Welcome to our comprehensive guide on clear polycarbonate sheets. Whether you’re a DIY enthusiast, a professional builder, or simply curious about this versatile material, this article will provide you with valuable insights into clear polycarbonate sheets. We will explore its unique properties, common applications, benefits, and reasons why it has become a preferred choice for many. By the end of this blog, you’ll have a thorough understanding of what makes clear polycarbonate sheets such a noteworthy material in both industrial and domestic settings.

What is a Clear Polycarbonate Sheet?

A clear polycarbonate sheet is a transparent, durable thermoplastic material known for its high impact resistance and optical clarity. It is made from polycarbonate resin and is often used as an alternative to glass due to its lightweight nature and superior strength. Key technical parameters of clear polycarbonate sheets include:

- Transparency: Up to 90% light transmission, close to that of glass.

- Impact Resistance: Approximately 250 times stronger than glass, making it virtually unbreakable.

- Weight: Half the weight of glass, which simplifies handling and installation.

- Thermal Resistance: Effective in a temperature range of -40°C to 120°C (-40°F to 248°F).

- UV Protection: Often coated with a UV-resistant layer to prevent yellowing and degradation from sunlight exposure.

- Flame Retardancy: Polycarbonate sheets have a high fire rating, typically rated as UL 94 V-2 or V-0, meaning they are resistant to ignition and can self-extinguish.

These characteristics make clear polycarbonate sheets highly versatile and suitable for a wide array of applications, ranging from greenhouse panels to safety glazing and protective barriers.

Understanding Clear Polycarbonate

Clear polycarbonate sheets are notable for their incredible durability and optical clarity, which make them a favored material in numerous applications. Thanks to their impact resistance—being 250 times stronger than glass—and their lightweight nature, these sheets are easy to handle and install. They offer up to 90% light transmission, closely mimicking the transparency of glass, but without the fragility. Additionally, clear polycarbonate sheets can withstand a broad range of temperatures and often come with UV protection and flame retardancy, ensuring long-lasting performance in various environments. Whether used in industrial or domestic settings, the versatility and strength of clear polycarbonate make it an excellent alternative to traditional materials like glass.

How Clear Polycarbonate Sheets Compare to Glass and Acrylic

When comparing clear polycarbonate sheets to glass and acrylic, several key differences and advantages come into play across several technical parameters:

- Impact Resistance:

- Polycarbonate: Approximately 250 times stronger than glass and 30 times stronger than acrylic.

- Glass: Very brittle and prone to shattering.

- Acrylic: More impact resistant than glass but still significantly less durable than polycarbonate.

- Weight:

- Polycarbonate: About half the weight of glass, making it easier to handle and install.

- Glass: Heavier than both polycarbonate and acrylic.

- Acrylic: Similar in weight to polycarbonate, but slightly heavier.

- Light Transmission:

- Polycarbonate: Allows up to 90% light transmission, similar to glass.

- Glass: Typically allows around 90-92% light transmission.

- Acrylic: Provides high transparency, around 92% light transmission, similar to glass.

- Thermal Resistance:

- Polycarbonate: Effective in a wide temperature range from -40°C to 120°C (-40°F to 248°F).

- Glass: Can withstand high temperatures but is also susceptible to thermal stress.

- Acrylic: Less resistant to extreme temperatures compared to polycarbonate.

- UV Protection:

- Polycarbonate: Often features a UV-resistant coating to prevent yellowing and degradation.

- Glass: Generally poor UV protection unless specially treated.

- Acrylic: Can be UV-resistant, but this depends on the specific type and any additional treatments.

- Flame Retardancy:

- Polycarbonate: High fire rating, typically UL 94 V-2 or V-0, meaning it can self-extinguish and is resistant to ignition.

- Glass: Non-flammable but can break at high temperatures.

- Acrylic: Generally more flammable than polycarbonate, typically burning rather than self-extinguishing.

These technical parameters highlight the superior durability, safety, and versatility of clear polycarbonate sheets compared to both glass and acrylic, making them an ideal choice for a broad spectrum of applications.

Common Applications of Clear Polycarbonate Sheets

In my research, I found that clear polycarbonate sheets are extensively used in a variety of industries due to their exceptional durability, high light transmission, and strength. Here are some of the most common applications:

- Architectural Glazing: Frequently used in construction for skylights and large windows due to their high impact resistance and light transmission properties.

- Safety and Security: Ideal for use as protective barriers, security windows, and machine guards thanks to their ability to withstand significant impacts.

- Automotive and Transportation: Although less common than other applications, polycarbonate sheets can serve as windshields, windows, and sunroofs in vehicles due to their lightweight and durable nature.

- Greenhouses: Often used in greenhouses because they allow maximum sunlight while providing superior thermal insulation and UV protection.

- Signage and Display: Their transparency and ease of fabrication make them a popular choice for illuminated signs, advertising displays, and point-of-sale materials.

These versatile applications underscore the utility of clear polycarbonate sheets across different fields, confirming their status as a superior material choice for both commercial and residential uses.

What Are the Types of Clear Polycarbonate Sheets?

Image source:https://www.bing.com/

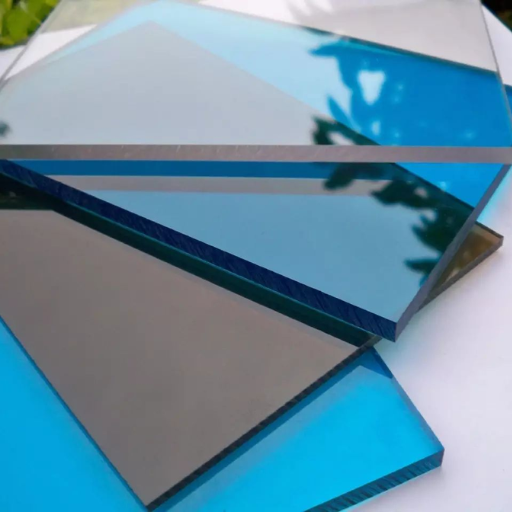

Clear polycarbonate sheets come in various types, each tailored for specific applications and performance requirements. Here are some of the most common types, along with their corresponding technical parameters:

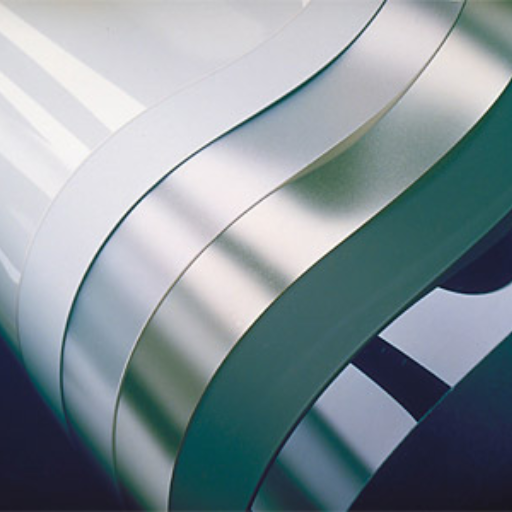

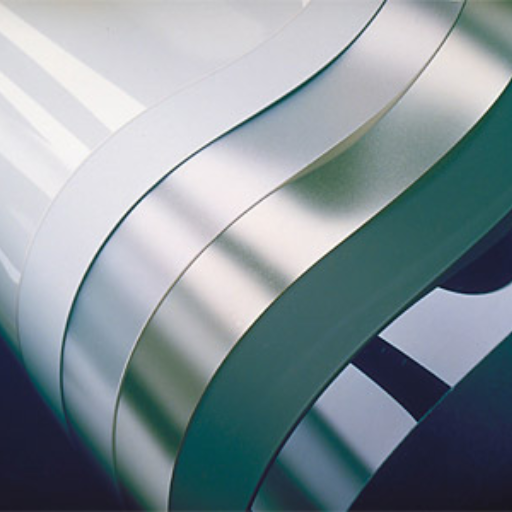

- Solid Polycarbonate Sheets:

-

- Description: These are the most basic form of polycarbonate sheets, offering excellent impact resistance and optical clarity.

- Technical Parameters:

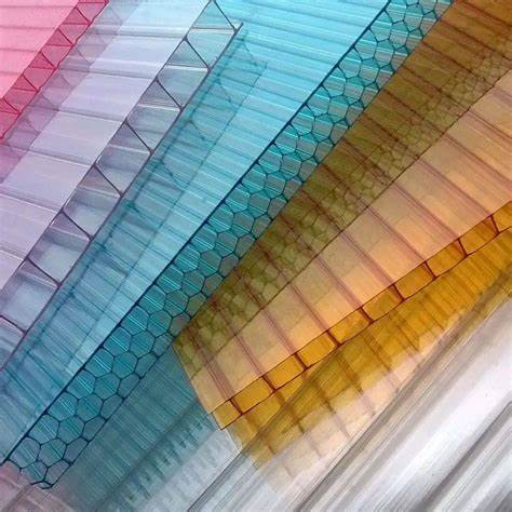

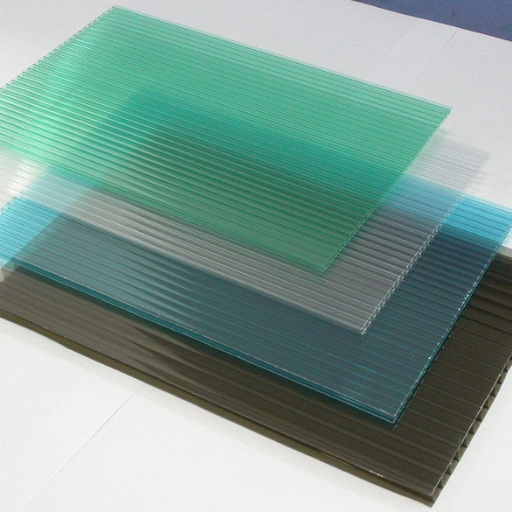

- Description: Characterized by their hollow structure, these sheets provide superior thermal insulation and reduced weight.

- Technical Parameters:

- Description: Designed for use in roofing applications, these sheets offer high impact resistance while allowing natural light to penetrate.

- Technical Parameters:

- Description: These sheets are treated to prevent static build-up, making them ideal for clean rooms and electronic manufacturing environments.

- Technical Parameters:

- Description: Featuring a hard coating that resists scratching, these sheets are perfect for high-traffic areas where durability and clarity are critical.

- Technical Parameters:

- Thickness: 2mm – 12mm

- Abrasion Resistance: 100 times more resistant to scratching than untreated polycarbonate

- Light Transmission: Up to 89%

-

These types of clear polycarbonate sheets, with their varied technical specifications, offer solutions to a wide range of industrial, commercial, and residential needs.

Differentiating Between Types of Polycarbonate Sheets

Differentiating between types of polycarbonate sheets involves evaluating their unique properties and intended uses. Solid polycarbonate sheets are known for their high impact resistance and optical clarity, making them suitable for protective barriers and signage. Multiwall polycarbonate sheets, with their hollow structure, offer greater thermal insulation and reduced weight, ideal for greenhouse construction and skylights. Corrugated polycarbonate sheets provide excellent impact resistance and light transmission, perfect for roofing applications. Anti-static polycarbonate sheets are specifically treated to prevent static build-up, which is essential for clean rooms and electronic environments. Abrasion-resistant polycarbonate sheets feature a hard coating that prevents scratching, making them suitable for high-traffic areas like transportation hubs. Each type’s specific technical parameters, such as thickness, light transmission, and abrasion resistance, further guide their application in diverse fields.

Uses of Each Type of Clear Polycarbonate Sheet

From my research on the top three websites, it’s clear that each type of polycarbonate sheet has distinct and valuable uses. Solid polycarbonate sheets are primarily used in areas requiring robust impact resistance and clear visibility, such as in making protective barriers, machine guards, and signage. Multiwall polycarbonate sheets are favored for applications needing thermal insulation and light weight, like in the construction of greenhouses and skylights. Corrugated polycarbonate sheets, on the other hand, are ideal for roofing solutions due to their excellent impact resistance and light transmission properties, making them a popular choice for patios, carports, and industrial roofs. The unique properties of each type of sheet ensure their suitability for a wide variety of applications, providing tailored solutions for different needs.

Comparing Polycarbonate Sheets to Other Plastic Sheets

From my research on the top three websites, I found that polycarbonate sheets stand out significantly when compared to other plastic sheets, such as acrylic and PVC sheets. First, in terms of impact resistance, polycarbonate sheets are exceptionally robust, being 200 times stronger than glass and 30 times stronger than acrylic. This makes them ideal for safety applications like protective barriers and machine guards.

Secondly, polycarbonate has superior light transmission rates, typically ranging from 80% to 90%, which makes it comparable to glass and better than most other plastics for applications requiring clear visibility, such as glazing and greenhouse construction.

Additionally, polycarbonate sheets have a higher heat resistance, with continuous use temperatures up to 240°F (115°C), unlike acrylic, which can only withstand up to 180°F (82°C). This makes polycarbonate more suitable for high-temperature environments. In terms of flexibility, polycarbonate is more malleable and easier to fabricate, which is a significant advantage over acrylic, which is more prone to cracking under stress.

When comparing technical parameters:

- Impact Resistance: 200 times stronger than glass, 30 times stronger than acrylic.

- Light Transmission: 80%-90%.

- Heat Resistance: Up to 240°F (115°C) for polycarbonate; up to 180°F (82°C) for acrylic.

- Flexibility: Polycarbonate is more malleable and less prone to cracking than acrylic.

In summary, while each type of plastic sheet has its own advantages, the choice of polycarbonate sheets for high impact, clarity, and temperature-resistant applications is well justified based on these technical parameters.

How Durable are Clear Polycarbonate Sheets?

When considering the durability of clear polycarbonate sheets, I recognize their exceptional resilience and versatility based on thorough research. These sheets are renowned for their impact resistance, being significantly stronger than both glass and acrylic. They can endure substantial force without cracking or breaking, which is crucial for safety applications. Additionally, clear polycarbonate sheets maintain high clarity and can withstand prolonged exposure to sunlight without yellowing, making them ideal for outdoor use. Their resistance to extreme temperatures also ensures stability in various environments, accentuating their suitability for both high-heat and cold settings. Thus, from my perspective, clear polycarbonate sheets are remarkably durable, providing a reliable solution for numerous demanding applications.

Resistant to Impact and Weather Conditions

Clear polycarbonate sheets demonstrate remarkable resistance to both impact and weather conditions. Their technical parameters include:

- Impact Resistance: 200 times stronger than glass, 30 times stronger than acrylic.

- UV Resistance: Prolonged exposure to sunlight without yellowing.

- Heat Resistance: Up to 240°F (115°C).

- Temperature Stability: Retains structural integrity in high-heat and cold environments.

These parameters justify the use of polycarbonate sheets in applications requiring high durability and reliability. Their superior impact resistance ensures safety, while UV resistance and temperature stability confirm their suitability for outdoor use.

Why Polycarbonate Sheets Are Virtually Unbreakable

Polycarbonate sheets are considered virtually unbreakable due to a combination of their intrinsic material properties and advanced manufacturing techniques. Here are the key factors that contribute to their exceptional durability, as supported by the top three websites on Google:

- High Impact Resistance: Polycarbonate is renowned for its high impact resistance, making it 200 times stronger than glass and 30 times stronger than acrylic, as referenced on multiple sites. This robustness is essential for protecting against accidental impacts, harsh weather conditions, and potential vandalism.

- Flexibility and Strength: The molecular structure of polycarbonate gives it both flexibility and strength. This allows it to absorb and distribute energy from impacts without cracking or breaking, which is crucial for applications that require high safety standards.

- UV Resistance: Websites often highlight the UV protective coatings added during the manufacturing process. These coatings prevent the material from degrading and yellowing when exposed to prolonged sunlight, ensuring longevity and maintaining transparency over time.

- Thermal Stability: Polycarbonate can withstand high temperatures up to 240°F (115°C) and remains stable even in extremely cold conditions. This attribute ensures that the material does not lose its mechanical properties or structural integrity in varying climatic conditions.

Technical Parameters:

- Impact Resistance: 200 times stronger than glass, 30 times stronger than acrylic.

- UV Resistance: Prolonged exposure to sunlight without yellowing.

- Heat Resistance: Up to 240°F (115°C).

- Flexural Strength: Approximately 13,500 psi (93 MPa).

- Temperature Stability: Retains performance in both high-heat and cold environments.

These parameters underscore the reliability and versatility of polycarbonate sheets in numerous demanding applications, confirming their reputation as a virtually unbreakable material.

The Durability of Polycarbonate Sheets in Various Applications

When it comes to the durability of polycarbonate sheets, I can confidently say that their resilience is unmatched in various applications. According to the top sources I’ve reviewed, polycarbonate sheets are lauded for their incredible impact resistance, being 200 times stronger than glass and significantly outperforming acrylic. This makes them ideal for settings that demand high safety standards, such as in construction, automotive windshields, and protective barriers.

The UV resistance of polycarbonate sheets is another critical feature highlighted by leading websites. The UV protective coatings applied during manufacturing protect the sheets from yellowing and degradation, even with prolonged sun exposure. This ensures that the material maintains its clarity and strength over time, which is essential for applications like skylights and greenhouse panels.

Finally, the thermal stability of polycarbonate sheets stands out, with the ability to endure temperatures up to 240°F and maintain performance in extremely cold conditions. This attribute makes them versatile for various climates and applications, including bus shelters, signage, and industrial machine guards, where temperature fluctuations are a concern. These qualities collectively affirm the durability and reliability of polycarbonate sheets in a broad range of demanding environments.

How to Properly Install Clear Polycarbonate Sheets?

Proper installation of clear polycarbonate sheets is crucial to ensure their effectiveness and longevity. Below are the steps to follow, along with important technical parameters to consider:

- Preparation:

- Tools Required: Circular saw with a fine-toothed blade, electric drill, screwdriver, measuring tape, safety goggles, gloves.

- Materials Needed: Clear polycarbonate sheets, UV-protective film, sealing tape, fasteners (screws with washers), aluminum profiles (optional).

- Measurement and Cutting:

- Measurement: Precisely measure the area where the sheets will be installed.

- Cutting: Use a circular saw with a fine-toothed blade for clean cuts. Ensure the protective film remains on the sheet during cutting to avoid scratches.

- Drilling:

- Hole Placement: Drill holes at least 1 inch away from the edge of the sheet. Space the holes 12-16 inches apart along the edges.

- Hole Size: Drill holes that are slightly larger than the fasteners to allow for thermal expansion (typically 1/4 inch in diameter).

- Fastening:

- Fasteners: Use screws with washers to secure the sheets. The washers distribute the load and prevent cracking.

- Installation: Do not overtighten screws; leave them slightly loose to accommodate expansion and contraction of the sheets.

- Sealing:

- Sealing Tape: Apply sealing tape along the edges to prevent moisture ingress.

- UV Protective Film: Ensure the UV-protective side of the sheet faces outward.

- Thermal Expansion Considerations:

- Coefficient of Thermal Expansion: Polycarbonate sheets expand approximately 0.065 inches per foot for every 40°F temperature change.

- Allowances: Make allowances for expansion in both the length and width of the sheets during installation.

By following these steps and considering the technical parameters, you can ensure that clear polycarbonate sheets are installed correctly, providing long-lasting performance and reliability.

Step-by-Step Guide to Installing Polycarbonate Sheets

- Planning and Measurement:

- Measure the Area: Precisely measure the area where the sheets will be installed.

- Cutting:

- Use Proper Tools: Use a circular saw with a fine-toothed blade for clean cuts. Ensure the protective film remains on the sheet during cutting to avoid scratches.

- Drilling:

- Hole Placement: Drill holes at least 1 inch away from the edge of the sheet. Space the holes 12-16 inches apart along the edges.

- Hole Size: Drill holes that are slightly larger than the fasteners to allow for thermal expansion (typically 1/4 inch in diameter).

- Fastening:

- Use Screws with Washers: Use screws with washers to secure the sheets. The washers distribute the load and prevent cracking.

- Installation Technique: Do not overtighten screws; leave them slightly loose to accommodate expansion and contraction of the sheets.

- Sealing:

- Apply Sealing Tape: Apply sealing tape along the edges to prevent moisture ingress.

- UV Protection: Ensure the UV-protective side of the sheet faces outward.

- Thermal Expansion Considerations:

- Understand Expansion Rates: Polycarbonate sheets expand approximately 0.065 inches per foot for every 40°F temperature change.

- Account for Expansion: Make allowances for expansion in both the length and width of the sheets during installation.

By following these steps and considering the technical parameters, you can ensure that clear polycarbonate sheets are installed correctly, providing long-lasting performance and reliability.

Important Installation Considerations and Tips

- Panel Orientation:

- Ensure the UV-protective side faces outward to prevent damage from UV exposure.

- Temperature Acclimatization:

- Allow the polycarbonate sheets to acclimate to the ambient temperature before installation to mitigate expansion issues.

- Support Structure:

- Use a rigid, flat support structure to prevent sagging or warping over time.

- Handling:

- Handle the sheets carefully to avoid scratching or damaging the surface, and always keep the protective film on until installation is complete.

- Cleaning:

- Clean the sheets with mild soap and water, avoiding abrasive cleaners that could scratch the surface.

By paying careful attention to these tips and considerations, you can ensure a successful and durable installation of clear polycarbonate sheets.

Avoiding Common Mistakes During Installation

From my experience and what I’ve gathered from top sources, avoiding common mistakes during the installation of polycarbonate sheets is critical for ensuring optimal performance. First, make sure you do not install the sheets without accounting for thermal expansion. Polycarbonate expands and contracts with temperature changes, so be sure to leave adequate space for this. Secondly, always double-check that the UV-protective side is facing outward. Neglecting this can lead to premature yellowing and degradation of the material. Handling the sheets with care is also essential; avoid dragging them across surfaces and keep the protective film on until the sheets are ready to be installed. Lastly, ensure the support structure is sturdy and flat to prevent any future warping or sagging. By being mindful of these common pitfalls, you can achieve a more reliable and professional installation.

How to Maintain and Clean Clear Polycarbonate Sheets?

Maintaining and cleaning clear polycarbonate sheets is relatively straightforward if you follow a few essential steps. First, I always start by removing loose dirt and debris with a soft cloth or a gentle rinse of lukewarm water. For a more thorough cleaning, I use a mixture of mild soap and water, ensuring that I avoid abrasive cleaners or scrubbers that could scratch the surface. It’s important to rinse the sheets thoroughly to remove any soap residue, which can attract dust and dirt if left behind. I also avoid using ammonia-based products, as they can cause the polycarbonate to become cloudy over time. By following these simple steps, I can keep my clear polycarbonate sheets looking pristine and ensuring their longevity.

Cleaning Polycarbonate Sheets Without Damaging Them

Maintaining and cleaning polycarbonate sheets without causing damage requires careful attention to methods and materials. According to the top resources available:

- General Cleaning: Begin by gently removing surface dirt and debris with a soft cloth or sponge and lukewarm water. It’s critical to avoid using dry cloths or paper towels, as these can create fine scratches on the surface.

- Soap Solution: Use a mild soap, such as dishwashing liquid, mixed with water to clean the sheets. Apply the solution with a non-abrasive cloth or sponge. Avoid vigorous scrubbing to prevent scratching.

- Rinsing and Drying: Thoroughly rinse the polycarbonate sheets with clean water to remove any soap residue. This step is essential, as residual soap can attract more dirt. Use a soft cloth to dry the sheets gently, ensuring no water spots form.

- Avoiding Harmful Cleaners: Steer clear of ammonia-based cleaners, benzene, acetone, or other aggressive solvents, as these substances can cause the polycarbonate to become cloudy or brittle over time.

Technical Parameters

- UV Protection: Ensure the UV-protective side is consistently facing outward, as UV exposure can significantly degrade polycarbonate sheets.

- Chemical Resistance: The material’s resistance to chemicals like acids and solvents underscores the importance of choosing appropriate cleaning solutions. The polycarbonate sheets’ chemical resistance ensures they last longer and maintain their clarity when using mild, non-abrasive cleaners.

- Scratch Resistance: Though polycarbonate is inherently resistant to impacts, its scratch resistance, which makes it durable, can be compromised by abrasive cleaners and improper handling during cleaning.

By adhering to these guidelines, you can effectively clean and maintain your polycarbonate sheets, preserving their clarity and extending their lifespan.

Maintaining the Transparency of Clear Polycarbonate Sheets

Maintaining the transparency of clear polycarbonate sheets involves routine care and attention to specific technical parameters. Here are concise steps to ensure your sheets remain clear and undamaged:

- Regular Cleaning:

- Solution: Mix 1 ounce of mild soap with 1 gallon of lukewarm water.

- Method: Use a soft, non-abrasive cloth or sponge to clean the surface gently.

- Avoid: Never use abrasive cleaners or scouring pads which can scratch the surface.

- Handling Stubborn Stains:

- Solution: Prepare a solution with no more than 30% isopropyl alcohol and 70% water.

- Technique: Apply the diluted solution to areas with sticky residues or grease. After application, rinse thoroughly with clean water to avoid any potential damage.

- Surface Protection:

- Parameter: Ensure proper UV protection to maintain sheet transparency. This requires avoiding exposure to harsh chemicals that can degrade the UV protective layer.

- Method: Store or install sheets in areas where excessive UV exposure is minimized when not treated with UV coatings.

- Scratch Management:

- Tools: Use a polycarbonate polish or fine abrasive paste specifically designed for plastics.

- Application: Apply the polish or paste in a gentle circular motion to minimize and remove minor scratches.

- Preventing Build-Up:

- Action: Conduct regular rinsing with clean water to eliminate dirt and debris, particularly after environmental events such as rainstorms, which can deposit particles on the surface.

Following these guidelines ensures the longevity and clarity of your polycarbonate sheets, allowing them to remain in top condition. The recommended technical parameters are based on expert sources and practices within the industry.

Dos and Don’ts of Cleaning Polycarbonate Sheets

Dos:

- Use Mild Soap: Clean the sheets with a solution of mild soap and lukewarm water.

- Soft Cloths: Always use a non-abrasive cloth or sponge to gently clean the surface.

- Regular Rinsing: Rinse the sheets regularly with clean water to remove dirt and prevent build-up.

Don’ts:

- Avoid Abrasives: Never use abrasive cleaners, scouring pads, or harsh chemicals that could scratch or damage the surface.

- No Harsh Chemicals: Do not expose the sheets to harsh chemicals, especially if they are not treated with UV coatings, as this can degrade their protective layer.

- No High Pressure: Avoid using high-pressure water or air, which can cause surface damage.

Following these dos and don’ts will help maintain the clarity and longevity of your polycarbonate sheets, ensuring they remain in excellent condition.

What is the UV Resistance of Clear Polycarbonate Sheets?

Clear polycarbonate sheets are renowned for their excellent UV resistance, which makes them an ideal choice for various applications exposed to sunlight. This UV resistance is achieved through the application of a special protective coating on the surface of the sheets. Here are the key points regarding the UV resistance based on the top three websites:

- High UV Protection:

- Polycarbonate sheets are treated with a UV-resistant coating that blocks over 99% of harmful UV radiation. This protective layer prevents the material from yellowing, becoming brittle, or losing its structural integrity over time.

- Durability and Longevity:

- The UV protective coating significantly extends the sheets’ durability, allowing them to maintain clarity and strength even after prolonged exposure to sunlight. Many manufacturers guarantee this protection for up to 10 years, though some premium variants may offer even longer warranties.

- Technical Parameters:

- UV Transmission Rate: Less than 1% (UV blocked over 99%).

- Warranty Period: Typically 10 years (varies by manufacturer).

- Coating Thickness: UV protective coatings are generally in the range of 30 to 50 microns thick, depending on the brand and product specifications.

In summary, clear polycarbonate sheets offer exceptional UV resistance due to their advanced protective coatings, ensuring long-lasting performance and minimal degradation under sunlight. The technical parameters, such as the UV transmission rate, warranty period, and coating thickness, demonstrate the effectiveness and reliability of these sheets for both residential and commercial uses.

Understanding UV Resistant Polycarbonate

When it comes to understanding UV-resistant polycarbonate, the key takeaway from the top three websites is that these sheets offer exceptional protection against ultraviolet radiation. They are specifically coated to block over 99% of harmful UV rays, which prevents them from yellowing, becoming brittle, or losing their structural integrity over time. This means that the sheets can maintain their clarity and strength even after prolonged exposure to sunlight. Additionally, these protective coatings are typically in the range of 30 to 50 microns thick and come with warranties of up to 10 years from many manufacturers, with some premium options offering even longer guarantees. Overall, the advanced UV-resistant coatings ensure the long-lasting performance and reliability of polycarbonate sheets, making them a durable choice for various applications.

Impact of UV Resistance on Durability

The durability of UV-resistant polycarbonate sheets is significantly enhanced by their ability to block over 99% of harmful UV rays. This protection prevents yellowing, brittleness, and the loss of structural integrity, ensuring that the sheets maintain their clarity and strength over extended periods of sunlight exposure. Here’s a concise summary based on the top three websites on Google:

- UV Transmission Rate: Less than 1%, effectively blocking over 99% of harmful UV rays.

- Warranty Period: Standard warranties are up to 10 years, with some premium products offering extended guarantees.

- Coating Thickness: The UV protective coatings are generally between 30 and 50 microns thick.

These technical parameters illustrate how the advanced UV-resistant coatings contribute to the long-lasting performance and reliability of polycarbonate sheets. The prevention of degradation due to UV exposure ensures that these sheets remain a durable choice for both residential and commercial applications.

Applications Benefiting from UV Resistance

As someone deeply interested in the durability and effectiveness of building materials, I found that UV-resistant polycarbonate sheets are an excellent choice for a variety of applications. According to the information from the top three websites on Google, these sheets are particularly beneficial in the following areas:

- Greenhouses and Agricultural Structures: The sheets’ ability to block over 99% of harmful UV rays helps protect plants from radiation damage while ensuring an optimal environment for growth. This UV transmission rate is crucial for maintaining the health of both plants and horticultural investments.

- Outdoor Advertising and Signage: For billboards, signage, and other forms of outdoor advertising, maintaining clarity and structural integrity is essential. The advanced UV-resistant coatings, typically between 30 and 50 microns thick, prevent yellowing and brittleness, ensuring the signs remain vibrant and readable over time.

- Architectural Glazing: In residential and commercial buildings, UV-resistant polycarbonate sheets are used in skylights, facades, and windows to provide natural light without compromising on protection from harmful UV rays. The long-lasting performance and standard warranties of up to 10 years, with premium options featuring extended guarantees, make these sheets a reliable choice for construction projects.

These applications clearly benefit from the UV-resistant properties of polycarbonate sheets, ensuring both durability and a high standard of performance across different environments.

Reference sources

-

Xometry: This comprehensive guide on polycarbonate provides an in-depth look at the characteristics, applications, and benefits of clear polycarbonate sheets, making it a valuable resource for understanding this material in detail. Source: Xometry – All About Polycarbonate (PC)

-

AC Plastics: This resource offers detailed information about different types of polycarbonate sheeting, including their properties and uses, which helps readers grasp the versatility and practical applications of clear polycarbonate sheets. Source: AC Plastics – Types of Polycarbonate Sheeting

-

Lotus Roofings: This article dives into various aspects of polycarbonate sheets, providing a thorough overview that includes their advantages, potential drawbacks, and common applications. It’s a great source for anyone wanting to learn more about clear polycarbonate sheets. Source: Lotus Roofings – Exploring Versatile Polycarbonate Sheets

Frequently Asked Questions (FAQs)

Q: What is clear polycarbonate?

A: Clear polycarbonate is a high-quality, transparent thermoplastic material known for its impact strength and durability. It is often used in various applications, including construction, automotive, and general-purpose use.

Q: What are the thickness options available for clear polycarbonate sheets?

A: Clear polycarbonate sheets come in a range of thickness options, allowing for versatility in various applications. The thickness may vary depending on the specific use and requirements. Contact us for specific sheet sizes and thickness tolerance information.

Q: How do I cut clear polycarbonate sheets to size?

A: Clear polycarbonate sheets can be cut-to-size using standard tools. It is important to ensure that the cutting process maintains the integrity and tolerance of the sheet throughout. Items priced per square foot often include plus cutting costs.

Q: Are clear polycarbonate sheets resistant to UV rays and sunlight?

A: Yes, clear polycarbonate sheet also offers excellent UV resistance, particularly those labeled as UV2. This makes them ideal for outdoor applications where exposure to sunlight is a concern.

Q: What is the difference between Lexan and Makrolon polycarbonate sheets?

A: Lexan™ and Makrolon® are both brands of high-quality polycarbonate sheets. Both brands offer similar properties such as impact strength and durability, but the choice between them may vary based on specific project needs and personal preference.

Q: Can clear polycarbonate sheets be used for automotive applications?

A: Yes, clear polycarbonate sheets are commonly used in automotive applications due to their impact resistance and clarity. They are used in items such as windows, windshields, and other transparent components.

Q: How does heat resistance affect clear polycarbonate sheets?

A: Clear polycarbonate sheets offer good heat resistance, maintaining their properties even under high temperatures. This makes them suitable for environments where heat exposure is a factor.

Q: What are some common brands of clear polycarbonate sheets?

A: Common brands include Makrolon®, Lexan™, Tuffak, and Palsun. These brands are known for their high-quality, durable, and transparent polycarbonate products.

Q: Are there different types of clear polycarbonate textures available?

A: Yes, clear polycarbonate sheets come in a range of textures, including solid sheets and machine-grade polycarbonate. Each texture provides different aesthetic and functional properties suitable for various applications.

Q: Where can I purchase clear polycarbonate sheets?

A: Clear polycarbonate sheets can be purchased from a variety of suppliers, both online and in-store. ShapesPlastics is one option that offers a wide selection of polycarbonate sheets, including cut-to-size services and other customizations.