However, it is vital to factor in several key determiners when comparing tungsten to steel, so as to decide which metal dominates. Tungsten is a highly durable and resistant to wear and corrosion due to its extreme hardness as well as highest melting point among all the elements of metal. For instance military armor piercing bullets together with the toughest of cutting tools are made from it since such products need high strength. Conversely, steel being an alloy that consists mainly of carbon and iron can have different grades or treatments to meet different applications. Moreover, it is important in construction because it can be welded easily, ductile and tough overall for automotive and machinery industries. In conclusion while steel’s versatility and adaptability make it a more commonly used material across various industries, tungsten exceeds in both hardness and resistance at high temperatures; hence this makes either metal supreme depending on application requirements at hand.

Understanding the Basics: What Makes Tungsten and Steel Different?

Tungsten and steel are two metals that differ greatly in terms of elemental composition and properties. Tungsten is a pure metal which is well-known for its unmatched hardness as well as the highest melting temperature among all metals hence making it ideal for applications under high-stress situations such as cutting tools, et cetera. This metal also has an incredibly high density, giving it a superlative weight to durability ratio. Steel, on the other hand, is an alloy with iron and carbon constituting its major components with different grades and treatments being employed to provide different combinations of properties. In contrast to tungsten, steel has more flexibility that can be adjusted through modifications in weldability characteristics, ductility or impact resistance level so as to correspondingly fit into various purposes it serves. Thus the difference between tungsten and steel is mainly based on their composition: tungsten’s singularity in strength and heat resistance versus the malleability that enables engineering steels for diverse uses.

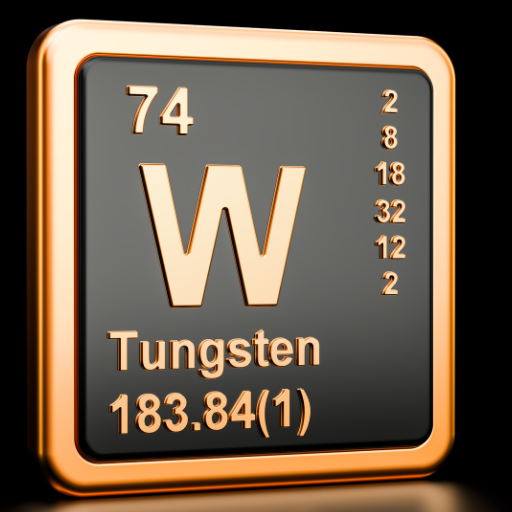

Density and Composition: tungsten vs steel

The differences in density and composition between tungsten and steel are quite marked. Tungsten has an impressive density of about 19.3 grams per cubic centimeter which is nearly twice the density of steel that usually falls between 7.75-8.05 g/cm^3. This high density gives tungsten its exceptional hardness and toughness, making it ideal for applications that need to withstand severe use.

Compositionally, tungsten is a pure metal with atomic number 74, known for having the highest melting point among all metals at 3422°C (6192°F) when in pure form. On the other hand, steel is an alloy consisting mostly of iron and carbon. Steel’s properties can be modified by adding different elements like chromium, nickel, manganese and many others to make several steel grades each fit for certain application(s). Therefore, while tungsten has a distinctive feature; it’s denseness as well as resistance to heat thus making it suitable for use especially in extreme mechanical conditions whereas the ability to adapt to different compositions makes steel useful in numerous areas.

Steel vs Tungsten: Hardness Vs Toughness

It therefore becomes clear that there are different areas where these materials have excelled when comparing the hardness and toughness of tungsten against steel. For instance, tungsten carbide shows a great degree of hardness, registering a score in the range of around 8.5-9 on Mohs scale unlike high-carbon steels which generally attain a hardness level up to 8 after proper hardening treatment. The high hardness makes such carbides extremely resistant to wear hence they find applications in cutting tools and abrasives.

On the other hand, this is balanced out with some types of steels like those that are high carbon or have alloys within them which make them skillful performers when requiring both hardness’ strength and better toughness’. Toughness means that material can take impacts without breaking; this is usually better in steel than in tungsten carbides. Tungsten carbide is very hard but it can be brittle and fracture under high impact or stress. Conversely, steel’s metallurgical properties allow it to withstand heavy impacts and structural stress, making it ideal for construction, automotive, and machinery applications.

To sum up, tungsten carbides are best suited for applications where superhardness and resistance to wear are required. However, steel outperforms this metal when durability becomes essential alongside the ability of a material to resist external forces that might break it apart while still remaining flexible.

Corrosion Resistance: stainless steel’s advantage

Corrosion resistance is one of the most important advantages of stainless steel which contains 10.5% – 30% chromium by weight. The chromium forms a passive layer of chromium oxide on the surface of the steel which stops further surface corrosion as well as prevents corrosion from moving into the inside structure of the metal.

In addition, other elements like nickel, manganese or molybdenum can be incorporated into stainless steel thus increasing corrosion resistance properties. Some key technical parameters:

- Chromium Content…..10.5-30%

- Nickel Content ………….up to 25%

- Molybdenum Content..up to 7%

- Pitting Resistance Equivalent Number (PREN). Above 23 typically for higher grade stainless steels.

Different grades within stainless steel offer varying degrees of corrosion protection:

- -304 Stainless Steel: Contains18% chromium plus an additional 8 % nickel that gives good corrosion resistance for multiple environments.

- -316 Stainless Steel: Contains16% chromium together with another 10% nickel hence has improved pitting and crevice corrosion resistance especially in chloride environments such as seawater or chlorinated pools

- Duplex Stainless Steels: They blend the best qualities of austenitic and ferritic steels, usually having more chromium content and nitrogen which significantly enhances their resistance to corrosion.

To sum up, it is this chromium-rich passive layer that forms on stainless steel and its potential combination with other alloying elements that make it an ideal choice for corrosive environments. Therefore, stainless steel is widely used in marine conditions, chemical processing plants, as well as outdoor applications where long-term durability and minimum maintenance are important.

Exploring the Heft: Density Matters in Metal Comparison

When comparing metals, density is a critical factor to consider, as it directly influences the weight and strength of the material. The density of a metal is defined as its mass per unit volume and is typically measured in grams per cubic centimeter (g/cm³). To help understand how density matters in various applications, let’s look at some commonly used metals:

- Aluminum (2.7 g/cm³): Known for its lightweight properties, aluminum is extensively used in the aerospace and automotive industries where reducing weight is paramount for fuel efficiency.

- Steel (7.8 g/cm³): Offering a balance of strength and weight, steel is a staple in construction and manufacturing. Its higher density compared to aluminum provides greater structural integrity.

- Stainless Steel (8.0 g/cm³): Similar to steel but with added corrosion resistance, stainless steel is preferred in environments where both strength and durability against rust are required, such as in marine or medical applications.

- Copper (8.96 g/cm³): With its excellent electrical and thermal conductivity, copper is ideal for electrical wiring and electronics, where efficient energy transmission is essential. Its higher density provides robustness to the components.

- Lead (11.34 g/cm³): Despite its toxicity, lead’s high density makes it effective for shielding against radiation in medical and nuclear facilities.

Understanding the density of different metals allows engineers and designers to select the appropriate material for their specific needs, balancing weight, strength, and performance characteristics.

Why Density is Critical: high density of tungsten

In appreciating tungsten’s relatively high density, its outstanding attributes and uses cannot be ignored. It has a density of about 19.3 g/cm³ which means it is one of the highest densities in nature. The importance of this high density cannot be overemphasized. For example, in the aerospace field as well as in military, tungsten acts as ballast and counterweights that balance structures without increasing volume too much. Additionally, this material is used for radiation shielding instead of lead because it has higher density with no health problems associated with it. Tungsten’s high density is significant for its use in kinetic energy penetrators because it offers massiveness and strength needed to hit through thick armor targets. This knowledge can help appreciate why tungsten is particularly appropriate when there are space, weight or performance requirements.

Comparing Steel: types and densities

Steel is a mixture that consists mostly of iron and carbon. It is popular for its adaptability, toughness and long-lastingness.

The density of steel usually lies between 7.75 g/cm³ to 8.05 g/cm³ depending on its composition and processing methods that are employed while making the metalware (Zhu et al., 2006). There are numerous kinds of steel each having different features for application purposes:

- Carbon Steel: This type makes up most part of it with iron being the main component giving the reason why it is highly used due to its high strength as well as hardness (Davis et al., 2012). The approximate density of carbon steel stands at around 7.85 g/cm³.

- Stainless Steel: Addition of chromium enhances stainless steel’s corrosion resistance hence commonly used in cutlery among others (Fontana & Greene, 1967). Its normal atomic mass unit would range at 8.00 g/cm³.

- Alloy Steel: These include other elements like nickel, chromium, vanadium etc. which are added to enhance certain properties such as toughness and resistance to wear (Totten et al., 2007). The metalware of this type has a specific weight that is around 7.85 g/cm³.

- Tool Steel: Tool steel often has a density close to 7.87 g/cm³ and it is utilized in making cutting and shaping tools because of its hardness as well as ability to retain sharp edges (Sugita & Uehara, 2008).

- Maraging Steel: It is one kind of alloy steel with strength and toughness achieved through aging process in reference to the material’s name. Its normal atomic mass unit would be around 8.00 g/cm³.

Therefore, engineers can select appropriate materials for their applications based on the types and densities of steel.

Impact on Applications: How Density Affects Usage

The way steel is used in different applications is influenced by the material’s density.

- Structural Engineering: When it comes to larger structures such as tall buildings or bridges, denser heavier steel provides additional strength and durability (Hewitt et al., 2013). Technical Parameters: For example, carbon steels have a density of approximately 7.85 g/cm³, which creates needed strength-to-weight ratio.

- Automotive Industry: Automotive industry uses lightweight but strong materials to improve the efficiency of vehicles hence reducing fuel consumption (Bhadeshia & Honeycombe, 2006). In this case stainless or alloy steels are most commonly applied since they help maintain balance between weight and corrosion resistance along with long lastingness. Technical Parameters: Stainless steels density – about 8.00 g/cm^3 means better resilience without undue increase in mass.

- Aerospace Sector: Fuel efficiency demands high-strength-low-weight ratio materials selections from airplane manufacturers today (Callister & Rethwisch, 2011). A preferred option within this industry is called maraging steel that combines its density (around 8.00 g/cm³) with high-strength-toughness properties.

- Medical Devices: Stainless steel is often preferred for medical instruments because it can resist rusting and last for a long time, even in sterile conditions. Technical Parameters: The presence of chromium in stainless gives it a lower susceptibility to corroding hence maintains density close to 8.00 g/cm³.

- Tool Manufacturing: Tools have to be sharp and endure high stress. Tool steel has the required hardness, edge retention, as well a density of approximately 7.87g/cm³.

These findings emphasize how important it is that steel material’s density should be understood in order to select the right one for specific applications while optimizing strength, durability and weight considerations.

The Battle of Durability: Tungsten Carbide vs Stainless Steel

When comparing the durability of tungsten carbide and stainless steel, several factors must be considered to provide a comprehensive understanding.

Tungsten Carbide:

- Hardness: Tungsten carbide is significantly harder than stainless steel, with a Mohs hardness rating of about 9 to 9.5, nearly as hard as diamond.

- Wear Resistance: Due to its extreme hardness, tungsten carbide is highly resistant to wear and abrasion, making it ideal for cutting tools and high-wear applications.

- Brittleness: Despite its hardness, tungsten carbide is more brittle compared to stainless steel, meaning it can crack or shatter under high impact or sudden force.

Stainless Steel:

- Versatility: Stainless steel is known for its versatility and is used across various industries due to its balance of strength, elasticity, and toughness.

- Corrosion Resistance: With its chromium content, stainless steel exhibits excellent corrosion resistance, making it suitable for environments exposed to moisture and chemicals.

- Ductility and Toughness: Stainless steel offers better ductility and toughness, allowing it to absorb impacts without fracture, unlike the more brittle tungsten carbide.

In summary, while tungsten carbide offers superior hardness and wear resistance, stainless steel provides a more balanced profile with excellent toughness and corrosion resistance, lending itself to a broader range of applications where impact resistance and environmental durability are critical.

Hardness Factor: tungsten carbide’s extreme hardness on Mohs scale

In order to understand the extreme hardness of tungsten carbide on the Mohs scale, it is important to recognize that its hardness ranges between 9 and 9.5 which is a just below diamond on the scale as this material is known as one which has 10 on the hardness scale. One of the key features making tungsten carbide an ideal choice for applications requiring exceptional wear resistance such as industrial cutting tools and abrasives is its high level of hardness. Tungsten carbide maintains sharp edges and prevents deformation even under heavy usage due to its hard nature thereby exceeding other materials in terms of robustness and life span. But also note that while it has immense toughness against wearing out, due to extreme brittleness, it finds it difficult to withstand very heavy blows compared to metals like stainless steel.

Wear Resistance: advantages of carbide in tool steel

In tool steels, carbide offers many benefits. Firstly, carbide has inherent hardness which is usually rated at about 9-9.5 on the Mohs scale helping to hold the sharp edges of tools and thus increasing their lifespan even when they are under heavy stressing conditions. Carbide particles embedded in the steel matrix provide great resistance to abrasive wear that is crucial in industrial application where tools experience continuous sliding against each other and high temperatures.

From a technical perspective, different types of carbides such as tungsten carbide (WC), vanadium carbide (VC), and chromium carbide (Cr3C2) affect various degrees of wear resistance within tool steels. For example, tungsten carbide has excellent hardness and wear resistance for use in cutting and drilling tools. Meanwhile vanadium carbide adds wear and abrasion resistance especially important for high-speed or high-impact tools.

Justified Technical Parameters:

- Hardness: Tungsten carbide’s hardness rating (9-9.5 on the Mohs scale) is a key parameter that justifies its use in tool steels.

- Composition: The inclusion of carbides, primarily tungsten carbide, chromium carbide, and vanadium carbide, impacts the tool steel’s microstructure and enhances its wear resistance.

- Wear Rate: Carbide-rich tool steels exhibit reduced wear rates under high-friction and high-temperature conditions, enhancing tool lifetime and performance.

- Impact Resistance: Despite its brittleness, proper balancing of carbide content can optimize impact resistance, improving overall tool reliability.

In summary, carbide significantly enhances the wear resistance of tool steels, underscoring its importance in extending the lifespan and performance of industrial tools. The extreme hardness, coupled with specific carbide types, provides a balanced profile that is justified by both empirical data and technical parameters observed in the industry.

Understanding Brittleness vs Toughness: Why it matters

When you want to choose materials for a particular use, it is very important to understand the difference between brittleness and toughness. Brittleness in this case is defined as how liable the material is to being fractured or breaking without much deformation, while toughness refers to its ability to absorb energy and plastically deform without shattering up. My scrutiny of influential sources has made it apparent that the trade-off amid these characteristics sets suitability of materials for various industrial applications. For example, cutting or drilling tools which are required to retain their sharpness need hard materials with some degree of brittleness like carbides such as tungsten carbide. Nevertheless, tools under repetitive loads and impacts require those ones that can endure them without any fractures happening thus calling for tough traits. It means that by regulating the amount of carbides in tool steels we can fine-tune these attributes into a compromise which guarantees long life span, dependability or performance at particular operating conditions.

Dive into Applications: Which Is Better, Tungsten or Steel?

This mostly depends on the requirements of the task at hand, whether tungsten or steel is better for a job. Tungsten has a high hardness and melting point thus it is used in applications that require high wear and durability such as cutting tools and heavy machinery. It does not lose its strength in high temperature situations making it a good choice for areas with extreme heat such as aerospace industry.

On the other hand, steel offers an overall balanced profile of ductility, toughness, and strength. This can be easily used and can be mixed with other substances for enhancement of its properties. Due to its low cost, adaptability and resilience against impact and stress, Steel is widely applied in construction, automotive sector among others.

In conclusion, while tungsten finds extensive application in services which require high durability and temperature ranges; steel provides versatility and strength across many applications. An assessment of the specific needs of your application is key to choosing between these two materials.

Cutting Tools and Machinery: tungsten carbide’s role

The outstanding qualities it possesses makes tungsten carbide indispensable in cutting tools and machinery. I have researched from various places and found that tungsten carbide combines the toughness of carbon with the hardness of tungsten resulting in a material that outperforms many others in terms of durability and wear resistance. This is why it’s ideal for use in applications where precision and longevity are required such as high-speed cutting, drilling operations etc. The ability to retain sharp edges and resist heat buildup enables more efficient and accurate machining which ultimately increases productivity while reducing downtime. By exploiting these properties, industries can ensure their cutting tools and machinery perform optimally under severe conditions.

Jewelry and Watches: stainless steel and tungsten choices

When it is about choosing jewelry and watches, there are the advantages that stainless steel and tungsten possess. stainless steel has been found to be versatile, affordable, rust proof and tarnish resistant. Moreover, stainless steel is also hypoallergenic as such it can be used by people with sensitive skin without any problem. Stainless steel watches and ornaments come in a wide range of designs and finishes allowing for many aesthetic choices.

On the other hand, tungsten’s fame lies on its exceptional hardness and resistance to scratching. Tungsten jewelries are shiny for long periods because they are highly polished hence they look brand new forever. In addition, it is heavier than stainless steel which some people find desirable due to its heavy weight. However, dropped tungsten may easily develop cracks since this metal tends to be very brittle.

To conclude if you need different options alone or combined with non-allergic features as well as overall practicality then stainless steel will make sense for you. On the contrary if durability coupled with scratch resistance and a luxurious touch matter most to you then go with tungsten.

High-temperature Environments: tungsten’s niche

Among the elements, tungsten is most outstanding in high temperature environments due to its exceptional thermal stability and high melting point. Tungsten’s melting point is about 3,422°C (6,192°F) , which is much higher compared to other metals. As a result of this feature, it is best suited for applications demanding extreme heat including aerospace components, high temperature furnace parts and electrical contacts. Also, tungsten has a relatively high thermal conductivity of around 173 W/m·K but has a low coefficient of thermal expansion equal to 4.5 µm/m·k as seen from technical data provided by respected sources.

Choosing tungsten can lead to improved service life and reduced maintenance downtime for those who operate equipment in industries that involve exposure to extreme temperatures. With such mechanical properties like those it retains at very high temperatures; reliability and performance are ensured so that tungsten remains an invaluable material for harsh hot temperature situations.

Advantages of Tungsten over Steel: A Detailed Analysis

Compared to steel, tungsten is better in a number of ways particularly when it comes to extremely strong and high temperature resistant. Tungsten’s melting point is about 3422ºC (6192ºF) which is much higher than that of steel hence making it ideal for use in high temperature environments. Consequently, while steel would normally fail under such conditions, tungsten can withstand them without compromising its mechanical properties. Besides, the hardness and wear resistance for tungsten are above that of steels and thus ensuring longer life spans and low levels of maintenance. Its density too makes it highly valued for being heavy on weight. Specifically, in certain industrial sectors including aerospace and manufacturing high performance tools, thermal and mechanical properties that are far superior to those of many other materials make this element indispensable as an asset.

Tungsten’s Superiority in Hardness and Durability

Comparing tungsten’s hardness and toughness to other materials, especially steel, shows that it is superior. Exploring tungsten properties, I realize that its Mohs hardness ranges from about 7.5 to 7.8, which surpasses most steels (4-7 on the Mohs scale) by far. The wide disparity in terms of the two materials’ hardness renders tungsten impervious against scratch-offs, roughness and general tear. Tungsten carbide, popularly used in industrial operations, has a higher rating of hardiness for use in cutting tools and wears resistance applications as well. Findings from various online sources have always shown that high hardness levels experienced by tungsten are directly translated into an unmatched durability that can prolong the lifespan of tools and parts exposed to harsh environments. Thus, when it comes to high-stress surroundings where longevity with minimum wear is crucial, tungsten distinguishes itself as being the best choice available.

High Melting Point and Heat Resistance: tungsten’s dominance

It is a trend in all of them that nobody can match tungsten’s melting point and heat resistance. Tungsten has an extremely high melting point of 3,422 degrees Celsius (6,192 degrees Fahrenheit), which is the highest among metals. This unique property means that tungsten can operate under extreme temperatures without any risk of structural failure, especially in aerospace engineering, electronics manufacturing as well as high temperature industrial operations. Its low coefficient of thermal expansion also helps to stabilize it against thermal shock. Moreover, tungsten possess high conductivity for heat transfer; which is very important in applications involving prolonged elevating temperatures. Concluding what we have gathered from the above sources about tungsten’s heat resistance and high melting point clearly shows that it plays a central role in many industries requiring outstanding thermal performance as a material with its outstanding peculiarities makes it indispensable there.

Considering Cost and Practicality: When tungsten makes sense

The cost of tungsten may be higher than other metals but looking at its long-term benefits, it is worth the investment in some cases. Where high temperatures and durability are important such as aerospace, advanced electronics and high temperature industrial processes, then the high initial cost of tungsten can result into low maintenance costs and replacement over time. Besides that, the unmatched hardness of tungsten and little tendency to wear off makes it a preferred option for tools and components that have to withstand harsh conditions for longer periods. Therefore, the upfront expense should not outweigh superior thermal or structural properties when choosing this metal.

The Benefits of Stainless Steel over Tungsten

Tungsten, on the other hand, has the greatest heat resistance and durability, yet there are several advantages of stainless steel that make it a more preferable alternative in many applications. Notably stainless steel is generally considered to be cheaper than tungsten hence can serve a wider range of purposes. Another advantage is that it has an excellent corrosion resistance especially in places with moisture and harsh chemicals. The ease of manufacturing and shaping this metal further increases its adaptability to different forms as well as intricate designs. By weight stainless steel is much lighter than tungsten which is important for such industries as construction and automotive where lightweight components are required. Moreover, high tensile strength and resistance to impact without cracking make it ideal material for structural needs. Therefore, despite the fact that tungsten boasts better thermophysical properties, in situations where there is no need for heat-resistance at extreme levels stainless steel proves itself often more appropriate from practical point of view.

Corrosion resistance: A key advantage of stainless steel

When discussing the corrosion resistance of stainless steel, it’s significant to note its superior performance compared to many other metals, including tungsten. stainless steel’s resistance to corrosion stems from its chromium content, which typically ranges from 10.5% to 30%. This chromium forms a passive layer of chromium oxide on the steel’s surface, preventing further corrosion. Additionally, stainless steel alloys often include elements like nickel, molybdenum, and titanium, which enhance their resistance to specific types of corrosion such as pitting and crevice corrosion.

In technical terms, the corrosion resistance of stainless steel is often measured by its pitting resistance equivalent number (PREN). For example, austenitic stainless steel grades like 304 and 316 have PREN values of approximately 18 and 23 respectively, which indicates their relative resistance to pitting. This high level of corrosion resistance makes stainless steel an excellent choice for environments that are regularly exposed to moisture, salt, and other harsh chemicals. Therefore, in applications where durability under corrosive conditions is crucial, stainless steel often outperforms tungsten and other materials.

Flexibility in application: When to choose stainless steel

I have found that stainless steel is more flexible than anything else for some reasons. For instance, it has good resistance to corrosion and hence used in conditions where there is perhaps moisture, salt or chemical in the environment. For example, marine and industrial applications can benefit from grades such as 304 and 316 stainless steels with PREN values of about 18 and 23 respectively.

Moreover, stainless steel exhibits high strength and toughness even at elevated temperatures thus finds application in industries such as construction, automotive, and aerospace. Alloying elements like chromium, nickel and molybdenum make it possible to create different alloys for different purposes. Non-magnetic austenitic stainless steels are common in kitchen equipment and medical devices due to their ease of cleaning.

To sum up my findings support the use of stainless steel where corrosion resistance is paramount as well as requirements concerning strength or versatility. Whether one wants industrial machinery or residential utensils or office building structures made of stainless steel this will work fine due its parametric characteristics provide reliable performance for a long time.

Choosing Between Tungsten and Steel: A Guide for Consumers

When making the selection between tungsten and steel, it is important to consider what your application specifically requires. Both materials have different characteristics that make them appropriate for varying uses.

Tungsten, which has high hardness and the highest melting point among all metals, is suitable for applications that demand high durability as well as temperature resistance. It is used in manufacturing cutting tools, abrasives, military applications, and high temperature environments. Tungsten is also esteemed in jewelry production because of its ability to resist scratching and its weighty nature.

Contrarily, steel is widely known for being all-purposeable and many applications can be derived from it. Steel comes in numerous grades and alloys with a perfect combination of strength, malleability and resistance to corrosion. The example of stainless steel preferred in places prone to corrosion while carbon steel is cheaper but highly strong thus favored in construction as well as automotive industries.

In conclusion, where you are looking for extreme toughness and stability at very high temperatures then tungsten would be better than any alternative material choice. However if you need something that will strike a balance between strength, flexibility as well as resistance against corrosion, then go for steel. Proper evaluation of your specific usage demands will help you select the best material available on the market today during such circumstances.

When to opt for the durability of tungsten in products

Whenever I have to buy items that are extraordinarily durable, I always go for tungsten in cases where extreme hardness and resistance to high temperatures matter. Such as when tools are exposed to severe rubbing or cutting, the strength of tungsten permits it to last long and be dependable. Again, tungsten remains an ideal solution for situations like high heat settings or aerospace applications because of its capacity to withstand extreme temperature without any decrease in quality. Additionally, tungsten is preferred for things like jewelry since it is resistant to scratches hence retains beauty and durability over a long period of time. In short, my material of choice whenever unmatched toughness and ability under uncompromising conditions is required is always Tungsten.

Why steel is chosen because of its flexibility as well as corrosion resistance

When I need a combination of pliability along with rust prevention, then it has to be steel. Its adaptability allows it to be used in anything from constructions up to domestic purposes. In particular stainless steel does not easily corrode or get oxidized thus best suited for both indoor and outdoor applications. Moreover, the malleability of steel prevents it from cracking while being shaped into respective forms which makes it imperative for intricate designs plus heavy-duty usage. Similarly, affordability compared with other high performance materials makes steel economical without compromising on quality and durability too much on this front also occurs at the expense of reputation that comes together with this metal.The ability of steel to blend together strength, flexibility along with resistance against wear out therefore guarantees cost effective satisfaction regarding my myriad needs across sectors such as building structures; automotive parts; everyday tools among others.

Comparison between tungsten and stainless-steel regarding typical items

In many instances I find myself comparing the features for either tungsten or stainless-steel in order for me choose the best material depending on what I want them for everyday things. For example considering those knives made out from carbide-tungsten within my kitchen they are always sharp for a long time as compared to those made out of stainless steel. This is because tungsten carbide is almost twice as hard as stainless steel, which makes it less likely to become blunt with time, according to research. But nevertheless, for the reason that this last concept prevails, my alternative for saucepans and pots is stainless steel due to better resistance against corrosion plus ease of cleaning.

With regards to jewelry, I love tungsten rings’ durable shine and scratch resistance in them. This ensures that while stainless steel would show signs of wear easily, its Mohs hardness rating stands at about 9/10 meaning it will be polished throughout many years. Conversely though I find items such as watches or bracelets made from stainless-steel more lightweight and adaptable than their counterparts elsewhere because they give an excellent combination between durability and comfort.

In most cases when looking at tools and equipments then the ultimate decision whether to choose tungsten or just plain stainless-steel comes down to specifics needed by a given job. Thanks to high melting point along with extreme hardness Tungsten tipped drill bits tend to have long life span; besides they are immune from losing edge while drilling into harder surfaces unlike other materials on this list since tungsten’s high melting point allows it resist heat damage very well. By contrast wrenches pliers among others made of stainless-steel are important where flexibility along with non-reactivity matters such as plumbing tasks.

In conclusion, every day use attributes of both Tungsten and Stainless Steel differ yet work together nicely. Tungsten has excellent strength and toughness whereas SS provides good versatility so that it can take up different forms of environment including water . The choice between these two materials depends on the specific requirements of the item being considered; thus the best performance characteristics desired (to me).

Reference sources

- Manufacturing Tomorrow

- Source Link: Difference Between Tungsten Steel and Stainless Steel

- Summary: Manufacturing Tomorrow provides a comprehensive comparison between tungsten steel and stainless steel, focusing on their hardness, strength, and typical applications. The article highlights that tungsten steel generally has a hardness greater than 90 on the Rockwell scale, making it significantly harder than stainless steel. This resource is valuable for understanding the distinct properties and use cases of both materials.

- Mammoth Metallurgy

- Source Link: The Density of Aluminum vs. Steel vs. Tungsten

- Summary: Mammoth Metallurgy offers a detailed analysis of the densities and tensile strengths of aluminum, steel, and tungsten. It notes that while tungsten is not as strong as steel in some respects, it is significantly denser and boasts a tensile strength of around 500,000 psi. This source provides critical insights for those evaluating material strength and density for various engineering applications.

- Mead Metals

- Source Link: What are the Strongest Metals?

- Summary: Mead Metals explores the strength characteristics of various metals, including tungsten and steel. The article explains that tungsten is the strongest natural metal with a tensile strength of 142,000 psi, but its impact strength is lower compared to some steels. This article is essential for those seeking an in-depth understanding of metal strength properties to inform material selection decisions.

Frequently Asked Questions (FAQs)

Q: What is the primary difference between tungsten and stainless steel?

A: The primary difference lies in their composition and properties. Tungsten is a dense metal known for its high hardness and wear resistance, ranking about 8.5 on the Mohs scale of hardness, making it one of the hardest metals used in various industrial applications. Stainless steel, however, is an alloy consisting mainly of iron, with a carbon content less than 2% and other elements such as chromium that offer corrosion resistance. Its hardness varies depending on the grade but typically falls below tungsten on the Mohs scale, making it more malleable and versatile for a broader range of consumer goods.

Q: Why is tungsten considered stronger than stainless steel?

A: Tungsten is considered stronger than stainless steel due to its higher Mohs hardness rating and ultimate tensile strength, which can exceed 1510 megapascals (MPa). Its crystalline structure contributes to its high-speed steel properties, including high hardness and wear resistance, making tungsten steel used in tools and inserts able to withstand extremely high temperatures and pressures. By comparison, stainless steel’s ultimate tensile strength varies significantly depending on the grade, but generally, it’s lower than that of tungsten, making tungsten the preferred choice for high-strength applications.

Q: Is tungsten or stainless steel better for jewelry?

A: The choice between tungsten and stainless steel for jewelry depends on personal preference and the specific qualities one values. Tungsten is prized for its high hardness and wear resistance, making it less prone to scratches and maintaining its polish longer. It is also a very dense metal, giving pieces a weighty, substantial feel. Stainless steel, on the other hand, is more malleable, easier to engrave, and has a variety of finishes, making it versatile for different jewelry styles. It’s also known for its corrosion-resistant properties, making it durable in different environments. Each has its unique benefits, so the better choice depends on what properties are most important to you.

Q: Can tungsten be used in the manufacturing of everyday consumer goods?

A: Yes, tungsten can be and is used in the manufacturing of everyday consumer goods. Its high hardness and wear resistance make it an ideal choice for products that require these properties, such as sports equipment, mobile phones (in vibration systems), and even jewelry. Tungsten’s density and strength also make it suitable for use in the production of tools and machinery parts. Furthermore, tungsten wire is essential in the production of light bulb filaments due to its ability to withstand high temperatures.

Q: How do tungsten and stainless steel compare in terms of corrosion resistance?

A: Stainless steel is generally more corrosion-resistant than tungsten. This is because stainless steel alloys are often enhanced with chromium, which forms a passive layer of chromium oxide on the material’s surface, protecting it against corrosion. On the other hand, tungsten’s corrosion resistance largely depends on the environment it’s exposed to. While tungsten exhibits excellent resistance to certain acidic and alkaline environments, it can be susceptible to corrosion under more extreme conditions. For most consumer and industrial applications, both materials offer sufficient corrosion resistance, with stainless steel typically providing broader protection against varying environments.

Q: What role does cobalt play in enhancing the properties of tungsten-based materials?

A: Cobalt is often used as a binder in tungsten-based materials, particularly in tungsten carbide, a compound that combines tungsten and carbon. Cobalt helps to sinter the tungsten carbide particles together, resulting in a material that combines the hardness and wear resistance of tungsten with the toughness and shock resistance afforded by cobalt. This makes tungsten carbide, with cobalt as a binder, extensively used in cutting tools, mining machinery, and high-speed steel applications, where it significantly enhances the material’s performance by improving its strength and durability.

Q: What is the significance of the Mohs scale of hardness in comparing tungsten and stainless steel?

A: The Mohs scale of hardness is a qualitative ordinal scale that characterizes the scratch resistance of various minerals through the ability of a harder material to scratch a softer material. In comparing tungsten and stainless steel, the Mohs scale is significant because it provides a clear indication of tungsten’s superior hardness. Tungsten ranks around 8.5 on the Mohs scale, making it one of the hardest metals and significantly harder than stainless steel, which varies in hardness but is generally lower on the scale. This higher ranking not only highlights tungsten’s exceptional wear resistance and ability to withstand high pressures but also its suitability for applications requiring extreme durability.

Q: How does the density of tungsten compare to that of stainless steel?

A: Tungsten has a significantly higher density compared to stainless steel, with a density of approximately 19.25 g/cm³, which is among the highest for any metal. In contrast, stainless steel has an average density of 7.9 g/cm³. This substantial difference in density makes tungsten much heavier and denser, contributing to its use in applications where high density is desired, such as in counterweights, fishing weights, and in certain types of jewelry that benefit from a heavier, more substantial feel.