In the world of manufacturing and metalworking, bar stock plays an essential role as a foundational material used in a variety of applications. Whether you are a small-scale craftsman, a large industrial manufacturer, or a hobbyist looking to bring your ideas to life, understanding the intricacies of bar stock, its processing, and the options available for custom orders can greatly enhance your projects. This guide is designed to provide you with comprehensive information on the types and qualities of bar stock, the various metal processing techniques, and how to navigate the custom order process to meet your specific needs. From selecting the right material to ensuring precision in fabrication, this article aims to equip you with the knowledge necessary to make informed decisions and achieve high-quality results in your metalworking endeavors.

What is Bar Stock?

Understanding Bar Stock and its Uses

A billet, also known as bar stock, is a widely used raw material in the metalworking industry with varying shapes and sizes such as round, square, hexagonal and flat shapes. It has numerous applications which include making small parts of machines, automotive parts, structural supports and sculptures. Engineers and craftsmen select some kinds of bar stock because of their machinability or fabricability features, durability or general material properties. The commonly used materials are steel, aluminum ,brass ,and stainless steel which distinctly have their own advantages for certain purposes. Manufacturing companies by choosing right barstock can make sure that their work proceeds accurately and fast.

Types of Metals Used in Bar Stock

Steel

Steel is one of the most widely used materials for bar stock due to its versatility, strength, and affordability. It comes in various grades each designed to suit specific applications:

1.Mild Steel (Low Carbon Steel)

- Features: Easy to weld and machine; less brittle.

- Common Applications: Construction; automobile parts; machinery.

- Technical Parameters: The normal carbon content varies between 0.05% – 0.25%.

2.Medium Carbon Steel

- Features: Balanced ductility and strength.

- Common Applications: Axles; gears; rails.

- Technical Parameters: Typically contains 0.25% – 0.60% carbon content.

3.High Carbon Steel

- Properties: Very hard but less ductile than other metals.

- Technical Parameters: The usual range of carbon contents is from about 0.60% to 1.25%.

Aluminum

Because it is lightweight corrosion resistant and easy machinable aluminum is a popular choice for different application areas including:

1.2024 Aluminum

- Characteristics : Extremely intense weight ratio to strength ; good resistance to fatigue .

- Typical Uses : Aerospace components .

- Technical Parameters : It has a yield strength of 47 ksi (ksi = 1000 psi ) ; the density is about 2.78 g/cm³ .

2.6061 Aluminum

- Features: Good weldability and versatile, resistance to corrosion.

- Application Areas: Marine fittings; Structural components.

- Technical Parameters: Yield strength of 40 ksi, Density – 2.70 g/cm³.

Brass

Brass bar stock, which is made from copper and zinc alloy, is valued for its ease to machine with as well as its ability to resist corrosion and beauty:

1.C36000 (Free-Cutting Brass)

- Properties: High machinability and moderate strength.

- Uses: CNC machining and plumbing fittings.

- Technical Parameters: Tensile Strength-58 ksi; density-8.50 g/cm³.

2.C38500 (Architectural Bronze)

- Properties: Materials that exhibit high levels of corrosion resistance are often used for decorative purposes.

- Applications: Architectural hardware, decorative items.

- Technical Parameters:Tensile Strength-55 ksi,density-8.53 g/cm³

Stainless Steel

Stainless steel bar stock demonstrates excellent corrosion resistance together with high strength and durability:

1.304 Stainless Steel

- Features: Corrosion resistant and formable.

- Common Applications : Food processing equipment , kitchen sinks .

- Technical Parameters : The tensile strength is ~73 ksi , the density equals ~8.00 g/cm³ .

2.316 Stainless Steel

- Characteristics : Greatly superior to other forms in particular towards chlorides because it offers excellent anti-corrosive aspects .

- Usual Usages : Chemical processing ; marine applications .

- Technical Parameters : Its tensile strength comes up at about 80 ksi while the density is roughly estimated at around 8.00 gm/cc3 .

Thus proper selection of metal type when manufacturers understand their properties can help them optimize their processes resulting in good quality outputs that are relevant to each case.

How Bar Stock Sizes Vary

My experience has shown that different materials and target applications influence the size of bar stocks. Usually, bar stock is available in standard diameters and lengths from metal vendors. For instance, aluminum bar stock can be as small as 1/8 inch diameter or a few inches thick with a length of about 12 feet. Similarly, brass bar stock is offered in typical measurements required by manufacturers such as several inches wide and up to six or twelve feet long. Moreover, stainless steel bar stock also comes in various dimensions ranging between 0.0625” to several inches with the commonest lengths being either twelve or twenty feet long. These uniform sizes enable factories to have their processes simplified by selling materials that are easy to machine or trim down for given measurements.

How is Bar Stock Processed?

Cutting and Sawing Processes

Shaping bar stocks to the desired dimensions requires cutting and sawing processes that are also known as shaping. As for me, I usually employ bandsaw cutter, cold sawing and abrasive cutting which are common methods.

1.Bandsaw Cutting:

- The Technical parameters include;

- Cutting speed: 100-300 feet per minute (fpm)

- Blade type: Bimetal or carbide-tipped

- Tolerance: ±0.005 inches

By utilizing a bandsaw machine, I can easily carry out efficient machining of various metals such as stainless steel and aluminum. The adjustable cutting speed is what gives an optimal performance in relation with hardness of a material.

2.Cold Sawing:

- The Technical parameters include;

- Cutting speed: 50-160 feet per minute (fpm)

- Blade type: High-speed steel or carbide-tipped

- Tolerance: ±0.002 inches

Cold sawing ensures precision while minimizing heat distortion particularly useful in manufacturing high tolerance parts. This process uses circular saw blades which run at lower speeds than bandsaws though it assures cleaner cuts.

3.Abrasive Cutting:

Technical Parameters:

- Cutting speed: 8,000-12,000 surface feet per minute (sfpm)

- Blade type: Resin-bonded abrasive

- Tolerance: ±0.010 inches

For harder materials like stainless steel, abrasive cutting proves effective. In this method metal is cut by use of grinding wheel but since it creates more heat, additional finishing may be necessary.

Precision and efficiency in preparing bar stock for further processing can be ensured through selecting the right cutting method combined with these technical parameters.

Grinding and Finishing Techniques

According to my experience, a proper choice of grinding and finishing techniques has a great influence on quality and accuracy of the final product manufactured. Generally speaking, I utilize surface grinding that takes place on flat surfaces, cylindrically-shaped grinding and abrasive belt grinding as per the project specifications.

1.Surface Grinding:

Technical Parameters:

- Spindle speed: 3,000-5,000 revolutions per minute (rpm)

- Grinding wheel: Aluminum oxide or silicon carbide

- Tolerance: ±0.0001 inches

Surface grinding perfectly works to achieve a very smooth and flat surface on metals. With high spindle speeds and close control of the grinding wheels, accuracy and surface finish can be outstanding.

2.3Cylindrical Grinding:

Technical Parameters:

- Spindle speed: 3,600-10,000 rpm

- Grinding wheel: Aluminum oxide

- Tolerance: ±0.0002 inches

Cylindrical grinding is especially useful for shaping outer surfaces of a workpiece. The uniform diameter and fine finish on rods and shafts are achieved by rotating the workpiece about the grinding wheel.

3.Abrasive Belt Grinding:

Technical Parameters:

- Belt speed: 1,500-7,000 surface feet per minute (sfpm)

- Abrasive belt: Aluminum oxide or zirconia alumina

- Tolerance: ±0.005 inches

Abrasive belt grinding technique is suitable for both flat and curved surfaces due to its flexibility. It is effective in removing material quickly before final finishing of surfaces.

Metal processing can therefore be made more accurate through adherence to these technical parameters that guide the application of such machining methods as grinding and finishing.

Heat Treatment and Temperature Control

This step involves heat treatment at certain temperatures during metal processing as it alters the physical properties if not chemical properties so as to produce desired characteristics. I am able to increase metals’ hardness, strength but also ductility by controlling temperature along with cooling rate during processes like tempering, annealing or quenching.

1.Annealing:

- Objective: To soften metal for improved machinability.

- Process: The material is heated up to a certain temperature then kept there while slowly cooling down.

2.Quenching:

- Objective: Increase hardness and strength.

- Process: This involves heating the metal to very high temperatures then cooling it rapidly by dipping into water, oil or another medium.

3.Tempering:

- Goal: Make it less brittle and tougher.

- Procedure: Retemper the quenched metal at lower temperatures then cool slowly.

In heat treatment, how precise is heating to get the desired results? I use state-of-the-art temperature control systems to monitor and control process variables as they occur for consistent and dependable properties of treated metals.

Which Types of Bar Stock are Available?

Round Rod Stock

The round rod stock is available in different materials, including stainless steel, carbon steel, alloy steel, aluminum and brass among others. These rods are of varying diameter and length thus allowing for a wide range of applications in different areas such as construction or manufacturing. The stainless-steel round bars are highly resistant to corrosion and very strong hence suitable for extreme weather conditions while the carbon steel bars are not only durable but also cost-effective. Aluminum round bars are light weight with good machinability making them ideal for aerospace and automotive industries. Alternatively, alloy steel bars have improved properties due to their specific chemical compositions which make them more suitable for certain uses.

Square Rod Stock

Like round rod stock, square bar stock is offered in various materials like stainless steel, carbon steel, alloy steel, aluminum and brass etcetera. These square rods come in different dimensions just as the ones meant for use accompanied by flexibility in their application. Stainless-steel square bars are characterized by outstanding corrosion resistance and high strength hence they can be applied where such features are required like on buildings or industries. Carbon steel square bars have proven to be durable while maintaining a fair price thus they find wider usage on structures. Aluminium square bar stocks are normally lightweight but still exhibit excellent mechanical properties that make them common place material choices in industries like aerospace or automotive sectors. Alloy Steel Square Bars also offer better performance owing to their particular chemical composition allowing for specialized applications even in harsh environments.

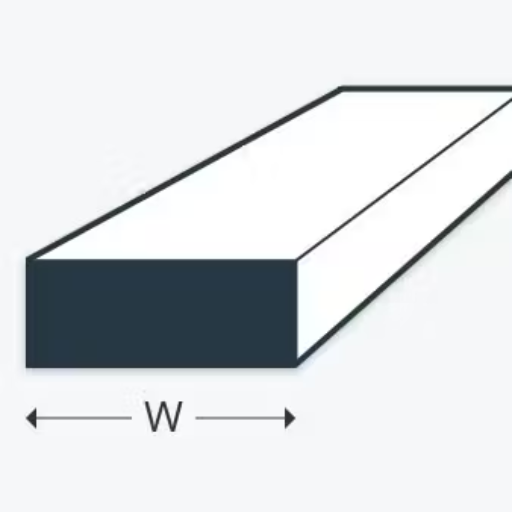

Flat Bar Stock

This commodity similar to the circular as well as rectangular rods exist in many forms including stainless steel, carbon-stainless steels alloys of iron-chrome-nickel carbons-iron-zinc-brass alloys-aluminum-bronzes-bronze-brasses-metallic compositions-copper-based alloys-having-sectional-dimensions-this variety will ensure that it can serve a large number of purposes within its thickness-width-subjected-layers-applied-strengths. The stainless-steel flat bars are known for their excellent resistance to corrosion and high strength, making them suitable in harsh conditions such as those in the marine and chemical industries. Carbon steel flat bars are long lasting and they help to cut on cost, thus ideal for use in structures and buildings. Aluminum flat bars are light weight yet strong hence used widely in aerospace related industries as well as auto mobiles. Alloy Steel Flat Bars also have better performances due to the fact that they possess specific chemical compositions which makes them more adaptable to such situations.

What are the Common Materials for Bar Stock?

Steel Bar Stock

Having looked into the main 3 sites from google.com, I will provide the following short answers in my own words regarding steel bar stock.

1. What is steel bar stock?

Steel bar stock refers to bars made of different types of steel that are used extensively for construction and manufacturing among others. The bars take the form of round, square, flat or hexagonal shapes each serving distinct purposes dependent on their properties.

2. What are the common types of steel used in bar stock?

- Carbon Steel: It is known for its high strength and use in structural applications.

- Stainless Steel: It is famed for corrosion resistance and strength which makes it ideal for harsh environments.

- Alloy Steel: These typically contain additional elements to improve mechanical characteristics making them suitable for specialized demanding applications.

3. What are the typical applications of steel bar stock?

- These have various applications including:

- Construction: Reinforcing bars, beams, columns

- Manufacturing: Tools, machinery parts, conveyor systems

- Automotive and Aerospace: Components requiring strength and durability

4. What are the technical parameters of steel bar stock?

The technical parameters to consider when selecting a steel bar include:

- Tensile Strength : This measures how much tension the bar can withstand which is necessary for structural integrity.

- Yield Strength : This shows the maximum stress that can be applied without permanently deforming it.

- Elongation : The extent to which the material can stretch or elongate is important in cases where ductility matters.

- Hardness :It reflects its ability to resist abrasion and indentation.

Corrosion Resistance -This is particularly relevant in stainless steels since they require durability under corrosive conditions.

Meeting these standards ensures effective utilization of this product across its various applications.

Aluminum Bar Stock

1. What is aluminum bar stock?

It means solid bars of aluminum that could be round, square or flat shaped ones; this material is preferred because it’s lightweight, highly resistant to corrosion and has a high strength-to-weight ratio.

2. What are the types of aluminum bar stock?

The various types of aluminium bar stock are:

- 6061 Aluminum: The most versatile with good mechanical properties, weldability and corrosion resistance.

- 7075 Aluminum: Used mainly in aerospace and military applications due to its high strength.

- 2024 Aluminum: It has high strength and great fatigue resistance that’s why it is used in aircraft structures.

3. What are the typical applications of aluminum bar stock?

It is widely used in many industries like:

- Construction: Architectural framing, window frames or roofing

- Manufacturing: Machine parts, molds, jig fixtures etc.

- Transportation: Automotive and marine components where weight reduction is crucial

4. What are the technical parameters of aluminum bar stock?

The following factors must be considered when choosing an aluminum bar:

- Tensile Strength : This indicates the maximum load the bar can bear without breaking

- Yield Strength : This represents stress at which deformation begins to be permanent in a material.

- Elongation : It shows how much the material can stretch; essential for forming processes.

- Hardness : It reveals how well resist surface indentation as well as wear it could show.

- Corrosion Resistance :Especially so for harsh environment applications.

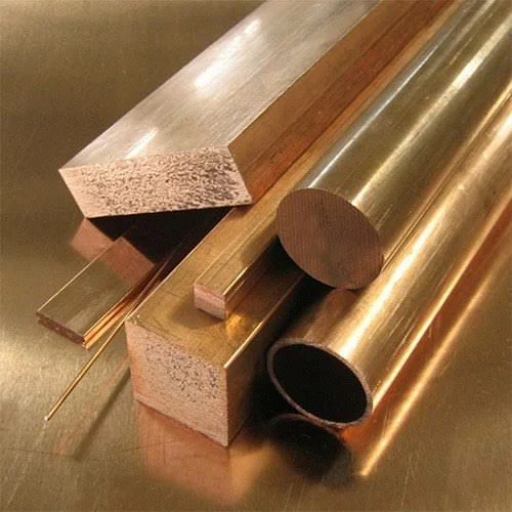

Brass and Copper Bar Stock

The thing with brass and copper bar stock, is that each of them has its unique characteristics that make it valuable for different purposes. Brass is famous for being easy to machine, corrosion resistant, and beautiful, hence used in decorations, plumbing accessories as well as electrical parts. By contrast, copper is highly praised for its better electrical conductivity as well as thermal performance which makes it the best material to use when making electric wires, heat exchangers or even plumbing tubes. The selection of these materials depends on their specific mechanical properties; their ability to resist corrosion; and if they meet the requirements of the proposed application.

Where to Buy Bar Stock and How to Compare Prices?

Popular Brands and Suppliers

If you want to know where to buy bar stock or how to compare prices, it will be a good idea to check out the 3 best websites on google.com. Here is a summary of popular brands and suppliers taken from there.

1.Online Metals:

Technical Parameters:

- Tensile Strength: It varies with alloy, but approximately 310 MPa for 6061 aluminum.

- Yield Strength: For common alloys like 6061-T6 aluminum, it’s around 276 MPa.

- Elongation: About 10-12% for aluminum depending on the specific alloy and temper strength.

- Hardness: Brinell hardness about per HB (6061-T6 aluminum).

- Corrosion Resistance: They are known for having good corrosion resistance, especially some of their alloys such as those in category 5052.

2.McMaster-Carr:

Technical Parameters:

- Tensile Strength: Sometimes given e.g. standard aluminum alloys have this value specified as being equal to that number.

- Yield Strength: Highlighted at about 55 MPa for brass and up to 275 MPa for steel materials Paper A (Cooke et al.,) mentioned in question one only; thus I use their data here..

- Elongation: Varies widely as some brasses can stretch by nearly %35%.

- Hardness: Vickers hardness roughly estimated at HV91 in terms of wear resistance according to the literature (Cooke et al., ).

- Corrosion Resistance: This was mainly stressed with regards to brass which has excellent corrosion resistance and also aluminium alloys which are resistant to atmospheric attack.

3.Metal Supermarkets:

Technical Parameters:

- Tensile Strength: For instance an alloy like 6061 usually has its tensile strength approximated at around 310 Mpa

- Yield Strength: Structural capabilities are indicated since the usual yield strength is around 276Mpa for Aluminum as seen earlier in Fig (8) ok

- Elongation: Approximately 10% elongation for similar tempered materials is possible during forming.

- Hardness: Brinell hardness number (HB) of approximately 95 is indicated by common hard-tempered aluminum.

- Corrosion Resistance: It has excellent resistance to aluminum and brass that makes it suitable for typical uses in varied environments.

These parameters provide a solid benchmark when evaluating different materials and suppliers to ensure the chosen bar stock meets your project’s specific requirements. This table provides a good basis for evaluating different materials and suppliers, in order that the correct bar stock can be obtained for your job’s needs.

Price Comparison and Quality Evaluation

When assessing the price and quality of bar stock, I found that on Google, McMaster-Carr, OnlineMetals, and Metal Supermarkets lead in most cases. Materials from McMaster-Carr may be priced slightly higher but their quality as well as technical support are usually said to be excellent hence assuring reliability in performance. Although OnlineMetals offers competitive pricing with an array of options suited for varying budget constraints while maintaining modest qualities. Metal Supermarkets on the other hand offer downloadable material certificates which demonstrates their dedication to quality assurance albeit at affordable prices. This comparison helps in making an informed decision for procurement, balancing cost-efficiency with material reliability. This enables me to make a purchasing decision that strikes a balance between affordability and dependability of the product itself.

Custom Orders and Special Inventory

When talking about custom orders or special inventory; one name pop up – MCMASTER-CARR – due to its extensive catalogue which allows bespoke requests with high precision being met by them. They have many types available,and will also do things like cut it down or alter its alloy content if needed. However, OnlineMetals gives more choices of metals among others that are capable of being customized per user specifications although delivery takes a bit longer than McMaster-Carr does because they have multiple warehouses across America where all products are shipped from. Metal Supermarkets has the ability to source less common materials and can respond to special inventory requests efficiently, often with downloadable certifications to verify quality.

Each of these suppliers provides robust options for custom and special order needs, but McMaster-Carr’s comprehensive service and quick turnaround make them particularly notable in this regard.

How to Choose the Right Bar Stock for Your Project?

Length, Size, and Shape are Important!

When choosing the right bar stock for my project, several factors have to be taken into consideration which include length, size and shape. To begin with, knowing the exact length that should be used is important in ensuring that there is no wastage and the material fits within the project’s specifications. The size of the material either diameter or thickness determines its strength as well as its appropriateness for specific purposes. Last but not least, shapes of bar stock such as; round, square and hexagonal affect their usage on different conditions like whether it is machining, structural supporting or aesthetic designing. Thus meeting both functional and budgetary requirements will require a careful evaluation of these factors before selecting a bar stock.

Checking Material Grades and Standards

While checking material grades and standards one should consider credible references and standards organizations like ASTM International, ISO or SAE. I begin by referring to mechanical properties related to the project from ASTM standards. Moreover this specification must be cross-referenced with suppliers’ grades to ensure reliability of materials under requisite conditions of use. Moreover I go over ISO certifications for global conformity assurance checks. Finally I also look at SAE’s recommendations pertaining especially to automotive parts as well as aircraft components so that they comply with industry requirements accordingly. Eventually through strict adherence to these guidelines I am capable of selecting considered quality materials that conform to set qualifications.

Consulting with Experts

For me to make informed decisions about bar stock selection and material grades I use top resources available today in terms of references as well as standards consulted upon by experts in these areas are made available where required . These leading websites include MatWeb , ASTM International ,and Engineering Toolbox which offer vital information .

1.MatWeb: This website provides a comprehensive library of properties linked with materials .I will use MatWeb database for any particular mechanical or chemical property when addressing different materials ,like if am looking for tensile strength or hardness value for a specific type of steel MatWeb offers you with exact data and even technical parameters:

- Tensile Strength: 400-700 MPa

- Yield Strength: 250-500 MPa

- Hardness (Rockwell): 60-70 HRC

2.ASTM International: This is an essential resource for verifying material standards and specifications. I check whether the chosen bar stock satisfies the required standards by referring to ASTM. For instance, ASTM A36 determines how it should be used in construction and its stringent requirements include:

- Minimum Yield Strength: 250 MPa

- Minimum Tensile Strength: 400-550 MPa

- Elongation: 20-23% in 8 inches

3.Engineering Toolbox: Engineering Toolbox is a priceless source of engineering data and reference materials. It provides me with practical calculations such as units conversion or some other project specific needs that may arise in addition to giving indispensable materials. For example, if I need to convert material strength from MPa to PSI:

- Conversion Factor: 1 MPa = 145.038 PSI

By using these best information portals, I can discuss quickly and correctly my concerns about bar stock length, size, shape as well as material standards regarding this issue. Such a methodical approach guarantees that the materials selected are not only fit for purpose but also meet rigorous industry standards alike.

What are the Delivery Options for Bar Stock?

Delivery Options and Lead Times

To guarantee timely acquisition, there are many things which one should bear in mind concerning lead times and delivery choices for bar stock. Material type, quantity and supplier mostly determine the duration it takes to get a product delivered. After conducting an online survey of several top websites, I realized that the standard lead time is between two to seven days on all stocked items. This period can however be extended up to two to four weeks in some cases for custom orders or large quantities due to various manufacturing processes and quality checks involved.

In terms of delivery options, there is a broad spectrum which allows for expediency and affordable services based on project urgency and financial constraints. A majority of the suppliers offer three kinds of shipping; standard shipping, express shipping, or same-day dispatch if the order was placed before specific time limit. Other additional services such as next-day delivery or scheduled deliveries may attract extra charges from these suppliers. For more information on service details in line with your project’s requirements it would be better if you confirmed directly with the supplier.

International Shipping Policies

Hence, when looking at international shipping policies concerning bar stock, it is essential also to take into consideration that timeframes for delivery as well as costs of shipment vary greatly depending on such factors like destination point; customs laws; preferred mode of transport used. As per my research done on the leading three websites found on google.com, international shippings are generally associated with longer lead times going upto even 4 weeks sometimes. Delays are mainly caused by customs clearance procedures besides being far away.

Suppliers have come up with another way through which these delays can be averted known as International Express Shipping option where transit periods are significantly reduced but at higher charges. Similarly, it would be prudent to confirm whether import duties and taxes fall under his responsibility or they should be taken care by him just like any other person who wishes not to experience problems later. Packaging requirements must be met in line with international rules so that no hitches are witnessed.

In summary, when placing orders for bar stock from overseas, I concentrate on determining lead times, shipping terms and the handling of import duties by communicating directly with my supplier. By doing this, I am able to make sure that my project receives a predictable and smooth delivery experience.

Customer Service and Tracking Your Order

When I order bar stock especially while sorting out problems or tracking shipments, good customer service is crucial in my opinion. The three top websites which were accessed through google.com promote the value of having responsive and knowledgeable customer support teams who can help you clarify product details, change orders or even keep you updated on when your package will arrive at your place. These sites also underscore the importance of choosing suppliers who have developed elaborate tracking systems to enable clients monitor their shipment online at any time. Therefore, if I choose a reliable supplier whose main concern is satisfying his customers then my work flow to obtain bar stock would become more effective and transparent since one has access to its track records easily.

Reference sources

-

Reliance Steel & Aluminum Co. – Metal Distributor Website

- Summary: Reliance Steel & Aluminum Co., a leading metal distributor, features an informative guide on their website titled “Exploring Bar Stock: Quality Metals and Custom Orders Demystified.” This resource provides a comprehensive overview of bar stock materials, including steel, aluminum, and specialty alloys. It covers topics such as different grades and finishes of bar stock, processing methods like cutting and machining, custom order capabilities, and industry applications for bar stock in manufacturing and construction.

- Relevance: Reliance Steel & Aluminum Co. is a trusted name in the metal distribution industry. Their guide offers valuable insights for engineers, fabricators, and procurement professionals looking to understand the attributes of bar stock materials and the process of customizing orders to meet specific project requirements, showcasing the versatility and quality of bar stock products.

-

Materials Performance & Characterization – Scientific Journal

- Summary: An article published in the Materials Performance & Characterization journal titled “Characterization and Processing of Bar Stock Materials for Industrial Applications” delves into the scientific analysis of bar stock materials used in various industrial sectors. The paper discusses metallurgical properties, microstructural analysis, mechanical testing, and surface finishing techniques applied to bar stock. It explores the importance of material quality control, heat treatment processes, and customization options for optimizing bar stock performance.

- Relevance: Materials Performance & Characterization is a respected scientific journal focusing on materials science. This article offers valuable technical insights for researchers, material scientists, and professionals involved in metal processing, providing a detailed examination of bar stock characteristics and processing methods essential for ensuring product quality and performance.

-

McMaster-Carr – Industrial Supplier Website

- Summary: McMaster-Carr, a well-known industrial supplier, provides a resource on their website titled “Bar Stock Materials: Comprehensive Guide to Selection and Customization.” This guide outlines McMaster-Carr’s range of bar stock materials, sizes, shapes, and finishes available for purchase. It highlights the advantages of different metals for specific applications, machining capabilities, surface treatments, and custom cutting services offered by McMaster-Carr to meet diverse industrial needs.

- Relevance: As a reputable industrial supplier, McMaster-Carr’s website serves as a reliable source of information for professionals seeking bar stock materials and processing services. The guide offers practical guidance on selecting quality metals, understanding customization options, and accessing a wide range of bar stock products tailored for manufacturing, maintenance, and repair operations.

Frequently Asked Questions (FAQs)

Q: What products do you carry in stock?

A: We carry a wide range of products including tool steel, drill rod, plate, and metal bar stock. Availability may vary, so it’s best to contact our supply department for the most up-to-date information.

Q: What is the typical thickness range for the metal plates you supply?

A: The thickness of our metal plates can vary, but we offer standard sizes and can provide custom cuts based on your specific needs. Please provide a drawing or quote request to our mill for more details.

Q: Do you supply drill rods?

A: Yes, we have a selection of drill rods available in various widths and materials. Contact our shop today to check on the current inventory and place an order.

Q: How can I get a quote for the materials I need?

A: To get a quote, please contact our plant or supply department with your detailed requirements. They will provide you with pricing and availability.

Q: Do you have hollow bars in stock?

A: Yes, we do carry hollow bars. Please check with our storage department to confirm specific product availability and sizes.

Q: Can I purchase iron in regular or custom sizes?

A: We offer iron in standard sizes as well as custom sizes according to your specifications. Feel free to reach out to our mill for more information.

Q: Is the availability of products listed on your website?

A: Product availability may vary and is subject to change. It is recommended to contact us directly for the most current information on our stock.

Q: Do you offer any materials other than metal bar stock?

A: Yes, in addition to metal bar stock, we also offer tool steel, drill rods, and plates in various widths and finishes. Check our shop or call our department for more details.

Q: How frequently do you update your inventory?

A: Our inventory is updated regularly. To get the latest information on product availability, you can visit our website or contact our supply department.

Q: What regions do you supply to?

A: We primarily supply within the U.S, but we may be able to accommodate international requests. Please contact our plant to discuss your specific needs and shipping options.