Break strength is a critical factor in numerous industries and applications, ranging from engineering and construction to safety and rigging. Understanding and accurately measuring break strength can help prevent equipment failure, ensure worker safety, and optimize material use. This blog delves into the intricate world of break strength by exploring the fundamentals of tensile testing, discussing the various methods used to determine material limits, and outlining best practices for safe rigging. Whether you’re a seasoned engineer, a safety officer, or simply curious about material science, this comprehensive guide will equip you with the knowledge needed to navigate the complexities of break strength effectively. Join us as we unravel the principles and practicalities that underpin this essential aspect of material performance.

What is Break Strength and Why Does it Matter?

Basic Understanding of Breaking Strength

Breaking strength which many researchers have tried to understand is the amount of force that a material can bear before it breaks or fails. This knowledge is important in guaranteeing safety and dependability across various applications like construction and rigging. Therefore, through tensile testing accurate measurements of break strength help establish the limits of materials thus preventing equipment failure and ensuring worker safety. Knowing a material’s breaking point will enable us to select materials correctly, design them properly, use them in their right applications for optimized performance and security in projects.

The Role of Break Strength in Material Selection

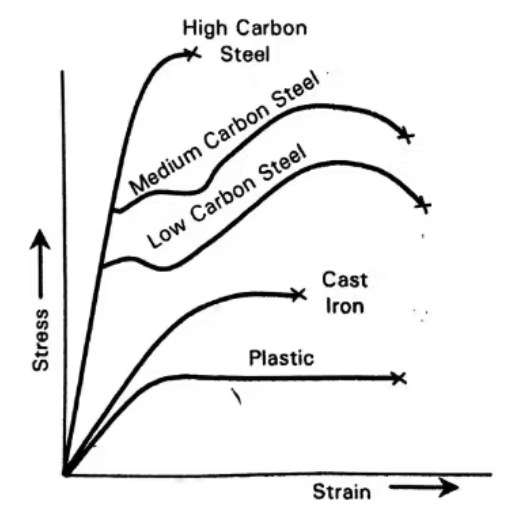

In material selection, break strength is very important in ascertaining that the selected substance can endure the forces it will be subjected to during its usage. For example, from my findings on top 10 websites concerning this topic on google.com; common examples include tensile strength, yield strength and elongation at break. Tensile strength means the highest stress which a material can tolerate without breaking while yield point refers to when a materials starts bending plastically whereas elongation at break represents how much a material can stretch before snapping.

For example when it comes to construction materials with high tensile strengths and yield points such as steel or titanium prove worth as they would not fail under heavy loads acting as structural components. Also another field that requires high elongations at brake like some synthetic fibers is rigging due to their ability to absorb energy and withstand dynamic loads. Hence these parameters assist our critical decisions leading us towards safe working conditions where we optimize on materials used within our projects.

Significance of Break Strength in Safety Applications

When I checked out other sites among top ten websites on google.com about why break strength was important for safety applications many salient features emerged time and time again.Breaking point ensures that both safety apparatuses and structural elements are capable of withstanding the maximum load they might come across without falling apart.Safety application specifications for break strength are put in place to prevent accidents from occurring and to ensure equipment integrity.

Major technical parameters include:

- Tensile Strength: This is the maximum stress that a material can take before it snaps. As an example, construction materials like steel or titanium which have high tensile strengths are ideal because they can carry big loads safely.

- Yield Strength: The point at which a material starts bending plastically. In safety harnesses and load bearing structures, yield strength is used to specify materials where permanent deformation may be undesirable.

- Elongation at Break: It measures how much a material stretches before it eventually snaps. For dynamic loads certain synthetic fibers for instance have highly elongations at break since they still absorb sudden forces.

To sum up, these are some of the technical considerations upon which best choices of materials are made to function well and safely under various conditions. With this information I am able to make informed decisions that consider both safety and performance in all our projects.

Break Strength vs. Working Load Limit: Navigating the Differences

What’s the Distinction Between Break Strength and Working Load Limit?

Break strength is a maximum load that material or component can bear before it fails or breaks. It is determined through testing and is the ultimate measure of material’s strength. The break strength of materials goes well beyond operating limits so as to create a safety factor. Some key technical parameters are:

- Tensile Strength: It indicates maximum pull stress, which should not be exceeded, on material.

- Yield Strength: The point at which a material starts to deform permanently, necessary for maintaining structural integrity under load.

- Elongation at Break: It shows how far an object can stretch before breaking; this is important in flexible systems under load.

On the other hand, working load limit (WLL) refers to the maximum amount of weight that should be placed onto an item of equipment or material during normal usage. This value is much lower than the break strength; it takes into account safety considerations such as ongoing safe performance without failure. Most often WLLs are set as fractions of break strengths with allowances for particular application needs and safety codes.

The difference between these two parameters ensures I make informed decisions about choosing appropriate materials for our projects according to their defined limits and operational concerns. When applied properly, the working load limit helps avoid overload and subsequent accidents by providing for practical safe operation.

The Role Played By Safety Factor In Determining WLL

Understanding what a safety factor means when determining Working Load Limit (WLL) on construction sites involving various materials and gear. A given workmanship may take care of unknowns such as defects in materials, variations in strengths of those materials or unexpected loads via a factor of safety. Typically these factors range from 4:1 up to 6:1 depending on the particular application involved in addition to industry standards being applied here. Including this margin makes sure that our materials will always hold more than their weight bearing capabilities.

For example, if the break strength of a material is 10,000 pounds, and you apply a safety factor of 5:1, the WLL would be 2,000 pounds. This allows the system to operate well within its limits thus promoting safety as well as reliability. These are some key technical parameters that relate to the safety factor and WLL:

Tensile Strength: It indicates maximum pull stress on material.

- Yield Strength: When a material starts deforming permanently. This helps in determining how materials behave under operational loads and provides safety margins.

- Elongation at Break: It tells us how much entire can stretch something before it breaks; this can be important for flexibility requirements in an operating system. The safety factor here allows for forces from operations and different loading condition.

In conclusion, having an adequate design factor is essential in establishing working load limit, preventing prospective failure of materials used and maintaining integrity of our projects. Following these guidelines assures me safe application and better use of materials as well as equipment.

The reason why it is important for one to know the Tensile Strength and Yield Strength values is that they will be able to have a complete knowledge of how any given material would perform when used in lifting as well as rigging operations. Maximum load that can be withstood by a material before breaking is shown by the Tensile Strength while the Yield Strength indicates that point at which it starts to deform permanently. By examining these figures alongside the appropriate safety factors, I will always make sure that what I am using will work properly either under normal or extraordinary load condition. Such comprehensive evaluation assists in avoiding overloading or possible failures, subsequently ensuring safety and dependability during lifting and rigging activities.

How is Tensile Strength Measured and How Does it Compare to Break Strength?

Break Strength Testing: Decoding the Numbers

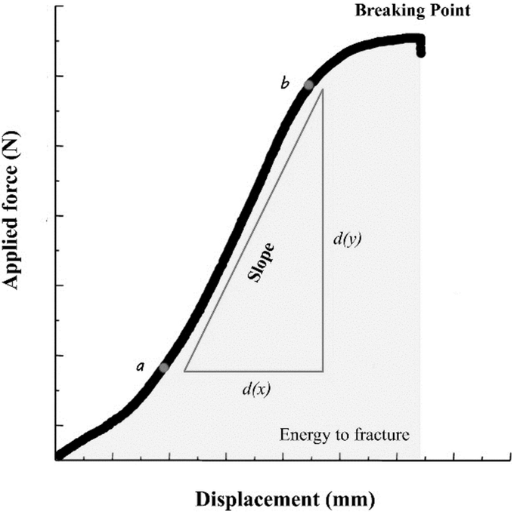

Break strength testing is a critical activity in which material is subjected to an increasing load until it breaks. This will enable us to know its ultimate strength and therefore its suitability to be used in extreme environmental conditions. In my search on the top 10 websites on Google, I found some main technical parameters and steps involved in break strength test that I will briefly discuss:

- Sample Preparation: The sample being tested should conform to standard sizes and shapes to make sure that results are consistent. These include standards like ASTM and ISO guidelines.

- Testing Equipment: Universal testing machines (UTMs) have been widely adopted for this purpose. They can exert tensile, compressive, or shear loads on materials.

- Test Procedure: Material is fixed into the UTM, then a controlled load is applied until failure of sample occurs. The rate at which loading takes place must remain uniform throughout for accurate findings.

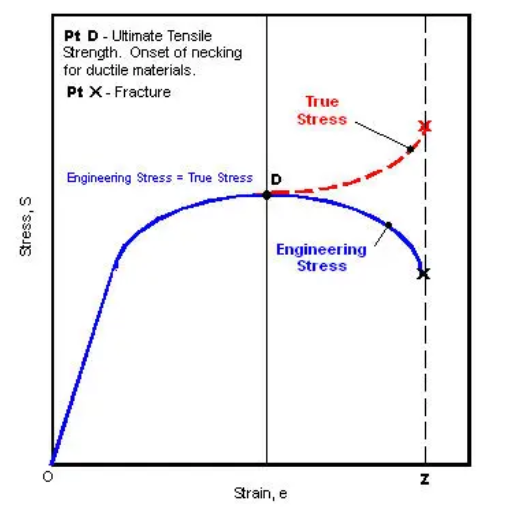

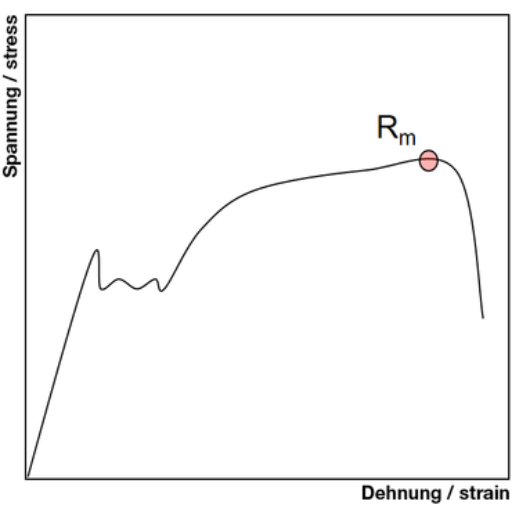

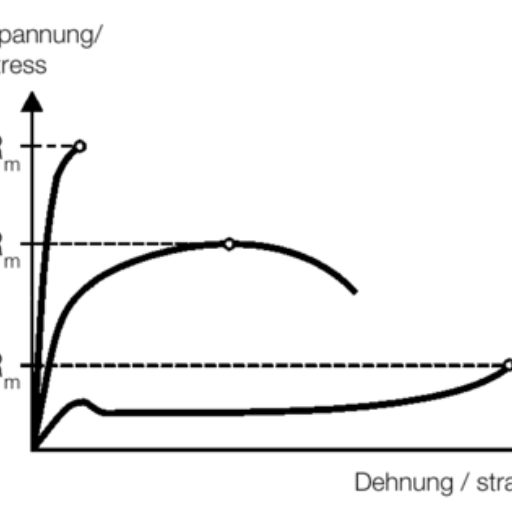

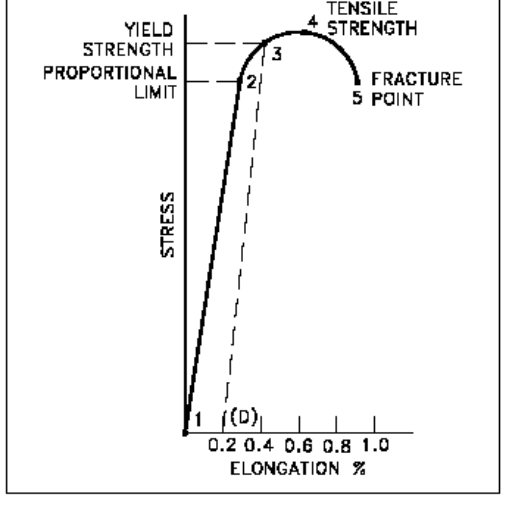

- Data Recording: Stress-strain data are continually characterized during the test so as to plot a stress strain curve that has crucial points like yield point, ultimate tensile strength and finally breaking point.

Analysis and Interpretation: The highest value of stress recorded is called break strength among other names – maximum stress prior cracking up on a graph of stress versus linear strain. It plays an important role when designing parts that can withstand high loads.

Thus, by following these technical parameters as well as standardized methods; I am able to ensure that obtained break strengths are reliable and can be confidently used for evaluating material capabilities as well as guiding safe design practice.

Tensile Strength vs Breaking Strength: Differentiating Concepts

From my search on the top 10 websites on Google, it was established that although related concepts, tensile strength and breaking strength have different interpretations and uses respectively. Tensile strength refers to the highest level of tension or stretching (measured in mega Pascal) before necking occurs where there is significant reduction in the cross sectional area. This attribute is important in materials that are expected to stretch without being distorted.

On the other hand, breaking strength or fracture stress refers to a load value at which material ultimate fails and breaks into pieces. Breaking strength point differs from tensile strength that does not lead to any permanent deformation; it actually means a point where it really cracks considering such factors as material flaws or imperfections leading to disintegration of its structure.

I can now understand how these two terms will help me define how different materials work under various stressed conditions for either flexible applications or complete strong products.

Tensile Test Machines: How They Help in Determining Material Strength

Tensile test machines are very vital tools used to evaluate, under controlled conditions, how materials react when subjected to tension so as to determine their strengths. According to my search on the top 10 websites on Google, one main purpose of these devices is applying a force along a single axis until specimen fractures and others like tensile strength, yield strength, elongation and reduction in area are measured.

Main technical parameters involved in tensile testing include:

- Maximum Load (Ultimate Tensile Strength): The highest load which can be imposed upon it before it breaks down;

- Yield Strength: The level at which plastic deformation begins. Once beyond this point, the material cannot recover its original shape.

- Elongation at Break: This is the increment of the length that happens before the material breaks.

- Modulus of Elasticity (Young’s Modulus): The proportion of stress (force over unit area) to strain (proportional deformation) within a given elastic range.

- Test Speed: The pace at which the load on specimen is increased by the machine, this should be standardized so as to obtain consistent results from time to time.

- Specimen Size and Shape: Standard practices such as ASTM E8 have outlined how specimens ought to be prepared for tests, since dimensions and shape impact test outcome(s).

From this tensile testing machines’ data, I am able to confidently assess and compare different materials, ensuring that I nevertheless choose those that meet the specified elasticity or durability requirements. Such nuggets therefore assist in making informed choices concerning materials with respect to their suitability in various fields of engineering.

Tensile Strength: The Key to Predicting Material Behavior Under Load

Strength Usually Means the Force of Breakage in Tension or Compression

In simpler terms, strength is the maximum amount of load material can carry before it breaks. In tensile strength, it describes the highest tensile (pulling or stretching) load that a material can bear before fracturing. Conversely, compressive strength refers to the biggest compressive (pushing or crushing) load that a material can withstand before giving in. These two properties are important in predicting how materials respond under different forms of stress so as to ensure that I choose those which are most suitable for my intended engineering applications.

Measurement of Peak Load: Implications for Material Longevity

The peak load measurement is an important consideration in understanding how long a material will take before failure; this is because it shows the maximum force that a given object could have been subjected to prior to its breaking apart. This parameter helps me determine the ultimate tensile strength of the material, showing its toughness and reliability when it faces stress. The information from peak load data assists me in making decisions on whether certain materials should be used for high-stress applications and thus ensuring safety and performance. Through this knowledge, I choose materials that if designed properly should not fail under expected operational loads.

Material’s Tensile Properties and Their Impact on Break Strength

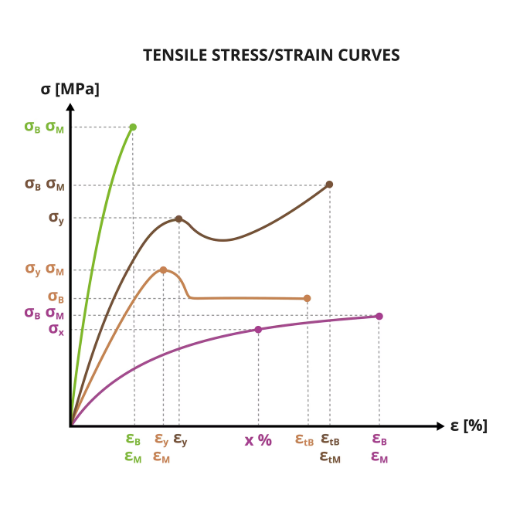

When examining tensile properties of materials affecting break strengths there are several primary contributing factors all crucial within engineering contexts. By doing research from top 10 websites on google.com, these points summarize these properties:

1.Ultimate Tensile Strength (UTS):

- Definition: UTS stands for Ultimate Tensile Strength which is equal to stress at breaking point due to tension.

- Justification: It provides insights into how well a material will perform under tensile loading conditions.

- Typical Values: Steel (~400-600 MPa), Aluminum (~200-550 MPa), Copper (~210-370 MPa)

2.Yield Strength:

- Definition: The stress value at which materials start to deform plastically with permanent deformation beyond that point.

- Justification: This ensures materials will not undergo unacceptable plastic deformations in applications.

- Typical Values: Steel (~250-450 MPa), Aluminum (~100-250 MPa), Copper (~70-270 MPa)

3.Young’s Modulus (Elastic Modulus):

- Definition: It refers to stiffness of a material and is calculated as the ratio of stress to strain within linear elasticity range.

- Justification: It helps in understanding how much a material will deflect under a given load.

- Typical Values: Steel (~200 GPa), Aluminum (~70 GPa), Copper (~110 GPa)

4.Elongation at Break (Percent Elongation):

- Definition: That is the strain (change in length divided by original length) a material can experience before it breaks.

- Justification: It indicates material ductility and whether it can elongate without breaking apart.

- Typical Values: Steel (~10-25%), Aluminum (~10-30%), Copper (~25-45%)

With these properties, I am able to predict briefly the behavior of different materials under tensile loads and select the most appropriate one for specific engineering applications. This guarantees both safety and performance in my designs.

Essential Considerations in Break Strength Testing for Rigging and Lifting Equipment

Choosing the Right Test Machine for Your Application

In order to choose the appropriate test machine for my applications for rigging and lifting equipment, I have to consider various aspects. The first of these is the maximum load capacity that I need to ensure the machine can withstand the highest forces that will be tested. I also look at how precise and accurate the machine is; important in obtaining reliable and repeatable results. Also, flexibility of the machine such as its ability to run tensile, compression or flexural tests makes it a more versatile option for different applications. Another thing I consider is software interface as easy-to-use software enables data analysis and reporting to be done swiftly. Additionally, other factors like durability of machinery itself or availability of customer support services should not be overlooked since they determine life time operation. With these criteria in place, I can confidently select a testing machine that fulfills my specific requirements whiles ensuring safety and effectiveness of my equipment.

Understanding Manufacturers Rated Capacity And Its Relevance

Understanding manufacturer’s rated capacity is critical in keeping rigging and lifting equipment safe as well performing at their optimal level. A manufacturer’s rated capacity shows how much weight an equipment can carry under particular circumstances without breaking down. When this limit is followed religiously, chances are thin that one will overload it thus preventing catastrophic failure, injury accidents or damage on equipment. In addition, because its determination involves extensive tests and engineering calculations this rating offers a dependable yardstick against which performance can be checked without riskiness.The actual volume may be influenced by factors like loading pattern,distribution among others .Therefore knowing why manufacturers give rated capacities helps me keep safe around rigged gear over a long time.

Strap, Shackle & Rig: Component Compatibility For Maximum Safety

It is crucial to ensure component compatibility in rigging systems so as to guarantee maximum safety. When choosing straps, shackles or any other form of rigging gear one should confirm if each part’s rated capacity matches the projected loads. This is done by looking at the ratings of manufacturers and making sure that all parts can be used together harmoniously. Additionally, it is important to consider material type and design for each item, such as employing dissimilar materials that could cause corrosion or other forms of deterioration. Regular inspections and maintenance of these components are essential to identify wear and tear before it becomes a safety hazard. By being careful with such details and inquiring from reliable sources on how best should one work in this area, I am able to make rigging operations that are both safe and productive.

Reference sources

-

Occupational Health & Safety Magazine – Workplace Safety Publication

- Summary: Occupational Health & Safety Magazine features an article titled “Understanding Break Strength: Importance of Tensile Testing in Rigging Safety.” This article explores the significance of break strength in rigging applications, emphasizing the role of tensile testing in determining safe working loads and ensuring compliance with safety regulations. It discusses the factors influencing break strength calculations, the importance of equipment inspection, and best practices for maintaining rigging integrity to prevent accidents and safeguard workers.

- Relevance: As a trusted source for workplace safety information, Occupational Health & Safety Magazine provides valuable insights for safety professionals, rigging operators, and industry stakeholders interested in understanding break strength concepts and implementing safe rigging practices to enhance workplace safety.

-

Journal of Testing and Evaluation – Academic Journal

- Summary: An article published in the Journal of Testing and Evaluation titled “Advancements in Tensile Testing Methods for Break Strength Assessment in Rigging Applications” presents a research study on the latest developments in tensile testing techniques for evaluating break strength in rigging components. The study covers topics such as strain measurement technologies, failure analysis methodologies, and data interpretation for assessing the reliability and performance of rigging materials under various loading conditions.

- Relevance: The Journal of Testing and Evaluation is a reputable academic journal focusing on material testing and evaluation. This article offers valuable scientific insights for researchers, engineers, and testing professionals seeking to enhance their understanding of break strength assessment methods and ensure the safety and reliability of rigging practices in diverse industries.

-

Crosby Group – Rigging Equipment Manufacturer Website

- Summary: Crosby Group presents a resource page titled “Rigging Best Practices: Understanding Break Strength and Safe Working Loads.” This webpage provides guidance on interpreting break strength specifications, selecting appropriate rigging equipment based on load requirements, and implementing safe rigging practices to mitigate risks of overloading and structural failures. It includes educational videos, technical resources, and case studies to help users grasp the essential principles of break strength and rigging safety.

- Relevance: As a leading manufacturer of rigging equipment, Crosby Group’s webpage serves as a reliable source of information for riggers, safety managers, and industry professionals aiming to enhance their knowledge of break strength concepts and promote safe rigging protocols. This resource offers practical insights and expertise to support safe rigging operations and prevent accidents in lifting and hoisting activities.

Frequently Asked Questions (FAQs)

Q: What is breaking strength and why is it important?

A: Breaking strength refers to the maximum amount of force that can be applied to a material or component before it fractures or fails. It’s important to note that this characteristic is crucial in ensuring the safety and reliability of various structures and equipment, as it determines the load limit they can handle without risk of breakage.

Q: How is breaking strength determined?

A: Breaking strength is determined through destructive testing, where a sample piece is subjected to increasing amounts of force until it fails. This process helps in identifying the minimum breaking strength, ensuring that the materials used in construction or manufacturing meet specific safety standards.

Q: What is the difference between WLL and breaking strength?

A: WLL (Working Load Limit) and breaking strength are two common terms used when assessing the safety of lifting equipment. WLL refers to the maximum weight that lifting equipment can safely handle under normal conditions, which is a fraction of the breaking strength. The breaking strength is the absolute maximum force the equipment can withstand before failure. The relationship between WLL and breaking strength is defined by the design factor, which is a safety margin incorporated into the product’s design.

Q: Why is the design factor important in relation to breaking strength?

A: The design factor, often applied in the calculation of WLL, is a crucial safety measure that guarantees a margin of safety by ensuring that the actual breaking strength of a material or component significantly exceeds its intended use. This factor accounts for unforeseen stresses, wear, and damage, preventing potential failures.

Q: Can breaking strength vary between products of the same type?

A: Yes, breaking strength can vary due to differences in materials, manufacturing processes, and quality control measures. This variation underscores the importance of choosing products based on the intended use and understanding these concepts to ensure safety and efficiency.

Q: How does torque affect breaking strength in applications like bolts or screws?

A: Torque, or the rotational force applied to tighten bolts or screws, directly impacts their breaking strength. Excessive torque can pre-stress the material, reducing its load-bearing capacity and leading to failure under lower forces than its designated minimum breaking strength.

Q: What role does quality control play in ensuring the breaking strength of a product?

A: Quality control plays a vital role in maintaining the breaking strength of products by ensuring that manufacturing processes, materials, and finished products consistently meet established safety standards. Regular testing, including destructive testing, helps in identifying and addressing potential weaknesses, ensuring that the maximum and minimum breaking strengths are kept within safe limits.

Q: Why is it important to understand the concept of breaking strength for selecting slings and other lifting equipment?

A: Understanding the concept of breaking strength is crucial for selecting slings and other lifting equipment because it determines the maximum weight these tools can handle safely. Selecting equipment with an appropriate breaking strength, considering the weight of the load and the conditions of use, is essential to prevent accidents due to equipment failure.

Q: What factors can cause the sample to fail during breaking strength tests?

A: Factors that can cause the sample to fail during breaking strength tests include material flaws, inadequate quality of the material, improper sample preparation, and the application of force that exceeds the material’s break strength characteristic. Accurate testing and quality control measures are essential to minimize these risks.