What is a Durometer and How Does it Work?

Image source: https://sybridge.com/

Understanding the Function of a Durometer

How Durometers Measure the Hardness of Materials

Durometer Calibration and Maintenance

To ensure Precisely reliable measurements, it is important to calibrate and maintain a durometer. To Calibrate a durometer, it needs the use of certified reference materials with known hardness values that cover the range of the durometer scale being used. Ideally, there must be regular calibration checks before each measurement session begins.. These involve placing the durometer on a calibration block and observing its reading; any deviation from the known value indicates that some adjustments are needed.

Maintenance also entails keeping instruments clean and free from dust or debris. It is vital to regularly assess for signs of wear and tear on the indenter because damage to this part will cause false readings. Additionally, intermittent checks should be made on loss of tension in the spring mechanism. Utilizing lubricants on moving parts and storing in protective cases whenever idle can increase service life. Hence, these practices make the durometer remain as an accurate and dependable tool for testing material hardnesses.

Exploring Different Durometer Scales

The Shore A Scale Explained

Comparing Shore A and Shore D Hardness

Why Use Different Shore Hardness Scales?

How to Measure Material Hardness with a Durometer

To measure the hardness of a material using a durometer, you need to:

- Select the Appropriate Durometer: Choose the appropriate type of durometer depending on the kind of material being tested. For example, use D shore durometers for harder materials while softer ones should be measured by A shore durometers.

- Prepare the Sample: Ensure that the sample material has a smooth and even surface with a thickness that is enough to avoid substrate effects typically above 6 mm.

- Place the Durometer: Stand with the instrument perpendicular to the test surface.

- Apply the Force: Press it down so that indenter touches completely on top of specimen and base of instrument rests stable on its platform.

- Read the Measurement: AAfter a specified dwell time (usually around 1 second), check out hardness reading displayed in digital format on durometer scale.

Following these steps will yield accurate and consistent measurements which are necessary for proper evaluation of material properties.

Steps to Measure the Hardness of Rubber and Plastics

The following are some steps one can use to measure rubber and plastics hardness:

- Select the Correct Durometer: Determine if you have Shore A rubbers or plastics (for softer materials) or Shore D durometers (for harder materials).

- Prepare the Sample Properly: The sample should have a flat and smooth surface with sufficient thickness normally at least 6mm to avoid any structural effects caused by substrate.

- Place the Durometer Firmly: Position your durometer orthogonally to the sample’s face.

- Apply Consistent Force: Push it down such that indenter fully contacts material ensuring base is stable on surface.

- Read and Record the Measurement: Read off hardness value from scale after dwelling about one second.

Interpreting Durometer Readings: What Do They Mean?

Troubleshooting Durometer Readings

When troubleshooting durometer readings, it is essential to consider several factors that may possibly affect accuracy:

- Sample Preparation: Ensure the sample is flat, smooth and uniform with a consistent thickness of at least 6 mm. Inconsistent readings could be caused by uneven surfaces or thin samples.

- Proper Usage of Durometer: Make sure that the durometer is standing vertically and the force applied in measurement is always the same. Unevenly done force application or tilting of this gadget can skew final figures.

- Instrument Calibration: The durometer needs regular calibration to guarantee accuracy. After some time, durometers lose their calibration settings hence giving false readings.

- Environmental Conditions: Temperature and humidity are both factors which affect hardness of a material. Conduct them under controlled conditions so as to obtain constant results.

- Operator Technique: Variations in operator technique such as speed of application or duration of pressure can result into disparities. To avoid inconsistencies among operators, all procedures must be standardized.

Applications of Durometer Hardness Testing

Industrial Uses of Durometer Testing

Durometers in Quality Control

Testing O-Rings and Other Elastomer Products

Shore Durometer Comparisons: What You Need to Know

When it comes to comparing Shore durometers, it is important to appreciate the various Shore scales particular the likes of Shore A and D. Shore A is commonly used for less hard materials such as elastomers and rubbers whereas shore D is usually applied in harder thermoplastics and rigid polymers. This depends on the planned use of material as well as its performance needs. Proper comparison between different scales allows manufacturers to choose appropriate hardness that will help in maximizing the performance efficiency, durability, and other specifications of a given material. The interpretation of these readings has to be done properly for them to be useful in maintaining product quality according to manufacturing norms.

Comparative Analysis of Shore A and Shore D

Analyzing shore A and shore D durometers comparatively necessitates an understanding that each scale caters for specific levels of materials’ hardness. On this note, softer materials such as elastomers, rubber and flexible plastics are primarily measured by Shore A. It sets ranges from 0 to 100 with higher values which indicate greater hardness as seen from indentation tests results on products that measure hardness using the same units of measurement found on products ranging from 0 to 100 since it ranges from about 0 or less than… Conversely, one would find that harder applications such as thermoplastics, rigid polymers and harder rubbers will employ a different test called shore D which also measures indentation hardness following a range going up-to 100 too.

Selecting the right Shore scale for your application ensures optimal material performance and durability. For example, items that fall under the shin gaskets category might be made up of substances measurable by Shore A test analyzing how flexible they become when weightless items are applied against them. In contrast, other consumer goods like certain industrial components required high ratings from shore D tests due their need for rigidity or structural integrity respectively (Kaminsky et al., 2008). These numbers have to be correctly interpreted; hence precise testing needs to accompany any material evaluation or specification.

Understanding Harder and Softer Materials

Using Shore Hardness Scale for Different Materials

Choosing the appropriate Shore hardness scale based on the intended application of material is critical when employing the shore hardness scale for different materials. For instance; Soft and flexible elastomers and rubbers are usually subjected to Shore A scales. Hardness in this case refers to indentation hardness, which is beneficial in various applications that require flexibility, cushioning, impact absorption etc. including seals, gaskets, and flexible connectors.

On the other hand, hard plastics and some polymers can be evaluated by means of the Shore D scale. These substances need higher mechanical strength, durability together with resistance to deformation that make them suitable for industrial components as well as many consumer goods where they are required for structural integrity.

Manufacturers can optimize performance and extend product lifespans by accurately measuring and interpreting shore hardness values so that selected materials meet specific application requirements.

Reference sources

-

Industrial Specialties Manufacturing (ISM) – What is Durometer?

- This source provides a comprehensive overview of the durometer, explaining what it is, how it functions, and its application in measuring the hardness of elastomers and plastics. It also discusses the various durometer scales used in the industry.

- Source: Industrial Specialties Manufacturing

-

Fictiv – Understanding Durometer: Rubber and Plastic Hardness

- Fictiv offers an in-depth explanation of durometer measurements for softer materials like plastics and rubbers. It covers the principles behind durometer usage, different hardness scales, and their importance in material selection and quality control.

- Source: Fictiv

-

Hapco, Inc. – Guide to Shore Hardness

- Hapco, Inc. provides a detailed guide on Shore hardness, including how durometers measure the hardness of plastics and elastomers using standardized methods. The guide highlights the significance of understanding Shore hardness for various industrial applications.

- Source: Hapco, Inc.

Frequently Asked Questions (FAQs)

Q: What is a durometer?

A: A durometer is a standardized instrument used to measure the hardness of materials like rubber, plastics, and elastomers. The unit of measurement is dimensionless and helps in comparing the hardness of different materials.

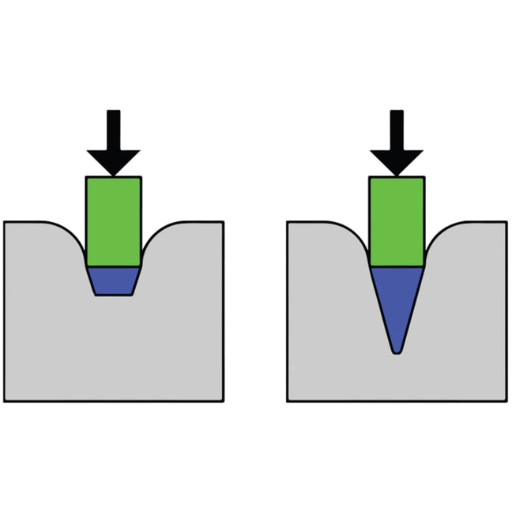

Q: How does a durometer tester work?

A: A durometer tester works by pressing an indenter into the material being tested. The depth of the indentation helps in measuring the hardness, typically shown in durometer numbers or shore hardness scales such as Shore A.

Q: Who invented the durometer?

A: The durometer was invented by Albert Ferdinand Shore in the 1920s. It has since become a standardized way to measure the hardness of materials.

Q: What does a Shore A hardness measurement indicate?

A: Shore A hardness measurement indicates the hardness of softer materials such as rubber and elastomers. The scale ranges from 0 to 100, with higher numbers indicating harder materials. For example, a material with a Shore A hardness of 70A is relatively hard.

Q: Is durometer hardness measurement dimensionless?

A: Yes, the durometer is a dimensionless measurement. This means it does not have any physical dimension like length or mass, making it easier to compare the hardness of different materials using the same durometer scale.

Q: How do I choose the correct durometer type for testing?

A: Choosing the correct durometer type depends on the material you are testing. For softer materials like rubber, a Shore A durometer is typically used. For harder materials, a Shore D or Rockwell hardness tester may be more appropriate.

Q: Can a durometer tester be used to measure the hardness of all materials?

A: While a durometer tester is designed to measure the hardness of various materials, it is most effective for rubber, plastics, and elastomers. Materials outside this range may require different types of hardness tests such as Rockwell hardness testing.

Q: What is the significance of durometer numbers?

A: Durometer numbers provide a standardized way to express the hardness of materials. These numbers help in comparing the hardness levels accurately when the same durometer scale is used.

Q: How does durometer hardness compare to other measures like Rockwell hardness?

A: Durometer hardness measures the indentation hardness of softer materials and is dimensionless. Rockwell hardness, on the other hand, is often used for harder materials and uses a different unit of measurement. Each measures hardness in a different context but can sometimes be cross-referenced for similar materials.

Q: Why is durometer hardness important for abrasion resistance?

A: The hardness of a material, as measured by a durometer tester, can indicate its resistance to abrasion. Typically, harder materials tend to have better abrasion resistance, providing better durability in applications where wear and tear are factors.