What is a Copper Vapor Laser?

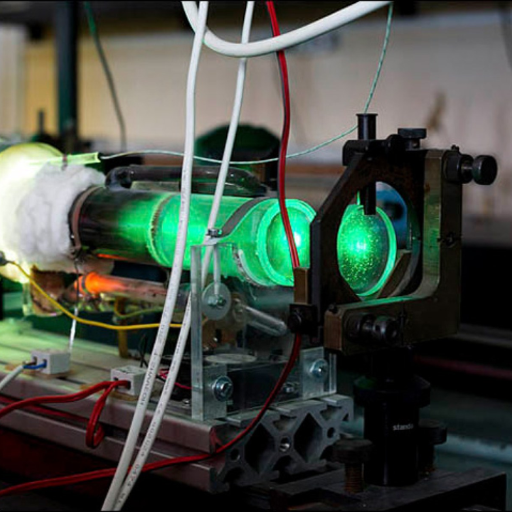

Image source: https://www.ibtimes.co.uk/

How does a copper vapor laser work?

What materials are used in copper vapor lasers?

Laser tube design and function in copper vapor lasers

How is the Laser Beam Generated in Copper Vapor Lasers?

Role of copper atoms and vaporized copper

Excitation process and pulse repetition

Laser light emission and wavelength specifics

What are the Different Types of Metal Vapor Lasers?

A specific set of gas lasers called metal vapor lasers utilize the metal vapors as their lasing media. They are classified into:

- Copper Vapor Lasers (CVLs): These lasers emit light in green and yellow regions, respectively at wavelengths 510.6 nm and 578.2 nm. Their high repetition rates and efficiency make them ideal for materials processing as well as medical applications.

- Sodium Vapor Lasers: Sodium is used as a lasing medium by these lasers with typical wavelength around 589nm. They are mostly employed in scientific research and atmospheric studies.

- Helium-Cadmium Lasers: Emitting UV together with blue light usually at wavelengths of about 325 nm and 442 nm, helium-cadmium lasers find applications in scientific research where precision is necessary.

- Gold Vapor Lasers: Gold vapor laser light emission occurs mainly in the yellow to orange spectrum; they have multiple uses including dermatology and fine materials processing.

Comparison of copper vapor lasers and alkali vapor lasers

Copper vapor lasers (CVLs) and alkali vapor lasers like potassium, rubidium, and cesium laser differ by their individual characteristics that make them suitable for certain applications. Thus, this is a review based on the latest information from top sources:

- Wavelengths and Emission:

- Copper Vapor Lasers (CVLs): Emit light at 510.6 nm (green) and 578.2 nm (yellow), which is optimal for high-speed imaging, materials processing, and medical treatments.

- Alkali Vapor Lasers: Usually produce radiation in the near-infrared range (e.g., potassium vapour laser at 770 nm). These wavelengths are useful for remote sensing, telecommunication, and laser cooling.

- Efficiency:

- CVLs: They are known to have high electrical-to-optical efficiency as well as high repetition rates, thus making them efficient in industrial processes and medicine.

- Alkali Vapor Lasers: They may exhibit low lasing thresholds while delivering high output powers with high quantum efficiencies due to these features. Consequently, they often require more elaborate support systems including setup design and cooling means.

- Operational Characteristics:

- CVLs: Work at temperatures that will allow vaporization of copper which implies they need robust thermal management systems. Their ability to produce numerous pulses per second makes them relevant for rapid applications such as precision work.

- Alkali Vapor Lasers: The temperatures of operation here are quite low but accurate density control over the vapours is required together with buffer gas pressures. In addition to having good beam quality that is important for scientific research or long distance communication,

- Applications:

- CVLs: Copper vapor lasers have found extensive use in dermatology, ophthalmology, high-speed photography and materials processing among others.

- Alkali Vapor Lasers: Atomic clocks largely employ these devices as do quantum information systems; spectroscopy or even laser cooling depending on wavelength specifics.

Key differences between copper vapor lasers and helium-cadmium lasers

- Wavelength Output:

- Copper Vapor Lasers (CVLs): Emit light chiefly in the green (510.6 nm) and yellow (578.2 nm) regions of the spectrum.

- Helium-Cadmium Lasers (HeCd): Generate laser radiation in the ultraviolet (325 nm) and blue (441.6 nm) parts of the spectrum.

- Efficiency:

- CVLs: Famously have high electrical to optical efficiency, making them useful for strong and efficient light sources applications.

- HeCd: Mostly have lesser efficiencies compared to CVLs that can impact on costs for running these lasers at high powers and their applicability at such levels.

- Operational Environment:

- CVLs: Require elevated temperatures for copper vaporization and maintenance of lasing action, necessitating robust thermal management systems.

- HeCd: Work at much lower temperatures using a gas discharge in helium, cadmium vapour which usually demands less exacting thermal controls.

- Applications:

- CVLs: Used extensively in materials processing, high-speed photography, dermatology as well as other medical procedures due to their high repetition rates coupled with good energy conversion efficiency.

- HeCd: Frequently employed in scientific research, spectroscopy, manufacture of microelectronics and fluorescence microscopy because they are characterized by definite ultraviolet-blue wavelengths

- Beam Quality:

- CVLs: Have good beam quality at high repetition rates making them suitable for intricate industrial or medical work.

- HeCd: Involving stable output provide excellent beam quality essential for highly precise and consistent processes.

Types of metal vapor lasers and their applications

There are metal vapor lasers that utilize atoms of metals as the active mediums. They are characterized by their high efficiency and ability to produce wavelengths that are not easily accessible using other types of lasers. Here, we will look at some common metal vapor lasers and the areas where they find applications.

- Copper Vapor Lasers (CVLs):

- Description: Generates laser light with copper atoms, usually emitting green (510.6 nm) and yellow (578.2 nm) light.

- Applications: CVLs have a wide range of applications including material processing, dermatology, ultra-high-speed photography and medical surgery because of their high repetition rate, efficiency as well as precise industrial processes.

- Helium-Cadmium (HeCd) Lasers:

- Description: It involves the use of helium and cadmium vapours to generate ultraviolet (325 nm) and blue (441.6 nm) radiations.

- Applications: Scientific research work, spectroscopic analysis, microelectronics manufacture and fluorescence microscopy majorly employ HeCd lasers due to their stability in output emission wavelength.

- Gold Vapor Lasers (GVLs):

- Description: Laser lights from GVLs are commonly generated by gold atoms within the green region of spectrum.

- Applications: In addition to these usages which are similar to those of CVLs, GVLs are employed in medical treatment, precision machining processes and studies on atmospheric conditions with superior pulse energy at high speeds.

What Applications Use Copper Vapor Lasers?

Industrial uses: cutting applications and laser cutting

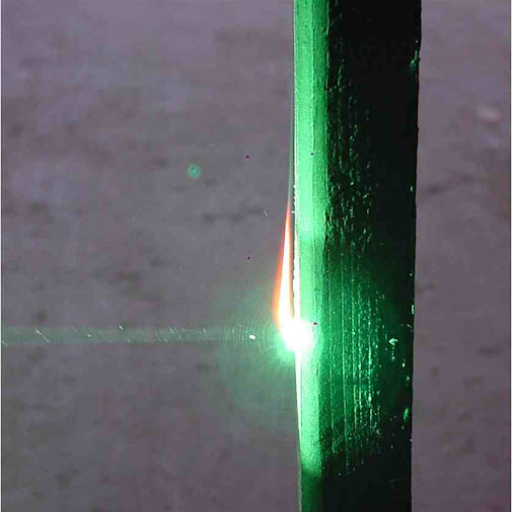

CVLs are commonly used in industrial applications for cutting, as they are highly precise, fast and efficient. They can do smooth and accurate metal, ceramic and plastic cuts at a high pulse repetition rate. This effectiveness makes them ideal in making parts of products that require a lot of attention to be given to patterns or designs. Moreover, the CVLs have high average power with excellent beam quality therefore reducing thermal impact on the surrounding materials leading to clean cuts with minimal distortion.

Most importantly, as far as laser cutting is concerned, these lasers reign supreme among other lasers when it comes to processing different materials through focused beams that efficiently vaporize the material being cut. They are employed in various sectors such as automotive, aerospace and electronics where accuracy and consistency reign supreme. The usefulness of CVLs in different substrates and cutting situations makes them an important tool in contemporary industry providing both high performance and affordability at the same time.

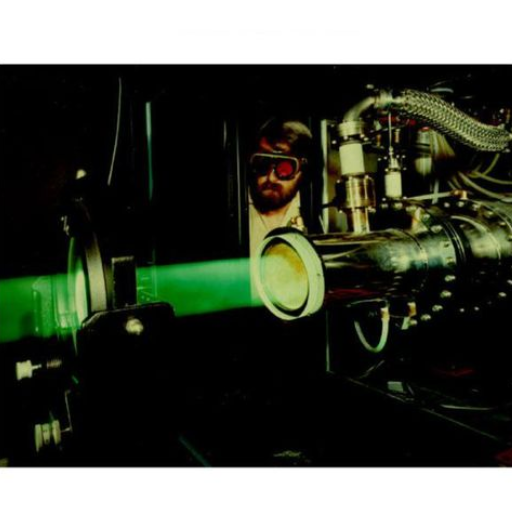

Scientific applications: isotope separation and laser isotope separation

The Copper Vapor Lasers (CVLs) are key players in the field of laser isotope separation which is an important component of isotope separation. This technique utilizes wavelengths specific to CVLs’ emissions for selective ionization of chosen isotopes of a substance. The first step involves tuning the laser to a wavelength matching that of the target isotope’s absorption spectrum. For example, if different isotopes are present in a material and light from a laser falls on it only atoms belonging to an isotope whose absorption wavelength matches that of the laser will be ionized. Subsequently, electromagnetic fields or other means can then separate these ionized atoms from non-ionized ones.

Their precision and efficiency make them ideal for this purpose. Also, their high pulse repetition rate and beam quality ensures rapid processing as well as high throughputs in areas like isotope separation. It has become an accepted practice in manufacturing isotopically enriched substances applied in various fields such as nuclear medicine, scientific research and environmental studies among others. With ability to control and separate isotopes without invasive measures, CVLs have significantly promoted industrial progressions while still advancing science.

Copper vapor laser uses in green laser light production

How Do You Maintain and Optimize a Copper Vapor Laser?

Required maintenance for laser tubes

To ensure longevity and efficient operation of the laser tubes, maintenance is important. Here, therefore, are some important steps I have gathered from top resources:

- Regular Cleaning: Keep cleaning this laser tube regularly to remove dirt particles and other pollutants that can obstruct the path of a light beam resulting in poor performance.

- Inspect and Replace Water in the Cooling System: Distilled water should be used in the cooling system and replaced frequently to avoid mineral build up and overheating which may cause damage to the laser tube.

- Check and Align Optics: Inspect mirrors and lenses periodically for re-alignment purposes so as to maintain an optimal beam quality with no energy loss.

- Monitor Electrical Components: Check power supplies and other electrical components regularly to make sure stable electric input is ensured by calibrating them.

- Replace Aging Components: Thus, once they reach their operational life spans or just before this happens, any such parts including those of the laser tube must be replaced before they fail abruptly so as not to lower its efficiency.

Increasing average power and peak power

A number of approaches can be taken to increase both the average and peak power of a laser:

- Optimizing the Pump System: The overall output power in a laser depends on how much efficient is its pump system. This could mean replacing low powered pump sources with high powered ones or improving coupling efficiency between the pump and the laser medium.

- Improving Cooling Mechanisms: A tighter control of the temperature within a high-power laser system is required for stability. Laser performance may therefore benefit from an upgrade to advanced cooling techniques including water-cooling systems or thermoelectric coolers that dissipate heat more efficiently.

- Using High-Quality Optical Components: The power output is influenced by such factors as mirror, lens, and other optical component qualities. High reflectivity mirrors and anti-reflective (AR) coated lenses minimize energy losses and improve laser system efficacy.

- Optimizing Cavity Design: Power output highly depends on the design of a laser cavity. Therefore using resonators with higher order modes or better mode matching inside the cavity can lead to an increased output power.

- Beam Combining Techniques: In some cases lasers don’t have sufficient power in one beam; therefore, multiple beams are combined into one single beam through either coherent beam combining (CBC) or spectral beam combining (SBC).

Ensuring high repetition rate and beam quality

To ensure that the laser system has a high repetition rate and beam quality, there are several significant factors and techniques to be considered:

- Advanced Laser Materials: The utilization of advanced gain materials such as fiber lasers or thin-disk lasers enables higher repetition rates and superior beam quality. These materials enable efficient thermal management and stable operation at high frequencies.

- Pulse Shortening Techniques: Q-switching and mode-locking among others can be used to produce short, intense pulses with superior beam quality. Such approaches facilitate precise control over pulse duration, which in turn increases both repetition rate and beam quality.

- Active Stabilization: By employing feedback loops and real-time monitoring systems to apply active stabilization techniques, it is possible to maintain constant performance of the laser. This ensures that the laser works steadily at elevated repetition rates without losing the quality of the beam.

- Optimized Laser Cavity Design: By minimizing losses in the laser cavity design through fine-tuning it to support higher-order mode suppression, it is possible to enhance beam quality. This encompasses use of high-quality optical components as well as accurate alignment within the cavity.

- Thermal Management: Adequate thermal management is essential for maintaining good beam quality at higher repetition rates. Advanced cooling options include liquid cooling or thermoelectric cooling which will prevent any form of distortion on thermal lensing.

Reference sources

- Wikipedia – “Copper Vapor Laser”

-

-

- Summary: This Wikipedia article provides a comprehensive overview of copper vapor lasers, including their operational principles, wavelengths, and applications. The article is well-cited and serves as a foundational resource for understanding the basic technology behind CVLs.

- Read more

-

Technical FAQ – “What is a Copper Vapour Laser?”

- Source: TWI Global

- Summary: This technical FAQ from TWI Global explains the functionality of copper vapor lasers, detailing their primary wavelengths and the properties that make them useful in various applications. It offers precise and authoritative information suitable for those seeking to understand the practical aspects of CVLs.

- Read more

-

Article – “Copper at the Cutting Edge: The Copper Vapor Laser”

- Source: Copper Development Association (Copper.org)

- Summary: This article discusses the benefits and applications of copper vapor lasers, particularly in precision micromachining. It highlights the laser’s characteristics and efficiency, providing valuable insights into the practical applications and advantages of CVLs.

- Read more

-

Frequently Asked Questions (FAQs)

Q: What is a Copper Vapor Laser?

A: A copper vapor laser is a type of metal vapor laser that uses vaporized copper atoms to produce laser light, typically at wavelengths of 578.2 nm and 510.6 nm. It is known for its high peak power and pulsed laser operation.

Q: How does a Copper Vapor Laser work?

A: Copper vapor lasers work by using electrical pulses to excite vaporized copper atoms. These atoms then transition from a higher energy state (upper laser level) to a lower energy state, emitting laser light in the process. This laser action is commonly achieved using copper halides like copper chloride or copper bromide.

Q: What are the common applications of Copper Vapor Lasers?

A: Copper vapor lasers are used in a variety of applications, including high-resolution printing, medical surgeries, laser cutting applications, and research. They are also employed to excite tunable dye lasers and as pointers in various scientific experiments.

Q: How do Copper Vapor Lasers excite Tunable Dye Lasers?

A: Copper vapor lasers emit high-intensity laser light which can be used to excite dye molecules in tunable dye lasers. The dye molecules then emit light at different wavelengths, which can be adjusted or tuned for specific applications.

Q: What are the advantages of using Copper Vapor Lasers?

A: Some of the advantages include high energy output (often measured in kW), high efficiency, visible laser emission, and the ability to operate at high repetition rates (measured in kHz). They also offer good beam quality and consistency for various industrial and scientific uses.

Q: What materials are used in the construction of Copper Vapor Lasers?

A: The lasing medium typically consists of vaporized copper atoms, and the lasers themselves often use copper halides like copper chloride or copper bromide. The construction also involves a laser head, electrodes, and a system to produce the necessary electrical pulses.

Q: How are Copper Vapor Lasers different from other Metal Vapor Lasers?

A: Copper vapor lasers specifically use vaporized copper atoms to produce laser energy, whereas other metal vapor lasers might use different metals like gold or nickel. Copper vapor lasers are particularly noted for their high power and efficiency in the visible spectrum compared to other types of metal vapor lasers.

Q: What is the significance of the laser wavelength 578.2 nm in Copper Vapor Lasers?

A: The wavelength 578.2 nm is one of the primary emission lines of copper vapor lasers and falls in the yellow region of the visible spectrum. This particular wavelength is useful in various applications like medicine and printing due to its high visibility and precision.

Q: How are electrical pulses used in Copper Vapor Lasers?

A: Electrical pulses are used to ionize and excite the copper atoms within the laser medium. These pulses have to be delivered at high frequencies, often kHz, to maintain continuous laser action and achieve the desired laser output.

Q: Why are Copper Vapor Lasers preferred for laser cutting applications?

A: Copper vapor lasers are favored in laser cutting applications due to their high power output (often in the kW range), efficiency, and ability to operate in a pulsed mode. This ensures precise and efficient cutting with minimal thermal damage to the materials being processed.