Various industries use drill bits for example construction, woodworking, metalworking and DIY home projects. Therefore it is important to identify the parts of a drill bit and know their functions so as to select the most appropriate tool for a particular task. This paper will talk about different components like shank, flute and cutting edge which make up a drill bit and what they do in relation to the overall function of the bit. In addition we shall also look at various types of drill bits which include twist bits, spade bits and masonry bits; with each type having its specific uses and advantages discussed. After reading through this article one should be well equipped with knowledge on drilling tools thus being able to choose rightly during their next drilling project.

What are the different types of drill bits?

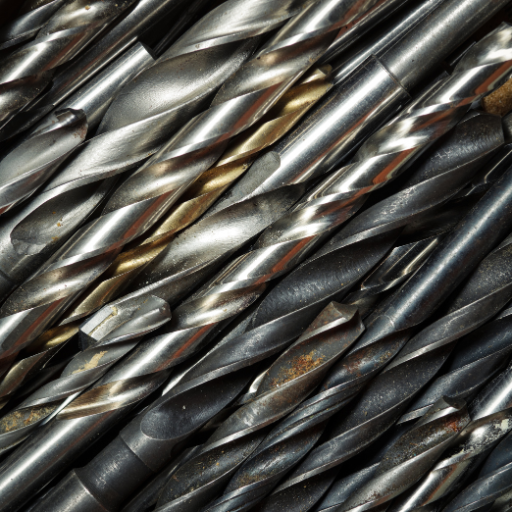

The drill bit universe is quite diverse, as individual types are created for use with specific materials and jobs. Some of them include:

- Twist Bits: These are the most adaptable and commonly used drill bits that can be used on wood, light masonry, metal and plastic. They come with a spiral groove which aids in clearing out chips when drilling into material.

- Brad-Point Bits: Woodworking is best done using these bits. Their tips have got sharp points that help in accurate positioning preventing wandering during drilling.

- Spade Bits: When wood needs to be drilled at a faster rate or in large sizes this type also referred to as paddle bits comes into play. It has got a flat wide blade having sharp point hence making chip removal more efficient.

- Masonry Bits: For drilling through hard stuff like stone, brick or concrete, these bits have carbide tips that can tolerate tough surfaces.

- Forstner Bits: If you want to bore flat-bottomed holes on wood then this is your ideal choice. They are common in furniture making and cabinetry industry.

- Hole Saw Bits: These are meant for cutting wider openings; they possess cylindrical shaped cutting edge featuring saw teeth thus suitable for cutting through pipes or installing doorknobs.

Every kind of drill bit has its own specific use so as to ensure accuracy while undertaking different drilling tasks across various fields at the same time saving on time.

Understanding the basic anatomy of a drill bit

Different sections make up the structure of a drill bit. These sections are pivotal for its operation as well as efficiency. These are the major parts:

- Shank: Clamped into the drill’s chuck, this part is cylindrical and has different diameters to fit various sizes of chucks.

- Body: The main part of the drill bit that includes the cutting area and fluting area.

- Point: It is at this tip where a drill bit touches material first. This jumpstarts drilling by acting as a chisel for accuracy purposes most times.

- Cutting Edges: Situated at the tip, these edges cut when the bit rotates into material.

- Flutes: Grooves spiraling around from one end to another on a body lengthwise; they help remove chips or debris out of hole being drilled thereby improving efficiency while preventing overheating.

- Web: A thin core which runs down through center of bit body giving support to cutting edges besides providing them with strength.

- Margin: Along edge of flutes there is always an elevated strip; it’s smooth drilling that takes place between walls of holes made by bits due to reduced friction caused by margins which also act as guides during drilling process.

Knowing what each of these parts does can help users choose the right type of drill bits for their needs and ensure proper usage/maintenance thus prolonging lifespan too.

What common types of drill bits are used?

Types of drill bits are abundant; here are a few commonly used ones:

- Twist Drill Bits: They are the most common type and can be used for drilling holes through metal, wood, plastics, and other materials. The helical flute design helps get rid of chips from the hole.

- Masonry Drill Bits: These are especially made for drilling into hard stuff like stone, brick or concrete. Their tips are made of tungsten carbide which withstands the impact and abrasion caused by drilling through masonry surfaces.

- Spade Drill Bits: They have wide flat blades so they’re great when you need to make big holes in wood. In addition to this there is a sharp point at their centre which keeps them steady while drilling.

When you choose an appropriate drill bit type for your project it will ensure that both – drill itself as well as its’ bit last longer and perform better too.

How do masonry drill bits differ from other bits?

The main difference between masonry drill bits and other types of bits lies in how they are made and what they are used for. A unique feature of these tools is their ability to deal with the hardness and fragility of materials such as brick, stone or concrete. Normally having a tungsten carbide tip – much harder and more resistant than that of a regular twist or spade bit – masonry drills can bear the brunt caused by intense impact and friction while cutting through robust surfaces like walls made out of rocks. Moreover, unlike flutes on common twist drills which may not be designed well enough to remove all dust produced during drilling, those found on most masonry bits should effectively carry away debris created from within a hole being drilled thus preventing blockages as well as ensuring neater finish holes are achieved in the process. Unlike twist drills that can work with different materials, hammer drills are best paired with masonry bits since they help deliver powerful blows required for breaking tough surfaces easily.

What is the anatomy of a drill bit?

To drill efficiently, there are a few important parts of the anatomical structure of a drill bit that work together:

- The connection: The part of the bit that is inserted into the drill chuck. It usually has a cylindrical shape but can also be hexagonal or some other shape for better grip.

- The main body: This covers everything between the shank and where the flutes (spiral grooves) start at the tip. These flutes help to take out material from the hole as it is being drilled.

- The point: The cutting section of the bit which may have different angles and materials depending on what type of bits they are and what they’re made to drill through.

- Grooves: There are spiral channels along its length which serve two purposes; one is to remove swarf up, thus clearing cutter path; secondly it acts as an air coolant during drilling operation by providing ventilation.

-

Point angle: This refers to angle ground onto either side at front edges where they meet forming ‘V’ shape when viewed from above; this affects performance characteristics under different conditions or materials being worked Understanding these parts will enable you select the most appropriate kind for your task.

Understanding these components can help you choose the right drill bit for your specific needs.

Explanation of the drill bit point

The drill bit point is an important part of the bit that affects how well it cuts and works with different materials. The point’s geometry, such as its angle and shape, determines how easily the drill goes into the material. A 118-degree conical point is a common design used in general-purpose bits for wood, plastic, and metal among others. For harder materials, a 135-degree point angle is preferred because it offers more stability and reduces walking. Also split-point designs have thinner ground central webs which makes them center bits more accurately hence minimizing the need for pilot holes. Therefore proper selection of point geometry will result in better performance from your drilling tool as well as its durability.

The significance of the shank

A shank is another significant part on any given drill bit; it has an effect on its performance together with being compatible across various drills. This refers to that section of a drill bit which gets held by chuck thus determining stability as well as power transmission depending on size or even shape thereof. Some commonly used types of shanks are straight shanks amongst others like hexagonal shanks which offer different benefits each. For instance hexagonally shaped ones provide better grip preventing slip especially when working with high torque impact drivers whereas straight ones can be fitted into traditional keyed chucks because they are versatile enough . Therefore one should consider not only efficiency but also wear & tear aspects concerning both bits and drills therefore correct choice should be made basing on specific needs of your drill machine.

The role of the flute in drill bits

One very important part of a drill bit is the flute. The flute’s main job is to work as a path for chips to be removed. This allows the material being drilled to come out of the hole, preventing clogs and overheating. A clean and accurate hole is maintained when chip removal is efficient, and this also increases bit life. In addition, coolant is directed to the cutting edge by the flute thus reducing friction which also helps in heat dissipation. They are spiral-shaped with different geometries depending on various drilling applications and materials used. Wide flutes clear chips better because of their increased clearance due to aggressive cutting action against softer materials whereas narrow ones offer more strength and stability hence suitable for harder materials. Hence overall efficiency during drilling processes greatly relies on design and configuration of flutes which also affect finished hole quality.

How to choose the right drill bit for your project?

When selecting a drill bit for your project there are few things you must consider. You should start by identifying what kind of material you want to drill through; wood, metal, masonry or plastic require different types of drill bits. For instance, wood drills usually have spur points while metals ones are made from high speed steel or cobalt alloys. Secondly, think about how big and deep the hole needs to be so that it can accommodate its corresponding size bit accordingly without breaking prematurely during operation etcetera . Furthermore; take into account shank type that matches well with your particular model such as hexagonal shaped shafts (hex) among others before settling on any specific one.Lastly look at chip removal ability along with heat dissipation properties associated with various flute designs accompanying coatings employed during manufacturing processes since these two factors play significant role towards achieving effective precision drilling.

Factors to consider when selecting a drill bit

When selecting a drill bit, consider these factors:

- Material Compatibility: What material are you drilling through – wood, metal, masonry or plastic? Each type needs its own specific kind of drill bits; for example, spade bits for wood and high-speed steel (HSS) or cobalt bits for metals.

- Bit Size and Length: How wide and deep is the hole that needs to be made? Make sure your project’s specifications are met in order not to compromise its integrity or efficiency.

- Shank Compatibility: Does it fit into my drill model? It can be hexagonal shaped (hex), straight one etc., but always choose right shank size as this affects stability during drilling process as well as ease of use.

- Flute Design: What shape should flutes have depending on material being worked with and desired outcome? In softer materials wider flutes allow better chip removal whereas narrower ones give more strength when drilling through hard stuffs.

- Coating and Finish: Are there any special coatings such as black oxide coating which makes them last longer while reducing friction between them and workpiece being drilled or titanium coating that improves their hardness level making them wear resistant than other types?

These points together guarantee accurate drilling with minimum effort required from you, the operator.

Understanding bit sizes and their applications

To make sure the best performance is achieved, each having its own intended use among many others, drill bits come in a wide range of sizes that can be used for different applications and materials. Standard drill diameters start from very small measurements in fractions or millimeters to larger ones for heavy duty jobs. In electronics and fine woodworking, micro-drills are commonly employed for precision tasks while medium-sized ones perform most DIY projects like drilling through metals, plastics or wood. Bigger drills can take care of harder materials including concrete and thick metals; hence they are often used with industrial applications where masonry is concerned.

Various bit sizes find application as follows:

- Small Bits (less than 1/8 inch or 3mm): These are ideal for delicate tasks such as making jewelries and creating pilot holes in woodworkings or plastics.

- Medium Bits (1/8 to 3/8 inch or 3 to 10mm): Versatility is the main characteristic of medium-sized bits because they are used for general purpose drilling during home improvement projects which require both accuracy and strength.

- Large Bits (greater than 3/8 inch or 10mm): This category consists of those bits that offer maximum power coupled with stability while drilling through things like thick sheets of metal or even blocks made out from stone works where large anchors need to be installed;

Knowing what size bit should be used where ensures faster drilling speeds with less tool ware resulting into better quality finished projects especially when dealing with construction sites involving brick walls etcetera.

When are countersink drill bits used?

A countersink drill bit is utilized to form a cone-shaped hole which allows the head of a screw to sit flush with or below the material’s surface being worked upon. This method is widely used in metalworking, carpentry, and woodworking projects for smooth finishes. They are especially helpful when it comes to installing flush screws in cabinetmaking or furniture making as well as creating pilot holes that help reduce wood splitting. Countersink drill bits also serve as tools for removing burrs left from drilling; moreover, they can create aesthetic and functional counter-sunk holes thereby giving finished carpentry look.

What are the uses of a twist drill?

Twist drills are multi-purpose instruments employed in making openings on different materials such as wood, plastic or even metals. Their helical shape aids proper removal of waste during drilling resulting into cleaner and more accurate drilled holes. In woodworking, twist drills can be used to bore both small and large diameter holes while working on projects like furniture-making or cabinet-making among others. For fabrication purposes fastening joints usually require some holes made by them in metalwork but these types of drills find great applications even at DIY tasks where people may need versatility during construction stages since various thicknesses will be encountered thus many materials shall be handled comfortably by twist drills used either in homes or industries that involve manufacturing processes due their wider range compatibility features.

Features of a twist drill bit

Twist drill bits, identified by their helical grooves or flutes, have a number of important characteristics. Here are the main ones:

- Composition: Usually made out of high-speed steel (HSS), cobalt or carbide which enables them to be strong and cut through many different materials fast.

- Point Angle: Normally has a 118-degree point angle which is great for general-purpose drilling; some may have a 135-degree split-point for less walking and more accurate starts.

- Flutes: The twisted flutes are meant to remove chips and dust from the hole as you drill ensuring cleaner and more accurate holes.

- Shank: Comes in various forms like straight shanks, taper shanks or reduced shanks so that it can fit into different types of drill chucks and machines.

- Coating: Coatings such as black oxide surface treatment, titanium nitride coating or diamond powder plating add hardness to the outside layer which increases heat resistance thus making them last longer.

All these components together forms twist drills; they are flexible in use, dependable on performance but necessary for variety drilling jobs.

Common applications of a twist drill

Because they can be used for many different things, twist drills are very popular in a wide range of industries. For example, in woodworking they can be used to drill pilot holes, create dowel joints or install hardware on furniture and cabinets. In metalworking they are commonly used for creating holes that will eventually hold bolts or rivets — an essential step during automotive, aerospace and general machinery fabrication. Construction workers often rely on them too as they’re great for drilling through wood, metal, brick or plastic while electrical conduits are being installed along plumbing fixtures within framework structures among other applications. This versatility demonstrates why twist drills should be considered indispensable items in any tool kit whether it belongs to a professional tradesman or someone working on their own projects at home.

Are specialized drill bits necessary?

There are times when one needs specialized drill bits so as not only to make work easier but also achieve accuracy in results. Although versatile themselves; twist drills may not cut across all grounds thus calling for unique bits like masonry bits, spade bits among others which have been designed with specific materials or tasks in mind hence can handle such jobs better than any other type would do. It is always good practice therefore to use correct bit while drilling since this improves efficiency levels besides prolonging both bit’s life span together with associated equipment while still delivering superior outcomes for various projects done by professionals as well as amateurs alike.

When to use a hammer drill bit?

When drilling through hard materials like concrete, brick or stone, a hammer drill bit is a must have. These bits can withstand the hammering force produced by hammer drills thereby enabling one to make clean and accurate holes on surfaces made of masonry. You will need this type of a drill bit when anchoring things or fitting electrical boxes but also when boring through concrete for plumbing purposes. It guarantees effectiveness; therefore, saves time as well as prevents any damage that may occur on both the tool itself and heavy-duty drilling machine hence leading into more successful outcomes.

The benefits of using a center drill

A center drill has many advantages which makes it become an essential item in precision drilling tasks. Firstly, it helps in creating accurate center holes before doing any other drilling operations so that subsequent drills can be aligned correctly with them. This significantly reduces cases where the drill bit may go off course and spoil the workpiece. Secondly, centersinks are designed to produce conical point shaped openings which acts as guides for bigger sized twist drills thus increasing accuracy during drilling while at the same time reducing wear on subsequent tools of larger diameter sizes used in boring operations. In conclusion but not least important is that using centresink speeds up initial centering process thereby saving time for various applications involving hole making processes. Metalworking and machining tasks require high levels of accuracy; hence this is where centre drills come in handy most often.

Applications for auger drill bits

An auger drill bit is used mainly to drill deep, neat and accurate holes in wood and other soft materials. These types of bits are perfect for do-it-yourself projects like making furniture, building wooden fences or fixing wooden beams/joists in place. Moreover, they can be of great help when it comes to gardening or landscaping as they enable one to bore holes for planting trees or shrubs, setting posts or fixing outdoor lighting fixtures among others. With its twist design that ensures easy removal of waste materials during drilling; an auger bit becomes more suitable for fast boring through thick woods without much effort being applied on them. Furthermore; these drills find their usage even in HVAC systems where holes need to be made for running cables/pipes through wooden structures.

Frequently Asked Questions (FAQs)

Q: What is drill bit anatomy?

A: Drill bit anatomy refers to the various components and features that make up a drill bit, including the shank, body, flute, and point. Understanding drill bit anatomy is essential for selecting the right bit for specific tasks.

Q: What are the different types of drill bits?

A: Drill bits come in various types, including twist bits, spade bits, masonry bits, and cobalt drill bits. Each type of bit is designed for specific materials and drilling applications.

Q: How are drill bits used for drilling?

A: Drill bits are used for drilling holes into different types of material. They are typically inserted into a drill, which provides the rotational force needed to penetrate surfaces like wood, metal, and plastic.

Q: What is a conventional drill bit?

A: A conventional drill bit refers to a standard twist drill bit commonly used for everyday drilling tasks. These bits are usually made of high-speed steel and can be used on various materials.

Q: How do you choose the right drill bit size?

A: To choose the correct drill bit size, you can refer to a drill bit size chart which provides the diameter of the bit for specific holes. This ensures you select the appropriate bit for the task at hand.

Q: What are the features of a cobalt drill bit?

A: Cobalt drill bits are used for drilling into hard materials like stainless steel and cast iron. They are made of a cobalt alloy, which provides increased heat resistance and durability.

Q: What is the significance of the drill point angle?

A: The drill point angle affects the cutting efficiency and precision of a drill bit. Different angles are recommended for different materials – for example, a 118-degree angle is common for general-purpose drilling, while a 135-degree angle is used for harder materials.

Q: What is an extra length drill bit?

A: Extra length drill bits have an extended body, allowing them to reach deeper or through thicker materials. These are typically used when a standard drill bit’s length is insufficient.

Q: How does the length of the bit affect its performance?

A: The length of the bit influences its stability and the depth of the hole it can drill. Shorter drill bits offer better precision and control, while longer bits allow for deeper drilling.

Q: Why is understanding the body of the drill important?

A: The body of the drill determines the bit’s structural integrity and affects its strength during drilling. Understanding this helps in selecting a bit that will perform optimally for the material and task at hand.