What is a Continuous Wave Laser?

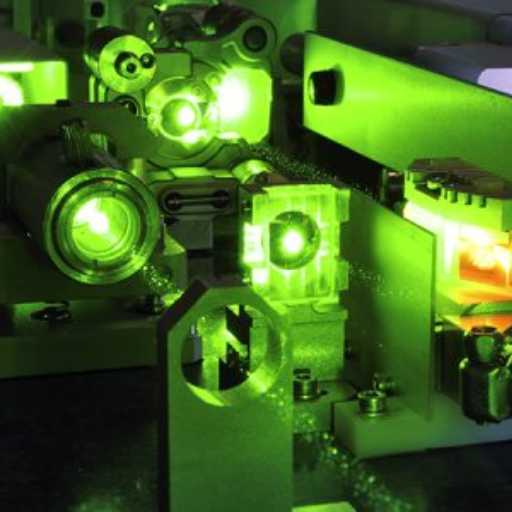

Image source: https://www.spectra-physics.com/

Definition of Continuous Wave (CW) Lasers

How CW Lasers Operate

Comparison with Pulsed Lasers

There are differences between CW (Continuous Wave) lasers and pulsed lasers in the way they work and their uses. Pulsed lasers on one hand generate light that is emitted in short bursts or pulses while CW lasers emit a steady continuous beam of light. This basic distinction results in different benefits and purposes for each kind.

Pulsed lasers are capable of producing high peak power since all the energy they emit is concentrated into very short pulse durations lasting from nanoseconds down to femtoseconds. Such ability is necessary for demanding applications such as medical laser surgeries, time-resolved spectroscopy scientific research, material engraving among others that need very high precision and power.

Moreover, when constant and uniform light sources are needed, like; fiber-optic communication, laser printings or continuous wave spectroscopy CW lasers with stable continuous outputs have found usefulness. For industrial processes requiring steady illumination and power like; medical processes in hospitals and telecommunication stations where reliable performance over extended periods is needed, CW lasers offer optimal solutions.

Furthermore, pulsed lasers usually require shorter duration with high intensity to minimize heat damage on surrounding materials whereas more effective cooling mechanisms may be required to manage heat dissipation from CW lasers over longer periods due to their constant operation.

To sum up the above ideas, the choice between pulsed laser systems or CW ones depends on what the application demands; pulsed laser gives desirable peak powers and precision while CFL provides consistent stable output that can be applied continuously

How Do Continuous Wave Lasers Work?

Basic Principles of CW Laser Operation

The main principles supporting the operation of a Continuous Wave (CW) laser are stimulated emission, population inversion, and optical resonance.

Stimulated Emission: An electron moving from an excited state to a lower energy level is this process. This process causes the photon to be emitted in the process. This photon that has been emitted stimulates other electrons in their excited states to emit more photons; which are coherent since they have the same phase, frequency and direction.

Population Inversion: To explain how a laser works; we can say that there should be more atoms or molecules occupying higher states of excitation energy than at other times by creating a population inversion. A state of population inversion is achieved through ‘pumping’ the gain medium with energy from an external source like electricity or another laser beam.

Optical Resonance: Optical cavities created by placing mirrors at both ends of the gain mediums cause photons to be reflected back and forth across these mediums. One can say that this reflection increases chances for stimulated emission thereby amplifying light as such. One of those mirrors is partly transparent thus letting some amount of light escape as laser beam.

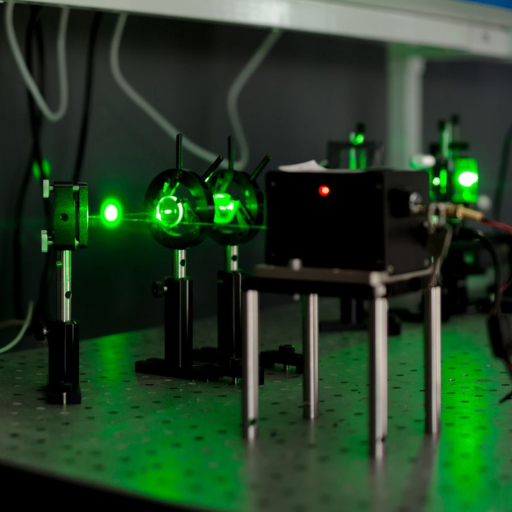

Roles of Wavelength and Optical Cavity

The wavelength of a CW laser is crucial in determining its operational efficiency and the appropriate application. The gain medium and the specific atomic or molecular transitions it supports basically specify the wavelength of the generated light. Different wavelengths have different uses, such as medical procedures and telecommunications.

The coherent light from the laser is partly facilitated by the optical cavity that consists of mirrors at both ends of the gain medium. The mode structure and stability of a laser beam depend on its dimensions and shape. For this reason, there must be an alignment between the length of an optical cavity with regard to standing wave pattern for chosen wave length hence only certain wave lengths are amplified while others are suppressed.

In conclusion, the relationship between wavelength and optical cavity affects various aspects like output power, beam quality, stability , among others which makes it necessary to optimize these parameters for desired outcomes.

Understanding Output Power and Beam Quality

Efficiency and CW laser practicality depend on output power, and beam quality. Output power is the amount of light energy the laser gives off in watts. This is mainly influenced by the gain medium, pump power, and optical cavity efficiency. In industries where significant energy transfer is necessary for medical applications higher output powers are often needed.

Conversely, beam quality measures how well a laser beam can be focused into a small spot. Typically, this measurement uses the M² parameter that has lower values implying better beam quality. Optical cavity design, uniformity of gain materials and alignment of optical components are key factors affecting beam quality.

However, a high output power laser with poor beam quality may not be applicable to precision demanding applications like material processing or high resolution imaging. Therefore it’s important to strike balance between output power and beam quality in order to optimize performance of CW lasers in various applications.

Applications of Continuous Wave Lasers

Use in Raman Spectroscopy

Fluorescence and Imaging Applications

Industrial and Medical Uses

In industrial contexts, continuous wave lasers are commonly used for activities like cutting, joining and processing materials finely. Their feature of delivering high intensity light in series makes them very suitable for applications that require power consistency over long durations. According to top sources, CW lasers are especially beneficial in manufacturing procedures as they are effective and accurate leading to improved products of a better quality and less waste.

In the field of medicine, continuous wave laser therapy has brought about tremendous advancements in different treatment methods as well as investigation techniques. For instance, these are employed in laser surgery, photocoagulation treatments etc because such devices can be adjusted to emit wavelengths which correspond exactly to vital tissues. Other latest developments indicate that CW lasers play a significant role in non-invasive imaging modalities and also photodynamic therapies which necessitate stable targeting accuracy thus enabling efficient treatment with the least possible side effects. In technological innovations or medical breakthroughs, these CW lasers come in handy due to their reliability and flexibility.

Different Types of Continuous Wave Lasers

Gas Lasers

Gas lasers, including the helium-neon (HeNe) and carbon dioxide (CO2) laser types, use gas as a medium to produce coherent light. They are famous for their stability and dependability, making them good candidates for applications in metrology, holography, barcode scanning and others. The CO2 lasers have continued to be widely used for cutting and engraving because of their high efficiency and compatibility with different materials.

Solid-State Lasers

Solid-state lasers refer to a category of lasers that use solid-state mediums that are usually doped with rare earth elements such as neodymium or ytterbium. For instance, there is neodymium-doped yttrium aluminium garnet (nd:yag) lasers as well as ytterbium-doped fiber laser examples. These are highly efficient lasers which can give very high power outputs. Their applications include industrial processing, medical procedures and scientific research.

Semiconductor Lasers

Diode Laser or the semiconductor laser diodes are based on semiconductors which make them small-sized devices; they also exhibit high efficiency and electrical direct control capability.Thus they find wide application in telecommunications,data storage,and consumer electronics.Moreover,recent developments have led to new uses like accurate spectroscopy as well as biomedical imaging.

Dye Lasers

The lasing medium in dye lasers consists of organic dyes dissolved in liquids.They are excellent for spectroscopy and analytical chemistry due to their broad wavelength tunability.These applications range from medical diagnostics to scientific research.

All continuous wave laser types provide unique advantages thus having diverse fields of application in industries, medicine and science.

Solid-State Lasers

Solid state lasers belong within a class of systems where the gain medium is a solid material such as crystals or glasses doped with rare earth ions like neodymium (Nd), erbium (Er),ytterbium(Yb). One of the common examples is Nd:YAG( Neodymium-doped Yttrium Aluminium Garnet) laser which emits light at 1064 nm. These lasers are appreciated for their high efficiency and robustness, which makes them useful in industrial precision cutting, welding and marking. For instance, Nd:YAG lasers play a role in laser eye surgeries and treating certain skin conditions due to its exact tissue interaction. Moreover, solid state military and defense sectors employ solid state lasers for targeting and range finding because they are reliable under hostile environmental conditions.

Fiber Lasers

Fiber lasers usually have an optical fiber that is doped with some rare earth elements like erbium (Er), ytterbium (Yb) or thulium (Tm) used as a gain medium. This category of lasers is known to possess very high power output, excellent beam quality as well as remarkable efficiency. Fiber lasers have gained popularity for various applications because they have low maintenance requirements and long operational life spans. They are widely used in industries for cutting, welding and engraving a range of materials from metals to polymers. Fiber lasers consist another group of tools applied by surgeons during highly precise surgical operations most especially in minimal invasive cases.The last but not least application can be traced back to energy amplification in telecommunications industry or critical roles played by these tools including accurate experiments which require high levels of precision.Such features make them applicable across many disciplines due to their reliability.

Diode-Pumped Lasers

Advantages and Disadvantages of CW Lasers

Advantages

- Continuous Operation: They can be on all the time, and hence continuous wave (CW) lasers provide a steady and constant laser output which makes them ideal for tasks that require constant laser emission.

- High Power: The high power levels of these lasers are critical in industrial cutting and welding.

- Precision: CIn medical surgeries or complex scientific tests, CW lasers have great precision.

- Reliability: On account of their rugged construction, they are considered reliable with long operational lives such that maintenance is not done frequently.

Disadvantages

- Heat Generation: For this reason, an efficient cooling system is necessary to avoid damage and maintain performance, as continuous operation has a tendency to cause a lot of heat generation.

- Energy Consumption: It would mean higher operational costs because generally, continuous wave lasers consume more energy than their pulsed counterparts do.

- Cost: Because advanced cooling systems must be used along with the laser source itself, the initial cost of CW lasers could be relatively high.

- Limited Modulation: Some communication types may operate at low frequencies so that these would be better suited as compared to CW lasers if it requires rapid oscillation like some forms of communication tasks and fast data processing.

Technological Advances in CW Laser Systems

Recent Advances in CW Fiber Lasers

Notably, the most recent advances in Continuous Wave (CW) fiber lasers have seen significant leap in power scaling, efficiency and beam quality. While maintaining superior beam quality; the greatest move has been increasing power output. As a result of new innovations, commercial CW fiber lasers today have powers above tens of kilowatts which is game-changing for cutting, welding and material processing.

The improvements in efficiency were also striking. Some reaches of designs with wall-plug efficiencies above 40% are made possible by new materials leading to reduced operation costs and minimized heat generation through these systems. These high power laser systems can now be allowed to work without over heating since there has been a substantial improvement on the cooling technology.

Finally, the development of new fiber designs and active beam control techniques have greatly enhanced beam quality. This has resulted into high throughput in industrial applications with less waste , more accurate material processing thus making them all round better than ever before in terms of versatility as well as reliability during use.

Innovations in Semiconductor CW Lasers

The recent changes in semiconductor Continuous Wave (CW) lasers have been focused on improving their power output, efficiency and versatility for different applications. It has also been possible for the continuous wave semiconductor lasers to be used in more demanding industrial and medical applications due to a major development of higher power outputs. These lasers are more cost-effective because they consume less electricity by being more efficient.

There have been new approaches to keep the maximum performance and prevent thermal degradation through novel cooling techniques. They include advanced heat sinks like high capacity microchannel cooling systems and other materials. This is because innovations in wavelength stabilization as well as beam quality have widened the range of uses of semiconductor CW lasers in such precision applications as high-resolution printing, telecommunications, medical diagnostics.

Inclusion of various semiconducting materials and external cavity designs has substantially increased tunability and wavelength versatility. As a result, these developments allow semiconductor CW lasers to perform uniformly over wide range of wavelengths thereby they become adaptable and effective in many occasions.

Reference sources

-

Article – “Continuous Wave Lasers: Understanding the Basics”

- Source: Novanta Photonics

- Summary: This article provides a foundational understanding of continuous wave (CW) lasers, covering their operational principles, advantages, and various applications. It is designed for both newcomers and professionals looking to deepen their knowledge of CW laser technology.

- Read more

-

Article – “CW Laser Basics and Technologies”

- Source: Laser Lab Source

- Summary: This comprehensive article from Laser Lab Source delves into the basics of CW lasers, explaining the fundamental differences between continuous wave and pulsed lasers. It also discusses the technological advancements and practical applications of CW lasers in various fields.

- Read more

-

Overview – “Continuous Wave Laser”

- Source: ScienceDirect

- Summary: This overview on ScienceDirect provides an in-depth look at continuous wave lasers, emphasizing their use in spectroscopy and other steady-state measurements. The material is detailed and authoritative, making it a valuable resource for understanding the technical aspects and applications of CW lasers.

- Read more

Frequently Asked Questions (FAQs)

Q: What is a continuous-wave laser?

A: A continuous-wave laser, often referred to as a CW laser, is a type of laser that emits a continuous, unbroken beam of light, as opposed to pulsed lasers which emit light in short bursts. These lasers produce a constant output of power and are used in various applications, including industrial, medical, and scientific fields.

Q: How does a continuous-wave laser differ from a pulsed laser?

A: Continuous-wave lasers emit a steady, uninterrupted beam of light, while pulsed lasers emit light in periodic bursts or pulses. This fundamental difference makes CW lasers suitable for applications requiring consistent, stable output, such as spectroscopy and holography, whereas pulsed lasers are preferred for applications like laser cutting and medical surgeries where high peak power is necessary.

Q: What are the main components of a CW laser system?

A: A typical CW laser system includes a laser head, power supply, and sometimes additional cooling components. The laser head contains the lasing medium and the cavity mirrors. The power supply provides the necessary electrical energy to excite the lasing medium, enabling it to emit a continuous beam of light.

Q: What is a CW diode laser?

A: A CW diode laser is a type of continuous-wave laser in which the lasing medium is a semiconductor diode. These lasers are known for their efficiency, compact size, and the ability to be driven by low voltages. CW diode lasers are widely used in applications requiring precision and reliability, such as in telecommunications and medical diagnostics.

Q: How do CW DPSS lasers work?

A: CW DPSS (Diode-Pumped Solid State) lasers use a laser diode to pump a solid-state lasing medium, such as Nd:YAG or Nd:YVO4, which then emits a continuous laser beam. These lasers are known for their high efficiency and high beam quality, making them suitable for applications in both research and industrial environments.

Q: What are some common applications of CW lasers?

A: Continuous-wave lasers are used in a wide range of applications, including telecommunications, medical procedures, materials processing, and scientific research. For example, they are used in spectroscopy to analyze the composition of materials and in holography to create high-resolution images. CW lasers are also used in laser displays and various measurement instruments.

Q: What factors should be considered when choosing a CW laser for your application?

A: When selecting a CW laser for your application, important factors to consider include the laser wavelength, average power, beam quality, and stability. Additionally, the specific requirements of your application, such as the need for tunable CW options, narrow linewidth, or specific infrared wavelengths, should guide your decision. Understanding these factors will help you choose the best CW laser for your application.

Q: Are there tunable CW lasers available?

A: Yes, tunable CW lasers are available. These lasers allow the user to adjust the laser wavelength within a certain range, providing flexibility for applications that require precise control over the laser output. Tunable CW lasers are used in spectroscopy and various research fields where different wavelengths are necessary for different experiments.

Q: What is the role of Lumentum Operations LLC in the development of CW lasers?

A: Lumentum Operations LLC is a leading company in the development and manufacture of advanced laser technologies, including continuous-wave lasers. They offer a range of CW lasers designed for precision and reliability across numerous applications. Their innovations and products help drive advancements in fields such as telecommunications, industrial processing, and medical diagnostics.