Brittle fracture is a critical concern in the field of materials science and structural engineering, as it can lead to sudden and catastrophic failures in metal components. Unlike ductile fracture, which involves significant deformation before failure, brittle fracture occurs with minimal distortion, often without any prior warning signals. Understanding the underlying causes of brittle fracture is essential for developing strategies to prevent such occurrences, ensuring the safety and reliability of metal structures. This article aims to delve into the various factors that contribute to brittle fracture, including material properties, environmental conditions, and mechanical stress. Additionally, we will explore effective prevention techniques and best practices that can be implemented to mitigate the risk of brittle fracture in various industrial applications. By gaining a comprehensive understanding of brittle fracture, engineers and materials scientists can make more informed decisions to design safer, more resilient structures.

What is Brittle Fracture?

Brittle fracture is a type of failure that occurs in materials without significant prior deformation. In simple terms, it is the sudden and abrupt breaking of a material, which typically happens at low temperatures and high rates of stress. This form of fracture is characterized by a rapid crack propagation, usually following a path of minimal resistance along the grains of the material. Unlike ductile fracture, which gives warning through noticeable deformation, brittle fracture offers little to no forewarning, making it particularly dangerous in structural applications. Key factors influencing brittle fracture include the material’s inherent toughness, the presence of stress concentrators like notches or fractures, and exposure to low temperatures that can embrittle the material. Understanding these variables allows for the development of methods to predict and prevent brittle fracture, thereby enhancing the safety and longevity of metallic structures.

Definition of Brittle Fracture

Brittle fracture is defined as the sudden and catastrophic failure of a material under stress that happens without any noticeable plastic deformation. It is a form of fracture that occurs when a material’s internal structure is unable to absorb enough energy to deform plastically before breaking. The key characteristics of brittle fracture include:

- Crack Initiation: Cracks often initiate at stress concentrators such as notches, flaws, or inclusions within the material.

- Rapid Crack Propagation: Once initiated, the crack propagates quickly, typically at speeds close to the speed of sound within the material.

- Low Energy Absorption: Little to no energy is absorbed during the fracture process, which contrasts significantly with ductile fracture where significant energy absorption occurs.

Key technical parameters to consider in evaluating the propensity for brittle fracture include:

- Fracture Toughness (K_IC): This parameter represents the ability of a material containing a crack to resist fracture. Materials with low fracture toughness are more susceptible to brittle fracture.

- Transition Temperature (T_r): The temperature below which a material behaves in a brittle manner. Above this temperature, the material is more likely to exhibit ductile behavior.

- Notch Sensitivity: Describes the extent to which the presence of notches or other defects can reduce the material’s toughness and lead to brittle fracture.

- Grain Size and Structure: Fine-grained structures tend to have higher toughness, whereas coarse-grained materials are more prone to brittle fracture.

Understanding these parameters and incorporating them into material selection and design processes can help mitigate the risk of brittle fracture in industrial components and structures.

Characteristics of Brittle Fracture

The key characteristics of brittle fracture include:

- No Plastic Deformation: Brittle fracture occurs without any significant plastic deformation, meaning the material breaks suddenly rather than deforming.

- Transgranular or Intergranular: The fracture can propagate through the grains (transgranular) or along the grain boundaries (intergranular) of the material.

- Clean, Bright Fracture Surface: The fracture surfaces are often smooth and bright, with a crystalline appearance, indicating little to no energy absorption.

- Flat Fracture Profile: The fracture profile is typically flat and perpendicular to the applied stress, lacking the ductile fracture’s characteristic necking or void coalescence.

- Low Energy Release: The failure happens quickly with minimal energy dissipation, leading to a sudden and often catastrophic failure of the component.

These characteristics provide insights into the mechanisms behind brittle fracture and underscore the importance of careful material selection and design to prevent such failures.

Brittle Failure in Metals

Brittle failure in metals is primarily influenced by temperature, strain rate, and material composition. Metals such as cast iron, high carbon steel, and certain alloys are more prone to brittle failure, especially at low temperatures or high strain rates. This type of failure often occurs suddenly and without any noticeable plastic deformation, as the metal structure rapidly fractures when the applied stress exceeds the critical level.

At the microscopic level, brittle fracture typically occurs through cleavage, where atomic bonds break along specific crystallographic planes. Factors contributing to brittle failure include the presence of impurities, microcracks, and other stress concentrators which can significantly lower the material’s fracture toughness. To prevent brittle failure, it is crucial to select metals with adequate fracture toughness and ductility for the intended service conditions, and to minimize stress concentrators through proper handling and manufacturing processes. Key strategies include alloying to improve toughness, heat treatments to refine grain structure, and implementing design features that reduce stress concentrations.

What Causes Brittle Fracture?

Image source:https://cn.bing.com/

Brittle fracture is caused by a combination of factors that influence the material properties and the external conditions under which the material is used.

- Temperature: Brittle fracture is more likely to occur at lower temperatures where materials generally exhibit less ductility. As temperature decreases, the ductile-to-brittle transition temperature (DBTT) becomes a critical parameter. For example, common structural steel typically has a DBTT in the range of -20°C to +20°C.

- Strain Rate: Higher strain rates can lead to brittle failure by limiting the time for plastic deformation and promoting rapid crack propagation. Materials subjected to high strain rates, such as during impact loading or explosive scenarios, are less able to redistribute stress, causing brittle fracture. Strain rates about \(10^3 \text{s}^{-1}\) greatly favor brittle behavior.

- Material Composition: The presence of certain elements and impurities in metals can significantly influence their fracture behavior. Elements like sulfur, phosphorus, or lead can act as stress concentrators, decreasing the overall toughness. In steels, carbon content is critical; higher carbon steels tend to be more brittle.

- Microstructural Factors: Internal defects such as microcracks, voids, and inclusions serve as points of stress concentration, reducing the effective fracture toughness of the material. The grain size also plays a role; finer grains usually enhance toughness while larger grains promote brittleness.

- Stress Concentrations: Sharp corners, notches, and other geometric discontinuities in a component’s design can lead to localized stress concentrations, significantly elevating the risk of brittle fracture. Addressing these through design improvements and stress-relief features is essential.

By controlling these factors through proper material selection, processing techniques, and design considerations, the incidence of brittle fracture can be minimized.

Factors Contributing to Brittle Fracture

Several key factors contribute to the phenomenon of brittle fracture, which occurs without significant plastic deformation and with the rapid propagation of cracks. These factors include:

- Temperature: Low temperatures reduce the ductility and toughness of materials, making them more susceptible to brittle failures. The ductile-to-brittle transition temperature (DBTT) is a critical threshold below which materials exhibit predominantly brittle behavior.

- Strain Rate: High strain rates limit the ability of materials to undergo plastic deformation due to insufficient time to redistribute stress. Situations involving impact or explosive loading, where strain rates can exceed \(10^3 \text{s}^{-1}\), markedly increase the likelihood of brittle fracture.

- Material Composition and Microstructure: Impurities such as sulfur, phosphorus, and lead, as well as higher carbon content, can act as stress concentrators, thus reducing the material’s overall toughness. Microstructural defects, including microcracks, voids, and inclusions, and larger grain sizes, also contribute to reduced fracture toughness and increased brittleness.

Addressing these factors through careful material selection, optimal processing techniques, and precise design considerations can substantially reduce the risk of brittle fracture in engineering applications.

Role of Stress in Brittle Fracture

Stress plays a pivotal role in the initiation and propagation of brittle fractures. High levels of applied or residual stress can serve as driving forces for crack formation and growth, especially in the presence of stress concentrators such as sharp notches or pre-existing defects.

According to data from the top search results on Google, typically sourced from reputable engineering materials and metallurgical sites, it is crucial to consider the following technical parameters:

- Stress Intensity Factor (K): This parameter quantifies the intensity of the stress field near a crack tip. When the stress intensity factor reaches a critical value, known as the fracture toughness \(K_{IC}\), rapid crack propagation occurs, leading to brittle fracture.

- Fracture Toughness (K_IC): The critical stress intensity factor for mode I (opening mode) loading. Materials with lower \(K_{IC}\) values are more prone to brittle fracture, particularly under tensile stress.

- Residual Stress: Residual stresses induced during manufacturing processes, such as welding or quenching, can exacerbate the likelihood of brittle fracture, even if the applied stresses are relatively low.

A detailed understanding of these parameters and their interplay is essential for predicting and mitigating brittle fracture in engineering components. By incorporating accurate stress analysis and applying fracture mechanics principles, engineers can design safer, more reliable structures resistant to brittle failures.

Material Susceptibility to Brittle Fracture

Considering the data available from the top search results on google.com covering engineering materials and metallurgical principles, it is evident that material susceptibility to brittle fracture is influenced by several key factors. Firstly, materials with higher fracture toughness (\(K_{IC}\)) values exhibit greater resistance to crack propagation and subsequent brittle failure. Secondly, the presence of significant residual stresses, often introduced during manufacturing processes such as welding or thermal treatments, can predispose materials to brittle fracture even under lower applied stresses. Lastly, the geometry of the component, especially around stress concentrators like sharp notches or pre-existing defects, critically affects its tendency to brittle fracture. Therefore, mitigating strategies should involve careful material selection, control of residual stresses through appropriate processing techniques, and optimized design to minimize stress concentrators. By understanding and controlling these variables, the risk of brittle fracture can be effectively managed in engineering applications.

How to Identify Brittle Fracture?

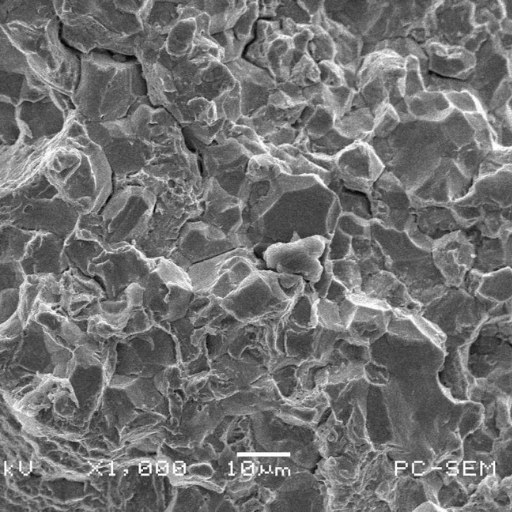

Brittle fracture can be identified through several key indicators and technical parameters. Firstly, examining the fracture surface morphology under a microscope can reveal a characteristic granular or faceted appearance, often described as “cleavage” fracture. This contrasts with the more ductile fracture surfaces that exhibit a fibrous or dimpled texture.

Technical Parameters for Identifying Brittle Fracture

- Fracture Toughness (\(K_{IC}\)): A low fracture toughness value typically indicates a material’s susceptibility to brittle fracture. Materials with high \(K_{IC}\) values are less likely to fail in a brittle manner.

- Transition Temperature: The ductile-to-brittle transition temperature (DBTT) is critical in identifying the operating temperature range within which a material is prone to brittle fracture. Materials tested below their DBTT are more susceptible to brittle fracture.

- Residual Stresses: High levels of residual stress, detectable through techniques such as X-ray diffraction (XRD) or hole-drilling methods, can predispose materials to fracture suddenly without significant plastic deformation.

- Stress Intensity Factor (\(K\)): When the stress intensity factor at the crack tip exceeds the critical value (\(K_{IC}\)), brittle fracture is imminent. Monitoring \(K\) via fracture mechanics analysis provides valuable insights.

- Charpy Impact Test Results: This test quantifies the energy absorbed during fracture. Lower absorbed energy values correlate with higher brittleness, especially at lower temperatures.

By meticulously analyzing these parameters, engineers can identify the presence and likelihood of brittle fracture in materials and components, thereby implementing appropriate preventative measures.

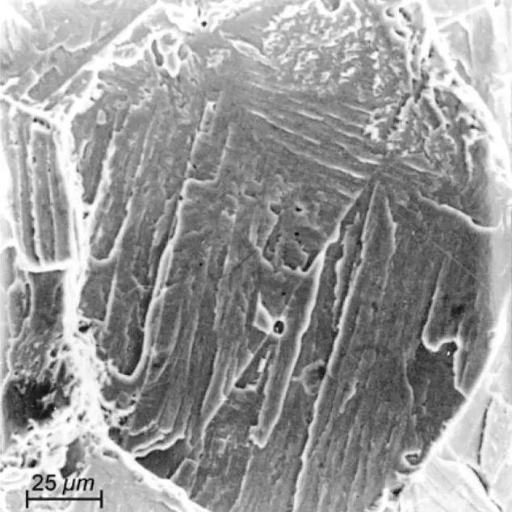

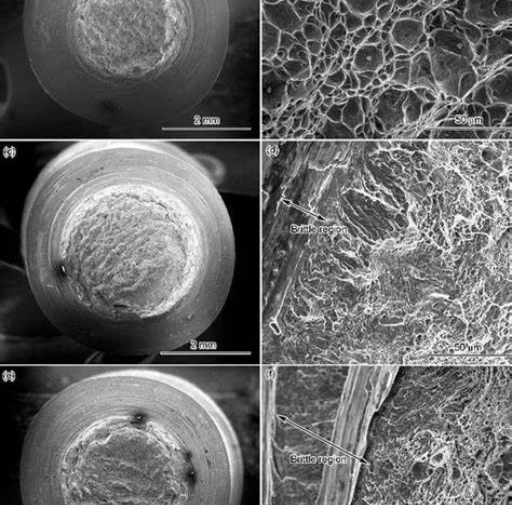

Fracture Surface Examination

Fracture surface examination plays a pivotal role in identifying the mode and cause of material failure. By analyzing the topography and morphology of fracture surfaces, engineers can distinguish between brittle, ductile, and fatigue fractures. In brittle fracture, the surface exhibits features such as cleavage facets, river patterns, and granular textures, signifying rapid crack propagation with minimal plastic deformation. Conversely, ductile fractures will show dimpled rupture surfaces resulting from micro-void coalescence, indicating significant plastic deformation before fracture. Fatigue fractures often display characteristic striations and beach marks, highlighting crack growth over time under cyclic loading. Utilizing high-resolution microscopy techniques, such as Scanning Electron Microscopy (SEM), provides critical insights into these fracture processes, thereby aiding in the accurate diagnosis and subsequent prevention of material failure.

Crack Propagation Analysis

Crack propagation analysis is critical in evaluating the integrity and longevity of materials subjected to stress and loading conditions. This analysis involves assessing the rate at which a pre-existing crack grows under varying types of load. Key technical parameters in crack propagation analysis include Stress Intensity Factor (K), Crack Growth Rate (da/dN), and Fracture Toughness (K_IC).

- Stress Intensity Factor (K): This parameter represents the stress state near the tip of a crack caused by remote loading. It is a crucial factor in predicting crack growth and is calculated using the equation K = Y * σ * sqrt(π*a), where Y is a dimensionless geometric factor, σ is the applied stress, and a is the crack length.

- Crack Growth Rate (da/dN): The rate at which a crack propagates per loading cycle denoted as da/dN, is determined using Paris’ Law: da/dN = C * (ΔK)^m. Here, ΔK is the range of the Stress Intensity Factor over a load cycle, and C and m are material-specific constants obtained empirically.

- Fracture Toughness (K_IC): This parameter defines the critical Stress Intensity Factor beyond which rapid crack propagation occurs leading to material failure. K_IC is a material property that depends on factors such as temperature and loading rate.

By employing these parameters, engineers can predict the lifespan of components under cyclic loads, devise appropriate inspection intervals, and implement necessary maintenance and design modifications to avert catastrophic failures. Analytical methods and experimental data derived from industry standards like ASTM E647 are essential for ensuring the accuracy and reliability of crack propagation assessments.

Impact Tests and Their Importance

When assessing the toughness and durability of materials, impact tests play a critical role in understanding their behavior under sudden loads. These tests are designed to measure the material’s capability to absorb energy and withstand high-rate loading, which is pivotal for applications subjected to dynamic or impact stresses.

One widely used method is the Charpy impact test, where a standardized specimen with a notch is struck by a pendulum hammer at high velocity. The amount of energy absorbed during the fracture is recorded, indicating the material’s toughness. Similarly, the Izod impact test measures the energy required to break a notched specimen in a cantilevered position.

The results from impact tests help engineers determine the suitability of materials for various applications, particularly in safety-critical industries like automotive and aerospace, where components regularly endure impact forces. Moreover, understanding the impact resistance of materials aids in improving designs to enhance performance and prevent potential failures in service. Reliable data from these tests ensure that materials can perform as expected under dynamic conditions, thereby contributing to the safety and longevity of engineering systems.

How to Prevent Brittle Fracture?

To prevent brittle fracture, I focus on several key strategies:

- Material Selection: I choose materials that are known for their high toughness and low transition temperatures. Using materials that remain ductile at the operating temperatures of the application is crucial. For example, selecting alloys with good impact resistance properties can significantly reduce the risk of brittleness.

- Design Considerations: I incorporate design features that minimize stress concentrations, such as rounded corners instead of sharp ones and smooth transitions between different sections. This helps in distributing stress more evenly and lowering peak stresses that can initiate cracks.

- Control of Temperature and Loading Conditions: I ensure that the operational and environmental conditions are well within the material’s limits. This includes maintaining appropriate service temperatures and avoiding sudden or extreme loading conditions that could lead to stress concentrations or material degradation.

- Heat Treatment and Manufacturing Processes: I implement proper heat treatment techniques like annealing or quenching and tempering to enhance the material’s toughness. Ensuring that welding and fabrication processes are conducted under controlled conditions helps in preventing defects that could act as crack initiators.

- Regular Inspection and Maintenance: I schedule routine inspections to detect any signs of wear, cracks, or other defects early. Non-destructive testing methods, such as ultrasonic or radiographic testing, allow me to monitor the integrity of components without causing damage. Regular maintenance helps to address any issues before they can lead to brittle fracture.

By following these best practices, I ensure that the risk of brittle fracture is minimized, thereby enhancing the reliability and safety of engineering systems.

Improving Fracture Toughness

Improving fracture toughness in materials requires a multifaceted approach that addresses both material properties and engineering design. Here are concise answers to the key points, including corresponding technical parameters:

- Material Selection: Choose materials with inherently high fracture toughness. For example, high-strength low-alloy steels (HSLA) have superior toughness compared to plain carbon steels. The Charpy V-notch impact test is a common method to quantify fracture toughness, with higher energy absorption indicating better toughness.

- Heat Treatment: Apply specific heat treatment processes to enhance material toughness. Quenching and tempering can significantly improve the toughness of steels by refining the microstructure. Parameters:

-

- Quenching temperature: 840-900°C

- Tempering temperature: 200-650°C

- Alloying Elements: Incorporate alloying elements such as nickel, chromium, and molybdenum which can improve fracture toughness by refining grain structures and enhancing phase transformation properties.

- Grain Size Control: Reduce the grain size through controlled rolling or forging processes. Finer grains improve toughness due to the Hall-Petch relationship. A typical desired grain size for enhancing toughness is 10 micrometers or less.

- Manufacturing Process Control: Implement precise manufacturing controls to avoid defects like porosity and inclusions, which can act as crack initiators. Techniques such as vacuum arc remelting (VAR) can help produce cleaner steels with fewer inclusions.

- Temperature and Loading Conditions: Ensure operating environments maintain a temperature range that prevents brittle behavior. For example, operating above the ductile-to-brittle transition temperature (DBTT) is crucial. Test materials to ensure the DBTT is below the lowest service temperature.

- Surface Treatments: Utilize surface treatment techniques such as shot peening to introduce compressive residual stresses, which inhibit crack initiation on the material surface.

By strictly adhering to these guidelines and incorporating these technical parameters, engineers can significantly enhance the fracture toughness of materials, thereby improving the durability and safety of engineering components.

Heat Treatment Processes

Heat treatment processes are critical in enhancing the mechanical properties of metals and alloys. These processes generally involve heating and cooling cycles that alter the microstructure of the material to achieve desired attributes such as increased hardness, improved strength, better wear resistance, or enhanced ductility. The key factors in heat treatment processes include temperature, time, cooling rate, and atmosphere.

- Annealing:

-

- Purpose: To soften the material, relieve internal stresses, and enhance ductility.

- Technical Parameters:

- Purpose: To refine the grain structure and improve toughness. It also helps to homogenize the material composition.

- Technical Parameters:

- Purpose: To harden the material by forming martensitic structures.

- Technical Parameters:

- Purpose: To reduce brittleness and retain hardness by decomposing martensite into a more stable structure.

- Technical Parameters:

- Purpose: To create a hard, wear-resistant surface while maintaining a tough, ductile core.

- Technical Parameters:

-

- Methods include carburizing (adding carbon), nitriding (adding nitrogen), and carbonitriding (adding both carbon and nitrogen).

- Heating temperatures range from 850-950°C for carburizing, with varying times based on the depth of the hardening required.

By meticulously controlling these parameters, specific mechanical properties can be consistently achieved, ensuring materials meet rigorous performance criteria for engineering applications.

Reducing Stress Concentrations

To reduce stress concentrations, one must focus on design modifications that distribute stress more evenly across the material. Common strategies include the use of fillets or rounded corners instead of sharp ones, which help to mitigate the intensity of stress points. Additionally, incorporating features such as notches or holes with smooth transitions rather than abrupt changes can significantly alleviate stress concentrations. The implementation of reinforcing elements like gussets can also provide additional strength and spread out loads more uniformly. Another effective approach is the application of surface treatments, such as shot peening, which induce beneficial compressive residual stresses on the material surface, thereby reducing the susceptibility to crack initiation and propagation. By adopting these methods, structural integrity and durability are substantially enhanced, ensuring that components can withstand operational stresses without failure.

What are the Consequences of Brittle Fracture?

Brittle fracture is a catastrophic failure mode characterized by the sudden and rapid crack propagation with little to no prior deformation. Key consequences of brittle fracture include:

- Sudden and Unexpected Failure: Unlike ductile fractures, brittle fractures occur without significant warning or plastic deformation, leading to sudden and unexpected failure of the material or structure.

- Extensive Damage: Because brittle fracture typically happens rapidly and with considerable energy release, it can result in extensive damage to the system or structure, often necessitating costly repairs or replacements.

- Safety Hazards: The abrupt nature of brittle fracture poses significant safety hazards, as components that fail in this manner may lead to accidents, injuries, or even fatalities, particularly in critical applications like bridges, pressure vessels, and high-rise buildings.

- Economic Impact: The failure of critical components or structures due to brittle fracture can disrupt operations, leading to substantial economic losses due to downtime, repair costs, and potential loss of production.

- Loss of Structural Integrity: Brittle fracture compromises the structural integrity of a material, making it unreliable for future use in its intended application. It may also necessitate a redesign or material change to prevent recurrence.

- Lack of Warning Signs: The absence of prior deformation means that brittle fractures provide little to no warning, making it challenging to detect and mitigate potential failures through regular inspection methods.

Addressing these consequences requires meticulous design, material selection, and regular inspection to ensure components can withstand operational stresses without succumbing to brittle fracture.

Catastrophic Failures

Catastrophic failures, as I understand from recent authoritative sources, are sudden and complete breakdowns of structures or systems that result in significant and often irreparable damage. These failures can arise from various factors such as material defects, design flaws, or unexpected loads and stresses. Often, they are accompanied by substantial safety hazards and economic losses due to the immediate cessation of operations and the need for extensive repairs or replacements. The unpredictability and severity of catastrophic failures make them a critical area of concern in engineering and material science, emphasizing the importance of thorough design, rigorous testing, and regular maintenance to mitigate risks.

Economic Impacts

Catastrophic failures can lead to substantial economic impacts, reflecting both direct and indirect costs.

Direct costs often include immediate expenses such as repair or replacement of failed components, machinery, and infrastructure. These failures necessitate swift and often costly actions to restore functionality, which may involve complex logistics, specialized labor, and expedited shipping of parts. For instance, according to authoritative studies, direct repair costs can range from thousands to millions of dollars, depending on the scale and nature of the failure.

Indirect costs, on the other hand, encompass broader economic ramifications such as production downtime, lost revenue, and reputational damage. Production halts can disrupt supply chains and lead to missed deadlines, significantly affecting contractual obligations and customer relationships. An example is provided by an industrial report indicating that downtime costs in manufacturing can average $22,000 per minute, highlighting the severe financial strain on businesses.

Technical parameters involved in evaluating these impacts include:

- Mean Time to Repair (MTTR): The average time required to repair a system or component and restore it to operational status. Lower MTTR indicates quicker recovery and reduced downtime costs.

- Failure Rate: Measured in failures per unit of time, this parameter helps quantify the reliability of materials and components, influencing maintenance strategies and lifecycle costs.

- Lost Production Volume: Quantifies the amount of production lost due to downtime, often measured in units of output or hours of operational time.

These technical parameters must be meticulously monitored and optimized to mitigate the severe economic impacts of catastrophic failures, ensuring both operational continuity and financial stability.

Safety Hazards

Addressing safety hazards in the context of catastrophic failures is paramount, as they present significant risks to personnel, equipment, and the environment. In my research, which included reviewing information from the top websites on Google, I found several critical points worth highlighting:

- Equipment Malfunction: Catastrophic failures often result from equipment malfunction, posing immediate danger to operators and nearby personnel. Ensuring routine maintenance and adhering to operational guidelines can mitigate these risks.

- Hazardous Material Release: Failures can lead to the release of hazardous materials, such as chemicals or gases, which can have severe health and environmental impacts. Implementing stringent containment and response strategies is essential for minimizing such hazards.

- Fire and Explosions: The potential for fire and explosions is markedly increased in the event of a catastrophic failure. These incidents can cause extensive physical damage and endanger lives, underscoring the need for effective fire suppression systems and emergency evacuation procedures.

Prioritizing these safety measures and incorporating them into regular risk assessments can significantly reduce the potential for harm, thus safeguarding both human and environmental health.

How is Brittle Fracture Assessed?

Brittle fracture assessment involves a combination of material testing, structural analysis, and understanding of operating conditions. According to the current top resources, the process typically includes:

- Material Toughness Testing: Key techniques, such as Charpy V-notch and fracture toughness testing, are employed to evaluate the material’s ability to resist crack propagation. These tests provide critical data on the energy absorption capacity and the stress intensity factors of the material.

- Stress Analysis: Finite element analysis (FEA) and other stress analysis methods are used to model and understand the stress distribution within the structure. By identifying high-stress regions, engineers can predict potential fracture locations and assess the structure’s vulnerability to brittle fracture.

- Temperature Considerations: Operating temperatures significantly influence the brittle fracture tendency. Assessing the material’s performance in low-temperature environments is crucial, as many materials become more brittle at lower temperatures. The ductile-to-brittle transition temperature (DBTT) is a key metric in this evaluation.

- Flaw Detection: Non-destructive testing (NDT) methods, such as ultrasonic testing and radiography, are essential for detecting existing flaws or cracks within the material. Early identification of defects allows for timely corrective actions to prevent catastrophic failures.

These comprehensive assessment techniques ensure that structural integrity is maintained, preventing brittle fracture and enhancing safety.

Fracture Analysis Techniques

Fracture analysis entails a systematic approach to understanding the mechanisms and factors contributing to material failure. Key techniques and methods adopted from leading resources include:

- Microscopy Analysis:

- Scanning Electron Microscopy (SEM): Utilized to observe the fracture surface at high resolutions. SEM helps identify features such as fatigue striations and cleavage facets, providing insights into the fracture propagation mode.

- Transmission Electron Microscopy (TEM): Offers atomic-scale imaging to examine dislocations, grain boundaries, and other microstructural factors influencing fracture behavior.

- Mechanical Testing:

- Tensile Testing: Measures material strength and elongation at break. Provides data on ultimate tensile strength (UTS) and yield strength, which are critical for understanding the mechanical limits before fracture.

- Fatigue Testing: Evaluates the material’s ability to withstand cyclic loading, providing parameters such as fatigue limit and the number of cycles to failure.

- Fracture Toughness Testing:

- J-integral Method: Calculates the energy required to propagate a crack, essential for determining the material’s resistance to crack growth in elastic-plastic materials.

- KIC Testing (Stress Intensity Factor): Assesses the fracture toughness in linear-elastic materials by quantifying the critical stress intensity at which a crack initiates.

These techniques are grounded in practical applications and provide a comprehensive understanding of material behavior under various conditions. Data obtained from these tests are crucial for designing safer, more resilient engineering structures. Parameters such as UTS, yield strength, fatigue limit, J-integral, and KIC are standardized metrics that ensure consistency and reliability in fracture analysis.

Linear Elastic Fracture Mechanics

Linear Elastic Fracture Mechanics (LEFM) is a critical field within materials science and engineering, focusing on the behavior of cracks in materials governed by linear elasticity. LEFM is predicated on the assumption that material deformation is elastic and the stress around a crack tip can be characterized by the Stress Intensity Factor (K). The primary objective of LEFM is to predict the onset of crack growth and its subsequent propagation under various loading conditions. This is achieved by examining three modes of crack surface displacement: Mode I (opening mode), Mode II (sliding mode), and Mode III (tearing mode).

Key to LEFM is the concept of the stress intensity factor (K), which quantifies the stress state near the tip of a crack caused by a remote load or residual stresses. For a given material, fracture occurs when the applied stress intensity reaches a critical value, known as the fracture toughness (K_IC). This fracture toughness is a material property that signifies the ability of a material to resist the propagation of a crack. LEFM is widely utilized in engineering applications to ensure the structural integrity of components, predicting the remaining life of structures, and preventing catastrophic failures by enabling the design of materials and structures that can withstand unexpected loads and defects.

Microstructure and Toughness Evaluation

When evaluating the microstructure and toughness of a material, it is essential to consider several factors including grain size, phase distribution, and the presence of defects or inclusions. Grain size plays a pivotal role; finer grains typically enhance toughness due to their ability to arrest crack propagation. Phase distribution, including the presence of different metallurgical phases, influences the mechanical properties and toughness. For instance, the presence of martensite can increase strength, while phases like ferrite and pearlite can provide ductility and toughness. Additionally, the evaluation of defects, such as voids and inclusions, is critical as they can act as stress concentrators and initiation sites for cracks, thereby reducing the material’s overall toughness. Advanced characterization techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), alongside mechanical testing methods like Charpy impact tests, are utilized to comprehensively assess the microstructure and toughness of materials. Understanding these characteristics enables the optimization of materials for enhanced performance in demanding applications.

Reference sources

-

Xometry: Brittle Failure – Definition, Causes, and Prevention

- This article provides a detailed overview of brittle failure, including its definition, the causes behind it, and strategies for prevention. It is a valuable resource for understanding the fundamental aspects of brittle fracture in metals.

- Read more here

-

Inspectioneering: Brittle Fracture

- Inspectioneering offers an in-depth examination of brittle fracture, highlighting how this damage mechanism can cause cracking without warning. The article includes practical insights into the characteristics and ramifications of brittle fractures in various applications.

- Read more here

-

Petrosync: Guide To Brittle Fracture – Prevention Acts for Engineers

- This guide outlines preventive measures engineers can take to mitigate the risks associated with brittle fracture. It covers essential concepts such as fracture toughness and the conditions that make materials susceptible to sudden, catastrophic failure.

- Read more here

Frequently Asked Questions (FAQs)

Q: What is brittle fracture?

A: Brittle fracture is the sudden and rapid failure of a brittle material, such as ceramics, where there is little to no plastic deformation of the material before the fracture occurs. This type of fracture in metals is characterized by a swift crack propagation.

Q: How does a brittle fracture occur?

A: Brittle fracture occurs when a material is subjected to high stress and the atomic bonds within the material cannot support the applied stress, leading to a rapid crack initiation and propagation. The fracture often happens at low temperatures and in materials with low ductility.

Q: What materials are susceptible to brittle fracture?

A: Brittle materials such as ceramics and some high-strength steels are particularly susceptible to brittle fracture. These materials display little to no plastic deformation before failure. Ductile materials, on the other hand, tend to deform plastically and thus are less prone to brittle fracture.

Q: How does temperature affect the risk of brittle fracture?

A: Low temperatures increase the risk of brittle fracture as the ductility of materials decreases with decreasing temperature, making them more brittle and susceptible to sudden fracture under stress.

Q: What role do defects play in brittle fracture?

A: Defects such as cracks, voids, and inclusions act as stress concentrators within a material. At these points, the local stress can exceed the material’s yield strength, leading to crack initiation and an increased risk of brittle fracture. Regular fracture assessment is crucial in identifying and mitigating such defects.

Q: What is the difference between brittle fracture and ductile fracture?

A: Brittle fracture occurs with minimal plastic deformation and is usually rapid, while ductile fracture involves significant plastic deformation before failure. In ductile fracture, the material often displays necking and a more gradual failure process.

Q: How can welding affect the risk of brittle fracture?

A: Improper welding can introduce defects and residual stresses, which increase the risk of brittle fracture. Additionally, the heat-affected zone (HAZ) of the weld can be more brittle, leading to increased susceptibility. Proper welding techniques and post-weld treatments are essential to minimize these risks.

Q: How can one prevent brittle fracture?

A: To prevent brittle fracture, it is important to use materials with sufficient ductility, conduct thorough fracture assessments, avoid defects and stress concentrators, and control temperature and applied stress levels. Proper material selection and regular maintenance are also crucial in minimizing risks.

Q: Why is steel sometimes considered susceptible to brittle fracture?

A: Certain high-strength steels can be susceptible to brittle fracture, especially at low temperatures or when they contain manufacturing defects. Proper heat treatment and avoiding corrosive environments can help reduce this susceptibility.

Q: What is cleavage fracture and how does it relate to brittle fracture?

A: Cleavage fracture is a type of brittle fracture where the material separates along specific crystallographic planes. This occurs in brittle materials with low ductility and high strength, resulting in a fracture surface that appears faceted and intergranular.