This mild steel material has garages ranging from EN8 to EN3B, indicating its versatility and many possibilities. It gives us a glimpse into the vast landscape of global mild steel needed for engineering and construction. Some distinguishing features and applications have been discussed while comparing the benefits among different categories, such as strength and toughness in EN8 or welding and forming in EN3B, thus pinpointing specific application areas more accurately. The journey through the land of mild steel explains why it remains the heart of modern industry, as well as some improvements related to its recent developments. We shall demonstrate this by explaining how simple tools to complex structures are made using only mild steel. This being so, we will illustrate why mild steel is vital in creating everything from basic instruments to elaborate buildings too.

Understanding the Basics: What is Mild Steel?

Mild the steel is a plain and carbon type, also known as mild. In the most basic form, it is an iron alloy with a small amount of carbon ranging from 0.05% to 0.25% by weight, which is responsible for its strength and ductility. Compared to high-carbon steels, it has low brittleness thereby making it among the most versatile and weldable materials available in construction and manufacturing industries. Given these qualities as well as its cost-effectiveness, this makes it an indispensable material for such things like bridges, buildings, automotive components etcetera. Mild steel’s unique combination of tensile strength that can be bent easily and inexpensively distinguishes it from others being a keystone in our designing and manufacturing toolbox but not least in importance because of its low price.

Defining Mild Steel and Its Core Characteristics

Mild steel is a workhorse of the industrial world. It is like that reliable, tough, but changeable friend you can trust for a variety of jobs. Technically, mild steel is low-carbon steel which means that it has relatively little carbon as compared to other types of steels. This critical characteristic has several advantages making it suitable in numerous applications.

To begin with, its strength and ductility are directly affected by its low carbon content. Mild steel is strong enough to take heavy loads without breaking hence able to resist impact expected in buildings where survival against such environmental stress is an issue say skyscrapers and bridges. Nevertheless, it’s also ductile implying that it can bend without fracturing. This equilibrium allows designers and engineers to create something new or different without being limited by the materials used.

Secondly, there is no match for its weldability and machinability. Such features enable mild steel to be easily joined with other pieces through welding and shaped into complex parts through various machining processes. This ease of fabrication benefits industries requiring customized solutions like automotive manufacturing as well as machinery manufacturing.

Another vital aspect of this material is its cost-effectiveness. Unlike high-carbon steels and other metals, mild steel doesn’t cost much so; this makes it a good choice for many large-scale construction works or massive conventional units.

Lastly, availability of mild steel makes it important resource in engineering and construction sectors. Due to its wide use and demand, it’s always available thus projects do not have long lead times as costs are kept lower too.

The simplicity of mild steel lies in beauty and balance between characteristics thereof. Its strength coupled with excellent weldability/machinability make this raw material ideal in construction/manufacturing sectors; moreover being cheaply available (cost-effective), economically viable for large size establishments especially those involved in heavy infrastructure development projects .

Finally, life is surrounded by structures made from mild steel as well as machines, a compelling evidence of its importance in the modern world. It is used in all engineering and construction activities since it has become so popular that it does not take a long time for them to be transported.

The Difference Between Mild Steel and High Carbon Steel

The main difference between mild steel and high-carbon steel is their carbon content, which determines their properties and applications. Mild steel is also called low-carbon steel and it typically contains 0.05% to 0.25% carbon by weight, making it more pliable and easy to shape. Thus, low levels of carbon in this type of metal make it easily shaped into any form, welded or cut thus meeting the needs of various construction as well as manufacturing processes. High-carbon steel on the other hand carries higher amounts of carbon normally ranging between 0.30% and 1.50%, thus giving it greater strength as well as hardness properties. Nevertheless, its harder nature makes welding less possible while ductility is also reduced thereby limiting the applications for high-carbon steel in processing metals generally making them hard for shaping purposes among others (Sinha & Ahn, 2018). Consequently, high-carbon steel is widely used in cutting tools, blades etc., springs etc., springs etc., spring etc., springs etic., springs atc., stringing wires eyc., strong wire e.g.wire etallic strings that experience rough treatment such as being cut up continuously thus requiring a lot of hardiness and ability to withstand wear over a long period before getting spoilt.High carbon steel vs mild differs on the basis of strength requirements; ductility requirement; weldability criteria; how much cost will be involved relative to the specific engineering project involved in this discussion?

Why Mild Steel is a Popular Choice for Construction

As a construction industry expert, I have seen for myself why this material is so unique. Firstly, it is a really cost-effective material. When compared to other types of steel or building materials, mild steel is relatively cheap thereby making it economical in the case of large-scale construction projects.

The second reason is its ductility. Due to its low carbon content, mild steel can be easily shaped twisted and moulded into different structures without losing its strength and robustness. For instance in the construction industry where there are complex geometrical formations that need custom shapes and sizes.

Thirdly we have weldability. This excellent weldability of mild steel means that buildings and infrastructure will contain strong seamless welds joints which helps maintain structural integrity of these components. Also easy welding speeds up the time spent on constructing buildings leading to lower labour expenses .

Another important factor is its versatility. It can be used in a wide range of construction applications ranging from skeletal frames for sky scrappers to fences around properties. With regard to contractors and builders, versatility makes it their most favored choice.

Finally ,the toughness and strength of mild steel present durable structures that can withstand everyday wear and tear as well as harsh climatic conditions . Despite not being as strong as high-carbon steel, it has an appropriate balance between strength and malleability for most design purposes needed in civil engineering.

In conclusion , the combination of low price , workability ,weld ability , adaptability and durability makes mild steel an unrivalled product for construction industry all over the world . These attributes have ensured that it plays a major role in this sector till today hence being widely applied globally .

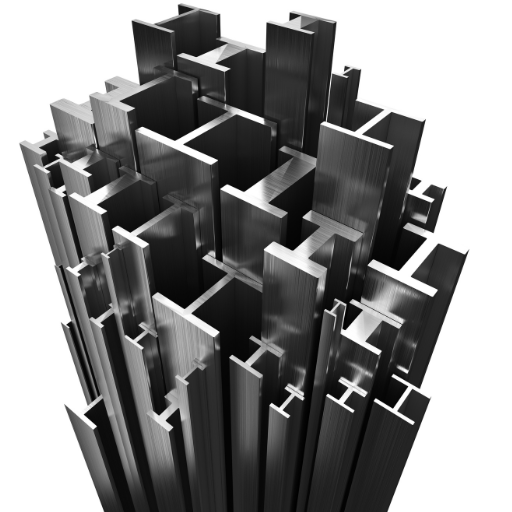

Exploring the Grades: EN8, EN3B, and Beyond

Mild steel grades such as EN8 and EN3B are examined in detail to reveal the fine adjustments possible in steel properties through alloying. My experience shows that EN8, which is a medium carbon steel, combines strength and toughness well. It is preferred for its high tensile strength required for applications like axles, gears, and shafts which also need wear resistance.

On the contrary, EN3B at the low end of the carbon scale has gained popularity due to its good weldability and formability. It’s what you would use if you wanted parts that machines easily or have complex shapes requiring good surface finish. As such, it is widely used in general engineering parts where materials undergo less stress.

However, there are many other mild steels besides these two examples like EN24 and EN19 that offer higher strengths and better fatigue resistance against more austere engineering duties. Each grade represents a careful balancing act between carbon content, alloying elements and the resulting mechanical properties so that materials can be precisely tailored to their function by engineers like me. This plasticity combined with variety found in mild steel allows us to make even what was considered unmakeable by fashioning structures and machinery beyond imagination.

Comparing the Chemical Composition of EN8 and EN3B

Comparing composition of EN8 and EN3B carbon steel grades, their difference lies in the content of carbon. EN8 steel is classified as a medium carbon steel under the standard EN 10083 which has carbon content ranging approximately between 0.35% -0.45%. Nonetheless, it lowers its weldability although high contents of carbon in it bestow greater strength and hardness on it than on low-carbon steels.

Contrarily, EN3B is a mild steel identified by EN 10277 with lesser amounts of carbon usually about 0.18%-0.20%. However, this lower concentration of carbon increases malleability and weldability while reducing the hardness and strength when compared to the mentioned grade.

The variance in their compositions regarding the amount of carbon causes differences between them concerning mechanical properties for different purposes. On one hand, while EN8 is known for its strength and often used in production of high tensile components, welding constructions require that possess better weldability and formability such as those made from EN3B that can be shaped extensively.

Physical and Mechanical Properties of Different Mild Steel Grades

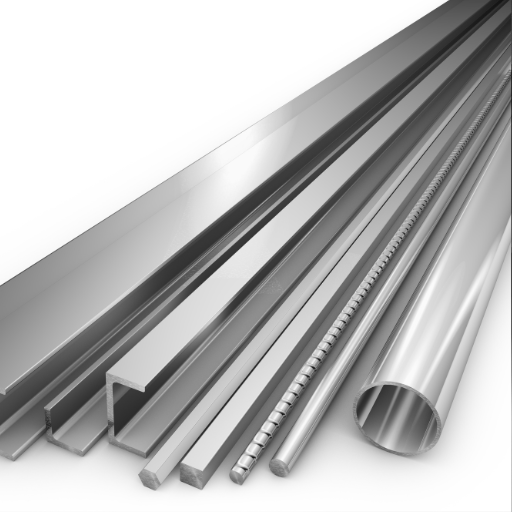

The physical and mechanical properties of mild steel grades change considerably, impacting their use in various industries. Here are some key attributes of different mild steel grades like EN8 and EN3B:

EN8 (080M40)

- Tensile Strength: It is between 400 and 700 MPa which is appropriate for high strength applications.

- Yield Strength: It stands at about 550MPa meaning that permanent deformation occurs when the stress exceeds this value.

- Hardness: Normally, it lies at around 200-300 BHN making it relatively hard and resistant to wear and tear.

- Impact Resistance: Moderate. Although low carbon steels can withstand impact better than it does.

- Elongation: About 16% shows that the steel is able to undergo plastic deformation before failure.

EN3B (070M20)

- Tensile Strength: It usually ranges from 370 to about 460 MPa hence less than EN8 which is ideal for products where formability matters most.

- Yield Strength: This type has yield strength of about 280 MPa hence its ability to be easily shaped because of its lower yield strength.

- Hardness: In approximately130-170 BHN which is a lot lower compared to EN8; this indicates higher malleability values.

- Impact Resistance: High. Less carbon content makes it more shock and impact proof than their equivalents with greater volumes or percentages of carbon content

- Extension: It extends up to approximately 20 percent or more indicating its ductility in comparison with steels having greater amount of carbon elements.

General Physical Properties of Mild Steel:

- Density: Roughly, it weighs around7.85 g/cm³ like other carbon steels used in structural calculations related to weight bearing capacity during design work.

- Melting Point: The melting point of mild steel falls within a temperature range of1425-1540°C (2600-2800°F) where it undergoes welding or casting.

- Thermal Conductivity: It is low as compared to other metals, and this affects its use in applications that require heat to be lost or gained.

- Electrical Conductivity: Mild steel has poor electrical conductivity hence it is unsuitable for electrical applications.

From these properties, one can see how mild steel grades are diverse in terms of strength, ductility and hardness among other physical properties, which mean each type can be best used in different conditions.

Choosing the Right Grade of Mild Steel for Your Project

The selection of mild steel grade is critical to achieving a balance between cost, performance and durability as required by the project. To make an informed choice, you need to know what your application requires and how different mild steel grades differ in properties to fulfill these requirements. Here’s my approach:

- Consider the Mechanical Requirements: Begin with assessing mechanical properties that your project needs. For example, if it requires a lot of formability such as deep drawing or complex bending operations, then EN3B or any similar grade might be ideal due to its high elongation and low yield strength. Conversely, if your aim is for tensile strength which assures integrity in structures, you may go for EN8.

- Assess Environmental Conditions: Different types of mild steels exhibit varying levels of corrosion resistance and durability across different environmental conditions. By knowing where the steel will be used can lead you into selecting a carbon level retaining steel grade along with additional protection measures like coating or galvanizing.

- Factor in Manufacturing Processes: On the other hand there are also manufacturing processes that dictate which type of steel to use. For welding applications like joining processes weldability is prioritized hence those steels with lower melting points like EN3B are favoured. In machining operations one may prefer choosing a type of a grading which balances hardness and machinability.

- Budget Considerations: Many times, cost becomes an overriding factor in decision making. Normally more carbon content and speciality grades come at an expensive price tag on them than others do. Therefore, it’s essential that before choosing the grade; conduct an extensive cost-benefit analysis to ensure that it fulfils both budgetary constraints set out as well as performance expectations.

- Future-proofing: Finally, consider not only current but potential future demands of your project too. A material fitting today’s specifications should also be adaptable for any new changes made either because of change in usage patterns or variations within environmental parameters.

Through carefully evaluating all of these aspects, you can pick the best mild steel grade that guarantees dependability, longevity and cost-effectiveness for your project. The key is knowing how to balance different physical and mechanical properties to meet specific requirements.

The Importance of Chemical and Mechanical Properties

For the choice of any venture, it is vital that one appreciates the chemical and mechanical properties of mild steel. Its ductility, strength and corrosive nature are determined by its chemical properties like carbon content and presence of other alloying elements. The behavior of steel under load, stress and specific environment can be largely influenced by its mechanical properties such as tensile strength, hardness, and impact resistance. These characteristics interrelate; for example a higher carbon content improves strength but reduces ductility. In this regard, understanding of these properties in totality facilitate materials optimization for given applications thus ensuring not only high performance and durability but also cost effectiveness of the steel itself as well as suitability for intended manufacturing processes and conditions.

How Carbon Content Affects Properties of Mild Steel

The proportion of carbon present is a crucial factor in determining the behavior or characteristics exhibited by mild steel with respect to its tensile strength, weldability along with ductility. Under lower levels or content which mostly ranges from 0.25% – 0.3%, mild steel demonstrates excellent weldability together with being excessively malleable to find application in many areas within industry. On the other hand, low-carbon composition results in reduced tensile strength making it less suitable for carrying heavy loads because it needs more reinforcement than necessary for bearing structures typically made from different materials including concrete or masonry. Conversely, increased carbon content enhances both hardness and strength thereby offering better wear resistance though at the expense of reduced ductility plus ability to welding them or bringing them together into one solid piece (Brittle). Thus balancing carbon contents becomes vital when tailor-making mild steel’s attributes so that they meet certain requirements leading to ideal combination of productivity features towards different industrial activities.

Analyzing the Tensile and Yield Strength of Mild Steel

Crucially, the tensile strength of mild steel is the maximum stress that can be put onto it before it will actually get stretched or pulled apart. This plays a key role in determining where this material can be used in various engineering and building construction projects. Typically, mild steel has a tensile strength range of 370 to 700 MPa making it useful for many applications where both force resistance and ductility are important. On the other hand, yield strength refers to the point at which mild steel becomes permanently deformed: this is an important consideration for design engineers when checking if structures can withstand any given loads without undergoing permanent deformation. Normally, yielding of mild steel occurs between 250 and 350 MPa, thus proving its usefulness as a material choice for structures emphasizing safety and durability. By balancing these strengths, engineers can effectively exploit those advantages offered by mild steel thereby ensuring its dependability in general use from creating structural frames to manufacturing car parts.

The Role of Alloying Elements in Enhancing Steel’s Properties

Meanwhile, alloying elements play a vital role in enhancing mechanical properties as well as chemical properties of steels so that they have broad range of applications across different industries. These metals include but are not limited to chromium, nickel, molybdenum among others introduced into the steel matrix by manufacturers with a view to giving specific characteristics to the resultant product. For instance, chromium enhances corrosion resistance consequently enabling such type of steel to be used within damp places while nickel increases toughness leading to improvements on low temperature performances. Molybdenum adds strength at elevated temperatures and improves weldability. Vanadium has increased hardness and strength hence its application results in thinner and lighter high-strength steel sheets but still capable of carrying heavy loads simultaneously.Consequently through strategic mixing of alloy elements;steel industry tailors durability,malleability,resistance against corrosion,and tensile strength towards meeting exact demands of diverse requirements ranging from manufacture to energy production and household applications.

How Ductility and Machinability Determine Steel Use

The ductility and machinability of steel play crucial roles in determining its suitability for various industrial applications. Here are some details and figures on the impact of these attributes on the use of steel:

- Ductility: This is the ability of steel to be stretched into wires or hammered into thin sheets without breaking under tensile stress. Therefore, this attribute is very important when it comes to construction where materials often have to be formed or bent to fit specific design configurations. For example, for earthquake-resistant structures, high ductility steels (elongation of 23% or more in a standard test) as defined by the American Iron and Steel Institute (AISI) are chosen since they can absorb and dissipate seismic energy during earthquakes.

- Machinability: Machinability is how easy it is to cut, drill, or machine steel into desired shapes and sizes. Mostly impacted by hardness, softer steels are usually easier to machine than harder ones. However, sulfur and lead alloying elements increase machinability by forming lubricating films on cutting tools thereby reducing wear rates reported after such operations. According to ISO standards, machining steels having carbon contents ranging from 0.2% up to 0.3% gives an optimum balance between hardness for durability as well as machinability for ease of manufacture making them suitable for automotive components including intricate machinery parts.

Manufacturers can create materials optimized for specific functions, from flexible structural elements to precision-engineered machine parts, by manipulating their ductility and machinability through careful adjustment of the composition and treatment of steel.

Assessing the Weldability and Fabrication Potential of Different Steel Types

- Carbon Steel: Carbon steel, which is known for its versatility, can be classified into three categories; low carbon steel, medium carbon steel and high carbon steel. Low carbon steel has up to 0.3% carbon content that makes it weldability excellent and highly fabricable because of low hardness and strength allowing it to be used in a wide variety of applications including building structures and automobile bodies. Medium carbon steels have from 0.3% to 0.6% carbon content are stronger but must be carefully welded so as not to become brittle. High carbon steels contain between 0.6% and 1% carbon content can lead to difficulties in welding by being prone to cracking due to their brittleness but this can be overcome by using preheating or post-weld heat treatments.

- Alloy Steel: Various elements like chromium, nickel and molybdenum are used in alloy steels achieve different properties. These types of steels possess improved toughness, strength levels as well as wear resistance. Weldability widely depends on the existence of some alloys within the material; those with higher contents are more challenging due to formation of hard brittle phases during welding process. Nevertheless, these issues can be addressed through careful controlled heat treatment of the material, combined with proper welding processes.

- Stainless Steel: Stainless steel is a corrosion resistant metal obtained from adding at least ten percent chromium content into an iron base matrix. They are grouped into austenitic, ferritic and martensitic based on their crystal structure. Austenitic stainless steels containing high levels of chromium and nickel provide good weldability but may produce sensitization if not properly treated during fabrication processes such as welding. Ferritic stainless steels can be welded but susceptible to grain growth whereas martensitic need preheat treatment before they are weld repaired for them not loose mechanical properties after welding.

- Tool Steels: Tool steels find use in making cutting tools, dies and molds. They are characterized by their hardness, abrasion resistance and ability to retain a sharp cutting edge. Welding in tool steel is difficult because they crack easily. Preheating before welding, keeping the welding temperature low and then subsequently heat treating after the welds have been made is vital to ensure successful welding.

Every type of steel has its own set of characteristics that affect its weldability and fabricability hence requiring specific techniques and precautions during welding processes. The understanding of these qualities is necessary for choosing the correct steel for particular applications which will guarantee that final products are structurally sound and perform as required.

Practical Applications: Welding and Fabrication with Mild Steel

Mild steel’s capacity to be used in welding and fabrication processes is best demonstrated by its fantastic weldability compared to steels with a higher carbon content. The reason behind this is that it has less carbon thus reducing the chances of producing defects when welding like cracking. Therefore, mild steel is widely used in the manufacture of motor vehicle components, construction materials and many kinds of machinery which require strong and tough welds. It can also be heated and shaped or molded into various products hence making it an ideal candidate for so many applications. From precise dimensions in intricate components to solid frameworks in buildings and bridges, mild steel forms a dependable base that engineers and fabricators trust. This is why mild steel remains a basic ingredient for worldwide building works and manufacturing.

Best Practices for Welding Mild Steel with Different Grades

When it comes to welding, each grade of mild steel must be understood well because they all have different properties. First of all, ensure that there is a clean environment free from dirt because mild steel rusts easily. In my experience, using a wire brush or grinder to prepare surfaces before welding significantly improves the quality of welds made on them I have found out moreover that choosing the right filler material is very important as well as applying it correctly during welding process: For instance, use a filler rod similar to your working grade as it will yield stronger bonds with similar expansion/contraction rates during welding.

On thin sheets of mild metals, TIG (Tungsten Inert Gas) method ensures more control and precision thereby minimizing possibilities for warping or burn-through effects. Conversely, MIG (Metal Inert Gas) becomes more preferable choice when welding thicker sections since it offers greater penetration ability as well as faster pace while doing so Nevertheless controlling heat input remains another important aspect; excessive heat may cause distortion or reduce strength. Thus if you are making something which is quite sensitive heat wise then try lower voltage settings while every now and then welding it in short bursts.

Finally, post-welding treatments like stress relieving might be used to improve the mechanical properties of welded joints, especially for critical applications. These methods have enabled me to experience the full range of application opportunities that exist for mild steel in any welding project.

The Importance of Weldability and Ductility in Steel Fabrication

Weldability and ductility are two major factors which determine how well a fabricated structure will perform or its quality. For instance, weldability is the ability of metal to be welded without affecting its strength. This means that when fabricating structures, it is important that they are strong enough to withstand different types of strains and pressures that may occur during use. On the other hand, steel’s ability to deform under tensile loads is known as ductility hence provides elasticity for structures so as to allow them take up energy without breakage. As far as structural applicability goes, having high ductiles very important since components made from this material can bend or stretch slightly before they fail thereby increasing safety and giving more durable products. These traits influence not only how easily a particular type of steel can be shaped and united but also dictate the efficiency of fabrication process ,longevity as well as safety levels seen in resulting constructions. This knowledge helps industry professionals choose proper grades depending on their project specifics thereby contributing to better performance and cost effectiveness.

Tips for Successful Steel Fabrication Jobs

A number of vital parameters have to be carefully paid attention to in order to ensure high-quality steel fabrication projects. Based on my own experience, here are some essential tips for maintaining the highest standards in your projects:

- This is how you choose material: Always use the right grade of steel for any given project. The weldability and ductility of these materials are vital. Consequently, select steel that balances these attributes with a view to meeting the specific needs of your assignment in terms of environmental conditions and stress levels.

- Proper Planning and Design: Detailed planning and design should proceed any cutting or welding operation. Employing computer-aided design (CAD) software, create a model for your project so as to simulate stress points. This helps identify existing problems before they come up during the fabrication process.

- The quality of workmanship in steel fabrication may influence its final appearance and functionality to a great extent. Thus, make sure that your team consists certified professional welders who have a good understanding of different types of steel grades.

- Welding Techniques: Ensure you use the right welding technique for both material and type of project at hand. For instance, TIG (Tungsten Inert Gas) welding may be recommended for thinner delicate sections while MIG (Metal Inert Gas) welding suits better thicker sections. Knowing what method is required can greatly influence both strength and appearance of final welds.

- Post-Weld Treatment: Residual stresses can be reduced whilst improving ductility through post-weld heat treatment (PWHT), thereby significantly enhancing the mechanical properties of welded joints. PWHT could be useful where welded joints play a crucial role in structural integrity

- Quality Control and Testing: Fabrication should involve thorough quality control throughout its entire process stage by stage. Non-destructive testing (NDT), such as ultrasonic or magnetic particle inspection methods, are excellent tools for spotting imperfections or weaknesses without having any impact on the component itself.

- Protective Finishes: Last but not least, the fabricated structure should be protected from corrosion and environmental damages. Therefore, proper coatings, galvanization or painting methods should be employed in order to increase the lifespan of a steel structure.

By always observing these tips which are rooted in an in-depth comprehension of material science and fabrication techniques, your steel fabrication projects will experience a huge improvement in quality and longevity.

Advancing with Heat Treatment: Enhancing Mild Steel’s Performance

Heat treatment operations such as annealing, normalizing and quenching and tempering with subsequent tempering can change the internal structure of mild steel to enhance its mechanical properties such as hardness, strength and ductility. For example, annealing entails heating the steel to a certain temperature and then cooling it slowly, hence making it more workable and suitable for machining and forming purposes. Normalizing however refines the grain structure of the steel leading to better strength and toughness. Quenching and tempering also increase further the hardness and strength of steel while maintaining its ductility for practical applications Incorporating these heat treatment techniques can significantly improve mild steel’s performance, making it suitable for a broader range of applications while extending the life of the final product.

Common Heat Treatment Processes for Mild Steel: An Overview

In materials science and metallurgy, knowing which heat treatments are appropriate is crucial in optimizing specific properties required in a typical kind of mild Steel. Here is some brief about widely used methods:

- Annealing: during this process mild steel is heated above its recrystallization point for some time then allowed to cool slowly from that temperature. The major aim is to lessen hardness, improve ductility as well as release internal stresses thereby facilitating easier machinability or shape formation.

- Normalizing: It involves heating a mild steel above its annealing temperature at which point it is air cooled within a controlled environment. It helps in refining grain structure in steels leading to improved uniformity in mechanical properties together with enhanced strength and toughness.

- Quenching and Tempering: Cooling hot iron rapidly by immersion into water oil or any other fluid coolant brings about high level hardness coupled with brittle nature due to quench-hardening effect; subsequent tempering provides toughness but still maintains significant levels of hardness from central regions of material. This technique mostly used after quench hardening processes whereby brittleness might have been introduced through rapid cooling process.

Every one of these processes alters the microstructure of mild steel, thus making it to be tailored for various industrial applications. Steel products can be made more durable and perform better by mastering these techniques during manufacturing.

Effect of Heat Treatment on the Mechanical Properties of EN8 and EN3B

The heat treatment effect on mechanical properties in the grades of steels EN8 and EN3B is fascinating and has a major impact in materials engineering. In this respect, EN8 is characterized by its strength along with toughness owing to being a medium carbon steel while EN3B is a low-carbon content mild steel renowned for its exceptional welding as well as formability characteristics. However, both materials undergo considerable changes when subjected to heat treatment that can be adjusted for specific end-use requirements.

- EN 8: Heat treating this material greatly improves its mechanical properties. For example:

- Annealing softens the steel making it easier to machine, reduces internal stresses This process enhances the ductility of component made out of EN8 especially those needing shaping or bending.

- Normalizing refines grain structure leading to increased strength and toughness in case of EN8 which makes it best suited for components under heavy load conditions.

- Increased hardness and strength are achieved by Quenching and Tempering EN8, although a close balance is essential between these features and toughness to avoid making the steel brittle thereby making it unsuitable for its intended application.

- Like other mild steels, heat treatment affects EN3B differently.

- Also, annealing softens straightened wire in EN3B so that it can be cold worked or machined with ease hence making it even more user friendly.

- Uniform mechanical properties of EN3B can be obtained through Normalization as it provides consistent basis for performance in applications.

- They might also carry out Quenching and Tempering but with less frequency for the lower carbon content of the material however if performed this could lead to a slight improvement in strength or wear resistance, which would make this type of steel more versatile.

Ultimately, this process alters the mechanical behavior of both types of steels that enhance their suitability for particular use. These include hardness or tensile strength, ductility, toughness as well as stress resistance. The method of heat treatment depends on what property needs to be achieved by the end product thus reflecting an interesting interplay between metallurgy and engineering design.

Customizing the Properties of Mild Steel through Controlled Heating

Mild steel and its properties can be customized through controlled heating which is a very complex but interesting subject matter of how heat interacts with metals at the molecular level. I have seen firsthand how certain types of heat treatment can change a steels characteristics. Talking about customizing properties such as hardness, strength, ductility and toughness there are some crucial parameters to consider:

- Temperature: The specific temperature at which the metal is heated has a vast impact on its properties since it enables us to alter the grain structure by cooling it down.

- Rate of Heating: The speed at which steel heats up influences the extent of heat penetration and thus affects the final microstructure.

- Holding Time: Also called soaking, this is the time during which the steel is being maintained in position before being cooled off so as to let uniform changes take place within it.

- Rate of Cooling: This is perhaps one of the most important factors since faster cooling (quenching) leads to harder steels while slower rates produce more ductile materials. While rapid cooling tends to increase hardness but can reduce toughness, slower cooling rates can produce a more ductile material.

- Atmosphere: The environment in which the metal gets heated determines whether surface reactions such as oxidation occur or not because these may influence some adverse events related to their physicality when they come into contact with gases.

Every one of these parameters must be closely knitted together and fine-tuned based on what we want from our steel. For example, if we need a toughened steel we would opt for reduced rate of cooling so that we enhance ductility or conversely where quenching has been done; hardening will occur rapidly. It’s all about finding an equilibrium between these conflicting characteristics that makes heat treatment both an art and science.

The Impact of Heat Treatment on Machinability and Durability

Heat treatment has a huge influence on machinability and durability whereby the process takes care of these features. The machinability can be enhanced through proper heat treatment, which refines grain structure, reduces internal stresses as well as increases surface hardness. Such changes ease cutting, shaping and forming of steel thereby increasing tool life and improving production efficiency.

On durability, however, heat treatment is significant in determining steel’s resistance to wear, fatigue and failure. Hardness toughness and ductility are adjusted by specific heating, holding and cooling processes that develop material strength for withstanding particular operational conditions. In high-wear applications hardness must be increased hence fast quenching maybe done. However components requiring higher toughness and resistance to cracking may need slower cooling rates.

In summary therefore; this practice is fundamental in ensuring that both machinability and durability are optimally achieved thus the resultant steel will exhibit characteristics necessary for its intended application in consideration of the desired performance attributes.

Preserving the Integrity: Corrosion Resistance and Maintenance

To keep heat-treated steel intact and increase its immunity to corrosion, observant care has to be practiced. Using protective coatings, like paints or galvanizing or plating shields this metal from direct contact with the corrosive components. In fact, frequent checks and maintenance are paramount in order for early signs of wear or corrosion can be identified and remedied in time. In areas where there is high humidity or near coastal region where salt exists more frequently inspections and specific anti-corrosion treatments are necessary. Besides that, including corrosion inhibitors into maintenance program significantly increases the life expectancy of heat treated steel structures. Additionally designing with corrosion in mind for instance through allowing sufficient drainage and airflow can help reduce incidences of corrosions. Finally, proactive maintenance as well as corrosion management strategies largely enhances durability and performance of heat-treated steel.

Strategies for Improving Mild Steel’s Corrosion Resistance

Three effective strategies discussed above can improve the resistance to rust of mild steel, a common material for making buildings and industrial goods. These are among the ways that help in ensuring that any structure or product made from mild steel last longer and remain safe and functional through its intended life expectancy.

- Coating Systems: For example, one of the simpler methods involves using a protective coating to enhance corrosion resistance. Protective barriers formed by paint systems, powder coatings and epoxy coats will prevent corrosive elements from directly coming into contact with the surface of the metal.

- Galvanization: This is where a protective zinc layer is put on steel. Zinc acts as a sacrificial anode which means it will corrode instead of the steel thus protecting it. Galvanizing is commonly used for outdoor structures and in environments with high moisture content.

- Cathodic Protection: Cathodic protection mostly applies to pipelines and underground tanks. Here, a more active metal is brought into contact with mild steel. Instead of corroding the steel corrodes providing protection against it.

- Environmental Control: Reducing exposure to elements such as salts, chemicals and water that speed up corrosion dramatically improves corrosion resistance. One way to do this would be designing so as not to allow accumulation of these substances near the metal or choosing materials according to their environment.

- Alloying: There are some specific additions that if put within mild steel will make it more resistant to corrosion. Even small proportions of chromium, nickel, molybdenum et cetera could enhance its ability to resist corrosion greatly.

- Maintenance and Inspection: Regular maintenance programs as well as frequent checks help in early identification and rectification of rust thereby preventing further destructions such as cleaning surfaces plus removing rust while adding more layers when necessary.

By incorporating these strategies during design, manufacture, installation and operation of mild steel products/structures; their life span, safety levels, aesthetics etc., would tremendously improve leading to better performance with low lifecycle costs in the end.

The Benefits of Galvanising in Protecting Mild Steel

Galvanizing is one highly effective way to keep mild steel safe from corrosion, thus extending its life and maintaining its usefulness in various applications. The process entails covering the steel with a layer of zinc for protection. Here is why galvanizing is good:

- Long-Term Protection: By acting as a barrier, the zinc coating prevents corrosive agents from reaching the surface of the steel. Provided it has been properly applied, galvanized mild steel can last for over 50 years even under severe conditions.

- Sacrificial Layer: Zinc corrodes more easily than steel; as such, it sacrifices itself through corrosion so as to give extra protection to the underlying mild steel. In other words, if you scratch off the coat, zinc will still help prevent rusting on your iron.

- Complete Coverage: In hot dip galvanizing stages every crimp and recess are filled with molten zinc so that there is no exposed portion of metal to start with rusting on contact with air. This means complete coverage including inside corners and areas which are difficult to access for uniformity against pitting.

- Cost-Effectiveness: In terms of total cost of ownership compared to other methods of protection galvanizing is economical. Over time it requires less repair and maintenance than the others hence saving money and resources.

- Reliability and Uniformity: Galvanization processes are well-monitored hence producing similar results across different pieces of steel. This helps in maintaining constant quality level at all times while also ensuring that performance remains high in such protected steels.

- Eco-friendly: Zinc used in the galvanizing process is a natural element found in earth’s crust. It does not harm living organisms when they come into contact with it thus making it environmentally friendly when used in making galvanized steels.

In conclusion, through sacrificial layers, long-term coverings, cost-effective defenses and green features or benefits involved in this type of operation called “galvanizing” it has improved the strength and existence of mild steel buildings in many sectors.

Maintaining Mild Steel Structures to Ensure Longevity

To ensure durability of mild steel structures, proper maintenance techniques must be employed because regular inspections and necessary repairs are needed. Moreover, the measures that extend the lifespan of these structures also help to keep their integrity and appearance. The following is a list of key considerations to make regarding maintenance of mild steel structures:

- Regular Inspections: Routine checks need to be done to identify any signs of depreciation or corrosion that may eventually lead to severe damage. This should include an examination for scratched or damaged galvanized coatings, which would expose the steel to its surrounding environment.

- Cleaning: Clear up dirt, grime and other pollutants from steel fabrications. Frequent cleaning prevents corrosive substances from accumulating and posing threats on the protective zinc layer over time.

- Protective Coatings: In harsh environmental situations, there may be a need for adding more layers of protection. Corrosion as well as aesthetic degradation can be prevented through painting or special coatings.

- Immediate Repairs: Timely remedial actions ought to be taken if corrosion is noticed during an inspection process. This may include re-application of a protective zinc coating or repair of damaged areas so as to arrest further rusting.

- Environmental Considerations: Take note of where the stainless-steel infrastructure is located in relation to its surroundings. As such, there might be requirement for more frequent maintenances schedules and increased protective measures especially along coastal lines or heavy industrial areas with high levels of pollutants.

- Proper Installation and Use: Proper installation according to its specifications should done while using it appropriately also prevent premature structural failure due overloading thereby influencing durability hence lifespan in use.

- Professional Guidance: Consult with maintenance professionals or corrosion specialists for tailored advice and advanced protection strategies. They provide information on latest technologies available and methodologies used in extending life span mild steel structures

By sticking to these rules it will definitely add age onto this kind structure only thus improving durability and operational safety that underlies them throughout years ahead .

Understanding the Physical Properties That Make Mild Steel Versatile

Mild steel, also called low carbon steel is celebrated for its versatility and it has found favor in many industries due to its unique blend of physical properties. Here are the properties that make it a common material:

- Ductility: Mild steel is highly ductile; this means that it can be drawn into a wire or bent into shapes without breaking easily. This is necessary for making shapes from materials.

- Malleability: Similar to ductility, malleability permits mild steel to be hammered or pressed into thin sheets easily. For instance, automotive body panels, construction materials and metal sculptures.

- Low Carbon Content: There is a lower percentage of carbon in mild steel as compared to high-carbon steels which means that mild steel is easier to weld and cut. Thus low carbon content reduces levels of carbon monoxide produced during welding thereby reducing risk of weakening the weld.

- High Strength and Toughness: Although the amount of carbon present in mild steel is very much low, it has an optimum strength-to-weight ratio. Thus it remains intact even when exposed to heavy loads and impacts hence widely used in building, bridge and infrastructure construction.

- Cost Effective: When compared with other types of steels or metals, mild steel production cost is relatively low. Additionally, the availability plus ability to recycle them makes them more affordable than any other materials for numerous applications.

- Weldability: The fact that mild steel has very little carbon content makes it one of the easiest metals to weld; a vital quality when constructing structures such as buildings and cars where very secure joints are required.

By keeping these physical characteristics in mind, engineers can always use cheaper mid grade stainless instead of stainless steels while not only being economical but also being durable enough less reduced lifetime expectancy on durability and integrity bases

The Role of Galvanized Mild Steel in Modern Construction

Having worked in the construction field, I can confirm that galvanized mild steel is an extremely essential component of recently built projects. There are several benefits of galvanized mild steel which make it a good material for builders and engineers. Here, we will discuss why we prefer to use this material in our projects and the relevant parameters that make it so popular.

Corrosion Resistance:

- To combat corrosion, mild steel is coated with zinc. This zinc coating acts as a sacrificial layer, corroding first and protecting the underlying steel. Considerations may include:

- Coating Thickness: The amount of protection offered depends on the thickness of the zinc layer measured in microns; for most external applications we tend to specify material with 85 microns coating.

- Environmental Conditions: The durability of the coating also depends on where it will be used. For example, thicker coatings are recommended for marine environments because they will have higher salt content.

Durability:

Galvanised Mild Steel has excellent durability and therefore is best suited for structures that must last many years. This is especially critical in demanding applications such as bridges and skyscrapers. Criteria include:

- Mechanical Properties: Durability of mild steel itself (such as tensile strength, yield strength and elongation) plus protective Zinc coat on top contribute to its overall quality.

- Maintenance Requirements: Low maintenance requirement complements high durability factor resulting in reduced life cycle costs.

Cost-Effectiveness:

Due to its low-maintenance nature leading to long lifespan, galvanised mild steel becomes a cost-effective solution for construction projects. These comprise:

- Initial Cost vs. Longevity: Although initial cost might be slightly more expensive than non-galvanized types of steels, the fact remains that over time this is more economical due to longer life span.

- Reduced Repair Costs: Less frequent repairs and replacement requirements mean fewer expenses throughout entire project execution stage.

Ease of Fabrication:

Galvanised Mild Steel can be easily fabricated into various shapes and sizes that are needed in contemporary construction. Parameters to consider include:

- Workability: How readily the material can be cut, welded, and shaped.

- Compatibility: Whether it can be used together with other construction materials; plus how easy it is to fit within an existing building’s frame.

Having all these parameters in mind proves that Galvanised Mild Steel is a crucial material in modern-day construction industry as it strikes a balance between cost, durability and performance.

EN8 Steel: A Case Study in Heat Treatment

My experience tells me that dealing with EN8 steel is both an exciting challenge and an opportunity of perfecting heat treatment conditions tailored for individual applications. This medium-strength steel, the EN8, has excellent tensile strength and ductility thus making it a common choice in several mechanical engineering applications such as shafts, stressed pins, studs, keys and others.

I remember that one of the projects was specifically meant to improve the hardness of EN8 steel without negatively impacting on its inherent toughness. To ensure temperature uniformity throughout the cross section of the steel, we heated it to its austenitizing temperature exactly 830°C (1526°F). The rate at which it was heated had to be checked so that there is no localized heating; this was gradually done over a period of about 45 minutes.

The holding time was approximately half an hour after reaching the desired temperature. It allowed for complete transformation into austenite across the whole volume of steel. I took extra care during this step by frequently assessing whether or not my thermocouple readouts agreed with one another.

In order to regulate cooling rate, oil rather than water was chosen as a quenching medium. Rapid water quenching on the other hand results in high hardness but may lead to internal stresses causing crack initiation during cooling. Oil had a slower cooling rate which helped strike balance between increased hardness and reasonable toughness; being around 70°C per second. Post-quenching hardness ranged between 48 HRC with respect to surface penetration.

Next step involved tempering of quenched EN8 at 450°C (842°F) aimed at stress relieving and further balancing between hardness and toughness characteristics. Tempering lasted for one hour before controlled aircooling followed through the oven opening door. This process produced a final hardness value equal to 42 HRC while increasing impact resistance significantly.

Thorough data logging characterized this case study. For example, we had hardness measurements of 48 HRC for the as-quenched sample and 42 HRC post-tempering. The ultimate tensile strength and yield strength were measured at 750 MPa and 465 MPa respectively. Ultimately, the steel elongated by fracture up to 16% after its treatment.

In conclusion, this particular heat treatment method for EN8 steel matched well with the mechanical requirements set for this project. It was learnt that precise adjustment of heating rate, holding time as well as cooling medium is crucial in achieving the desired material properties.

Innovative Techniques in Steel Fabrication

Laser Cutting and Welding

The revolution in the steel fabrication industry is due to laser cutting and welding which have provided a high degree of accuracy as well as control over heat input.

- Detail: Laser cutting is based on the use of a powerful light beam in making accurate cuts. The same concept is employed in laser welding, where a beam of light is used as a source of heat for joining two or more pieces together.

- Data: The technique can attain tolerances of ±0.1mm hence it suits complex designs. Since laser welding has fine control over the amount of energy delivered it results in minimum distortions making possible the joining materials that are different in thickness.

3D Printing and Additive Manufacturing

The printing models on three dimensions also referred to as 3D Printing creates complex geometries that could not be produced by conventional methods.

- Detail: Most commonly, this technology uses material such as stainless steel and titanium alloys to construct its objects layer by layer.

- Data: Some research shows that through 3D printing similar mechanical properties are seen for parts like those produced through traditional means. Typical tensile strengths around 600MPa have been achieved with some stainless steel components made this way.

Advanced Coating Techniques

These include Physical Vapour Deposition (PVD) and Chemical Vapour Deposition (CVD) among others as important ways of improving surface properties of steels called Advanced Coating Techniques.

- Detail: It improves characteristics like erosion resistance, corrosion resistance and thermal stability among others.

- Data: For instance, PVD coatings achieve hardnesses up to 2,500 HV compairing to hardened steels at about 55 HRC; thus, greatly extending tool life and other mechanical components’ life expectancy.

Cryogenic Treatment

Mechanical properties are improved once one plunges this type into extremely low temperatures (to -196°C).

- Detail: Heat treatment changes retained austenite into martensite thereby increasing wear resistance and dimensional stability.

- Data: Wear resistant ability of cryogenically treated steels is about 100-150% more than that of conventionally processed varieties.

Ultrasonic Impact Treatment (UIT)

This method employs ultrasonic energy to improve the mechanical properties of welded joints after welding such a process as Ultrasonic Impact Treatment (UIT).

- Detail: In other words, tensile residual stresses are reduced and fatigue strength is elevated by employing this procedure.

- Data: The fatigue life exhibited by welds which were subjected to UIT increased up to 35%.

Reference sources

- Xometry

- Source Link: All About Mild Steel: Definition, Composition, and Properties

- Summary: Xometry provides a detailed explanation of mild steel, including its definition, composition, and properties. The article outlines the varying levels of carbon and manganese typically found in mild steel, offering insights into how these elements influence its characteristics. This source is valuable for understanding the fundamental attributes and applications of mild steel.

- Metals4U

- Source Link: What is Mild Steel? An In-Depth Guide to Carbon Steel

- Summary: Metals4U delivers an in-depth guide on mild steel, focusing on its carbon content, melting point, and other essential properties. The article highlights the range of carbon percentages in mild steel and explains how these contribute to its thermal and mechanical behavior. This comprehensive guide supports a deeper understanding of mild steel’s versatility and practical uses.

- Metal Supermarkets

- Source Link: What Is Mild Steel?

- Summary: Metal Supermarkets offers a thorough overview of mild steel, detailing its production process, composition, and typical applications. The article explains how mild steel is manufactured from iron ore and coal and discusses its low carbon content. This resource is essential for readers seeking to grasp the basic and advanced aspects of mild steel in various industrial contexts.

Frequently Asked Questions (FAQs)

Q: What are the chemical properties of mild steel?

A: Mild steel, also known as low-carbon steel, contains a relatively low amount of carbon, typically around 0.05% to 0.25%. This low carbon content is a key chemical property that contributes to its ductility and malleability. In addition, mild steel may contain traces of other elements, such as manganese, which is added to improve its strength and weldability. The chemical composition of mild steel makes it a versatile material suitable for a wide range of applications.

Q: What makes mild steel a type of low-carbon steel?

A: Mild steel is categorized as low-carbon steel because it contains a lower percentage of carbon compared to higher-carbon steel grades. The amount of carbon in steel determines its hardness, strength, and ductility. Mild steel’s low carbon content, ranging from 0.05% to 0.25%, gives it its characteristic qualities of being softer, more ductile, and easier to machine compared to high carbon and other types of steel. This is why mild steel is often used in engineering and manufacturing applications that require materials to be easily shaped or welded.

Q: What are the physical properties of mild steel?

A: The physical properties of mild steel include its high ductility, weldability, and malleability, thanks to its low carbon content. It has a relatively high tensile strength and is also magnetic. Due to its iron composition, it is prone to corrosion if not protected. Mild steel also has a good surface finish when in the form of bright steel or bright mild steel, making it suitable for aesthetic purposes in addition to structural ones.

Q: How is mild steel used as structural steel?

A: Mild steel is widely used as structural steel due to its strength, ductility, and cost-effectiveness. The material’s ability to withstand significant force without breaking or deforming makes it ideal for constructing buildings, bridges, and other structures. Its excellent weldability also allows for easy joining of parts, which is crucial in construction projects. Furthermore, the various grades of mild steel can be tailored to meet specific load-bearing requirements, making it a flexible choice for structural applications.

Q: Can you machine mild steel?

A: Yes, mild steel is relatively easy to machine due to its low carbon content, which makes it softer and more ductile than higher carbon steels. This property allows for easier cutting and shaping processes, making it a preferred material for manufacturing steel products that require precise dimensions and shapes. The ease of machining mild steel also contributes to its cost-effectiveness, as it reduces the time and effort needed to produce components.

Q: What is bright steel, and how is it related to mild steel?

A: Bright steel, also known as bright mild steel, refers to mild steel that has been processed through cold drawing or peeling and polishing. This process gives the steel a bright, clean, and shiny finish, improves its dimensional accuracy, and enhances its mechanical properties by increasing tensile strength. Bright steel products are often used in applications where both aesthetic appeal and precise dimensions are important, such as in the manufacture of automotive parts, fasteners, and tools.

Q: How do you speak to a steel supplier about mild steel products?

A: When speaking to a steel supplier about mild steel products, it’s essential to specify the grade of steel, the required dimensions (such as thickness, width, and length), and the desired form (such as sheets, bars, or rolled steel). Providing details about the intended application can also help the supplier recommend the appropriate mild steel type. Additionally, inquire about any treatments or processing the steel has undergone, such as hot rolling or cold drawing, to ensure it meets your project’s specific needs.

Q: What advantages does mild steel offer in engineering applications?

A: In engineering applications, mild steel offers several advantages, including high strength, exceptional flexibility, and weldability, which make it capable of withstanding significant stress and forming into various shapes without compromising its structural integrity. Its cost-effectiveness and these properties make it a popular choice for a wide range of engineering projects, from infrastructure to machinery. Moreover, the various grades of mild steel allow engineers to choose the best specification for their specific application, enhancing design flexibility and efficiency.