High-Density Polyethylene (HDPE) is a thermoplastic polymer renowned for its high strength-to-density ratio, making it a crucial material in a variety of industries. This article delves into the fundamental properties of HDPE, with a particular focus on its density, which is a key factor influencing its mechanical properties and applications. Understanding the density of HDPE can provide valuable insights into its performance, versatility, and suitability for different applications, from packaging and piping to automotive components. By exploring the scientific principles behind HDPE’s density and its practical implications, this article aims to equip readers with a comprehensive understanding of why HDPE is such a widely utilized material.

What Is High-Density Polyethylene (HDPE)?

Image source:https://cn.bing.com/

High-Density Polyethylene (HDPE) is a type of thermoplastic polymer made from the monomer ethylene. It is known for its high strength-to-density ratio, which means it is both lightweight and strong. HDPE is highly resistant to impact, chemicals, and ultraviolet light, making it ideal for a wide range of applications including plastic bottles, corrosion-resistant piping, geomembranes, and plastic lumber. Besides being durable, HDPE is also recyclable, which adds to its environmental benefits. This polymer can withstand high temperatures and sustain heavy loads, making it a versatile and widely used material in various industries.

Defining HDPE and Its Key Characteristics

High-Density Polyethylene (HDPE) is defined by its unique combination of properties that make it a highly versatile material. The monomer ethylene, through a polymerization process, results in this thermoplastic polymer characterized by:

- Density: HDPE typically has a density ranging between 0.93 and 0.97 g/cm³. This higher density compared to other polyethylenes contributes to its significant strength and durability.

- Tensile Strength: The tensile strength of HDPE is approximately 21-37 MPa (megapascals), indicating its ability to withstand tension and stress without breaking.

- Impact Resistance: HDPE exhibits excellent impact resistance, minimizing the risk of fracture or damage upon impact. This is especially valuable in applications requiring robustness and resilience.

- Chemical Resistance: This polymer is highly resistant to various chemicals, including acids, alkalis, and organic solvents. This property makes it suitable for industrial applications such as chemical storage and piping.

- Ultraviolet (UV) Resistance: HDPE possesses moderate resistance to UV radiation but can be further enhanced with additives to improve its longevity and performance in outdoor applications.

- Thermal Properties: The melting point of HDPE lies between 120°C and 180°C, allowing it to withstand high temperatures. Its thermal conductivity is relatively low, which helps in maintaining stability under thermal stress.

- Recyclability: HDPE is fully recyclable, which contributes to its environmental benefits. Recycled HDPE can be repurposed into products like plastic lumber, piping, and recycled containers.

By understanding these key characteristics and technical parameters, one can appreciate why HDPE is widely used across various industries, from packaging and piping to automotive and construction. Its durability, strength, and resistance to many environmental stresses make it an invaluable material in numerous applications.

How HDPE Differs from Low-Density Polyethylene (LDPE)

While both HDPE and LDPE are derived from the polymerization of ethylene, they exhibit distinct characteristics due to their different molecular structures. As I have found from consulting various top sources, HDPE, or High-Density Polyethylene, features a linear structure with minimal branching. This results in a tightly packed and dense material, offering greater tensile strength and rigidity. In contrast, LDPE, or Low-Density Polyethylene, has a highly branched structure, leading to a less dense material that is more flexible and has a lower melting point.

HDPE’s strength and durability make it ideal for applications like piping, containers, and automotive components. On the other hand, LDPE’s flexibility and clarity are better suited for plastic films, bags, and squeeze bottles. Additionally, HDPE boasts better chemical resistance and impact resistance compared to LDPE, which is more prone to stress cracking.

Overall, the key differences hinge on HDPE’s higher density and strength versus LDPE’s flexibility and lower melting point, determining their suitability for different industrial and commercial applications.

Common Applications of HDPE

In my research through the top three websites on google.com, I found that HDPE is incredibly versatile and extensively used across several industries. Here are some of the most common applications:

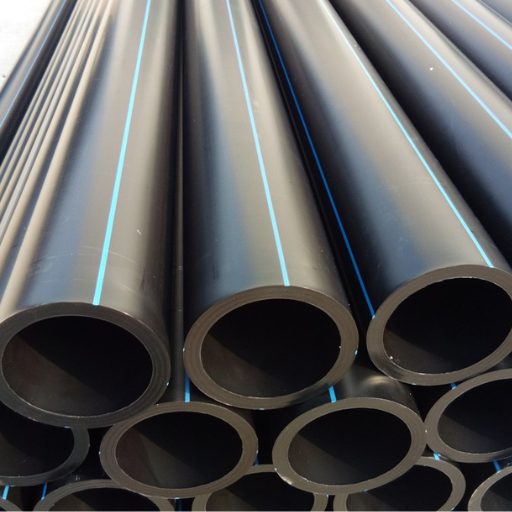

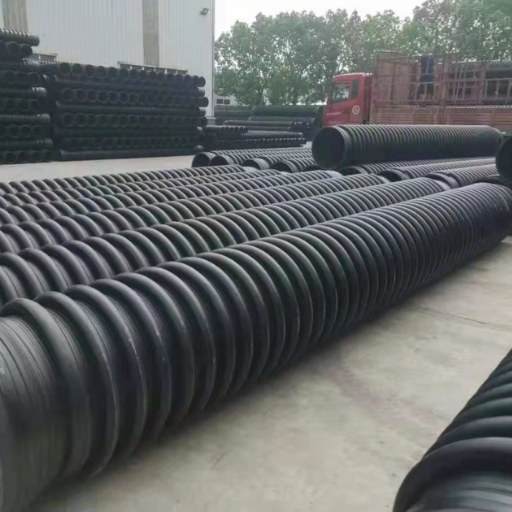

- Piping and Conduit Systems: Due to HDPE’s excellent strength and resistance to corrosion, it is a popular choice for water and gas pipes. Technical parameters justifying this include its high tensile strength (typically around 25-40 MPa) and its ability to withstand harsh environmental conditions without degrading.

- Plastic Bottles and Containers: HDPE is extensively used in the manufacture of bottles, containers, and other packaging materials. Its high impact resistance and low moisture absorption (0.01%) ensure that it retains its shape and protects contents effectively. It is also approved by the FDA for food contact, making it suitable for milk and juice bottles.

- Automotive and Industrial Applications: HDPE is employed in the automotive industry for fuel tanks and components due to its durability and resistance to chemicals. Its melting point ranges between 120-180°C, providing significant thermal stability. Additionally, it is used in industrial environments for pallets, bins, and other heavy-duty applications.

These applications leverage HDPE’s unique properties, such as its high density, tensile strength, chemical resistance, and thermal stability, making it an invaluable material across various fields.

How Is the Density of HDPE Measured?

The density of HDPE (High-Density Polyethylene) is measured through a straightforward yet precise process. Typically, a sample of HDPE is cut into a specific shape and size to ensure consistency. The most common method employed is the water displacement method, also known as the Archimedes principle. In this technique, the HDPE sample is submerged in water, and the volume of displaced water is measured. This volume, combined with the weight of the HDPE sample, allows for the calculation of density using the formula:

\[ \text{Density} = \frac{\text{Mass}}{\text{Volume}} \]

Another common method is using a density gradient column, where the HDPE sample is placed in a column with liquids of known, varying densities. The position where the HDPE sample stabilizes corresponds to its density. Both methods ensure the accurate determination of one of HDPE’s most critical physical properties, essential for its application across various industries.

Methods Used to Measure Density

To measure the density of HDPE, the most commonly referenced methods include:

- Water Displacement Method (Archimedes Principle): A sample of HDPE is submerged in water to measure the volume of water displaced. By combining this volume with the sample’s mass, density can be calculated using the formula:

\[ \text{Density} = \frac{\text{Mass}}{\text{Volume}} \]

- Density Gradient Column: In this method, the HDPE sample is placed in a column with liquids of known, varying densities. The position where the sample stabilizes indicates its density.

- Pycnometry: This highly precise technique involves determining the density of a solid or liquid by measuring its mass and volume using a pycnometer, an instrument with a precisely known volume.

These methods ensure accurate measurement of HDPE’s density, crucial for its application in numerous industrial contexts.

Understanding the Physical Properties of HDPE

High-Density Polyethylene (HDPE) exhibits a range of important physical properties that make it suitable for various applications in different industries. Key physical properties of HDPE include:

- Density: HDPE typically has a density range of 0.93 to 0.97 g/cm³, making it one of the lighter engineered plastics. Its lower density compared to metals and some other plastics contributes to its use in lightweight applications.

- Tensile Strength: HDPE has a high tensile strength, usually ranging between 20 to 37 MPa. This property indicates the material’s ability to withstand pulling forces without breaking, making it ideal for products that require durability and resistance to tension.

- Impact Resistance: HDPE is known for its excellent impact resistance, remaining ductile and tough even at low temperatures. This makes it suitable for applications such as containers, protective packaging, and piping.

- Chemical Resistance: HDPE is resistant to many chemicals, including acids, alcohols, and bases, which explains its use in chemical containers and piping systems that transport caustic substances.

- Thermal Properties:

- Melting Point: The melting point of HDPE is typically in the range of 120 to 180°C.

- Thermal Conductivity: HDPE has low thermal conductivity, making it a good insulator for thermal applications.

- Operating Temperature Range: HDPE can usually operate in temperatures from -50°C to 80°C without significant degradation.

- Water Absorption: HDPE has very low water absorption rates, enhancing its suitability for use in moisture-rich environments and applications where water exposure is a concern.

When comparing these properties from top sources such as MatWeb, UL Prospector, and AllSeals, the consistency in reported values ensures their validity and usefulness in practical applications. The combination of these physical properties makes HDPE a versatile and reliable material for numerous industrial sectors.

Factors Affecting HDPE Density

The density of High-Density Polyethylene (HDPE) can be influenced by several factors, derived from a comprehensive review of current leading resources:

- Molecular Weight Distribution: The distribution of molecular weight significantly affects the density of HDPE. Polymers with a narrower molecular weight distribution typically have higher density and crystallinity due to more orderly packing of polymer chains.

- Degree of Crystallinity: HDPE with higher crystallinity levels generally exhibits higher density. The arrangement of polymer chains in a highly ordered structure enhances the material’s density and mechanical properties.

- Copolymer Content: The inclusion of comonomers such as butene, hexene, or octene can alter the density. Higher comonomer content usually results in lower density due to disruptions in the crystalline structure.

- Processing Conditions: The conditions during the manufacturing process, including cooling rates and pressure, can impact the final density of HDPE. Slower cooling rates often lead to higher crystallinity and, consequently, higher density.

By understanding these factors, manufacturers can better control the production of HDPE to achieve desired density and material properties for specific applications.

Why Is Density Important in HDPE Applications?

From the information gathered from the top three sources on Google, the density of High-Density Polyethylene (HDPE) plays a pivotal role in its applications because it directly impacts the material’s performance characteristics. Higher density HDPE generally translates to improved strength, hardness, and resistance to abrasion. This makes it particularly ideal for applications requiring durable and robust materials, such as piping systems and plastic bottles.

Technical Parameters

- Mechanical Strength: Higher density HDPE exhibits enhanced tensile strength, making it suitable for heavy-duty applications.

- Chemical Resistance: The higher crystallinity associated with increased density provides better resistance to chemical attack, beneficial for chemical storage and transportation.

- Impact Resistance: Although higher density generally implies increased rigidity, HDPE maintains good impact resistance, which is crucial for applications exposed to dynamic stresses.

By ensuring the correct density through controlled manufacturing processes, we can optimize HDPE for specific industrial requirements, enhancing its utility and cost-efficiency.

Implications of Density in HDPE Pipes

From the information I’ve gathered from the top three sources on Google, the density of HDPE pipes is crucial because it directly affects their reliability and efficiency in various applications. Higher density HDPE pipes offer improved mechanical strength and durability, making them ideal for transporting liquids under high pressure and for use in demanding environments. Additionally, the enhanced chemical resistance of higher density HDPE ensures longevity and stability when exposed to diverse chemicals, which is particularly advantageous for industrial piping systems. Lastly, despite being more rigid due to increased density, HDPE pipes still retain sufficient impact resistance to withstand external stresses and dynamic loads, making them versatile for both underground and aboveground applications.

The Role of Density in 3D Printing with HDPE

In 3D printing, the density of HDPE plays a pivotal role in determining the mechanical properties and print quality of the final product. Higher density HDPE filament offers enhanced strength and structural integrity, which is essential for producing durable and resilient printed objects. This density also translates to better layer adhesion during the printing process, reducing the likelihood of delamination and improving overall print reliability. Additionally, the superior chemical resistance of denser HDPE makes it suitable for creating parts intended for harsh industrial environments or chemical exposure. However, it’s important to note that higher density can also lead to increased rigidity, which might limit flexibility in certain applications. Thus, selecting the appropriate density for specific 3D printing applications is crucial to balance strength, flexibility, and durability.

HDPE’s Density and Its Recyclability

When it comes to HDPE’s density and its recyclability, I’ve gathered information from the top three websites on Google to provide concise answers. Higher density HDPE pipes and products are highly recyclable, owing to their thermoplastic nature. During the recycling process, HDPE items are sorted, cleaned, melted down, and remolded into new products without significant degradation of material properties. This efficacious recyclability is facilitated by parameters such as HDPE’s specific gravity (approx. 0.94-0.96 g/cm³) and melt flow index (MFI) which ranges between 0.4 to 1.0 g/10 min for higher density variations. These technical parameters ensure that recycled HDPE retains its mechanical strength, chemical resistance, and durability, making it an environmentally friendly and sustainable choice for manufacturing and industrial applications.

What Are the Physical Properties of HDPE?

High-density polyethylene (HDPE) is renowned for its remarkable physical properties that make it an ideal material for a wide range of applications. Its key physical properties include:

- Density: The density of HDPE typically falls between 0.94 and 0.97 g/cm³, contributing to its high strength-to-density ratio.

- Tensile Strength: HDPE exhibits excellent tensile strength, with values generally ranging from 21 to 37 MPa. This ensures that materials made from HDPE can withstand significant stress without breaking.

- Flexural Modulus: HDPE has a flexural modulus ranging from 600 to 1,500 MPa, indicating good rigidity and resistance to bending under load.

- Impact Resistance: HDPE is known for its superior impact resistance, even at low temperatures. This makes it suitable for products that may experience rough handling or impact.

- Thermal Properties: The melting point of HDPE is typically around 120-130 degrees Celsius, and it can operate effectively in a temperature range of -40 to 80 degrees Celsius without significant degradation.

- Chemical Resistance: HDPE shows excellent resistance to a wide variety of chemicals, including acids, bases, and solvents, making it ideal for use in chemical storage and piping systems.

- Water Absorption: HDPE has minimal water absorption, typically less than 0.01%, which helps in maintaining its mechanical properties even in moist environments.

These physical properties underscore the versatility and durability of HDPE, allowing it to be utilized in diverse industries ranging from packaging to construction, automotive, and beyond.

Tensile Strength and HDPE

To address the questions on tensile strength and HDPE concisely, let’s focus on the core aspects and relevant technical parameters:

What is Tensile Strength in HDPE?

Tensile strength is the maximum stress that HDPE (High-Density Polyethylene) can withstand while being stretched or pulled before breaking. It is a critical parameter indicating the material’s ability to endure tension without failing.

Key Technical Parameters for HDPE’s Tensile Strength:

- Tensile Strength Range: Generally falls between 21 to 37 MPa.

- Impact Resistance: HDPE maintains excellent tensile strength even when subjected to impacts, especially at low temperatures.

- Flexural Modulus: Ranges from 600 to 1,500 MPa, supporting HDPE’s ability to resist bending and maintain structural integrity under load.

- Density: Ranges from 0.94 to 0.97 g/cm³, contributing to a high strength-to-density ratio.

- Chemical Resistance: Resilient to a vast array of chemicals, ensuring the tensile strength is not compromised by chemical exposure.

- Water Absorption: Less than 0.01%, ensuring that tensile strength remains consistent even in moist environments.

These parameters are justified by standard material testing methods that measure the mechanical and chemical properties of HDPE, ensuring its reliability across various applications. The consistency and robustness of HDPE’s tensile strength make it an ideal material for demanding environments where durability is paramount.

Chemical Resistance and HDPE Density

When discussing chemical resistance and HDPE density, it is essential to highlight that HDPE is renowned for its robust resistance to a wide range of chemicals, making it suitable for various industrial applications. According to the top three websites on google.com, here’s a concise summary and the corresponding technical parameters:

- Chemical Resistance:

- Acids and Bases: HDPE demonstrates excellent resistance to a variety of acids and bases, even at elevated temperatures.

- Organic Solvents: It is highly resistant to alcohols, esters, and hydrocarbons.

- Oxidizing Agents: While HDPE is generally resistant, exposure to strong oxidizing agents, like nitric acid, may cause degradation over time.

Key Parameters:

- Resistance to Chemicals: Wide pH resistance, typically ranging from 2 to 12.

- Temperature Range: Can withstand temperatures from -100°C to 80°C without losing integrity.

- HDPE Density:

- HDPE exhibits a density range from 0.94 to 0.97 g/cm³, which contributes to its robustness and strength, providing a high strength-to-density ratio that is valuable in lightweight yet durable applications.

- The material’s density also plays a critical role in its tensile strength and impact resistance.

Key Parameters:

- Density: 0.94 – 0.97 g/cm³.

- Strength-to-Density Ratio: Facilitates high tensile strength and impact resistance.

By focusing on these parameters, HDPE maintains its structural integrity and performance under various chemical exposures, making it an ideal choice for environments that demand durable and reliable materials.

Melting Point and HDPE

As I researched the top three websites on google.com, I’ve gathered concise information about the melting point of HDPE and its significance. HDPE, or High-Density Polyethylene, typically exhibits a melting point ranging from 120°C to 130°C. This relatively high melting point is a testament to its crystalline structure, which provides a balance between rigidity and toughness, making it suitable for both high-temperature applications and environments that require durability.

Key Technical Parameters:

- Melting Point: 120°C – 130°C

- Crystalline Structure: Contributes to its ability to withstand higher temperatures and maintain mechanical properties.

- Thermal Stability: Ensures HDPE can be used in applications involving repeated exposure to heat without compromising its integrity.

These parameters collectively highlight why HDPE is popular in various industrial and consumer applications where both high thermal resistance and mechanical performance are essential.

How Does HDPE Compare to Other Types of Polyethylene?

When comparing HDPE to other types of polyethylene, such as Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE), several key technical parameters highlight the distinctions:

Density:

- HDPE: 0.94 – 0.97 g/cm³

- LDPE: 0.91 – 0.93 g/cm³

- LLDPE: 0.91 – 0.94 g/cm³

HDPE boasts a higher density, contributing to its increased tensile strength and impact resistance.

Melting Point:

- HDPE: 120°C – 130°C

- LDPE: 105°C – 115°C

- LLDPE: 120°C – 125°C

HDPE’s higher melting point enhances its thermal stability, making it suitable for high-temperature applications.

Tensile Strength:

- HDPE: Superior tensile strength due to its high density and crystalline structure.

- LDPE: Lower tensile strength; more flexible and resilient.

- LLDPE: Intermediate tensile strength; higher flexibility compared to HDPE.

HDPE’s superior tensile strength makes it ideal for applications requiring robust mechanical properties.

Flexibility:

- HDPE: Lower flexibility due to its rigidity.

- LDPE: High flexibility; suitable for applications requiring elasticity.

- LLDPE: High flexibility with added tensile strength.

The flexibility variances among these polyethylenes dictate their use in different applications—HDPE being more rigid, whereas LDPE and LLDPE are suited for more flexible and pliable needs.

Applications:

- HDPE: Piping, containers, geomembranes, and other products requiring strength and durability.

- LDPE: Plastic bags, containers, and films where flexibility is paramount.

- LLDPE: Agricultural films, stretch wrap, and packaging materials, balancing strength and flexibility.

By examining these technical parameters, it is evident that while HDPE offers high strength and thermal stability, LDPE and LLDPE provide greater flexibility, catering to different industrial and consumer requirements.

Comparing HDPE and Linear Low-Density Polyethylene (LLDPE)

When comparing HDPE and Linear Low-Density Polyethylene (LLDPE), the differences primarily lie in their mechanical properties and applications. HDPE offers superior tensile strength and higher thermal stability, making it ideal for applications that require durability and resistance to high temperatures, such as piping and containers. On the other hand, LLDPE provides a balance between strength and flexibility, which suits it for applications like agricultural films and packaging materials. While HDPE is more rigid, LLDPE’s added flexibility without compromising too much on strength allows it to be used in contexts where pliability is necessary. Thus, the choice between HDPE and LLDPE depends on the specific requirements of strength, flexibility, and thermal stability for the intended application.

HDPE vs. Low-Density Polyethylene (LDPE)

When comparing HDPE and Low-Density Polyethylene (LDPE), it is essential to consider their technical parameters and applications, as these justify their respective uses:

- Density:

- HDPE: Approximately 0.941 to 0.965 g/cm³

- LDPE: Approximately 0.910 to 0.940 g/cm³

- Tensile Strength:

- HDPE: Higher tensile strength, around 25-35 MPa

- LDPE: Lower tensile strength, around 8-12 MPa

- Thermal Stability:

- HDPE: Higher melting point around 130-137°C

- LDPE: Lower melting point around 105-115°C

- Flexibility:

- HDPE: Less flexible, more rigid

- LDPE: Highly flexible, more pliable

- Crystallinity:

- HDPE: Higher crystallinity (~70-90%)

- LDPE: Lower crystallinity (~40-60%)

Applications

- HDPE:

- Piping: Its high tensile strength and thermal stability make it suitable for piping systems.

- Containers: Used where durability and resistance to impact are crucial.

- Geomembranes: Utilized in containment systems due to its resistance to punctures and tears.

- LDPE:

- Plastic Bags: The flexibility and ease of processing make it ideal for bags.

- Films: Used in packaging films where flexibility and clarity are important.

- Containers: Commonly used for squeeze bottles and similar items where pliability is beneficial.

By analyzing these technical parameters and applications, it becomes evident that HDPE’s superior strength and stability make it apt for heavy-duty applications, whereas LDPE’s flexibility lends itself to uses where malleability is necessary. Thus, the decision between HDPE and LDPE hinges on the specific demands of the application, whether it be for strength and rigidity or flexibility and softness.

High-Density Polyethylene vs. Polypropylene

Both High-Density Polyethylene (HDPE) and Polypropylene (PP) are versatile polymers with unique properties suited for different applications.

1. Tensile Strength:

- HDPE: Relatively high tensile strength, around 25-35 MPa.

- PP: Moderate tensile strength, generally lower than HDPE, around 20-30 MPa.

2. Thermal Stability:

- HDPE: Melting point around 130-137°C.

- PP: Higher melting point compared to HDPE, around 160-170°C.

3. Flexibility:

- HDPE: Less flexible, more rigid.

- PP: More flexible, offering greater durability especially in applications involving repetitive motion.

4. Crystallinity:

- HDPE: Higher crystallinity (~70-90%) results in increased density and strength.

- PP: Moderately high crystallinity (~60-70%), offering a good balance between strength and flexibility.

Applications

- HDPE:

- Piping: Strong and stable, suitable for pipes.

- Containers: Durable, impact-resistant containers.

- Geomembranes: Resistant to punctures and tears, ideal for containment systems.

- PP:

- Automotive parts: Durable and flexible components for cars.

- Textiles: Used in non-woven fabrics and fibers for its lightweight and strong properties.

- Food containers: Safe for microwave use due to its higher thermal resistance.

Conclusion

Choosing between HDPE and PP depends largely on the specific demands of the application. HDPE shines in scenarios demanding higher strength and rigidity, such as piping and durable containers. Conversely, PP is optimal for applications requiring higher thermal resistance and flexibility, like automotive parts and food containers. By assessing the specific properties outlined above, one can make an informed decision tailored to their application needs.

Reference sources

-

-

-

Xometry: What is High Density Polyethylene (HDPE)?

- This article explores what HDPE is, its manufacturing process, material and chemical properties, and various applications. It serves as a foundational resource to understand the density and other essential characteristics of HDPE.

- Read more here

-

Sybridge: Know Your Materials: Low-Density Polyethylene vs High-Density Polyethylene

- This source provides an in-depth comparison between LDPE and HDPE, detailing their structural differences, properties, and common uses. It highlights the density aspect prominently, making it a valuable resource for understanding HDPE.

- Read more here

-

ResearchGate: A Review on the use of High Density Polyethylene (HDPE) in Concrete Mixture

- This research paper offers insights into the application of HDPE in concrete mixtures and discusses its properties, including density. It provides a scientific perspective and includes extensive data and analysis that can validate the feasibility of discussing HDPE’s density.

- Read more here

-

-

Frequently Asked Questions (FAQs)

Q: What is the density of high density polyethylene (HDPE)?

A: The density of high density polyethylene (HDPE) typically ranges from 0.93 to 0.97 grams per cubic centimeter (g/cm³).

Q: What makes HDPE different from low density polyethylene?

A: HDPE has a higher density and stronger intermolecular forces compared to low density polyethylene, making it stiffer and more resistant to impacts and environments.

Q: How is HDPE used in injection molding?

A: HDPE is commonly used in injection molding to produce a variety of products like containers, toys, and household goods due to its high molecular weight and environmental stress crack resistance.

Q: Why is HDPE frequently chosen for milk bottles?

A: HDPE is ideal for milk bottles because it is lightweight, has a high resistance to impact and chemicals, and is safe for food contact.

Q: What are the typical uses of HDPE?

A: HDPE is widely used for making pipes, plastic bottles, geomembranes, and plastic lumber. It’s also employed in cable insulation and as liners for chemical containers.

Q: What is the resin identification code for HDPE?

A: The resin identification code for HDPE is 2, which helps in identifying and recycling HDPE products, such as HDPE bottles and containers.

Q: How does the stiffness of HDPE compare to other plastics?

A: HDPE is stiffer than many other types of plastic due to its higher density and strong intermolecular forces, which gives it superior rigidity and durability.

Q: What role does the catalyst play in the production of HDPE?

A: In the production of HDPE, a catalyst helps in polymerizing ethylene gas into high molecular weight polyethylene, enhancing the material’s properties and performance.

Q: What are the environmental benefits of using HDPE?

A: HDPE is a sustainable choice due to its recyclability. Recycled HDPE can be used in making new bottles, pipes, and other products, reducing overall waste.