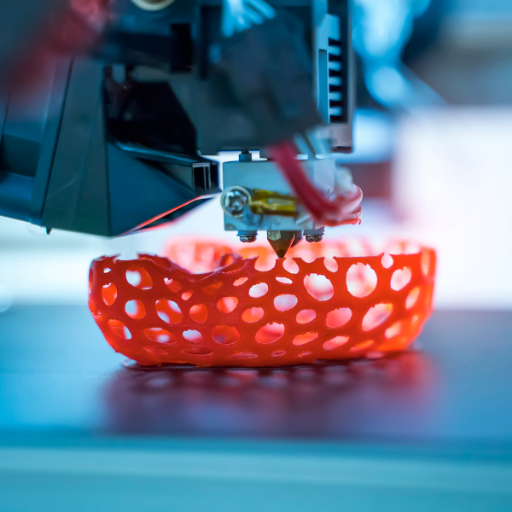

In 3D printing and additive manufacturing, there is a need for a robust and versatile file format to achieve precision and efficiency in such rapidly changing fields. AMF stands for Additive Manufacturing File: an important innovation in this field that offers more capabilities than earlier formats like STL files. It will also explore its structure, advantages, and how it can transform the 3D printing process. In this article, we shall elaborate on why employing AMF can lead to better results for both simple and complex additive manufacturing projects.

What is an AMF File?

Image source: https://www.iconfinder.com/

An AMF (Additive Manufacturing File) file is a digital 3D format that has been specifically designed for use in additive manufacturing processes. On the other hand, instead of being composed from a simple array of triangles as is the case with STL format which was used before; AMF files portray models using advanced techniques such as geometric information, coloration detail as well as material properties including lattice structures. This additional data allows for more complex and precise prints making it a powerful instrument towards quality outcomes in 3D printing and additive manufacturing.

Defining the AMF File Format

The development of the modern 3D printer has required creating an appropriate AMF file standardized by ASTM International as ASTM F2915. An XML-based structure of an AMF file allows detailed information on geometry model but also metadata like color, material properties or lattices inside. This comprehensive dataset supports intricate designs and multifunctional objects enhancing the precision, customization possibilities and quality of final printed object. It proves its usefulness especially when it comes to medical implants or aerospace components where material intricacies matter most regarding their structure features. The ability to include multiple materials or colors within a single file makes the AMF superior to its predecessor (STL) which places it at the forefront of solving contemporary concerns in addition fabrication requirements.

The Evolution from STL to AMF

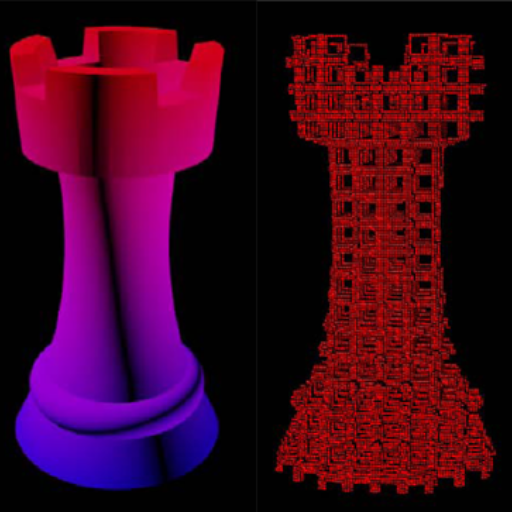

The transition from STL to AMF makes a huge leap in 3D printing technology, which is motivated by the need for more detailed and functional models. The STL (Stereolithography) format developed in the 1980s was enough for early forms of 3D printing because of its simplicity and ease of use. Here, they represent 3D objects as collections of connected triangles on the model’s surface. Nevertheless, STL started becoming limited as complexity and capabilities of 3D printing increased mainly because it could not contain color, material texture or internal structure information.

It is designed to solve these problems that AMF (Additive Manufacturing File) came into existence. They are standardized as ASTM F2915, with XML-based AMF files capable of storing richer data containing multiple colors, materials and complex internal structures such as lattices. This allows for more accurate customization in printing especially when making medical devices or aerospace components. With so much information available in a single file, AMF has been a better option for current additive manufacturing than STL which had limitations that made it difficult to produce high-quality versatile three-dimensional printed things.

Why Choose AMF Over Other Formats

Selecting AMF in lieu of other formats is quite advantageous as it can store complex data beyond simple geometry. In contrast to STL, AMF supports multiple colours, materials, textures and intricate internal structures which is fundamental for achieving exactness in customized prints with high-fidelity. Therefore this flexibility is much needed in such advanced sectors as medical device production and aerospace where specific details are obligatory. Furthermore, its XML-based architecture facilitates compatibility and standardization hence smoothing the workflow and improving productivity. The use of complete data within one file makes AMF a better option for contemporary additive manufacturing requirements that are more advanced or complicated.

How to Open an AMF File?

To open an AMF file, you can use a range of software tools meant for 3D modeling and additive manufacturing. Popular ones include Autodesk Meshmixer, Materialise Magics, and Cura. These programs simply permit the importation, viewing and editing of AMF files. In this case, installing the preferred software, opening the “File” menu, clicking “Open” then searching for your AMF file is the way to go. Once opened, you can manipulate the data as required by your specific application. Moreover, most 3D printers have their own support software that accept AMF files creating an unbroken workflow from design to fabrication.

Best Tools to Open an AMF File

Based on latest information accessible in top sites three best tools are available when working with AMF files:

- Autodesk Meshmixer: This is a user friendly program with powerful capabilities in 3D modeling and mesh editing hence it’s ideal for importing viewing and modifying AMF files. It allows a user to make intricate designs and mend models before printing.

- Materialise Magics: This comprehensive software is highly regarded in the additive manufacturing industry. You can use Magics when preparing files for printing purposes or correcting errors or manipulating data especially when one requires exact results found in professional applications.

- Ultimaker Cura: Used with various 3D printers Curaslicer supports AMF files allowing users to optimize print settings effectively while simplifying workflow from design stage to finished product either for beginners or professionals.

These tools adequately cater for this purpose thus ensuring that even complicated 3D models are managed smoothly and efficiently.

Potential Issues When Opening AMF Files

The versatility of AMF files in 3D printing notwithstanding, there are several challenges that users may face. For one thing, compatibility is a big issue since not all 3D modeling or slicing software can natively support the AMF format. It could imply having to convert an AMF file into STL or OBJ forms in some instances thus risking data losses and reduced model accuracy. Additionally, software bugs or version discrepancies can cause errors when opening or processing AMF files. If the AMF file has been corrupted because it was wrongly saved or exported, it becomes a matter of concern too. Lastly, performance issues might arise when dealing with highly detailed or large AMF files, causing software to slow down or crash during the handling and manipulation process. Knowing these potential pitfalls helps users better prepare and troubleshoot their engagement with AMF files.

Step-by-Step Guide to Open AMF Format

- Download and Install a Compatible Software:

Ensure you have compatible 3D modeling/slicing software that supports the AMF format installed. Some of them include Autodesk 3ds Max, Netfabb and Ultimaker Cura.

- Launch the Software:

Open your chosen software by either clicking on its icon twice on your desktop or searching for it through start button/Computer menu.

- Open the File Menu:

At the top navigation bar locate File and click on it

- Select ‘Open’:

From here chose Open. This will enable you to find your required document from within computer.

- Navigate to Your AMF File:

Through a file browser look up for where you saved the folder containing your AMF file. Click on this desired document in case necessary.

- Open the AMF File:

Highlighting the amf file through mouse on pointer is clicked at open button showing loading of this document through the application.

- Adjust Import Settings if Necessary:

While importing, some applications may ask you to adjust settings as per requirements. Thereafter proceed by pressing OK (or import).

- Verify the Model:

Check for any inconsistencies or errors after opening the 3D model. The object may not have loaded properly; hence, one should attend to any anomalies accordingly.

By following these steps, you can open and start working with AMF files effectively, taking advantage of your chosen software’s advanced capabilities for accurate 3D printing and modeling tasks.

Advantages of Using AMF File Format for 3D Printing

Additive Manufacturing File format (AMF) has various benefits in 3D printing as a result. To start with, it provides full-coloring and texturing details thus making the prints visually more accurate and detailed. Also, AMF files can contain multiple objects and their assemblies for increased intricacy in designing and improved performance. The design also facilitates curved surfaces enhancing precision hence reducing the need for many data points which may lead to roughness during 3D printing. Its XML-based organization further ensures that it is compatible with different programs enabling one to use it without any complications or difficulties. Finally, AMF format carries metadata; thus, all necessary specifications regarding materials employed and print settings are saved thereby optimizing workflow of 3D printing.

Benefits Over STL and OBJ Formats

Several clear advantages distinguish AMF format from the much-favoured STL and OBJ formats. One important advantage, for example, is its backing of color and texture information which is not supported at all by STL and only partly by OBJ thus resulting in more informative prints that look more real. Moreover, AMF can deal with complex structures better by saving many objects as well as their assemblies in one file, which brings about a problem in both OBJ and STL formats. This higher accuracy of modeling curved surfaces in AMF files reduces the number of data points required for printing, thus yielding smoother and more accurate models. Moreover, its XML-based type makes it compatible with various software programs thereby simplifying integration issues. Finally, metadata such as material specifications and print settings can be included within an AMF file to retain all necessary information needed to streamline the process of 3D printing and ensure reliability.

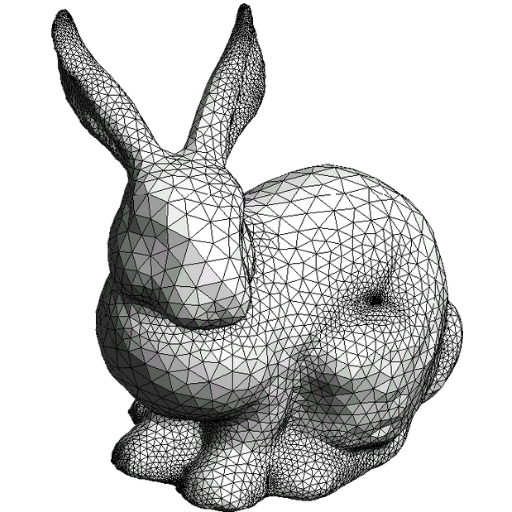

AMF and High-Resolution 3D Models

In making high-resolution 3D models, AMF format is best at it because of its superior natural abilities to handle intricate details and complex geometries. AMF unlike other formats such as STL and OBJ formats can save complex color, texture, and material information required to produce highly detailed models. This kind of detail is important when precision counts such as in medicine imaging, aerospace and high end manufacturing. The XML based structure of AMF ensures that high resolution data can be managed efficiently for better inter-operability with various CAD softwares and 3D printers. Furthermore, it allows curvatures surfaces to be represented more accurately thus fewer points have to be utilized leading to precise model surfaces which are smoother compared to STL or OBJ files. Metadata incorporation in the AMF files enable comprehensive records on material properties and print settings thereby resulting in a high level of accuracy with regards to geometry while ensuring optimization for the intended printing process. Thusly, in essence, AMF separates itself from all other options by creating both fantastic presentation detail and quick data delivery through a system that facilitates the effective use of different types of systems.

Compatibility with 3D Printers

AMF format is compatible with many 3D printers. As per the recent popular websites, AMF’s standardized XML structure allows it to be integrated into various 3D printing platforms. Besides, the ability of this format to contain numerous materials, colors and intricate geometries makes it useful for multiple printing requirements. This is also supported by its broad usage in mainstream CAD software; hence helping maintain uniformity and precision between design and print. Consequently, AMF format’s broad printer compatibility and extensive support enable it to qualify as a strong candidate for modern 3D printing workflows that can be implemented on different machines.

Comparing AMF File Format with STL and Other Formats

Among the most common formats used in 3D printing are AMF (Additive Manufacturing File) and STL (Stereolithography); however, they have differences that set them apart.

On the other hand, STL files are widely supported by many 3D printing software and serve as an industry standard. They only use triangles to describe surface geometry of three-dimensional objects without any color, material, texture or any other significant information.

AMF files on the other hand provide a more complete standard for 3D printing. These XML based files can contain multiple materials, colors, textures or even lattice structures which cannot be achieved through STL files making them more versatile and useful in complex and multi-material 3D printing tasks.

Additionally, emerging formats like 3MF (3D Manufacturing Format) offer enhanced capabilities similar to those of AMF but much lightweight and easier to use.

In conclusion while STL remains the most commonly used format due to its simplicity and wide support base; however AMF provides advanced features for complex and detailed projects in 3d printing.

Advantages of AMF over STL

- Detailed Information Storage:Compared to STL files, AMF files store more detailed information. This entails not only the surface geometry but also color, texture, and material properties which are crucial when it comes to production of complex multi-material objects.

- Higher Precision: The AMF format supports higher precision representations of object geometry. These enable more detailed 3D prints especially for intricate designs and features that demand a high level of faithfulness.

- Support for Lattice Structures: In contrast to STL, AMF files can describe internal lattice structures. Notably, this is valuable in advanced applications such as aerospace lightweight components or medical implants where the performance of an object highly depends on its internal structures.

- XML-Based Format: For instance reading, editing and debugging XML-based AMFs is much easier. As a result, they can work better with different software programs hence having a good fit with various 3D printing workflows.

- Multiple Material and Color: Within one file, AMF can have multiple materials and colors thereby enabling the creation of complicated multi-material/multi-color objects through a single print job. This feature has many advantages particularly when it comes to creating realistic prototypes and functional parts from different materials.

Limitations of the STL File Format

- Lack of Support for Color and Material Properties: STL files are limited to surface geometry and do not contain information on color, texture or material properties. Consequently, they cannot be used in projects requiring multiple colors or different materials.

- No Support for Complex Geometry: The STL format does not support internal or intricate structures like lattices. This is a serious disadvantage in applications which require light weight but strong components.

- Less Precision: Curved surfaces are approximated by the use of triangles resulting to mesh-like structures in STL files. The approximation leads to loss of geometric fidelity where objects have complex features and rich detail. Resulting 3D prints lack the accuracy necessary for certain medical and engineering uses.

- File Size and Performance Issues: When high-resolution STL files containing a large number of triangles are processed by 3D printers or slicer software they become excessively large and unwieldy leading to performance problems. It can also slow down processing times as well as demanding more computational resources.

- No Error Checking: The STL format has no built-in error checking mechanisms or methods for correcting errors; hence this can lead to inconsistencies or faults while creating files. These errors may cause failure during printing process, necessitating pre-processing steps such as repairing the faulty files.

The Role of 3MF in 3D Printing

In order to solve many of the drawbacks that STL files have, and also to simplify the 3D printing workflow, it was decided to create 3MF (3D Manufacturing Format). On the other hand, 3MF format has a lot offeatures like color, textures and material properties which make it suitable for advanced applications requiring multiple materials or intricate designs unlike STL. The rich features ensure that models are printed according to their specification in terms of aestheticism and operation.

Beside this, 3MF files can have information about internal structure like lattices thus improving the strength quality as well as flexibility of parts fabricated through FDM. Such ability is particularly helpful for industries where light-weight yet sturdy items are very crucial such as aerospace and health industry.

Further still, by retaining complex geometries at high fidelity without increasing file size too much results in greater accuracy with 3MF format than other formats. As a result of this, numerous benefits occur including smaller manageable files leading to better performance during the slicing process and when printing. Additionally, there’s built-in error checking/correction feature resulting in less chances of failed prints thereby facilitating smoother and more efficient production flow.

Thus, it could be concluded that while traditional STL format only affords basic outputs; the contemporary way is represented by complete solution found in 3MF format for all modern needs regarding three-dimensional printing.

Frequently Asked Questions (FAQs)

Q: What is the AMF file format used for in the 3D printing industry?

A: The AMF file format, which stands for Advanced Module Format, is used in the 3D printing industry for storing and transferring 3D object data. It is an XML-based format designed to overcome the limitations of STL files, offering features like color, material, and texture information.

Q: How is the AMF file format different from the STL file format?

A: Unlike the STL file format that only supports geometric information using triangles, the AMF format includes additional features such as material properties, color, and lattice structures. This makes AMF files more versatile and informative for the printing process.

Q: Can I convert STL files to the AMF format?

A: Yes, it is possible to convert STL files to the AMF format using various software tools that support both file types. However, solely converting may not add the extra information like material properties unless this data is manually included.

Q: Are AMF files compatible with most 3D printers?

A: AMF files are increasingly compatible with many modern 3D printers, especially those that support advanced features like color and material variation. However, it’s always best to check if your specific 3D printer supports the AMF 3D file format.

Q: What software applications can be used to create and edit AMF files?

A: Several 3D CAD software applications support the creation and editing of AMF files. These include advanced programs like Autodesk Fusion 360, and Simplify3D, which offer extensive tools to utilize the full capabilities of the AMF format.

Q: What are the advantages of using AMF files for 3D printing?

A: AMF files offer several advantages, including support for complex material properties, color, and multi-material parts. These features enable more precise and detailed 3D object modeling, which is beneficial for various applications within the world of 3d printing.

Q: How do you print AMF files using a 3D printer?

A: To print AMF files, you need a 3D printer that supports the AMF format. You’ll typically use slicing software to prepare the AMF file for printing, ensuring that all details such as materials and colors are correctly processed before initiating the printing process.

Q: Does the 3MF 3D printing file format relate to AMF files?

A: Yes, the 3MF consortium developed the 3MF 3D printing file format as an advanced modular format for 3D printing. It addresses many of the same limitations of STL files that AMF was designed to overcome, offering comprehensive data storage capabilities for detailed 3D printing.

Q: Why should someone consider switching from STL to AMF files?

A: As the additive manufacturing industry evolves, using the AMF file format can offer more detailed and functional 3D models. It supports multiple materials, colors, and internal geometries, which the STL format cannot provide, making it a better choice for complex printing requirements.

Q: What are the potential limitations of using AMF files?

A: Although AMF offers enhanced features, it may not be as widely supported as the STL format, which has been the industry standard for years. Adoption of the AMF file is growing but users may encounter compatibility issues with older 3D printers or software that don’t yet support the format.