be addressed if dependable ECT values are to be achieved, thus ensuring effective evaluation of packaging materials.

Common Errors in Test Method Implementation

To make sure that the Edge Crush Testing (ECT) is accurate and dependable, it is very significant to evade some common mistakes in implementing this test method:

- Inconsistent Sample Preparation: One of the major mistakes is having samples that are not prepared uniformly. Disparities in terms of sample dimensions, edge quality, or surface characteristics can profoundly affect outcomes hence making it hard to compare results.

- Equipment Calibration and Maintenance: It is important to ensure that testing equipment undergoes regular calibration and maintenance. Employing out-of-calibration equipment or poorly maintained ones can lead to wrong measurements thereby undermining data integrity.

- Operator Training and Technique: Another issue for testing inconsistencies arises from human errors. This may result from poor training or applying incorrect techniques during a test which introduces variations on application of pressure as well as timing thus leading into unreliable conclusions.

By now doing systematic preparation, accurate calibration, and comprehensive training, these error will be minimized thereby ensuring ECT values are more uniform and reliable.

Troubleshooting Incorrect ECT Results

When you come across inaccurate ECT results, it is important to identify and solve the possible issues systematically. Consider the following steps:

- Review Sample Preparation: Make sure that all samples are prepared in a similar way. Make certain that all test sample have same size, edges’ condition and outer appearance.

- Check Equipment Calibration: Ensure that the testing equipment has been calibrated properly. Use certified reference materials to calibrate every instrument in order for the machine to give exact measurements.

- Evaluate Operator Technique: Determine whether the operator has been trained properly or uses standardized methods. Teach explicit pressure applying procedures and timing techniques in testing to eliminate human faults.

- Environmental Conditions: Study environmental factors such as humidity and temperature which might affect results of tests. Always maintain constant testing conditions while carrying out any test.

- Re-validate Methodology: Match up your testing methods with industry benchmarks (like ISO or ASTM). Check whether these standards are observed in all your processes so that accurate and dependable outcomes can be achieved.

Through analyzing these areas one at a time, it is easier to recognize what causes wrong ECT results then shift towards corrective actions aimed at improving accuracy and consistency of tests carried out so far.

Best Practices for Accurate Testing

To ensure accurate test results, there are several best practices that must be implemented:

- Consistent Sample Handling: To prevent introduction of variability, samples should always be handled and prepared in the same way. Before testing, these samples have to be stored properly and carefully.

- Regular Calibration: Based on the manufacturer’s instructions, you should routinely adjust and maintain your testing equipment. The use of certified reference materials helps to check the accuracy of equipment as well as its consistency in performance.

- Standard Operating Procedures (SOPs): Detailed SOPs that describe how tests are undertaken with regard to sample preparation, equipment setup and test conditions must be formulated and followed. It is important to regularly review SOPs in line with changes in industry standards.

- Training and Competency: All personnel involved in testing process should undergo thorough training. This is important for operators to ensure they are conversant with SOPs as well as correct techniques application on a consistent basis.

- Environmental Control: Conduct all tests under controlled environments whereby temperature, humidity etc. are monitored and maintained within specified ranges. This ensures that environmental factors do not interfere with the outcome of tests.

- Documentation and Record Keeping: Records which show sample preparations details, equipment calibration or environmental conditions shall be maintained accurately at all times. Proper documentation can help track trends or identify potential issues.

By adhering to such best practices you will boost the accuracy along with faithfulness of your test outcomes leading to better quality control and product performance improvements.

Frequently Asked Questions (FAQs)

Q: What is the Edge Crush Test (ECT) for corrugated boxes?

A: The Edge Crush Test (ECT) is a measure of the edgewise compressive strength of corrugated board. This test determines how much peak load a box can withstand before the edges buckle under pressure. The results are typically reported as an ECT value, measured in pounds per lineal inch of load bearing edge.

Q: How does the Edge Crush Test differ from the Mullen Test?

A: The Mullen Test measures the burst strength of corrugated board by determining how much pressure is required to puncture the face of corrugated material. In contrast, the ECT measures the edge compressive strength perpendicular to the direction of the flutes, which is crucial for understanding a box’s stacking strength.

Q: Why do box manufacturers use the ECT?

A: Box manufacturers use the ECT to ensure that their cartons have sufficient compression strength for stacking during storage and transportation. This helps in predicting how much weight a box can handle when multiple boxes are stacked on top of one another.

Q: What equipment is used for the Edge Crush Test?

A: The ECT is conducted using an ECT tester, which applies pressure to a sample of corrugated board until it crushes. This sample is typically a small segment of the board, placed perpendicular to the direction of the flutes.

Q: What is the significance of the ECT value?

A: The ECT value is significant as it quantifies the strength of the carton. A higher ECT value indicates a stronger carton capable of withstanding greater compressive forces. This measurement helps in determining the suitability of boxes for various applications.

Q: How are ECT values reported and what do they mean?

A: ECT values are reported in pounds per lineal inch (lb/in) of load bearing edge. For example, an ECT value of 32 lb/in indicates that the edge of the corrugated board can withstand a compression strength of 32 pounds per inch before failing.

Q: Can the ECT be used for different types of corrugated board?

A: Yes, the ECT can be used for single-wall, double-wall, and triple-wall corrugated boards. It provides a consistent method for evaluating the compression strength across various types of corrugated materials.

Q: Are there international standards for ECT?

A: Yes, international standards such as ISO 3037 specify the method for conducting the Edge Crush Test. This ensures consistency and accuracy in the results across different laboratories and for various corrugated testing purposes.

Q: Where can I find more information or get in touch for specific queries about ECT?

A: For more detailed information or specific queries about the Edge Crush Test, you can always contact us. Your queries will be addressed by experts who can provide detailed explanations and recommendations tailored to your needs.