Metal 3D printing is an innovative technology that has caused a revolution in many sectors, such as aerospace, automotive, and healthcare. One of the most common methods is direct metal laser sintering (DMLS), used to make highly complex and precise metal objects. In this technique, a high-powered laser selectively scans a powder bed to fuse individual particles, forming one layer of the object before lowering the platform to apply another layer of powder to repeat the process. It uses powerful lasers to melt metallic powders layer by layer, thus producing solid but light structures that are usually impossible through other conventional methods. This blog post will discuss what DMLS means, its benefits, and its uses, among others, in the modern-day manufacturing sector. Whether you are a veteran engineer or just interested in discovering what can be achieved with 3D printing technology, this discussion will give you a general review of DMLS concerning future manufacturing developments.

What is Direct Metal Laser Sintering (DMLS)?

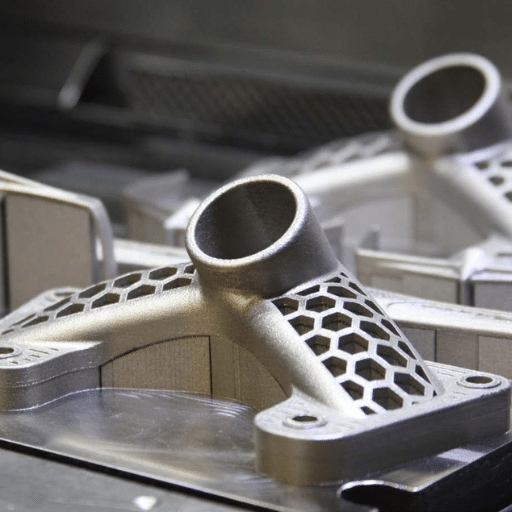

Image source: https://www.protolabs.com/

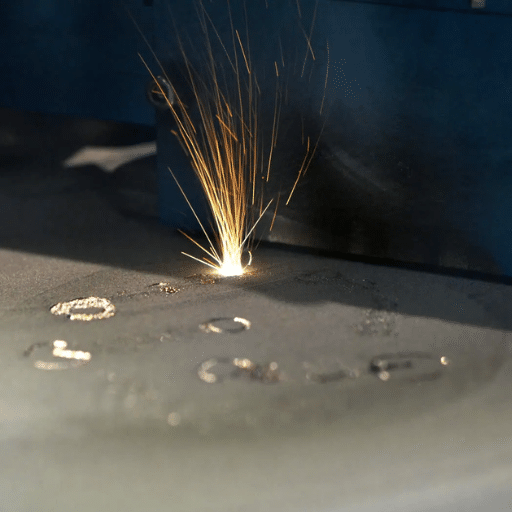

Direct metal laser sintering (DMLS) is an advanced form of 3D additive manufacturing technique that utilizes a laser beam to melt/fuse powdered metal particles together to create solid components. At least five hundred W/cm^2 power density is necessary during DMLS for forming a molten pool and subsequent melting of metal powder into pores. The first step involves spreading a thin layer of metal powder over the build platform. A powerful beam scans across each cross-section, fusing specific areas according to the digitally designed design. After every scan, the elevator lowers by one thickness, after which the application of a new layer of powdered material goes on until the complete object is developed through repetitive scanning action. The realization that traditional machining cannot compete with additive manufacturing techniques like DMLS when it comes to creating complex designs and shapes that enhance performance while reducing wastage was vital.

How does the DMLS process work?

The Direct Metal Laser Sintering (DMLS) process starts when a three-dimensional model is created using computer-aided design (CAD) software. This digital model is then divided into thin layers that serve as the blueprint for the print process. A thin layer of metal powder is spread over the build platform, and a high-powered laser selectively melts the powder according to the cross-section of the sliced model. After fusing each layer, the platform lowers, bringing a brand-new layer of metal powder to be coated on top. The entire part will be formed through this layering action. Post-processing may involve heat treatments and surface finishes that improve mechanical properties and surface finish quality of end products.

What materials are used in DMLS 3D printing?

In DMLS 3D printing, we can use different types of performance metals to create strong and durable parts. Commonly used materials are stainless steel, titanium alloys, cobalt chrome, and nickel-based superalloys. These materials possess unique qualities such as corrosion resistance, high strength-weight ratios, and the ability to withstand high-temperature environments, making them ideal for aerospace applications, automotive uses, and other medical equipment manufacturing industries. The product’s Mechanical specifications and environmental conditions must be considered when choosing a suitable material for a specific job.

What are the advantages of DMLS technology?

DMLS technology is popular due to its several advantages across various sectors. Firstly, it makes the production of highly complex geometries possible, which could not be achieved with traditional manufacturing methods. This flexibility allows for greater design freedom and the possibility of creating strong, lightweight structures. Secondly, DMLS reduces material wastage significantly by using only the powder required to make parts, hence becoming more responsible for production. Lastly, DMLS is highly effective in producing smaller to medium quantities within short delivery times, thereby making it ideal for rapid prototyping as well as customized manufacturing, especially in industries that have stringent requirements for accuracy and precision.

How does DMLS compare to other metal 3D printing techniques?

DMLS, or Direct Metal Laser Sintering, is unlike other metal 3D printing techniques mainly because of its process and applications. Compared with Selective Laser Melting (SLM), where the powder is completely melted into metal, DMLS involves fusing together powders without complete melting, meaning more materials can be used, and lesser residual stresses are observed. On the other hand, Binder Jetting replaces heat with a bonding agent, resulting in better part density and mechanical properties than DMLS but at a higher price point coupled with more extended pre-production periods because of the multi-step procedure involved. Moreover, even though Metal Extrusion is similar to FDM, metals now have material restrictions and poor quality concerns compared to DMLS, which is highly precise and thus suitable for OK detail jobs. The main strength of DMLS is its ability to create complex solid parts with excellent material properties, making it an ideal choice for high-performance applications.

What is selective laser melting?

An advanced method for 3D printing called Selective Laser Melting (SLM) uses a high-power laser to melt and fuse metal particles together. In the process of SLM, a thin layer of metal powder is evenly distributed on top of a building platform, and then the laser selectively scans and melts the powder as per the 3D model. After this, the platform descends a little, and another layer of powder is added; this cycle continues until the entire part is built up. This technique is handy in making highly dense components with excellent mechanical properties; hence, it can be found in aerospace, automotive, and medical implants, where accuracy and material performance are critical. Equally important to note is that SLM has a wide range of metals it works with, which include titanium, aluminum, and nickel-based superalloys, thus making it more versatile in different fields.

How does DMLS differ from traditional metal sintering?

The Direct Metal Laser Sintering (DMLS) technology differs from traditional sintering methods mainly due to its technique and capabilities. Instead of heating metal powders below their melting points to bind particles together as done traditionally during the sintering process, DMLS completely melts the metallic powder by using a high-powered laser, enabling fully dense parts to have superior mechanical properties. Furthermore, DMLS allows more freedom to create complicated shapes and intricate designs that are difficult or impossible for other techniques, such as conventional machining. Unlike traditional sintering, which results in porous elements leading to low-reliability levels, DMLS forms almost 100% dense components, meaning they have increased strength over those made using other methods under harsh application conditions.

What are the limitations of DMLS compared to other methods?

However, DMLS also has some limitations. One such limitation is the high cost of equipment and materials, making it less accessible to small-scale or budget-conscious projects. Moreover, the complexity of this process requires skilled operators, making consistency and quality control more challenging. DMLS has relatively slower production speeds compared to some traditional manufacturing methods. In particular, large volumes are required. Other than this, there is a constraint regarding the range of materials: DMLS can process a wide range of metals but not as much as other techniques like powder metallurgy. Finally, residual stresses produced during laser melting can lead to distortion or dimensional inaccuracies in finished parts, necessitating post-processing operations, which increase time and costs.

What are the applications of DMLS in manufacturing?

DMLS is used widely in various industries because it allows for intricate geometries and unique customizations. For example, lightweight is essential in the aerospace industry due to fuel efficiency and performance; thus, complex brackets are made using DMLS housing components, among others, turbine blades being an example of highly detailed products manufactured. Besides, the medical sector applies DMLS technology when designing bespoke implants and prostheses, improving implant performance and comfort. On the other hand, automobile manufacturers use DMLS for rapid prototyping and lightweight component building that enhances overall vehicle performance. In addition, the tools and tooling industry utilizes DMLS by creating custom tooling aids such as jigs and fixtures, among other items used in precision manufacturing processes. All in all, modern manufacturing is heavily supported by DMLS, hence enabling tailor-made solutions across applications with different quality requirements.

How is DMLS used to produce metal prototypes?

A technology referred to as DMLS, direct metal laser sintering is an essential means of producing metal prototypes by translating 3D CAD models into physical components. The process starts by creating thin layers of metallic powder over a build platform. A powerful laser selectively fuses the powder according to the design specifications, layer by layer, allowing for the production of complex geometries that are often impossible with traditional manufacturing methods. This tool enables rapid prototyping whereby designs can be iterated faster and cheaper than conventional techniques. Moreover, DMLS enables designers to test their ideas in metal before moving on to full-scale production, reducing the time to market for new products.

What industries benefit from DMLS technology?

There are a few industries that benefit significantly from DMLS technology. The aerospace industry primarily uses DMLS to build lightweight and intricate parts that increase fuel efficiency and performance. Similarly, the medical field depends on DMLS when making custom implants and prosthetics with better fit and operation ability for patients. Furthermore, this technology is used in automobile manufacturing for fast-tracking design processes and high-performance part productions through rapid prototyping. It does not matter what industry one belongs to or what one manufactures because its versatility makes it worthwhile across such sectors, thereby fueling innovation while ensuring efficiency during production.

How does DMLS support additive manufacturing?

The Direct Metal Laser Sintering (DMLS) technique is a critical additive manufacturing player with several significant advantages. To start with, DMLS allows for the production of parts with an intricate design and geometric complexity that cannot be achieved using traditional production methods. This leads to greater freedom in design and more innovation in general. Secondly, DMLS supports material efficiency by reducing waste by using only the powder quantity required per build. Thirdly, this technology promotes rapid iteration of designs for faster prototyping and concept validation, vital in fast-moving industries like aerospace or medical devices. Lastly, DMLS can produce parts with tailored material properties that can optimize performance based on specific applications, thereby improving total quality and functionality.

What are the critical factors to consider when using DMLS?

Several critical factors must be considered when using Direct Metal Laser Sintering (DMLS) to ensure successful outcomes. First, the choice of materials is highly significant; selecting the suitable metal powder influences its mechanical properties and suitability for application intents. Second, the complexities that DMLS can handle should be considered when designing support structures and part orientation for optimal strength and surface finish. Thirdly, machine parameters, including laser power scanning speed and layer thickness, require careful calibration to achieve the desired results. Additionally post, processing requirements such as heat treatment or surface finishing should be planned to enhance product performances. Lastly, building environment controls such as temperature and humidity are necessary to minimize defects and maintain consistency throughout manufacture process.

What are the common challenges in DMLS 3D printing?

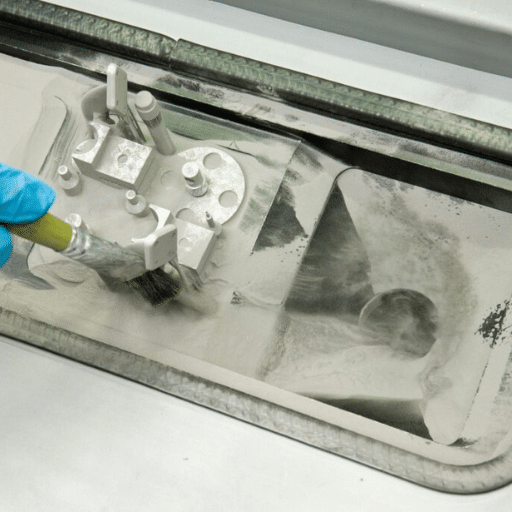

Principally, thermal stresses linked to warping or cracking during printing are common challenges in DMLS. Another challenge is powder handling since metal powders are hazardous and call for appropriate management to prevent contamination. Poor surface finish quality is also a significant problem because most parts require a lot of post-processing to achieve the required tolerances. Also, layer adhesion and defect minimization are essential considerations because poor bonding between layers can affect the structural integrity of the final product. Lastly, the high cost of machine operation and materials impedes many users; hence, economic viability assessments should be made before opting for DMLS that consider specific applications.

How do we ensure the quality of DMLS printed parts?

To ensure high quality in printed parts using DMLS, I concentrate on several vital practices. First, carefully selecting high-grade metal powders is crucial as their purity and size distribution equally determine the properties of the end part. Additionally, I pay attention to scanning speed parameters used by my machines; laser power calibration and setting optimal layer thicknesses are fundamental aspects, too. Routine maintenance plus regular calibration ensure that common defects associated with wear and tear do not occur in DMLS machinery. Furthermore, thorough post-processing, such as heat treatment or surface finishing, is always carried out to improve performance and ensure that the part maintains its surface integrity well over time. Finally, strict control is maintained over the making environment so that temperature and humidity remain constant throughout each print job, thereby reducing any flaws in these objects produced through AM processes. By carrying out these procedures, I can significantly enhance the quality while at the same time increasing the reliability of my DMLS components produced hereafter.

What are the best practices for preparing CAD files for DMLS?

Preparing CAD files for Direct Metal Laser Sintering (DMLS) is imperative to ensure successful prints. Below are some of the best practices recommended majorly:

- Design for Additive Manufacturing (DfAM): Recognize the unique capabilities of DMLS as a 3D printing technology, which includes manufacturing complex geometries and lightweight structures. Use lattice designs and avoid too many overhangs, which would require support structures.

- Optimizing File Format: Export your design files in widely accepted formats such as STL or OBJ, ensuring that the mesh is watertight and error-free. The file resolution must be checked to maintain sufficient detail for the intended design.

- Correct Scaling and Orientation: Make sure you scale your model properly, taking into account how it will be oriented during printing. These factors influence layer adhesion and mechanical properties. Trying out different orientations can reduce the need for support while improving the strength of the printed part.

By incorporating all these, you can significantly improve the quality and performance of direct metal laser sintering components.

How do you start your metal 3D printing journey with DMLS?

Beginning with starting points like Direct Metal Laser Sintering (DMLS) entails various critical steps to have a good experience. Firstly, familiarize yourself with the fundamental principles of DMLS and common types of metals used, like titanium and stainless steel. It is also crucial to purchase a reliable DMLS printer that suits your requirements, including build size, resolution, speed, etc. Equally importantly, however, one should acquire skills in CAD software for designing parts specifically intended to be utilized in an Additive Manufacturing context. This could begin with simple designs, intending to grow your design abilities to more intricate forms/sketches. Finally, engage in forums, attend workshops, and utilize online resources provided by the 3D printing community to share knowledge and keep yourself updated regarding industry trends, including what’s going on in this field lately. These steps will establish a strong beginning for your journey in 3D metal printing.

What equipment is necessary for DMLS?

To get better results in Direct Metal Laser Sintering (DMLS), some equipment that is crucial for this purpose includes:

- DMLS Printer: The main technology, a DMLS printer, uses a high-energy laser to sinter metal powder layer after layer. Notable brands include EOS, 3D Systems, and SLM Solutions, which vary in terms of size, speed, and build properties, among other things.

- Metal Powder: It is important to ensure that quality metal powder is sourced since it has a direct effect on the performance of the printed parts. Some common materials include titanium, stainless steel, aluminum, and cobalt-chrome alloys, with specifications that suit your printing requirements.

- Post-Processing Equipment: Most parts need post-processing to ensure the best performance after printing. For instance, stress-relieving ovens for heat treatment of the parts may be required, as well as CNC machines for acceptable finishing purposes or shot peening equipment to improve surface characteristics.

These elements create a streamlined workflow for manufacturing high-quality metal components through DMLS.

Where to find DMLS 3D printing services?

To find DMLS/3D printing services, I usually start by looking at the industry’s leading platforms, such as 3D Hubs, Shapeways, or Xometry. These sites offer a variety of services and also help me compare prices on different materials and turnaround times. Instant quotes can be made by submitting my designs directly while choosing from several experienced service providers. Also, local machine tools shops can provide such services. However, they are not commonly known, except those who use them mostly rely on online directories or networks around the 3d printing community.

Frequently Asked Questions (FAQs)

Q: What is direct metal 3D printing?

A: Direct metal 3D printing refers to the additive manufacturing process where metal parts are created layer by layer using a high-power laser to fuse metal powder, specifically in techniques like direct metal laser sintering (DMLS).

Q: How does direct metal laser sintering (DMLS) work?

A: DMLS uses a laser beam to selectively melt and fuse metal powder particles together according to a digital 3D model. This process allows for the production of complex geometries and high-quality metal parts.

Q: What types of metal powder are used in DMLS?

A: Various metal powders can be used in DMLS, including titanium alloys, stainless steels, aluminum alloys, and cobalt chrome. The choice of metal powder affects the properties of the final printed parts.

Q: What are the advantages of using DMLS to manufacture metal parts?

A: The advantages of DMLS include the ability to create parts with complex geometries, reduced material waste, the production of lightweight structures, and the capability to manufacture functional metal components quickly.

Q: Can DMLS be used for both prototypes and production parts?

A: Yes, DMLS is suitable for both metal prototypes and production parts. Its flexibility and efficiency make it ideal for rapid prototyping and creating end-use functional metal components.

Q: What are some typical direct metal laser sintering 3D printing applications?

A: DMLS is widely used in industries such as aerospace, automotive, medical, and tooling, where it is essential to produce high-quality metal parts that meet strict tolerances and performance requirements.

Q: What factors affect the quality of metal printed parts in DMLS?

A: Factors affecting the quality of metal-printed parts include the type of metal powder used, the settings of the 3D printer, the design of the part, and the parameters of the metal 3D printing process, such as layer thickness and laser power.

Q: How does the DMLS process compare to selective laser sintering?

A: While DMLS and selective laser sintering utilize a laser to fuse powder materials, DMLS focuses explicitly on metals, whereas selective laser sintering typically involves polymers. DMLS offers higher density and strength in the final metal parts.

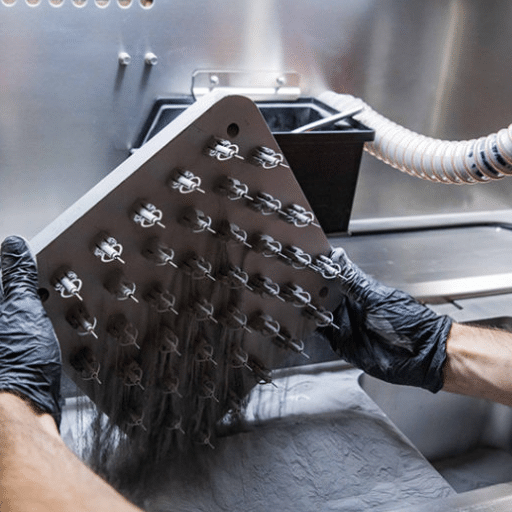

Q: What are the post-processing steps involved in DMLS?

A: Post-processing steps for DMLS may include removing support structures, heat treatment to relieve stress, surface finishing for improved aesthetics, and additional machining to achieve precise dimensions for the metal printed part.