In recent years, 3D concrete printing has emerged as a revolutionary technology in the construction industry. Promising rapid construction times, reduced waste, and innovative architectural possibilities, these printers are seen by many as the future of building. However, as with any cutting-edge technology, understanding the true cost involves more than just the initial purchase price. This blog aims to delve into the various factors that contribute to the overall expense of acquiring and operating a 3D concrete printer. From the upfront costs of the machine itself to ongoing maintenance, materials, and potential hidden fees, we explore what it truly takes to bring this remarkable technology to your construction project.

How Do 3D Concrete Printers Work?

Image sources:https://apple-tree.co.jp/

3D concrete printers operate by using a computer-controlled process to layer concrete material in precise shapes and patterns. The process begins with a digital model designed in CAD software. This model is then divided into thin horizontal layers, which serve as the blueprint for the printer. The printer extrudes a special concrete mixture through a nozzle, laying down one layer at a time based on the digital model. Each layer is carefully deposited to bond with the previous one, gradually building up the structure. This method allows for intricate designs and reduces the need for traditional formwork, making the construction process more efficient and versatile.

What Is a 3D Concrete Printer?

A 3D concrete printer is a specialized machine that automates the construction of concrete structures using additive manufacturing techniques. It works by extruding a concrete mixture layer by layer, guided by a computer-designed model, to form buildings and other architectural elements with precision and efficiency. These printers eliminate the need for traditional formwork, offering new possibilities for innovative designs and streamlined construction processes.

How Does 3D Printing Technology Apply to Construction?

In the construction industry, 3D printing technology allows for the creation of complex and customized structures with greater speed and less waste. As I explore the top resources online, I find that this technology can drastically reduce labor costs and construction time by automating the creation of building components. Additionally, 3D printing enables the efficient use of materials, reducing the environmental impact traditionally associated with construction. With the capability to produce intricate designs that would be difficult or impossible with conventional methods, 3D printing has the potential to revolutionize our approach to building and architecture.

What Are the Benefits Over Traditional Construction Methods?

3D printing technology in construction presents several advantages over traditional methods. First and foremost, it significantly reduces construction time by automating the building process, which can lead to faster project completion. This automation minimizes the need for manual labor, thereby reducing labor costs. Additionally, 3D printing allows for precise material usage, resulting in minimal waste and a lower environmental impact. Complex and customized designs are effortlessly produced, thanks to the precision of computer-guided models.

Technical Parameters:

- Speed: Traditional methods involve longer setup times and multiple stages of construction. A 3D printer can complete a building structure in a fraction of that time.

- Labor Costs: Automation reduces the number of workers needed on-site. Operating a 3D printer often requires fewer skilled laborers compared to traditional construction teams.

- Material Efficiency: Precise layer-by-layer material deposition minimizes waste. This is crucial for sustainability and cost reduction.

- Design Complexity: Traditional methods are limited by formwork and manual labor capabilities. 3D printing can create intricate designs that would be difficult to replicate manually.

- Sustainability: Reduced waste and optimized material use contribute to lower environmental impact.

By integrating 3D printing technology into construction, projects can achieve greater efficiency, cost-effectiveness, and sustainability.

How Much Does a 3D Printer for Construction Cost?

The cost of a 3D printer for construction can vary significantly depending on the printer’s size, capabilities, and the manufacturer. Entry-level construction 3D printers might start at around $100,000, while high-end models with advanced features and larger build capacities can exceed $500,000. Additionally, potential buyers should consider ongoing costs such as maintenance, training, and material expenses, which can also impact the overall investment. Despite the initial high cost, the benefits in terms of reduced labor, faster construction times, and material efficiency can make it a worthwhile investment for many construction projects.

What Factors Affect the Price of a 3D Concrete Printer?

Several factors influence the price of a 3D concrete printer:

- Printer Size and Build Volume: Larger printers that can construct bigger structures generally cost more. The build volume capacity directly impacts the machine’s price due to the increased material and engineering complexity.

- Material Compatibility: Some 3D printers are designed to handle a variety of concrete mixtures and additives, which can affect their cost. Machines with higher versatility in material use often have a higher price tag.

- Technological Features: Advanced features such as automated calibration, integrated sensors, and quality control systems enhance the printer’s functionality but also increase the cost. Machines with better precision, speed, and user-interface integration are typically more expensive.

- Manufacturer and Brand Reputation: Established brands with a track record of reliability and innovation may charge premium prices for their products. The reputation and customer support provided by the manufacturer can influence the overall cost.

- Maintenance and Operating Costs: Some printers require specialized parts and regular maintenance, contributing to ongoing expenses. These costs need to be considered alongside the initial purchase price.

- Software and Licensing: Proprietary software and additional licensing fees for operating the 3D printer or using advanced features can add to the cost. Comprehensive software solutions that offer robust design and planning capabilities may also be a factor.

By understanding these factors, potential buyers can make informed decisions about which 3D concrete printer best suits their project’s needs and budget.

How Do Costs Compare to Traditional Construction?

When comparing the costs of 3D concrete printing to traditional construction methods, several factors must be considered. According to the top resources available, 3D concrete printing can offer significant cost savings in several areas:

- Labor Costs: Traditional construction is labor-intensive, often requiring a large workforce over an extended period. In contrast, 3D concrete printing reduces the need for manual labor by automating much of the building process. One estimate suggests that labor costs can be cut by up to 80% with 3D printing techniques.

- Material Efficiency: The precision of 3D printers allows for the exact amount of material to be used, minimizing waste. Traditional construction methods typically have a higher wastage rate due to inefficient material usage and cutting processes. Studies show that material costs can drop by approximately 60% using 3D printing technology.

- Construction Speed: 3D concrete printing significantly reduces the time required to complete a construction project. For example, while conventional methods might take several months to build a structure, a 3D printer can complete the same building in mere days or weeks. This rapid construction translates to lower overall costs associated with project timelines, such as financing and management expenses.

However, there are some technical and initial investment considerations that affect cost comparisons:

- Initial Investment: The upfront cost of a 3D concrete printer can be high, ranging from $180,000 to $1,000,000, depending on the machine’s capabilities and features. Traditional construction does not require such a significant initial outlay for equipment but may incur other costs over time.

- Operating Costs: Operating a 3D printer includes costs for energy, maintenance, and specialized training for operators. Over time, these operating expenses should be weighed against the ongoing labor and material costs of traditional methods.

In conclusion, while the initial acquisition of 3D printing equipment can be expensive, the reductions in labor and material costs, combined with faster construction times, often result in lower overall expenses compared to traditional construction.

Are There Cost-Saving Benefits?

Yes, there are significant cost-saving benefits to using 3D concrete printing in construction. The technology offers considerable reductions in material and labor costs due to its precision and efficiency. Additionally, the accelerated construction speeds decrease project timelines, which in turn lowers financing and management expenses. While there is a high initial investment for 3D printing equipment, the long-term savings and increased efficiency typically offset these upfront costs, making 3D concrete printing a cost-effective alternative to traditional construction methods.

Which 3D Concrete Printers Are Available for Purchase?

Several 3D concrete printers are available for purchase, catering to various needs and project scales. Some notable options include:

- Apis Cor: Known for its mobile and versatile design, Apis Cor’s printers can build structures on-site, reducing transportation costs and enabling a more streamlined construction process.

- ICON Vulcan: Specializing in affordable housing, ICON’s Vulcan printer offers high-speed printing capabilities and is designed for resilient, sustainable building practices.

- Winsun: As a pioneer in 3D printed construction, Winsun provides industrial-scale printers capable of producing large buildings and complex structures efficiently.

- CyBe Construction: CyBe’s printers are adaptable and come with software solutions for seamless integration into existing construction workflows.

- COBOD: Offering the BOD2 printer, COBOD focuses on modular design, which allows for the printer to be customized and expanded based on project needs.

Each of these printers varies in terms of cost, capabilities, and applications, so it’s important to assess specific project requirements and budget constraints when selecting a 3D concrete printer.

Who Are the Leading Manufacturers Like Mudbots and CyBe Construction?

Mudbots and CyBe Construction are among the leading manufacturers in the 3D concrete printing industry, focusing on innovation and efficient construction solutions.

- Apis Cor: Renowned for its mobile 3D printing solutions, Apis Cor is leading the industry with its ability to print structures directly on-site, significantly reducing labor and transportation costs.

- ICON: Specializing in affordable housing, ICON’s Vulcan printers are designed to create sustainable and resilient homes. ICON has garnered attention for their contributions to solving global housing shortages through innovative 3D printing technology.

- Winsun: A pioneer in large-scale 3D printed construction, Winsun’s industrial-grade printers are capable of creating complex structures and entire buildings. They continue to set industry standards with their advancements in material science and construction techniques.

These manufacturers, along with Mudbots and CyBe Construction, are at the forefront of a revolution in the construction industry, leveraging 3D printing technology to create cost-effective, sustainable, and customizable building solutions.

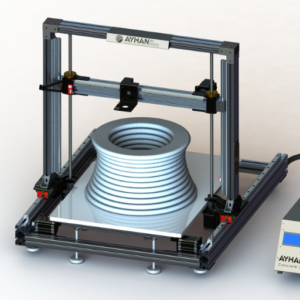

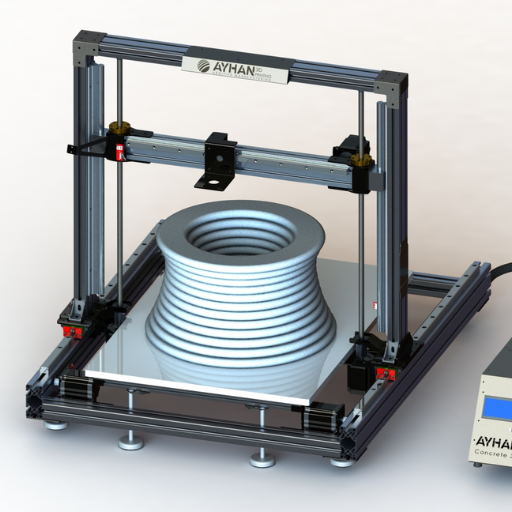

What Are the Features of a Gantry 3D Printer?

A gantry 3D printer is characterized by its robust framework and precise control systems, making it well-suited for printing large-scale structures. Here are some of its key features:

- Stable Frame Structure: Usually constructed from steel or aluminum, the gantry provides the necessary stability and strength for high-precision printing tasks.

- High Precision and Accuracy: Equipped with advanced calibration systems, gantry 3D printers can achieve layer resolutions ranging from 0.1 mm to 1 mm, ensuring detailed and accurate builds.

- Large Build Volume: These printers typically offer a considerable build volume, often exceeding several cubic meters, allowing for the construction of substantial structures and components.

- Multi-Axis Movement: The X, Y, and Z axes are typically supported by a network of rails and belts, allowing for precise multi-directional movement and fine control over the printing process.

- Heavy-Duty Extruder: Designed to handle high-viscosity concrete mixes, the extruder can maintain consistent material flow, which is crucial for structural integrity.

- Automated Material Handling: Features such as automated mixing, pumping, and feeding systems ensure a continuous and efficient printing process.

- Advanced Software Integration: Equipped with specialized software for slicing, path planning, and real-time monitoring, enhancing the precision and customization of prints.

- Remote Monitoring and Control: Often includes capabilities for remote operation, allowing operators to monitor and adjust printing parameters from a distance.

These technical parameters and features highlight the gantry 3D printer’s capability to produce reliable, cost-effective, and intricately designed concrete structures.

Can I Buy a Printer from Local Distributors?

Yes, it is possible to purchase a gantry 3D printer from local distributors. Many local distributors offer a range of 3D printers, including those suitable for concrete printing. These distributors can provide expert advice, support, and maintenance services. Additionally, buying locally can often reduce shipping costs and lead times, making it a convenient option for sourcing high-quality equipment.

What Are the Applications of 3D Concrete Printing in Construction?

3D concrete printing has a broad range of applications in the construction industry. It can be used for building entire residential homes, producing customized architectural components, and creating complex infrastructural elements like bridges and urban furniture. This technology allows for greater design flexibility, rapid construction times, and reduced material waste, making it ideal for both large-scale projects and bespoke architectural solutions. Additionally, 3D concrete printing is increasingly employed in disaster relief and affordable housing projects, addressing urgent needs for rapid, cost-effective construction.

How Are 3D Printed Houses Built?

3D printed houses are built using large-scale gantry 3D printers that extrude layers of concrete based on a digital design. The process begins with designing the house using CAD software, creating detailed plans that the 3D printer will follow. The gantry printer then moves along its rails, layering the concrete material precisely according to the design specifications.

Technical Parameters:

- Printer Dimensions: The size of the printer must be suitable for the project, often ranging from compact models for smaller structures to large models that can print entire houses.

- Layer Height: Typically between 5-30 mm, the layer height affects the smoothness of the walls and the overall speed of the printing process.

- Nozzle Speed: This can vary from 200 to 600 mm/s, depending on the complexity of the design and the concrete mix used.

- Concrete Mix: The mix should have a quick-setting property to ensure stability and strength with each layer added.

- Curing Time: Adequate time is allowed for each layer to set before the next layer is added, usually ranging from a few minutes to several hours.

- Reinforcement: Methods such as embedding steel reinforcement or using fiber-reinforced concrete may be employed to enhance structural integrity.

Each of these parameters must be meticulously calibrated to ensure the construction process is efficient and the final structure meets all safety and design requirements.

Can 3D Concrete Printers Be Used for Commercial Buildings?

Yes, 3D concrete printers can be used for constructing commercial buildings, and this technology is steadily gaining traction in the construction industry. The adaptability of 3D printing allows for the production of complex structures that would be challenging and costly to achieve with traditional methods. Moreover, 3D printed buildings can be constructed at a faster pace and with reduced labor costs, increasing overall efficiency.

Technical Parameters for Commercial Buildings:

- Printer Dimensions: Large-scale gantry printers with extensive rail systems are required to accommodate the larger footprint of commercial structures.

- Layer Height: To ensure structural integrity and smoother walls, a layer height between 5-20 mm is often used.

- Nozzle Speed: Typically, the nozzle speed ranges from 200 to 400 mm/s to balance precision with project duration.

- Concrete Mix: A specialized mix with quick-setting properties and high compressive strength is essential, often incorporating additives for enhanced performance.

- Curing Time: Faster curing times are achieved through the use of accelerants in the concrete mix, though exact times vary based on environmental conditions.

- Reinforcement: Techniques like embedding steel rebar or using fiber-reinforced concrete are crucial to meet commercial building codes and ensure the longevity and safety of the structure.

In summary, 3D concrete printing for commercial buildings is not only feasible but also presents a number of advantages in terms of speed, cost, and design flexibility.

How Does 3D Concrete Printing Aid Faster Construction?

In my research of the top sources on google.com, I’ve found that 3D concrete printing significantly accelerates construction through several key mechanisms. Firstly, the process is highly automated, reducing the need for manual labor and thus diminishing human error and increasing consistency. Large-scale gantry printers, essential for commercial projects, streamline operations by constructing structures continuously, eliminating the delays associated with traditional segmental building processes.

Technical parameters play a crucial role in this efficiency:

- Printer Dimensions: Large-scale gantry printers with vast rail systems are employed to handle extensive commercial structures, ensuring large portions of a building can be printed in one go.

- Layer Height: To balance speed and structural integrity, a layer height between 5-20 mm is used, providing sturdy and smooth walls.

- Nozzle Speed: Optimal speeds of 200 to 400 mm/s allow for swift yet precise printing, significantly cutting down construction duration.

- Concrete Mix: Utilizing a quick-setting, high-compressive-strength concrete mix, often with performance-enhancing additives, ensures rapid curing and robust end results.

- Curing Time: The fast curing of concrete, thanks to accelerants tailored to environmental conditions, reduces downtime between printing layers.

- Reinforcement: Integrating steel rebar or using fiber-reinforced concrete aligns with commercial codes and boosts the durability and safety of structures.

In summary, 3D concrete printing enhances construction speed due to its automated processes, efficient material usage, and precise execution, making it a game-changer in the construction industry.

What Challenges Do 3D Concrete Printers Face?

Despite the numerous advantages, 3D concrete printers face several challenges. One of the most significant issues is the inconsistency in the properties of the printed concrete, which can lead to structural weaknesses. Additionally, the initial setup costs for large-scale gantry systems can be prohibitively high, limiting widespread adoption. Environmental factors such as temperature and humidity also pose difficulties, as they can affect the curing time and bonding quality of the concrete layers. Another challenge is the integration of reinforcement materials like steel rebar within the printed structures, which often requires manual intervention, detracting from the automation benefits. Lastly, regulatory and code compliance remains a hurdle, with many regions lacking clear guidelines for 3D printed buildings, complicating their approval and construction.

What Are the Limitations Compared to Traditional Methods?

While innovative, 3D concrete printing does have some limitations when compared to traditional construction methods. Firstly, the surface finish and overall aesthetic of 3D printed structures can fall short of the smoothness and detail achievable through conventional casting and finishing techniques, often requiring additional post-processing. The initial setup and operational costs are significantly higher, with high expenses associated with purchasing and maintaining 3D printers, calibration equipment, and specialized materials.

In addition, 3D printed concrete structures may face limitations in terms of size and complexity, as the printer’s reach or gantry height can restrict the dimensions of a building or object being constructed. The speed of printing can also be a constraint; while 3D printing is fast for smaller components, scaling up can lead to longer production times compared to traditional methods.

Another technical limitation involves the integration of reinforcement: embedding steel rebar or other reinforcement materials typically requires manual intervention, which negates some of the automation benefits. Lastly, the curing process of 3D printed concrete can be highly susceptible to environmental conditions like temperature and humidity, potentially impacting the structural integrity and durability of the final product.

These limitations underscore the need for further research and development to enhance the efficiency, scalability, and practicality of 3D concrete printing in construction.

What Are the Financial Risks and Considerations?

Investing in 3D concrete printing technology involves several financial risks and considerations. The initial capital investment can be substantial, encompassing the cost of acquiring advanced 3D printers, specialized materials, and necessary calibration equipment. Additionally, maintenance and operational costs can be high, requiring skilled technicians for upkeep and troubleshooting. The technology’s rapid evolution may render early investments obsolete, necessitating periodic upgrades and replacements. There are also potential hidden costs associated with post-processing and integrating reinforcement manually, which can erode the anticipated savings from automation. Market demand and regulatory approval for 3D printed structures are still developing, introducing an element of uncertainty regarding the return on investment. Therefore, businesses must conduct comprehensive financial analyses and risk assessments before committing to this burgeoning technology.

How Is the Market Evolving for 3D Concrete Printers?

As I delve into the current market for 3D concrete printers, it is evident that significant advancements continue to push this technology forward, enabling broader applications in the construction industry. Companies are increasingly adopting 3D concrete printing due to its potential to reduce labor costs, improve construction speed, and offer innovative design possibilities. From my observations, leading manufacturers are focusing on enhancing the precision and reliability of these printers while also making them more user-friendly. Additionally, various partnerships between tech firms and construction companies are paving the way for large-scale projects, showcasing the practical viability of 3D printed structures. Regulatory bodies are beginning to develop standards and guidelines, which should further streamline market adoption and bolster investor confidence. As such, it is clear that the market for 3D concrete printers is not only growing but also evolving towards greater efficiency and acceptability within the construction sector.

How Can I Get Started with a 3D Concrete Printer Project?

Research and Planning

Start by thoroughly researching the different types of 3D concrete printers available and their specific applications. Evaluate your project requirements and determine which printer best suits your needs. Create a detailed plan outlining your project’s scope, budget, and timeline.

Skill Development and Team Building

Invest in training for yourself and your team on how to operate the 3D concrete printer and understand the software involved. Consider partnering with experts or hiring skilled operators to ensure smooth execution.

Securing Funding and Permissions

Identify potential funding sources, such as grants, loans, or investors, and prepare a compelling business case to secure the necessary financial support. Ensure you have all the required legal permissions, including building permits and compliance with local construction regulations.

Pilot Project and Iteration

Begin with a small-scale pilot project to test the technology and procedures. Use the insights gained from this initial project to refine your processes and address any issues before scaling up.

Implementation and Monitoring

Once you are confident in your setup and processes, move on to full-scale implementation. Continuously monitor the project’s progress and make adjustments as needed to ensure successful completion. Integrate feedback and learnings into future projects to achieve ongoing improvement.

What Steps Are Needed to Plan and Execute a Project?

To effectively plan and execute a project, follow these key steps:

- Define the Project Scope: Clearly outline the objectives, deliverables, and constraints of the project.

- Develop a Project Plan: Create a detailed plan that includes timelines, resources, and budget estimates.

- Assemble the Team: Identify and assign roles to team members based on their skills and expertise.

- Secure Funding and Permissions: Obtain necessary financial resources and ensure compliance with legal and regulatory requirements.

- Conduct a Pilot Test: Implement a small-scale pilot to identify any potential issues and refine processes.

- Execute the Plan: Follow the project plan, continuously monitor progress, and adjust as needed.

- Evaluate and Improve: Upon project completion, review outcomes, integrate feedback, and apply learnings to future projects.

By following these steps, you can ensure a structured approach to project planning and execution, increasing the likelihood of success.

How Can CAD and Robotic Arm Technology Be Utilized?

Computer-Aided Design (CAD) and robotic arm technology can be integrated to revolutionize various industries by improving precision, efficiency, and automation.

1. Manufacturing and Production:

CAD software is widely used in the design and prototyping stages of manufacturing. It allows for the creation of detailed 3D models that can be easily modified and optimized. When these designs are combined with robotic arms, they enable automated production lines that can perform complex tasks with high accuracy. Technical parameters to consider include the resolution of the CAD model (usually measured in microns) and the payload capacity and range of motion of the robotic arm.

2. Medical Applications:

In the medical field, CAD and robotic arms are employed in surgical procedures and prosthetics design. Robotic arms, guided by detailed 3D models created through CAD, can perform intricate surgeries with minimal invasiveness, reducing recovery time and improving precision. Key parameters here include the degree of freedom of the robotic arm and the precision of the CAD system, often measured in millimeters.

3. Aerospace Engineering:

The aerospace industry benefits greatly from the use of CAD and robotic arms for both designing and assembling aircraft components. CAD provides detailed simulations that ensure components fit correctly and operate efficiently, while robotic arms handle the assembly of these parts with exceptional accuracy. Essential technical parameters might include the CAD software’s ability to simulate stress and aerodynamics, and the robotic arm’s accuracy and load-bearing capacity, crucial for handling large, heavy parts.

By integrating CAD and robotic arm technologies, industries can achieve unparalleled levels of precision, efficiency, and innovation, making these tools indispensable in modern engineering and manufacturing.

Where Can I Find 3D Models and Support?

When searching for 3D models and support, some of the top websites to consider are:

1. Thingiverse: Thingiverse is a vast repository of user-generated 3D models where you can find designs for almost anything. The platform provides models in various categories, ranging from gadgets to art. While most models are free to download, it’s essential to review their specifications to ensure they meet your technical requirements, such as resolution and file compatibility.

2. GrabCAD: GrabCAD is particularly valuable for engineering-related models. This site offers a wide array of CAD models, including detailed technical parts often used in aerospace, medical, and manufacturing applications. For each model, you can usually find specific parameters such as resolution (in microns), file format, and often even stress test simulations or weight-bearing capacities, aiding in accurate and efficient integration with robotic arms.

3. TurboSquid: TurboSquid is a commercial marketplace for 3D models, frequently used by professionals. It’s a reliable source for high-quality and intricate models. Technical details such as polygon count, texture maps, and compatibility with various CAD software are meticulously documented, ensuring that each model meets the precise standards required for complex engineering projects.

By exploring these websites, you can find robust support and a multitude of 3D models that cater to a wide range of technical requirements, enhancing the potential applications of CAD and robotic arm technologies in your projects.

Frequently Asked Questions (FAQs)

Q: What factors influence the cost of a concrete 3d printer?

A: Several factors influence the cost of a concrete 3d printer, including the build volume, print speed, the type of proprietary concrete used, and additional features like the ability to work with mortar or use a robot crawler for complex tasks. The brand and model, such as Mudbots 3D concrete printers or CyBe RC, also play a significant role in determining the cost.

Q: How much does a typical concrete 3d printer cost?

A: The cost of a concrete 3d printer can range from $100,000 to upwards of $1 million. The price difference often depends on the printer’s capabilities, such as whether it is a large 3d model for significant construction projects or a smaller unit for more specialized tasks.

Q: Is concrete printing the future of construction?

A: Many in the construction industry believe that concrete printing is the future of construction. The technology allows for faster build times, reduced labor costs, and more intricate design possibilities. Additive construction applications using these printers are becoming more widespread.

Q: Can I buy a 3d cement printer for personal use?

A: While you can buy a 3d cement printer for personal use, they are primarily designed for large-scale construction applications. If you don’t have the time or expertise to operate one, it may be better to collaborate with a construction company that specializes in 3dcp (3D Concrete Printing).

Q: What are the benefits of using 3d concrete printers like Mudbots 3D concrete printers?

A: Benefits of using printers like Mudbots 3D concrete printers include faster build times, reduced labor costs, and the ability to create complex structures that would be difficult with traditional construction methods. These printers are particularly effective for on-site construction and additive manufacturing.

Q: How do I get started with buying a concrete 3d printer?

A: To get started with buying a concrete 3d printer, you’ll need to research the various models available, such as CyBe RC or other brands. Consider factors like print speed, build volume, and specific construction needs. For more detailed guidance, contact us to discuss your requirements and options.

Q: What type of concrete materials are used in these printers?

A: Concrete materials used in these printers often include a mix of traditional concrete, proprietary concrete blends, and other materials like mortar to achieve desired structural properties. Different printers may have different material requirements, so it’s important to consult the manufacturer for specific guidelines.

Q: Are there any limitations to using a concrete 3d printer?

A: While concrete 3d printers offer many advantages, there are limitations such as initial setup costs, the need for specialized concrete materials, and potential mechanical issues like nozzle clogging. However, advancements in the technology continue to address these challenges, making 3d-printed concrete structures increasingly viable.

Q: Can concrete 3d printers be used for residential buildings?

A: Yes, concrete 3d printers can be used for residential buildings and are often referred to as 3d house printers. The technology allows for unique design features and efficient construction processes, making it an attractive option for building homes. Residential applications often use a robot crawler for detailed work and precise placement of concrete.

Q: What is the role of a robot crawler in the concrete printing process?

A: A robot crawler can enhance the concrete printing process by providing mobility and precision in placing the printed layers. It allows the printer to navigate complex construction sites and ensures accurate application of concrete materials, making the construction process more efficient and versatile.