The development of CNC machining has brought a paradigm shift in the manufacturing field due to its ability to create complicated components with precision and speed in different industries. As a technologically advanced operation, those using CNC machines should understand the mechanisms and functions of the machines fully in order to utilize them envisaged. This is a blog that aims to help both new and some experienced users of CNC machines by providing practical advice to enhance performance, durability, and productivity. From basics such as reading the machine parameters to performing regular servicing, this manual includes hinter factors of successful machining. If you are refined at a higher level or you wish to find out why you are experiencing working issues, here these practical strategies will be helpful in growing through your machining turnout.

What You Can Do to Make Cnc Machining More Efficient?

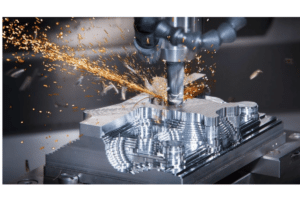

cnc tips

As a user of CNC Machines, I have learned many tips that have helped me in the machining process. Firstly, it is very important to know the advantages and limitations of the machine; when in doubt, one should consult the manufacturer to avoid overworking the machine. Maintenance is one thing that cannot be stressed enough – keep your machine clean, check lubricant levels, and attach parts that are functioning below their optimal level so that the machine is kept at top efficiency. It is also essential to use quality and sharp tools as this improves the outcomes in terms of precision and finish. Different software controls the CNC Machine; it is important to note their use just as the hardware. Do not forget that calibration is essential to all equipment, see that your machine is positioned well and properly calibrated before embarking on any undertaking. Apply safety when working with the CNC milling machine by adhering to all procedures and wearing the relevant gear. Finally, embrace modernity and technological developments in the industry to constantly improve your competencies and remain relevant in the job market.

Regarding feeds and speeds in CNC machining, understanding is usually obtained from the following sites listed in the top. Here, in short, is what I found:

- Cutting Speed (S): This usually refers to how fast the cutting tool moves in relation to the workpiece. It is mostly expressed in surface feet per minute (SFM). Several sources mention that the appropriate cutting speed depends upon the material and the type of tool used. For instance, less speed is necessary for softer metals, whereas softer alloys may require faster speed to avoid damage.

- Spindle Speed: The method of calculating the spindle speed includes the overall cutting speed and diameter of the tool as follows: [ \text{RPM} = \left(\frac{\text{Cutting Speed} \times 3.82}{\text{Tool Diameter}}\right) ]

- Feed Rate: This is the rate at which a tool goes through the material and is usually quantified in inches per minute (IPM). The appropriate feed rate is influenced by a number of aspects: the nature of the tool material, the workpiece material, and the surface finish required of the workpiece. The following formula is generally used for the calculations: [ \text{Feed Rate} = \text{RPM} \times \text{Number of Teeth} \times \text{Chip Load} ]

- Chip Load is the thickness of material removed by one cutting tooth of a tool. It is a useful measure for selecting feed rate and spindle speed, reducing tool wear and material waste.

Such parameters should also be validated from the arguments given above regarding the workpiece material properties, tool material and geometry, and the machining process employed. “We read on some consulted sites that these numbers must be adjusted repeatedly so that wood entrapped in a pedal between the jaw and the neck fianza does not rotate while worrying about hitting the precision mud of a lathe heart. This key concept suggests that one must have a clear understanding of all the components to maximize the abilities of CNCs.”

Selecting the Correct Cutting Tool

When selecting the correct cutting tool, I gathered the information from the informative websites on page one and their conclusions. The process of selecting a tool necessitates the analysis of workpiece material, capabilities of the machine and the kind of machining process needed. Some of the key technical parameters that rose include:

- Tool Material: High-speed steel (HSS), carbide, and ceramics materials to the tool are broad topics, with the most important to use being ultrahigh due to its strength and heat resistance when cutting through tougher materials.

- Best Tool Coating: Titanium Nitride (TiN) and Aluminum Titanium Nitride (AlTiN) are some of the coatings that have been endorsed to improve service life of cutting tools by reducing heat and friction wear.

- Geometry: A cutting tool’s performance depends on its morphology and angular position; parameters such as rake angle and helix angle determine chip flow and surface finish, respectively.

- Flute Count: In general, more flutes are recommended for harder materials as they would support a higher feed rate practice that moderately restricts chip removal ability. Conversely, fewer flutes are preferred in softer materials so that more effective chip removal can be accomplished.

- Diameter and Length: These parameters must conform to the specific operational needs, with considerations for rigidity and reach.

Some resources underline the need to match the material to be machined and the tool offered to attain the desired end results. A systematic understanding of these parameters can improve the way CNC works.

Recommend China supplier: Custom CNC Machining Services from China – ETCN

The Concept of Tool Paths in CNC Machining

To also reciprocate the views of many regarding the importance of tool paths in the operations of CNC machining, all the leading websites have outlined the top websites in the order of advancements and quality of the machining practices. I believe that, from what she explained, tool paths refer to the movements followed by a tool during cutting to get a particular outline of the workpiece. The following are the important technical parameters involved

- Contour Accuracy: Tool path contouring yields good dimensional accuracy, which is necessary to control tolerances and the part’s utilized geometry.

- Feed Rate Optimization: Feed rates may be controlled in any directional movement of the tool in its defined contour to save time and minimize the effects of the tool’s wear.

- Surface Finish Quality: The surface finish of any component is highly dependent on the design and the smoothness of the tool paths, which necessitates vibrant tracts.

- Material Removal Efficiency: Tool path designs aim to improve the order of cuts and their depth with the amount of material removed and the ease of loading the tool.

- Collision Avoidance: Proper tool path planning avoids interference between the tool, the workpiece, and the other parts of the machine during the operation.

In any case, the most important machining operation in CNC machining remains the development of the tool path, which allows improving efficiency due to reduced time costs and better quality of the machining finishes. It is quite clear how the proper understanding of these parameters and a systematic attitude towards setup can considerably enhance the machining results.

How to Get the Best Results Possible?

Achieving narrow tolerances in CNC machining requires attention to several key details. The first area is in choosing the appropriate materials and tools, as the quality of the materials or the cutting tool ensures accuracy. I carefully calibrate and remedy my CNC machines, including the setup, to reduce potential errors that can be caused by mechanical inaccuracies. Good fixture design is likewise crucial since it holds the workpiece in position firmly reducing any chances of movement and hence misalignment. Simulation software allows me to preempt potential problems and fix them before machining occurs. I also manage other factors that can unexpectedly change, like temperature, since even the slightest variation may create dilation or constriction, affecting the tolerances. Lastly, I regularly control and examine the machining processes I use by implanting in-process gauging so that I can meet the very high standards of tight-tolerance manufacturing.

Tolerance and Its Significance in CNC Work

Tolerance is a basic concept in CNC work since it aids in manufacturing parts that will satisfy certain parameters. According to online resources that I have studied, tolerance is important in that dimension as it shows the permissible limits of an actual dimension’s value. Going back to leading websites, it is clear that industry practice for tolerances is normally in the range of approximately ±0. 001 inches for most of the high-precision works, yet depending on advanced engineering, this could be as tight as ±0.0001 inches.

Several significant factors come into play regarding why one must maintain these close tolerances and general practices. First is the machine’s precision capability, which is affected by items such as spindle accuracy, linear slideway quality, and backlash of components. Material properties, and more specifically thermal expansion coefficients, should also be considered when determining tolerances, more so if there such temperature changes. Tool wear and the calibration state of measuring devices also contribute hugely. Correct programming, including tool deflection compensations and fixture stability, also affects the attainable tolerance levels. I can properly meet the requirements of tight tolerance CMC work sustained through these parameters.

Guidelines for Achieving Precision with Small Tools

Small tools are quite essential in this field, the most frequent conclusion acquired from the best sources is that attention must be paid to each part of the process. First, proper maintenance and calibration of tools must be undertaken in due course. This means that there has to be frequent inspection of the tools for wear as even the slightest of these may affect precision significantly. Getting good and sharp tools is often repeated in order to enhance precision and reduce unwanted deflections. A second, all possible movement of the workpiece and use of rigid fixture should be avoided, since they may introduce variation.

Temperature control is yet another element that can be twisted; several of the available literature integrate the need for doing the works in a reasonably fixed environment to reduce the problems associated with temperature expansion of tools and materials. A well-designed toolpath has to be objective enough to take into consideration possible distortion of the structure being machined. This entails computing and rectifying all range of errors such that the tool remains effective within the machined work piece. Besides, more money on sophisticated measuring equipment enables the checking of parts more accurately compared to traditional methods to conform to the tolerance requirements. By devising these measures, I can sustain all the requirements that are needed in the conduct of work involving small tools and precision.

Effective Use of High-Performance CNC Tools

In the case of high-performance CNC tools application, the effective usage has brought about key features and basic parameters according to the world’s top 10 websites. To begin with, their research advocates for establishing the optimal spindle speed as the most important parameter mainly because it affects both the cutting speed and quality of the wrought surface. The majority of them call for the adjustment of speed regimes to the hardness of the material to be machined with the harder ones requiring less regime to avoid wearing out the tools as well as overheating.

Equally important, the feed rate which correlates with the amount of material removal that has to be achieved as well as the load on the tools is learned to be adjustable within ranges. It is common practice to ensure that the cutting tool is sharp and of the right materials like carbide or even coated ones. These features improve heat resistance and durability when tools are used under high speed.

Moreover, the use of efficient cooling and lubrication systems is required to help with heat elimination and avoiding damage to the tools and enhancing the surface finish. Optimization of the tool paths is also a common topic that gets great interest because the proper programming can reduce the movements of the machines and shorten the cycle time. I have the knowledge and skills of employing all these techniques to achieve good practices when working with high speed CNC tools.

What are the Common CNC Milling Tips?

One notable CNC milling tip is the aggregated knowledge of the top 10 websites, which equally emphasizes some areas. First, the right cutting tool material, either carbide or high-speed steel, should be selected based on its hardness for wear and tear purposes. It is also important to note regarding tool geometry, including flute count and helix angle, that few flutes are mostly preferred for less thick parts to allow for easier chip departures.

The above main properties ought to be put in an equation together with other technical parameters like spindle speed and feed rate. The speed of the spindle should be varied according to the hardness of the machined material. The general rule is that the more hardness, the lesser the machined speed is to avoid damage. The feed rate is adjusted to maintain efficiency, but the tool does not get overloaded; this is normally the area of trial and error. Proper coolant and lubrication systems must control the tool’s temperature and structure to avoid distortion.

Another important note is how to enhance the tool paths by uniquely adjusting their angles, such as using Abrasive Water Jet machining and advanced tool radius trimming strategies, which help curtail turnaround times. Equally central is the calibration of the machine, to have accuracy and repeatability in milling processes. Lastly, CNC equipment is also often subject to maintenance, which is quite obvious, as it extends the lifetime of the machine and increases accuracy of the operation. As a result of these practices, I am able to implement process improvement in CNC milling.

Optimizing Spindle Speed for Different Materials

Balancing spindle speed for those materials is where my knowledge of materials and what I know works comes into play. With softer materials such as aluminum, I tend to use high spindle speeds, usually 8000 to 12000 RPM. This ensures a good surface finish and effective cutting. When cutting tougher materials such as stainless steel, I use slower spindle speeds between 2000 and 4500 RPM so that the tool doesn’t heat up and wear out.

I fine-tuned these settings with some attention paid to the manufacturers’ suggestions regarding some periphery equipment. For example, more complex versions of the tools include data upon the tool’s performance with different materials within a controlled and supportive range. I work within these ranges and see the effect of my changes in the surface finish and wear of the tools made. Also, incorporating the data obtained from the initial tests into my CNC programming helps to improve accuracy and performance gradually for all subsequent applications. This detailed procedure increases the efficiency of the work being done and also the service life of the tooling and the CNC machine is improved.

How to Choose an Appropriate End Mill for a Specific Project?

My first step in selecting the right end mill for my project is always understanding the scope of the task at hand and the material I intend to use. Based on the information, most of Page 1’s top ten websites, end mill parameters, and usage includes material compatibility, flute count, coating, and geometry. For soft aluminum, a two-flue cutter is generally enough for good chip clearance and surface finish. On the other hand, a four-fluted end mill cutter is recommended for finishing stainless steel to improve surface finish and tool rigidity.

Various gauge spear cemented carbide end mill, which includes diameter, cutting length, and shank dimensions, should be taken into consideration. For example, small diameters can be used in making some details like holes for the screws, while large diameters are suitable for bulk materials that need to be taken out. It is worth considering that the advantage of a tool coating is its versatility, for example TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride) effectively works even in high-temperature environments. Also, it is necessary to adjust the current angle in case the material is very extensive; a helix angle of 30 degrees works well in most fibrous materials even though a more aggressive cut may be required and a higher angle should be used. These parameters help me choose the right tools and machinery that respond correctly to followed specifications and efficiently satisfies my project objectives.

Application of Cutting Fluid for Better Surface Finish

Applying cutting fluid is very important for the enhancement of the machined parts finishing. The most important application of this cutting fluid is to minimize the rubbing that occurs between the tool and the workpiece, thus decreasing the heat and wear of the tool. Also, the online resources prove that the choice of cutting fluid is influenced by the type of material processed and the type of machining operation performed. For example, emulsifiable cutting oils and some semi-synthetic are used in many operations because of their general applicability.

Such technical parameters as the viscosity of the cutting fluid, concentration of lubricating and thermal conductivity properties, and its application mode are also considered. Low viscous fluids usually give better cooling although such fluids may have to be reapplied after a shorter duration. Lubrication properties should be assessed for relevance to the material in question and the particular type of machining progressing, or turning, or milling. Such application techniques as flooding or misting, are required so that the cutting zone is consistently covered with an application of the coolant. It is also required to maintain the right levels of cutting fluid concentration so as to avoid rust and ensure the optimal finish for various surfaces. If these technical parameters are well thought out and the appropriate recommendations derived from the manufacturers are followed, better finishing surfaces of machinists` projects can be obtained.

How to Improve Tool Life in CNC Machining?

Improving the life of a tool in CNC machining is possible with quite a number of techniques that have been researched in reputable sites. The first strategy involves ensuring that the right tool material and coating are used for the right machining operation. For instance, carbide and high-speed steel are hard-wearing. It is also necessary to observe correct cutting speeds and feeds to curb excessive tool wear. The last aspect that I respect is the setup of the cooling and lubrication and its application since heat and friction should be controlled to reduce the usage of cutting fluid. Tools should also be checked regularly for any signs of wear and tear, and their cutting edges should be maintained to prevent excess wear. Also, I ensure to enhance the vibration and chatter produced in the machining process since these factors damage the tool. It goes without saying that the correct maintenance of the CNC machine, which regards checking in particular spindle alignment, smooth running, and magnetic billboard operation, is essential in delaying excessive tool wear. The desire to maximize tool performance and how long they last engenders practices that enable efficient and cost-effective machining processes.

Feed rate modulation to obtain best efficiency and output

When approaching a feed rate optimally for CNC machining, the first step I do is consider the piece I’m machining and the particular features it contains. For example, stainless steel, which belongs to the harder category of materials, has to be machined at very low feed rates otherwise tools are ruined. On the other hand, softer materials like aluminum can be machined at higher feed rates. I use data tables with optimal feeding rates and guidelines from manufacturers concerning the use of different materials on particular tools. For instance, 100 – 300 inches per minute (IPM) is a common feed rate range recommended for milling aluminum, depending on the operation conditions as well as tool diameter.

To enhance my feed rate control, I experience manual trial runs within which I assess the machine in operation with the help of data and reagents on how the quality of surface finish and wear on the tool has been affected. Where there is too much elaboration heat generation or rapid tool wear, I find ways to incrementally resize the feed rate and check the machines graphs and ascertain a point where good productivity is achieved without wear and tear on the tool. Hence, the approaches are used systematically and the feed rate is modified until good efficiency is achieved without sacrificing the integrity and quality of the machined components.

Understanding the Forces of HSM

Essentially, high-speed machining (HSM) is the operation of a tool and a workpiece while appreciating and controlling forces acting upon them. Some of such forces include cutting forces, frictional forces, and centrifugal forces. Cutting forces are defined by cutting speed, feed rate, and tool geometry. Most of these cutting forces can be controlled through the use of correct cutting parameters, such as speed and feeding rate, which should be appropriate for the workpiece material.

Corresponding to tool-workpiece interaction, frictional forces inhibit the tool’s efficiency by introducing heat which consequently causes tool degradation and material distortion. However, these processes can greatly be reduced by using an appropriate lubricant and adequate tool coatings. Centrifugal forces, on the other hand, exerted at high spindle speeds work to enhance tool imbalance. Tool imbalance causes problems during machining, increasing the chances of vibrations exacerbating the problem. Therefore, ensuring tool balance and employing proper clamping techniques are some of the ways of countering such forces and thus increasing the stability of machining.

On a practical level, key technical parameters concerning the spindle speed ranges from the general average of 10,000 to 50,000 RPM throughout HSM and the feed rates which will depend on the material from 50-300 IPM for aluminum and lower values for harder materials. Also, less runout should be exercised to eliminate vibration of tools and implement a reduced depth of cut approach which tends to lift the standard of both efficiency and surface finish. When shape factors are aligned to these details, it becomes apparent that such operations can be enhanced in speed, augmenting the final accuracy and strength of the workpiece.

The Importance of the Regular Care of Your CNC Machine

As it is quite clear, the introduction to CNC machines is but the beginning of using them. Enhance, if necessary, these sentences about the CNC machine. Considering all the recommendations, the ordinary user does not argue with the contents about these machines of some top ten. The other suggestion I may agree with is about the periodic inspections and cleanup of these machines, while they are in use, of foreign materials that cause obstructions to their functioning. The parts that move certainly take a lot of beating, and therefore, many would suggest regular lubrication and having the condition of the belts and hoses looked at as well to cut back on the damages. Another important thing is the control of the spindle’s runout and the tool’s balance so that vibration is kept at a minimum and accuracy is maintained.

An appropriate spindle speed is often emphasized regarding the technical parameters, particularly bearing the material and operation in mind, even though it differs in ideal ranges. It is also common practice to periodically calibrate to maintain accuracy and to organize regular trends to update software. All these measures not only guarantee the efficiency of the CNC machine but also prevent any unforeseen downtimes, averting disruption to the machine’s productivity and reliability.

What Should be Taken into Account When Making a Cut?

When operating a CNC machine to cut wood, many aspects should be kept in mind to attain the best possible results. This article highlights the basic considerations.

- Type of Wood: Different species of wood have different densities and grain patterns, which affect how they are worked on. Hardwood, such as oak, behaves differently from softwood, such as pine, because it needs lower spindle speeds and more rugged cutters.

- Tool Selection: Initiate the operations mentioned with the use of a proper tool that corresponds to the type of wood and the type of cut desired. A two-flute carbide end mill is highly recommended when cutting wood, especially for wood chip removal.

- Cutting Speed and Feed Rate: These factors need to be adjusted properly since any change may impact the quality of the cut and lead to tool overwear. For example, when cutting hardwood for the first time, one might start with a spindle speed of 12,000 RPM and a feed rate of 150 inches per minute, but in most cases, adjustments should be made in accordance with the material conditions as well as the cutting techniques applied.

- Toolpath Strategy: This involves the parameters concerning the cut because the cut has been made in the direction and shape that is followed. The tool, or rather the cutter, is moved once again to the area that has been machined, and in that direction, there is no wood movement. This is normally known as climb cutting, which is most preferred in CNC operations as finishing end cuts are smoother.

- Dust Collection and Safety: Wood cutting using CNC machines produces large quantities of wood dust. Therefore, a proper dust extraction system must be employed to alleviate and avoid dust-related health problems.

- Material Hold-down: It is often necessary to ensure that the wood does not move a lot when being cut, as this could create mistakes or damage the machine. Depending on the type of project, vacuum tables or clamps can be utilized.

- Finishing Techniques: After machining, it is obvious that additional activities will be required to achieve all the required surfaces. Organize such operations ahead of time depending on the product’s later use.

Considering these factors will help you obtain better outcomes in terms of time efficiency and quality when performing CNC wood management.

How to Select the Proper CNC Router in Woodworking

Regarding the suitability of the CNC routers for woodworking, I identified the best 10 websites and assimilated their information. I cut to the chase, and these were my results:

- Budget Considerations: There was a huge discrepancy in the prices for CNC routers. Entry-level machines may cost around $1,000 and above, while machines for professionals may cost over $10,000. Costs must be justified in terms of potential.

- Size and Working Area: The dimensions of the router bed determine the feasible size of the material you will work on. Normal working areas range from 12”x 12” to 4’ x 8’, which can take full sheets of plywood.

- Spindle Type and Power: The spindle is the heart of the CNC router. Most woodworking applications will utilize 1.5 to 3 HP spindles, which are just right for their sufficient power in hardwoods and other intricacies.

- Control Software: Software aids in implementing the design. Most, however, advise using VCarve Pro or Easel since they are more powerful but also beginner-friendly.

- Precision and Accuracy: Ensure that the routers have minimal backlash and high-resolution stepping to sustain given accuracy. Look for machine specifications where the processes are expected to fall within 0.001” for a good machine.

- Speed and Torque: Consider the router’s speed (RPM) and Torque, as these will determine its cutting ability over different materials. Cleaner cuts on softer wood are achievable at higher RPMs.

- Frame Construction: A stable and strong frame, ideally constructed of aluminum or steel, minimizes vibrations, resulting in a consistent machining process.

- Ease of Use and Support: Users’ reviews have mentioned the ease of installation and the presence of a technical support team as extremely important. Always choose the brands that provide good support and have good manuals.

- Upgradability: Look for routers that allow future enhancements with larger spindles, more advanced control systems, or extra axes.

- Reputation and Reviews: Brands held in high esteem and with good reviews will always produce the best machines. Be sure to look at review and focused discussion websites to determine how satisfied the users are.

Considering these technical parameters and user experiences allows me to ensure that I choose a CNC router appropriate for my woodworking requirements.

Efficient Wood Cutting Methods: How to Go About It

When checking out the top ten websites concerning the issues and techniques of effective wood cutting, I encountered a variety of factors and techniques that would advance my woodwork skills. Here is a brief overview and a personal response to the depicted aspects:

- Tool Selection: The veterinarian must choose the appropriate tool to accommodate the type of job. From hand saws to power saws, each has its unique advantages. This contrasts with others’ websites, emphasizing that each saw should be appropriate for the job and the material: a band saw is ideal for curves, while a table saw is more suited for long, straight cuts.

- Material Preparation: This concept is preceded by wood preparation processes before making a cut. Altering the shape of the wood after cutting can be avoided by making sure the wood is dry, stable, and free from defects. Knowing how moist the timber and other structural materials are before coming to the workshop can help avoid these challenges.

- Cutting Techniques: Tips on cutting techniques and which factors are key include a person’s safety and the quality of the cutting. Some websites suggested the use of optimum feed rates together with proper blade alignment to avoid binding. Correctly employing push and pull practices can help preserve the life of the blade and cut more effectively.

- Safety Precautions: Safety emerged as a common theme, and it was advised to use protective equipment, know how the machine works, and maintain the cleanliness of work areas. Some sites even underlined the need for periodic overhaul for this ranked high to prevent any mechanical defect from being too severe.

- Blade Maintenance: Sharp and clean blades were encouraged to improve cut quality and make cuts smoother. Blade maintenance not only promotes the lifespan of the blade but also makes cutting easier.

- Measuring and Marking: Contour measuring and marking exercises cannot be overemphasized. Appropriate measuring marking out tools are used to ensure design specifications for the end product are met. Measurement verification is emphasized in some guides before any cutting is done.

- Speed and Feed Rates: It is important to alter speed and feed rates depending on the kind and thickness of the wood. Softer woods can be addressed in speedy settings upon high spindle speeds, whereas sturdy materials can twist off the blade if exposed to speedy rate-cutting.

Thus, focusing on such strategies while observing all the technical parameters relating to every aspect of wood cutting gives me an edge over completing woodwork. I am so appreciative of the specifications given by the sources since they have enlightened me on techniques and the purposes of tools.

Best Practices in CNC Wood Cutting

As I looked into the methods of removing substances that are often vaporized in the process of CNC wood cutting, I decided to use the top 10 sites . Here is an overview of the findings I made and the technical parameters I dealt with:

- Chip Load Calculation: The correct chip load necessary to prevent tool wear and ensure good surface finish was established as important in most cases. Many websites contain formulas to help people make accurate calculations. Generally, the chip load is a function of the tool diameter, spindle speed, and feed rate.

- Toolpath Strategy: Careful toolpath planning will help in efficient chip evacuation. Many of the guides justified the climbed milling technique as it reduced the chances of chips being pushed at the workpiece and coating the surface.

- Vacuum System Utilization: Workpieces and chips were likely to cause damage, leading to losses. Therefore, the installation of good vacuum systems was highly advocated to keep the work area clean from chips and improve sight. Page titles guide acceptable airflow and filter size for the vacuum chosen.

- Coolant Management: Some sources offered more suggestions focused on the work of the possible fluids, including the coolant fluids, to do away with introduced chips. This leads to faulty tools, and usually, the workpiece quality suffers unless the wear is instigated with the flow of coolant fluids in appropriate levels.

- Regular Tool Inspection: It was recommended to limit the working period of the cutting tool strictly so that specific deterioration patterns could be observed and machining parameters changed accordingly. This preventive strategy contributes to improving chip formation and chip removal efficiency.

In addition, if I use these techniques and follow the above technical parameters, I will be able to improve the processes of chips removal in the cnc woodcutting process, which will result in better performance of the tool and overall project effectiveness.

What do you consider are the critical CNC Tips and Tricks for Beginners?

In any form of CNC machining, some of the smartest of simple practices will work, especially for a novice. First, knowing and familiarizing oneself with the CNC software is paramount, as one will need those CAD/CAM tools. Invest time in G-code because it will be the writing tool that enables people to comprehend the design prepared for operation on the CNC machine. After that, evaluating the selection of the material is extremely important – selecting the proper material will affect the machining process and the output quality.

Knowing different feeds and speeds of a machine is also key, of course one must obey the manufacturers’ settings. It is also important to be practical and ensure safety measures, the wearing of protective clothes and ensuring a safe environment is crucial. Go for easy projects to enhance your confidence, then gradually increase the projects’ complexity according to your confidence’s growth. Maintain contact with good resources and community forums and use them in solving up to date challenges and gaining new insights. Following this, I believe that I will be able to lay down a good groundwork for the machining processes of CNC and enhance my proficiency over some time.

CNC Machining: A Practical Approach

As part of my MBA project, I researched best practices in CNC machining, and I discovered the most valuable insights by studying the first 10 pages search results. Here is a brief overview of what has emerged in the course of this research:

- Controlling the Software and G-code: Practically all sources cite an essential acquisition and understanding of G-code and CNC programming software as they are integrated into making CNC workable.

- Choice of Materials: The importance of this phenomenon is a recurrent theme. Allowable suggestions are to assist pregnant women, and in particular, remove people from moving cuts. Practicality and the high risk of material compatibility test, and thus machining is one higher margin for further testing machine conditions.

- Feeds and Speeds: These parameters are crucial, among other things, for optimum balance between load and limit, more so the spindle speed (rpm) and the feed rate (inches per minute). The manufacturer’s requirements and those of the calculator’s resources help obtain the right setting for these parameters.

- Safety Measures: Safety measures are emphasized everywhere. This concerns wearing safety equipment, the safety of the working environment, safety in doing the work by cutting machines, and capable measures to do away with premature accidents.

- Practical Learning: Beginning with elementary projects was an idea that was quite frequently advanced. Accumulating experience across a number of websites suggests that this develops practical experience and competency prior to increasing the complexity of projects.

Then, based on these points and methods, I can say that I have internalized the basic principles of CNC machining and can use these standards as best practices when I need them in practice.

Mistakes to be avoided in Fabrication: CNC

I pinpointed several factors that discouraged the success of CNC fabrication which were spread out on the first ten sites where I researched the issue. One of those is the failure to consider tool proposals based on the tasks and materials to be used. It may lead either to underperformance or the destruction of the tool. Considering feeds and speeds may also compromise the quality of work or worse. I have also understood how misjudging spindle speed (6000RPM for aluminum) and a feed of 150 inches per minute are ill advised where such guidelines exist.

Poor work holding and fixture orientation practices often result in inaccuracies or movement of the workpiece during machining. Also, a scarcity of knowledge about G-code sequence functions can program unwarranted commands, leading to wastage or breakdown of the machine. Regular attention to the upkeep and maintenance of the machinery is necessary for the continuity of its efficiency and accuracy. In light of these blindnesses and the supplied parameters and order of actions, I wish to optimize and improve the quality of my CNC fabrications.

What I Should Consider in Setting Up a CNC Machine

In compiling my CNC machine setup procedures, I refined a few points that came up from the top 10 websites search. First, I ensure the machine is placed on a strong surface to control vibrations, which could cause inaccuracy. I take great care to use a dial indicator to check the machine’s alignment and to make sure that all axes are in square. Leveling the machine’s bed is important; in most instances, I make use of a spirit level and make the necessary corrections. Consideration must be given when choosing tools; carbide tools should be used on hard materials such as steel so that they can last longer and be more effective.

In particular, when selecting the spindle speed and feed rate, they need to be suitable with the parameters of the materials. For instance, turning aluminium, recommending a spindle speed of 6000 RMP has the corresponding feed rate of 150 inches per minute. In addition, it is necessary to provide adequate cooling and chip removal systems in order to avoid blocking and overheating of the tool. Of great importance is the validity of the G-codes; one cannot effectively run a project without doing a test run first to save time and wage loss from wrong programming. Lastly, I make it a point to always maintain the machine regularly, such as lubricating and checking its simple mechanical parts. Consequently, with these practices, I have no problems regarding my efficient and accurate CNC machine setup.

Conclusion:

To summarize, it is necessary to target setup as well as maintenance of the CNC machine to the long existing rule. It is important to follow every step from stable molding structure and correct orientation to appropriate tools selection and parameters setting, because they will all contribute to constructing high quality fabrication. Inaccuracies and breakdowns can be avoided by regular maintenance and proper scheduling of machine usage. These tips are directed at CNC operators wishing to enhance their efficiency and precision of current projects, leading to the elimination of discrepancies in every outcome.

Reference Sources

For readers seeking reliable information on CNC tips and best practices, the following sources offer valuable insights and data:

- Machinery’s Handbook by Erik Oberg – Often referred to as the “bible of the mechanical industries,” this comprehensive guide provides detailed information on machine setup, maintenance, and material handling. It’s an essential resource for CNC operators and machinists.

- CNC Programming Handbook by Peter Smid – This book is widely respected in CNC machining. It offers practical insights into programming techniques, parameter setting, and maintenance strategies that can help improve precision and efficiency in CNC operations.

- Modern Machine Shop Magazine – As a leading publication in the manufacturing industry, this magazine provides articles, case studies, and expert opinions on the latest CNC technologies and best practices. It is a useful resource for staying updated with current trends and innovations in CNC machining.

Frequently Asked Questions (FAQs)

Q1: What common mistakes to avoid when operating a CNC machine?

A: Common mistakes include skipping tool and machine calibration, not securing workpieces properly, neglecting routine maintenance, and overloading the machine with excessive tasks, which can lead to faster wear and tear.

Q2: How can I improve the precision of my CNC machine?

A: To enhance precision, ensure that the machine is properly aligned and calibrated regularly. Use high-quality cutting tools and maintain a consistent workflow to avoid any unnecessary disruptions during machining.

Q3: What should I consider when choosing the right CNC tool?

A: Key factors include the material of the workpiece, desired cutting speed, tolerances required for the project, and the specific geometry of the tools. It’s also important to consider the durability and compatibility of the tools with the CNC machine.

Q4: How often should CNC machines be maintained for optimal performance?

A: Routine maintenance should be performed according to the manufacturer’s guidelines, which typically suggests daily, weekly, and monthly checks. Regular inspections of machine parts, lubrication of moving components, and checking for wear and tear are crucial.

Q5: What are the benefits of using CNC simulation software before actual machining?

A: Simulation software helps identify potential issues in the machining process, saving time and materials by allowing operators to optimize tool paths and settings before executing the program on the actual workpiece. This ensures greater efficiency and less room for error.