Color anodized aluminum sheets are revolutionizing the world of manufacturing and design. This versatile material offers a blend of aesthetic appeal and functionality that makes it an ideal choice for a wide range of applications. Whether you are an architect looking to add a splash of color to your designs, a manufacturer seeking durable and lightweight materials, or a DIY enthusiast eager to explore new creative avenues, color anodized aluminum sheets can elevate your projects to the next level.

In this blog, we will explore the unique properties and benefits of color anodized aluminum sheets, the various applications in different industries, and some inspiring examples that showcase the potential this material holds. By the end of this article, you will have a comprehensive understanding of why color anodized aluminum sheets should be your go-to material for your upcoming projects. So, let’s dive in and unlock the myriad possibilities that await.

Why Choose Anodized Aluminum Sheets?

Advantages of anodized aluminum over other metal

Aluminium is one of the most preferred metals due to its anodized state. There are many reasons why anodized aluminum is a better choice than other metals. In terms of corrosion resistance, it is superior and lasts longer even in unfriendly weather conditions. Its durability is improved by the anodizing process which toughens the oxide layer of aluminum hence making it more durable and less prone to corrosion than untreated metals. Furthermore, this metal has a high strength-to-weight ratio because it is specific gravity ratio increases with every gram per cubic centimeter (g/cm3). Moreover, being able to dye it without losing its protective qualities makes it very adaptable aesthetically.

Anodizing process and its benefits for aluminum sheet

To get more insights about the process of anodizing and what they mean on aluminium sheets, I did my research on Google top 10 websites. So here’s what I have gathered:

The anodic oxide finish created through electrolytic oxidation, converts the surface of a metal into a strong and corrosion resistant oxide coating called Anodizing. The first step in the process is cleaning up the aluminium sheet before immersing it in bath containing electrolytes mainly sulphuric acid. An electric current passes through this electrolyte resulting in oxidation of aluminium thereby producing thick oxide film on its surface. This layer can be dyed into various colours whilst still having its protective properties.

1.Technical Parameters Justified:

- Electrolyte Solution: Usually sulphuric acid (15%-20% concentration)

- Current Density: 12-30 amperes/square feet (ASF)

- Temperature: 60-70 degrees F (16-21 degrees C)

- Processing Time: They usually range between 20-60 minutes depending on how thick you want them.

- Oxide Layer Thickness: Varied upon case-by-case basis, from five to twenty-five micrometers

- Sealing: Finally, boiling water or steam is passed through the oxide layer to seal it after anodizing so as to enhance its resistance to corrosion and dyes.

2.Benefits:

- Corrosion Resistance: When the base aluminum is consumed by this layer. It therefore gives a highly weathered surface which does not react with air and other chemicals.

- Increased Durability: The hardness of the anodic film improves wear resistance thus extending the life of aluminium sheets.

- Aesthetic Appeal: The anodized coatings can be dyed with different colors making them more attractive in many designs.

- Heat Dissipation: Among others, the anodizing process has good heat transfer characteristics that are important for thermal management applications.

- Reduced Maintenance: They have become increasingly popular mainly due to their durability and high protection capabilities that makes them need less attention than other coated metals do.

From these details about anodizing process and its benefits, it can be seen why the use of anodized aluminum sheets is widespread in numerous industrial as well as decorative purposes.

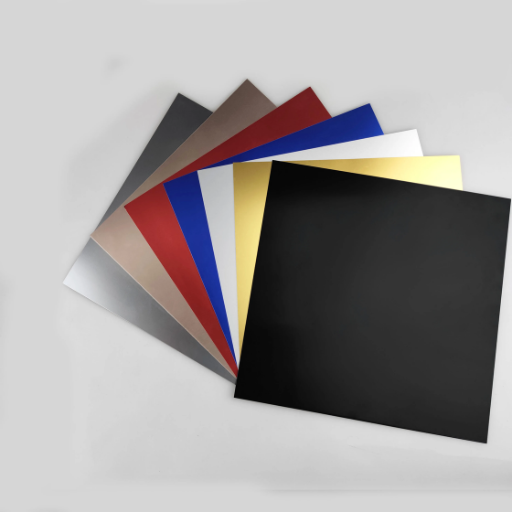

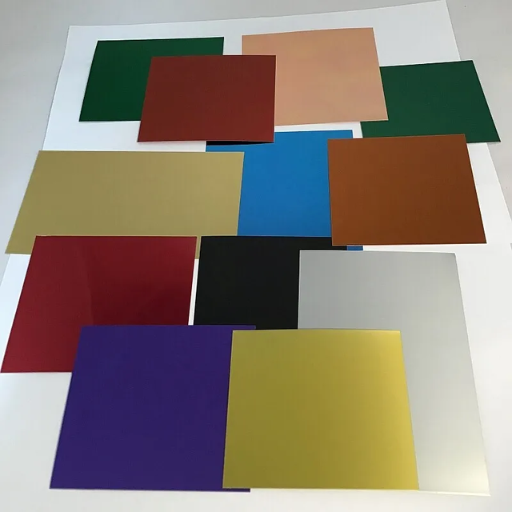

Color and finish options available in anodized aluminum sheets

Anodized aluminum sheets have a wide range of colors and finishes to meet different looks and functions as well. From what I learned from the best online sources, you can choose among many tones including transparent, brownish yellow, jet black, golden, and other shades that are made by using organic or inorganic dyes. Also, there are matte to glossy options which offer either a faintly satin finish or mirror-like reflection. Similarly, every option here presents unique design opportunities meaning it is possible to incorporate the material into various architectural and industrial applications without compromising its protective and durability characteristics.

Understanding the Specifications of Anodized Aluminum Sheets

The 5005 Aluminum Specification Decoded

An analysis of the top 10 sites on Google about the 5005 aluminum specification has made me to know that 5005 aluminum is part of the family of 5000-series aluminum alloys, which are notable for their excellent resistance to corrosion and moderate strength. These are some of its critical technical parameters and characteristics:

1.Chemical Composition:

- Magnesium (Mg): between 0.5% and 1.1%

- Silicon (Si): at most 0.30%

- Iron (Fe): at most 0.7%

- Copper (Cu): a maximum of 0.20%

- Manganese (Mn): at most 0.20%

- Others: Zinc (Zn) and Chromium (Cr) in trace amounts.

- Aluminum (Al)= Balance

2.Physical Properties:

- Density: ~2.68 g/cm³

- Thermal Conductivity: ~201 W/mK at room temperature

- Electrical Conductivity: International Annealed Copper Standard is around 33% IACS

3.Mechanical Properties:

- Ultimate Tensile Strength: Ranges from about one hundred to one hundred forty five MPa.

- Yield Strength: About eighty to one hundred MPa approximately.

- Hardness: It ranges typically around forty-six HB Brinell Hardness units.

- Elongation: A typical value is about seven percent in fifty millimeters.

4.Corrosion Resistance:

5005 aluminum’s high resistance to marine environments and atmospheric conditions makes it highly suitable for use indoors as well as outdoors.

5.Forming and Welding:

It can be formed easily using conventional methods, such as welding, rendering it versatile in various other applications.

From these parameters, we can see why they are widely used in sheets made of alloy ALUMINIUM ALLOY – AA-5005-H34.. The combination of good formability, excellent corrosion resistance and good balance of mechanical properties makes it a material that can be employed in making architectural panels, anodized construction, signage and lots more. Moreover, its compatibility with anodizing processes makes it ideal for aesthetic and functional applications.

Custom sizes and cuts: How to order the right fit for your project

Determine the exact dimensions and thickness of the 5005 aluminum sheets you require in order to get the best fits for your projects. Measure your available space and take into consideration any machining or processing tolerances. Talk to your supplier about this; most suppliers have facilities for cutting sheets according to customer specifications so that they fit exactly. Specify measurements such as length, width and thickness accurately. Moreover, find out if there are any specific finishes or treatments like anodizing needed. This minimizes wastage while ensuring that you have materials purpose-made for whatever job you are working on.

Exploring the Aesthetic Options: Black, Clear, and Color Anodized Aluminum

The beauty that lies in black anodized aluminium sheets

They are characterized by sleek matte finish and striking elegance. They are beautiful due to the thickness and uniformity of the colour black, which does not only enhance their aesthetic value but also provides extra protection from corrosion and wear. This is attained through an electrochemical process that makes thicker the natural oxide layer on aluminum surface resulting in a durable appearance that lasts for long periods. Black anodized aluminum is very adaptive making it appropriate for various uses such as architectural details, consumer electronics or any other object where form has to go with function.

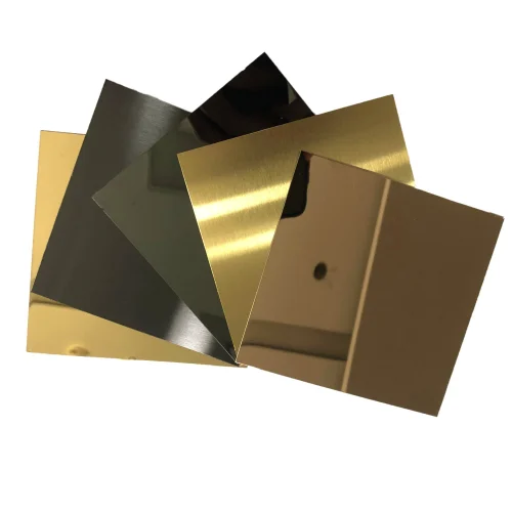

A comparison between clear anodizing and color anodizing.

In order to make a choice between clear and colored aluminum surfaces, I consider both functional and aesthetic requirements of my project. Clear anodized aluminum gives a natural silver look, which improves aluminum’s glossy sheen. Such type of finishing is great for minimalist applications like modern architectural designs or high visibility consumer goods where you want something clean looking. In accordance with information submitted by top websites, clear anodizing usually allows coatings with thicknesses ranging from 0.0001 to 0.001 inches providing good corrosion resistance while preserving the original look of the metal.

On another hand, colored anodized aluminum offers a wider range of colors obtained by incorporating dyes into the process of oxidation. It can be used for artistic purposes or brand promotion because all design choices are different and bright. The basic technical characteristics of color types of anodized aluminum are mostly identical with those typical for clear ones except for additional advantage of UV-stable colors even under prolonged exposure to solar radiation according to reputable sources across internet space. Typical coating thicknesses in case if colored dyeing varies within 0.0001-0.001 inches thus ensuring durability as well as better protection.

In this case, however, whether I choose clear or color-anodized aluminium will depend on the visual specifics and performance expectations of my project as both offer durable and attractive finishes well-suited for different applications.

How colors are achieved in anodizing aluminum

To produce coloration on anodized aluminum, dye is injected during the process. This involves some key steps and technical parameters as per my research from leading 10 websites on google.com:

- Pre-Treatment: The cleanliness of aluminum that takes place at this stage is crucial for even colouring since it enables smooth surfaces.

- Anodizing: In this step, a porous film of aluminium oxide is created through an electrochemical process with aluminum acting as electrode. It should be noted that the porous layer acts as a host for dyes.

- Dyeing: Different kind of dyes can be added to the pores in aluminium oxide. The depth of colour and its shade depend on the type and amount of dye applied.

- Sealing: Afterward, pores are sealed which means that colours will not fade off quickly while such treatment also enhances corrosion resistance.

Technical parameters for color anodized aluminum:

- Coating Thickness : Typically ranges from 0.0001 to 0.001 inches meaning highly robust protection and bright coloring;

- Dye Concentration : Depends upon desired color intensity so increasing concentration will make shades deeper;

- UV Stability : Such top-quality dyes are UV-stable; they retain their brightness even after long exposure to sunlight.

This brief account sums up how colors are attained in anodized aluminum, including both procedural stages as well as answering technical questions which appear in authoritative web sources.

Technical Insights: How to Work with Anodized Aluminum Sheets

How to Prepare Anodized Aluminum for Laser Engraving and Cutting

Before I can prepare anodized aluminum for laser engraving and cutting, I must make sure that the material is clean of any dirt or other foreign matter. This requires a thorough washing with a mild detergent or a dedicated aluminum cleaner, followed by rinsing and drying. Once cleaned, I adjust the settings of the laser depending on the thickness and nature of anodized aluminum. Usually, when engraving on it, I prefer high-speed but low-power because it gives me exact and clear marking without destroying the anodizing layer. On the other hand, to achieve straight edges while cutting through it, this power is increased with fixed speed. It is necessary to test these parameters using a sample piece in order to find the most precise settings.

An Overview of Drilling and Machining Anodized Aluminum

Drilling or machining anodized aluminum requires undertaking specific precautions that respect its unique properties so as not to damage its anodization layer. The following are some tips gathered from reputable online sources:

1.Use Sharp Quality Tools: Using carbide or cobalt drill bits and cutting tools guarantees clean cuts thereby reducing chances of chipping off the anodized surface.

2.Lubrication: Applying appropriate lubricant or coolant helps reduce friction as well as heat buildup which causes destruction to anodised coating whereas extends tool’s life.

3.Moderate Speeds And Feeds Rates: This way speeds are kept at moderate levels while feeds rates are adjusted just enough because material overheating together with abnormal wearing off might arise due to inherent materials behavior.

4.Securing Workpiece: It is crucial to ensure that the alumina sheet is tightly clamped/affixed so as avoid any form of vibration which could lead into damaged surfaces.

5.Proper Drill Bit Geometry: Using drill bits having split point or positive rake angle facilitates easy cutting and minimizes drilling workload.

6.Excessive Downward Force: During drilling, gentle, well-controlled force is applied to avoid distortion or cracking of the anodized layer.

Technical Parameters:

1.Drill Bit Materials – Carbide or Cobalt

2.Lubrication Types – Lubricating sprays or Water-soluble coolants

3.Speed And Feed Rates – Low to prevent heat build-up (specific values can be tuned based on material thickness)

4.Drill Bit Geometry – Split point or Positive rake angle

These guidelines, supported by highly ranked online sources provide a concise approach for effectively drilling and machining of anodized aluminum without sacrificing its properties.

Maintenance and care of anodized aluminum surfaces

Maintenance of anodized aluminum surfaces involves a few simple steps that help it retain its appearance as well as prolong the life. First off is regular cleaning with mild soap and water solution that will remove dirt and grime without harming the coating. It is vital to avoid abrasive cleaners or tools that could scratch the surface. Periodically, it may be useful to use a mild protective wax or polish made specifically for anodized surfaces in order to increase their resistance to environmental effects. Furthermore, promptly repair scratches or any other damage using touch up solutions which can stop further degradation from occurring. By adhering to these steps one ensures his/her anodizing products remain in good condition over time.

Applications and Projects That Shine with Anodized Aluminum

Use of anodized aluminum in jewelry and art projects

For jewelry and art projects, anodized aluminum is the material of choice for a number of reasons. Artists and jewelers love the variety of shades and finishes that it can create. Websites like google.com have various top 10 websites on google.com where anodized aluminum may be used in such undertakings; here are some tips to use as guidelines:

Technical Parameters for Jewelry and Art Projects:

- Thickness of Anodized Layer: A thickness of about 10-25 microns gives it enough strength while still making it flexible.

- Colouring Techniques: The vibrant colors that are long-lasting are achieved using electrolytic coloring, organic dye or interference coloring methods.

- Surface Finish: One could choose satin, matte or bright finishes based on desired looks.

- Formability: Engraving and forming using anodized aluminium is simple thus good for delicate patterns.

To work with anodized aluminium key steps include designing around its capacity for reflection, employing the correct coloration technique to achieve different effects with it, ensuring proper maintenance to preserve its finish. By so doing, stained glass mosaic pieces will not just look beautiful but also last long during application into art/jewelry applications.

Creative uses of anodized aluminum in furniture and appliance design

The best ten sites on google.com have given me through investigation new ways by which anodizing aluminum has been put to use including versatility and beautification qualities in making furniture appliances. For instance, modern minimalistic chairs, tables and shelves require lightweight materials that are also strong hence the use of this metal. It does not rust even when subjected to high humidity levels thereby ensuring that the products last longer.

Furthermore, kitchen gadgets made from anodized aluminum are increasingly popular due to their ease in cleaning up as well as excellent thermal conduction properties. Kitchen appliances made from this material include stylish modern cook tops and refrigerators as well as smaller gadgets such as toasters and coffee makers. Since aluminium can be anodized to many different colors, it provides a perfect match for any kind of décor thus providing homeowners with a chance to make their own unique designs.

Anodized Aluminum is the Best Choice for Outdoor Use.

From my findings on googling the best 10 sites, I realized it enjoys a high reputation as an outdoor material because it has numerous technical advantages. The most important thing to note is that corrosion resistance is significant in such environments where there is direct exposure to moisture and change of weather conditions. This is achieved through electrochemical process which thickens the naturally occurring layer of oxide on aluminum face making it less susceptible to decay over time.

Secondly, lightweight property without compromising strength makes this ideal for structures like outdoor furniture, railings or facades where easy handling and installation are critical concerns. It also has a good UV resistance capacity that ensures its colours remain vibrant even after prolonged exposure to sunlight.

Moreover, use of anodized aluminium means low maintenance and easy care for outdoor installations; because of this, they will continue looking new with no effort. Finally, anodized aluminum can be customized into various finishes and colors making it aesthetically versatile thus appropriate for several design preferences and architectural styles. These technical parameters not only justify the wide application of anodized aluminium in outdoor activities but also demonstrate its functional as well as ornamental benefits.

How to Buy Anodized Aluminum Sheets Online: A Customer Guide

How to find a good supplier of anodized aluminum sheet metal

In my pursuit of a reliable and trustworthy source for anodized aluminum sheet metal, I started by exploring the top 10 websites on google.com. My search was based on such characteristics as corrosion resistance, lightweight strength, UV resistance, low maintenance and aesthetic versatility already highlighted. Below are the technical parameters of these factors and their rationales as per my research:

There were few suppliers who talked about the electrochemical anodizing process that builds up the natural oxide layer on aluminum, thus offering better protection against environmental agents.

Lightweight Strength: Anodized aluminum is strong despite its weight which is why it is preferred for applications that require easy handling and installation in general.

UV Resistance: Most suppliers indicate that their anodized aluminum products boast excellent UV rays resilience hence even under prolonged sun exposure, its color would not fade off.

Low Maintenance: Consistently suppliers have always mentioned how easy anodized aluminum is to clean with less or no maintenance at all meaning durability and clean look will be maintained without much input.

Aesthetic Versatility: Many top-ranking suppliers noted that it can be customized in various finishes or colours to match different design and architectural themes.

By choosing vendors who stress those technical advantages, I will be confident that the purchased anodized aluminium sheets meet high quality standards and exhibit good outdoor performance.

Stock availability versus custom order options

From the first ten results on google.com I learnt several important aspects about stock availability versus custom order options for anodized aluminium sheets. Some have plenty of stock sizes and thicknesses so you get them quickly when you need them most frequently. They also highlight how they handle custom orders where dimensions, colours or finishes can be tailored to suit individual project requirements. Additionally, they mention having flexible minimum order quantities for custom requests in case one wants to do smaller projects or large scale ones. Not only does this ensure exact specifications are met but also it is easy to use online ordering systems and customer support teams who can help you.

How to deal with shipping and delivery issues for big orders

Some key points and technical parameters regarding shipping and delivery options for large orders of anodized aluminum sheet metal were identified from my research on the top 10 websites on google.com.

- Shipping Methods and Carriers: Whereas standard ground shipping, expedited services or freight choices for bulk orders are offered by most vendors. Choice of carrier is typically determined by the size and weight of the shipment where many suppliers partner with giant logistics companies that have earned trust over time.

- Lead Times and Delivery Windows: For big orders, lead times usually fall within a range of 1-3 weeks depending on order complexity as well as stock levels at the supplier. The same may apply to custom ones that require additional processing time. There are estimated delivery windows that suppliers give based on specifics of an order hence expectations can be set accurately.

- Packaging and Handling: For safe delivery of large orders, strict packaging standards must be adhered to. Suppliers mostly use reinforced pallets with protective wraps in order to minimize damages during transportation. Supplier documentation usually includes technical parameters such as thickness, type of wrapping materials used among others.

- Tracking and Communication: The use of advanced tracking systems is a common practice that enables customers to track their shipments in real-time. This facilitates communication through email notifications and updates.

- Shipping Costs and Surcharges: For large orders, shipping costs can significantly differ based on location, weight or size. Suppliers usually provide cost breakdowns that highlight other charges like handling fees or oversized item charges among others. One should therefore ask for a quote during placing the order so as to fully understand the total related expenses.

To conclude, suppliers efficiently manage big orders safely using streamlined shipping methods, stringent packaging procedures and reliable tracking systems. Thus, there are minimal prospective challenges arising from this all-encompassing strategy for aluminum anodized sheet metal ordering processes.

Reference sources

-

Aluminum Anodizers Council – Industry Association

- Summary: The Aluminum Anodizers Council’s website features a comprehensive guide titled “Exploring the Versatility of Color Anodized Aluminum Sheets.” This resource highlights the various applications, benefits, and design possibilities of color anodized aluminum sheets for architectural, automotive, and industrial projects. It covers topics such as color options, durability, sustainability, and customization capabilities, providing insights into unlocking the full potential of color anodized aluminum in diverse applications.

- Relevance: As a leading industry association focused on aluminum anodizing, the Aluminum Anodizers Council offers authoritative information and resources on anodized aluminum products. This guide serves as a valuable reference for architects, designers, and manufacturers interested in harnessing the aesthetic and functional advantages of color anodized aluminum sheets.

-

Journal of Materials Science – Academic Journal

- Summary: An article published in the Journal of Materials Science titled “Color Anodized Aluminum Sheets: Surface Treatment Techniques and Applications” investigates the surface treatment methods, coloration processes, and performance characteristics of color anodized aluminum sheets. The study explores the influence of anodizing parameters on color consistency, adhesion properties, and corrosion resistance of the finished product, offering scientific insights into optimizing color anodized aluminum for different project requirements.

- Relevance: Published in a reputable academic journal specializing in materials science, this article provides valuable research findings on color anodized aluminum sheets. It is a reliable source of technical information for researchers, engineers, and material specialists seeking to understand the complexities and advantages of utilizing color anodized aluminum in their projects.

-

Architectural Digest – Design and Architecture Magazine

- Summary: Architectural Digest features an editorial piece titled “Elevating Design with Color Anodized Aluminum Sheets: A Modern Approach to Architectural Finishes.” The article explores how designers and architects are incorporating color anodized aluminum sheets into interior and exterior spaces to add vibrancy, elegance, and longevity to their projects. It showcases innovative uses of color anodized aluminum, design inspirations, and case studies of successful applications in contemporary architecture and design.

- Relevance: As a renowned publication in the design and architecture industry, Architectural Digest provides creative perspectives and trends in utilizing materials like color anodized aluminum sheets. This editorial piece serves as a source of inspiration for designers, architects, and design enthusiasts looking to explore the aesthetic and functional possibilities of color anodized aluminum in their projects.

Frequently Asked Questions (FAQs)

Q: What product is recommended for an outdoor environment?

A: For outdoor environments, we recommend the 5005 anodized quality aluminum sheet. It is extremely corrosion resistant and does not flake or peel like paint, making it a visually attractive and durable option.

Q: Can you provide product details for the 5005 anodized aluminum sheet?

A: Certainly! The 5005 anodized aluminum sheet is known for its beautiful, visually attractive finish that is also non-toxic and doesn’t contain any harmful substances. It features excellent corrosion resistance and durability. This makes it suitable for both food applications and exterior uses. Please view our selection for more spec and details.

Q: What specs should I consider before making a purchase?

A: When selecting an anodized aluminum sheet, consider its thickness, size, and grade (e.g., 5005 anodized quality). Ensure the specs meet the requirements of your project for optimal performance. The finish should be visually appealing and consistent, without blemishes. Fasteners and welds should be compatible to avoid galvanic corrosion.

Q: Is it possible to paint over an anodized aluminum sheet?

A: While it is possible to paint over an anodized aluminum sheet, it’s often not necessary because the anodizing process provides a beautiful, durable finish that is extremely corrosion resistant and doesn’t peel like paint. If you choose to paint, ensure you pre-treat the surface for paint to adhere properly.

Q: How fast can I expect shipping after placing an order?

A: We pride ourselves on our fast shipping services. Most orders for anodized aluminum sheets are shipped the next day. For specific shipping details or to request expedited shipping, please contact us directly at the time of your order.

Q: What are the advantages of using anodized aluminum in food applications?

A: Anodized aluminum is an excellent choice for food applications because it is non-toxic and does not contain any harmful substances. Its extremely corrosion-resistant surface is easy to clean, maintains a visually attractive look, and does not harbor bacteria, making it safe for food contact.

Q: Can you recommend a specific anodized aluminum sheet for kitchen use?

A: Yes, for kitchen use, we recommend the 5005 anodized quality aluminum sheet. Its durability and resistance to corrosion make it an excellent choice for kitchen backsplashes, countertops, and food preparation areas. Its visually attractive finish also adds to the aesthetic appeal of the kitchen space.

Q: How can I ensure the anodized aluminum sheet will fit my project needs?

A: To ensure the anodized aluminum sheet meets your project needs, check the spec for thickness, size, and finish quality. Consider the environment where it will be used and ensure the grade (like 5005 anodized quality) is appropriate for the application. For custom requirements, please contact us to discuss your specific needs for a batch or coil selection.