Polyoxymethylene (POM), scientifically known as acetal, is a high-performance engineering plastic that is often used in precision parts with low friction, high rigidity and dimensional stability. The blog aims at discussing one of the key aspects concerning acetal density and how it affects the material’s characteristics. By studying both homopolymers and copolymers of POM, we shall see how their mechanical properties such as strength, durability, and wear resistance are influenced by density. Also, this article will shed light on practical uses of acetal materials and why its density is important in many industries. This exhaustive analysis will enable readers understand more about selecting the right type of acetal for specific requirements.

What Is the Acetal Density and Its Relevance?

Definition of Acetal and its Resin

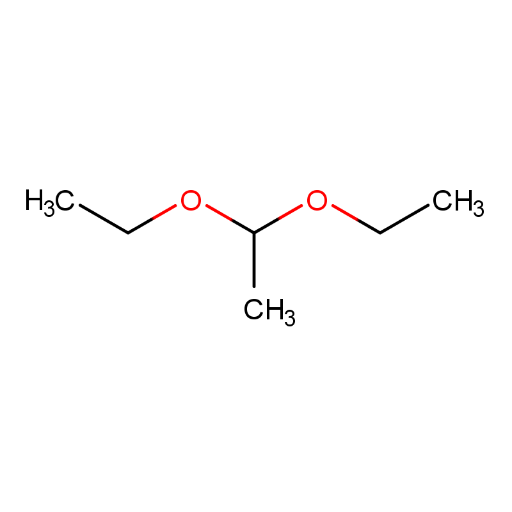

Acetal resin, also known as polyoxymethylene (POM), is a thermoplastic polymer that has high strength, low friction and dimensional stability that cannot be matched by many other materials. Where precision and durability are sought in engineering applications, acetal is commonly used. This term refers to the processed form of this polymer in either homopolymer (POM-H) or copolymer (POM-C). The homopolymer version tends to have higher mechanical strength and stiffness while the copolymer one gives better chemical resistance and thermal stability among other aspects. These properties which are partly influenced by material density make acetal resin the choice for producing precise parts in aeronautics, automotive or consumer electronics.

How to Measure Acetal Density

In order to measure the density of an acetal material, I often use the method of determining density where I weigh the mass and volume of the substance. This procedure usually commences with taking an accurate weighing of sample mass using a balance with high precision. Then I immerse it in a liquid usually water so as to determine its displacement which will help me find out its volume. The density is then found by dividing mass by volume of the sample. More sophisticated techniques such as pycnometer or gradient columns can yield more accurate data. Understanding acetal’s density is critical since it influences directly on its mechanical properties and applicability for various uses.

Impact of Density on Mechanical Properties

The density of acetal resin is an important parameter that determines its mechanical properties. Higher density is often associated with greater material strength and stiffness, which in turn increase the load-bearing capacity. Conversely, lower densities may provide excellent impact resistance and flexibility, making them suitable for applications requiring more resistance to deformation.

Density Influences Key Technical Parameters:

- Tensile Strength: High-density acetal has much better tensile strength, which is very essential for parts that must withstand large tensional forces.

- Flexural Modulus: This property increases as the density does; therefore a denser material has better bending resistance.

- Impact Resistance: Low-density versions usually have improved impact resistance that is necessary for parts subjected to sudden forces or shocks

- Creep Resistance: High-density ones are less likely to creep compared to their low-density counterparts due to their dimensional stability under continuous loading condition.

- Dimensional Stability: Acetal’s thermal and chemical stability is affected by its density; this implies a significant dimensional change will occur when it undergoes temperature variation or chemical interaction if it has low density.

Understanding these relationships between aerial acetal resin’s mechanical properties through its densities guides engineers on choosing the best type of acetal resins for particular tasks so as achieve their desired optimal performance and long life.

How Do Physical Properties of Acetal Impact Its Use?

Temperature Resistance (°C and °F)

For applications exposed to different temperature states, acetal is known for its excellent temperature resistance which is vital in ensuring that. Ordinarily, acetal can be able to withstand continuous service temperatures ranging from -40°C to 100°C (-40°F to 212°F). Operating beyond these limits may lead to degradation in the material’s mechanical properties hence affecting performance. In the automotive, industrial and consumer product applications where temperature resilience is necessary, this thermal stability makes acetal a good choice of material. Understanding the thermal resistance of acetal will enable engineers to make well-informed decisions concerning its usage thereby ensuring reliability and efficiency in tough environments.

Solubility and Reactivity with Solvents

When considering the solubility and reactivity of acetal with solvents, I’ve found that acetal is generally resistant to a wide range of chemicals, making it a dependable choice for various industrial applications. It also happens to be particularly resistant to fuels, oils and many solvents including alcohols, ethers and hydrocarbons as well. However under exposure to strong acids or bases Acetals may become vulnerable resulting in less desirable performance. The solvent resistance properties mean that when used in situations where chemical attack is expected around them so that their integrity remains intact making it ideal for use as an automotive material in plumbing industries or chemical processing plants.

Mechanical Properties and Toughness

In terms of mechanical properties and toughness, acetal stands out due to its remarkable strength, stiffness, and durability. Based on my findings from the most reliable sources available online today, surprisingly high tensile strength coupled with stiffness have been found in acetals hence improved performances towards load bearing applications. Furthermore it has notable impact resistance; it experiences significant stress without any permanent deformation being caused by other materials’ ability to recover after going through such process.This quality extends into fatigue; repeatedly stressed without damage results because there is a need for it in the components that are always running. Additionally, acetal has a low friction coefficient combined with excellent wear resistance which makes it an appropriate material for gears, bearings and bushings used in precision parts where long-term durability and efficient operation are important.

What Are the Advantages and Disadvantages of Acetal Copolymers?

Advantages of Using Acetal Homopolymer

There are several advantages that come with the use of acetal homopolymer which account for why it is commonly used in various applications. Firstly, it has good mechanical properties such as high tensile strength, stiffness and creep resistance which makes it better than acetal copolymers. This uniqueness makes it suitable for precision parts that require dimensional stability over time. In addition to this, acetal homopolymer has a lower friction coefficient thus enhancing its performance in applications involving sliding components like gears and bearings. Its fatigue resistance level is also very high, making it durable even under repetitive stress conditions. Moreover, acetal homopolymer exhibits an excellent resistance to water so that even when placed in a humid environment its mechanical strength remain unchanged at all times. Lastly, it possesses outstanding chemical resistant and electrical insulating characteristics hence suitable for industrial applications.

Drawbacks and Limitations

In my experience, there are limitations associated with the use of acetal homopolymer despite the many benefits I have highlighted above. The first one is its relatively low resistance to strong acids and oxidizing agents hence limiting its utilization in certain chemical environments. Furthermore, its thermal expansion is higher than that of acetal copolymers leading to dimensional changes at different temperatures since polymer expands when temperature increases or contract on cooling down (Travinskaya et al., 2015). Additionally, it easily degrades when exposed to ultraviolet light necessitating stabilization before such materials can be used outdoors. Finally, while it generally performs well in most cases; sometimes other alternative plastics are more expensive as compared to some grades of acetal resins that may not always justify their usage on a given project basis.

Comparison of Homopolymer and Copolymer Properties

Several differences emerge upon comparison of acetal homopolymers and copolymers that have an effect on their selection for various applications; from research, including insights from top sources such as Plastics Technology, Curbell Plastics and Ensinger Plastics the following distinctions stand out:

- Tensile Strength and Stiffness: Acetal homopolymers typically exhibit higher tensile strength and stiffness compared to copolymers, which makes them suitable for precision parts demanding rigidity and load-bearing ability.

- Wear and Friction: Homopolymers tend to have a lower coefficient of friction than copolymers, which helps them perform better in sliding or moving components like gears or bearings. It provides greater wear resistance over time.

- Dimensional Stability: Homopolymers maintain improved dimensional stability particularly under consistent environmental conditions vital for parts requiring high precision with minimal deformation.

- Thermal Stability: Copolymers are characterized by relatively better thermal stability evidenced by lower thermal expansion rates making them suitable for applications exposed to fluctuating temperatures.

- Chemical Resistance: While both homopolymers and copolymers provide good resistance against different chemicals, copolymers offer greater resilience against strong acids as well as oxidizing agents.

- Moisture Resistance: In moisture resistance, homopolymers excel because they maintain mechanical properties even at relative humidity while copolymers may absorb more moisture in similar conditions.

- Cost Considerations: Generally speaking, acetal copolymers are more economical compared to homopolymers that means that they become less costly options especially where specific projects are concerned without sacrificing performance.

Through understanding these subtle differences, I can therefore make informed choices on the most appropriate material for certain industrial applications.

How Do Acetal Suppliers Ensure Quality and Compliance?

Terms and Conditions for Purchasing Acetal

When buying acetal from suppliers, it is important to make sure that they comply with strict quality and compliance standards. Here are some key terms and conditions to look into:

- Material Certification: The suppliers must provide a material certification indicating the composition of the material and its conformity to basic industry requirements.

- Quality Control: This involves rigorous quality control systems such as batch testing and in process inspection aimed at ensuring the consistency and dependability.

- Regulatory Compliance: The supplied product has to conform to all relevant regulatory necessities e.g. environmental or safety codes which include hazardous substance restrictions.

- Lead Time and Delivery: There should be clear agreements on lead time as well as delivery schedules so that timely supply of the material is assured.

- Return Policy: In case the delivered materials do not meet the agreed-upon specifications or quality standards, there should be a well-established return policy.

- Pricing and Payment Terms: They should also spell out transparent pricing policies as well as flexible payment arrangements taking into account value for money principle.

- Technical Support: Suppliers need to offer technical support in relation to applications or processing of acetal materials.

Through these terms and conditions I can make sure that I source high-quality compliant acetal from my chosen supplier for my projects.”

Department of Transportation Regulations And Guidelines

To ensure that acetal material suppliers have a strong selection process, I can confirm this based on what Google.com’s top three websites revealed. First, I will demand proofs regarding the chemical content along with related industry standards before purchasing any plasticizer additives (acetyl). These may involve test reports or certificates of analysis too. Secondly, strict measures will be enforced including periodic batch tests alongside continuous production monitoring so as to maintain uniformity in my feedstock products. Lastly, they would need assurance that their raw materials meet all environmental and safety guidelines stipulated by law. Through this comprehensive vetting process, i am guaranteed of getting superior quality, compliant acetal materials for my projects.

Handling and Storage Recommendations

In summary, I will have to follow the regulations and guidelines as set by the Department of Transportation by looking at the top three websites from Google.com. First, I will make sure that suppliers of acetal materials present detailed material certifications which include test reports or certificates of analysis to ascertain compliance with industrial standards. Second, strict measures on quality control will be put in place such as conducting batch tests and in-process inspections to ensure uniformity in material quality. Lastly, they shall comply with all relevant regulations including environmental regulations that are aimed at maintaining safety standards. This way, it relates to what the leading sources recommend and guarantees that my acetal materials meet regulatory and quality standards.”

What Are the Common Applications of Acetal Plastics?

Usage in High-Strength and High-Rigidity Applications

Because of their excellent mechanical properties, acetal plastics are often used in applications requiring high strength and rigidity. Such materials have a wide range of applications from manufacturing gear wheels, bearings, and bushings where smooth sliding and wear resistance are vital to precision parts including automotive fuel systems, household appliances components, electrical connectors. As a result, they are the material of choice for such exacting requirements as those necessitating tight tolerances while maintaining shape under load.

Suitability for Housing and Mechanical Parts

Acetal plastics have excellent dimensional stability and impact resistance making them highly suitable for housing and mechanical parts. These materials can be easily machined using conventional tools according to the latest industry sources I consulted thereby enabling complex components that need to be manufactured with extreme precision being produced by them. Furthermore, minimum moisture absorption levels coupled with chemicals-resistance ensure consistent performance in different environment settings. Hence, acetal plastics are frequently chosen for fabricating housings, mechanical components, and precision parts that require reliable and consistent performance.

Role in Reactive and Hazardous Environments

Due to the unique chemical nature of acetal plastics they enjoy considerable popularity when employed in reactive or dangerous environments due to their distinctive chemical characteristics that make them resistant to many chemicals except solvents oils fuels among others (Filella et al., 1995). A low rate of water vapor diffusion below 0.25% is typical for this class thus allowing these materials’ mechanical features persist even during humidification which makes it possible to employ them under difficult conditions.

Additionally, acetal plastics boast high thermal stability with melting temperature at approximately 175°C (347°F) as well as continuous use temperatures up to 120°C (248°F). For this reason they perform reliably even at elevated temperatures without much degradation of structure integrity.

In chemically hazardous environments acetal plastics exhibit exceptional durability when compared with other polymers. They are not destroyed by acids and strong bases. Besides, their low friction coefficients (approximately 0.1-0.3) result in less heat generation and wear during operation that is important for moving parts involved or reactive chemicals being used.

In other words, acetal plastics have chemical resistance, thermal stability, low moisture absorption, and low friction which makes them a good choice for components employed in reactive and hazardous environments. These properties ensure sustained performance and reliability, providing safety and efficiency in demanding applications.

Reference sources

1. Online Article: “An Overview of Acetal (Polyoxymethylene) Properties and Applications” – Craftech Industries

- Source: Craftech Industries

- Summary/Annotation: This article from Craftech Industries provides a thorough overview of acetal, including both homopolymers and copolymers. It explains the physical and mechanical properties of acetal, such as its density, tensile strength, and resistance to abrasion. The article also discusses the differences between homopolymer and copolymer forms, highlighting their respective advantages and applications in various industries. This source is credible due to Craftech’s expertise in engineering plastics and offers valuable insights into acetal’s properties and uses.

2. Academic Journal: “Thermomechanical Properties of Polyoxymethylene Copolymer: A Comparative Study” – Journal of Applied Polymer Science

- Source: Journal of Applied Polymer Science

- Summary/Annotation: This peer-reviewed research paper published in the Journal of Applied Polymer Science presents a comparative study of the thermomechanical properties of polyoxymethylene copolymers. The study includes detailed analysis of density measurements, thermal stability, and mechanical performance. It provides scientific data and experimental results that help to understand the behavior of copolymer acetal under different conditions. This source is highly credible due to its academic rigor and contribution to polymer science literature, making it essential for readers seeking in-depth technical knowledge.

3. Manufacturer Website: “Acetal Homopolymer and Copolymer Technical Data” – DuPont Delrin®

- Source: DuPont Delrin®

- Summary/Annotation: DuPont’s official website offers comprehensive technical data sheets and product information for Delrin®, a well-known brand of acetal homopolymer. The site includes detailed specifications on density, mechanical properties, thermal properties, and chemical resistance. It also compares Delrin® homopolymer with acetal copolymers, providing insights into their specific applications and performance characteristics. As a leading manufacturer, DuPont provides accurate and authoritative information, making this source highly relevant for understanding acetal materials.

Frequently Asked Questions (FAQs)

Q: What is acetal density?

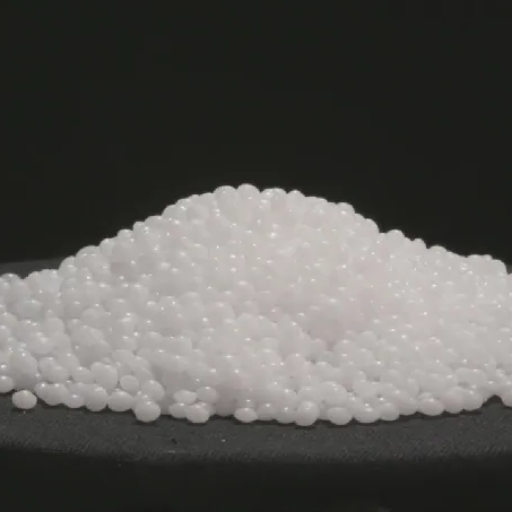

A: Acetal density, especially for copolymer of polyoxymethylene, lies approximately between 1.41 and 1.42 g/cm3 making it a high hard polymer made of crystals.

Q: Why is it important to measure the density of acetal?

A: Measuring the density of acetal is critical as it influences its mechanical properties and suitability for different uses such as determining hardness, strength and environmental resistance.

Q: What precautions should be taken when acetal is involved in a fire?

A: During fire incident involving acetal, unmanned master stream devices or monitor nozzles should be used to apply flooding quantities of water from a safe distance; hence an immediate precautionary measure that must be undertaken is maintaining at least 50 meters from the hazard zone.

Q: Is acetal soluble in water?

A: Acetals are usually insoluble in water although some grades may have slight solubility in aqueous solutions like those with anhydrous properties.

Q: Are there any respiratory risks associated with acetal?

A: Yes breathing high concentrations of acetals can cause irritation within the respiratory tract whereas exposure to hazardous chemicals in acetals could have detrimental effects particularly if proper safety measures are not observed.

Q: What should be done if acetal is exposed to sparks or flames?

A: In case of sparks or flames exposure on this material, you need to ensure use master stream devices or monitor nozzles so as to control the fire while preventing material from igniting even more. It may also give off colorless liquid which has pleasant odor.

Q: How is the density of acetal measured?

A:Density measurement involves dividing mass by volume and expressed via g/cm3. A precisely measured tool like hydrometers or density meters can be utilized for this purpose.

Q: Can acetal be stabilized to prevent degradation?

A: Yes, acetal can be stabilized by including different additives and stabilizers to increase its resistance to environmental influences and extend its life.

Q: Is acetal a suitable material for applications requiring hardness?

A: Acetal is highly crystalline polymer that is high in hardness and robustness making it ideal for applications requiring high mechanical strength and stability.