In the rapidly changing world of 3D printing, picking the right file format is key for project success. STL (stereolithography) and 3MF (3D manufacturing format) are two most typically utilized file formats. Each of these formats has its own strengths and weaknesses and the choice between them will depend on your individual objectives and requirements. This guide breaks down both STL and 3MF formats in terms of their features, benefits as well as possible demerits. This article will be helpful to you whether you are a novice starting out with 3D printing or an industry expert searching for optimal workflow adjustments; it will enable you to make a decision that matches your specific aims in relation to 3D printing.

What is the Difference Between STL and 3MF File Formats?

Image source: https://www.3dnatives.com/

3D printing uses two different file formats—STL and 3MF—that serve the same purpose but differ from each other. Being an older format, STL saves only the surface geometry of 3D models as a set of triangles without any information about color, material properties or internal structures. It is simple enough to be supported by many applications, but this simplicity may lead to larger files and loss of details in designs. On the other hand, 3MF is a more recent format that can save not just geometries, but also metadata such as colors, materials used and sometimes even slicing parameters. As a result, most 3MF files are efficient and adaptable hence smaller sizes compared to STL with higher precision in generating outputs. Primarily developed for basic models’ use; while 3MF on enhanced features in complex & multicolorations products.

Understanding the Basics of STL Format

STL files, which were developed by 3D Systems in 1987, are one of the most commonly used file formats in 3D printing. The simplicity and universality of this format account for its popularity.

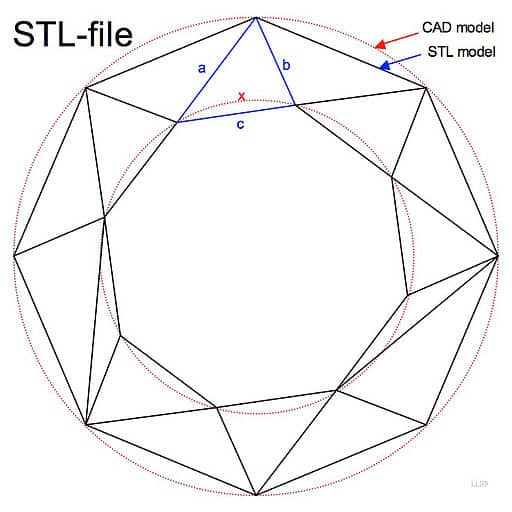

STL files do not have any color, texture or other attributes but only represent the surface geometry of a 3D object. It does this through encoding the object as a collection of small triangles called facets that make up the object’s surface. The use of more triangles gives more details to a model but it also makes file sizes bigger.

Nevertheless, there are disadvantages of STL files. Thus they cannot store additional information such as colour, material properties and internal structures which may be crucial for complex or multi-material models. However, despite these limitations, STL files being simple mean that they can be easily adopted by various printers and software making them popular among many areas where 3D printing is applied.

Advantages and Disadvantages of 3MF File Format

Advantages

- Enhanced Capabilities: They can store other information such as shades, texture and material properties hence richer datasets compared to STL files.

- Smaller File Sizes: Due to better compression and more efficient data storage, 3MF files often have smaller sizes compared to their STL counterparts.This is because they are better compressed and their data is stored more efficiently than those of STL format.

- Interoperability: 3MF has a universal compatibility with almost all software or hardware solutions that promotes its integration across different platforms.

- Error Reduction: The purpose of the format design is to minimize errors and ambiguity in order to produce accurate and reliable 3D prints.

- Support for Complex Models: 3MF provides options for internal structures, which makes it suitable for intricate and multi-material projects.

Disadvantages

- Compatibility Issues: Currently, 3MF cannot be used in some older software programs or even on printers because it has less support than STL does.

- Complexity: These features make the file type harder to use, especially if one needs much advanced software or a user who knows how to use these formats well enough.

- Learning Curve: Individuals who have been using STL may find it hard understanding advanced functionalities offered by the 3MF since this requires them to adjust their perception.

Comparing STL vs 3MF: Key Differences

It is worth noting that there are some differences between the two file formats – STL and 3MF, which can affect the decision on which one to use depending on specific needs or preferences:

- Data Richness:

- If we focus only on geometric shape information being stored in STL files, it means they capture the surface geometry of a 3D model leaving out its color, material and texture. It’s so basic such that almost any system can read them.

- Unlike STL files, 3MF files add more data: geometric plus color shaping, textures and materials etc. That’s why these have more detailed three-prints.

- File Size and Efficiency:

- This means that if you want very detailed models with many triangles, your files could become massively large once uncompressed as in .stl format.

- So often times while maintaining quality precision of 3D printing items like size we consider using efficient storage techniques and compressions for 3MF file types making them tiny yet detailed.

- Compatibility and Adoption:

- This has made it easier to make any of your CAD modeling product prints since most printers support .stl engineering format.

- STL is basically still widely used by majority of companies involved in manufacturing industries; hence it is compatible with lots of associated software than other formats available today too

- Error Handling:

- STL files may contain such defects as holes or duplicated planes, overlapping triangles etc. – this can lead to printing faults later.

- These types of errors are mitigated against by the structure of a 3MF file format which makes it stronger and thus reliable during this particular process since all necessary factors required here are provided in order to ensure higher fidelity when transforming a digital design into a physical object.

- Support for Complex Models:

- The problem with STL is that it does not support multi-materials or internal structures hence you cannot create complex objects using multiple materials at once.

- There’s also another type known as Multi-Material Format (MMF) which supports multi-materials as well as internal structures.

Understanding these differences can help users to decide whether they should be using STL or 3MF for their own 3D printing needs, based on the model’s complexity, desired detail and compatibility.

Why Choose 3MF Over the Traditional STL?

Opting for 3MF in place of the traditional STL format has a lot of benefits, especially for those engaged in delicate or complex 3D printing jobs. First, the files are small in size and can be compressed to ease storage this does not affect the quality or details of a model. Secondly, it also has robust error handling feature that minimizes common issues such as holes and overlapping triangles present with STL files. Moreover, 3MF files also support multiple materials and intricate internal structures thus allowing more advanced and accurate prints. Nevertheless, even though STL is widely used since it is compatible with many printers; there is an increasing number of new 3D printers and software with added support for 3MF making it more forward-thinking option for modern 3D printing applications.

Enhanced Metadata and Geometry Handling

3MF goes beyond the basic geometry of 3D models by incorporating rich metadata and advanced geometry handling capabilities. Unlike STL, which focuses only on the shape of objects, 3MF can also include information about color and material as well as texture and printability characteristics. This detailed data makes it possible to manufacture more precise and sophisticated prints, giving users much greater control over what their final outputs will look like.

Moreover, 3MF is better at managing complex geometries than STL does. It allows for internal structures and multi-part assemblies that are important for intricate designs or engineering purposes. By including these innovative attributes in its software platform, 3MF not only streamlines the process of printing things in three dimensions but also improves the accuracy of how printed models feel which makes it slightly better suited for highly complicated projects demanding a high level of precision

Impact on File Size and Storage

Evaluating the impact on file size and storage, 3MF files are better than STL files because of their efficient data encoding and compression mechanisms. According to Autodesk, 3MF files can reduce file sizes by up to 40% compared to STL without compromising the quality of the 3D model. This is supported by Ultimaker which explains why smaller file sizes result in faster processing times and reduced storage costs. Additionally, MatterHackers notes that detailed metadata and comprehensive geometry handling can be maintained without bloating the file for effective storage. Therefore it is a wise choice for both individual and commercial 3D printing projects as it reduces workflow steps and maximizes resource utilization.

Improvements in Print Quality

Advantages in print quality are witnessed with the adoption of 3MF files. In particular, Ultimaker states that a complete data structure for 3MF can better represent color, texture and material attributes resulting into very precise and visually attractive prints. Likewise, Stratasys reports that 3MF files have supported higher detail resolution which is vital for making complex and finely detailed models. Furthermore, according to 3D Hubs, one thing about 3MF is its ability to keep the model’s geometry intact thereby ensuring that the final printed product closely resembles the original designs hence reducing printing mistakes made by firms. This emphasis on specific and accurate data handling has enabled it to be excellent in delivering high standards of print quality in various three-dimensional printing projects which are carried out within different settings.

How to Use and Export a 3MF File for Your 3D Print?

Steps to Use and Export Your 3D Print as a 3MF File

- Create or Import Your Model: Using your preferred CAD software, create a 3D model for yourself, or alternatively import an existing one in the same software.

- Prepare the Model: Eradicate any discrepancies that may exist in the model so that it is fit for printing. This entails repairing of holes, ensuring that the orientation is correct, and optimizing geometry.

- Export as 3MF: Once you are through with the model you can export it using the export function on your CAD software into a file of format 3MF. Normally this option is found at ‘File’ > ‘Export’ or ‘Save As’. It is important when exporting to include all necessary data such as color; texture or material properties should be included in export settings.

- Verify and Slice: Open slicing software with this 3MF file to prepare this model for printing by converting it to layers. Check if everything is fine until finally adjusting print settings like layer height, infill density and support structures.

- Export Sliced File: After slicing, save the G-code or any other relevant format for your printer from slicer software. The final file should contain instructions on how to run your printer.

- Start Printing: A sliced file on USB, SD card or Wi-Fi has been transferred to a 3D printer then begin printing. To detect problems before they ruin anything look at first few layers of prints as adhesive bond gets established properly.

This way you will utilize and export a 3MF file efficiently as regards your multiple 3D printing tasks where quality outputs are required.

Common Software and Tools That Support 3MF File Format

Different software packages and applications can work with the 3MF file format, hence enabling it to be used in various parts of the process of printing a 3D object. Some of them include:

- Microsoft 3D Builder: This Windows application is particularly easy to use meaning that beginners as well as hobbyists are able to view, modify, or mend their 3MF files.

- Autodesk Fusion 360: It is known for its strong design tools and also supports 3MF files which can be used to do some complex engineering and designing before exporting the model for printing. In both professional and learning institutions, Fusion 360 has been highly regarded.

- Ultimaker Cura: Being one of the most popular slicing programs, this one supports 3MF files as well as comes with enhanced slicing features which include customizable print settings that aid in achieving accurate and high quality output.

These demonstrate how versatile and flexible the utilization of the 3MF file format is within the whole system of producing items in three dimensions, addressing diverse needs from simple modifications to detailed designs leading to manufacture.

Troubleshooting Common Issues in 3MF Export

It is common to encounter challenges while exporting 3MF, but several problems can be sorted out if few simple steps are taken:

- File Corruption or Errors: In case you encounter file corruption or errors when trying to export a 3MF file, make sure your design software is not outdated. Additionally, try saving the file as another format before back converting it to 3MF to check for persistent issues. Sometimes, updates of such software will somewhat mitigate these bugs.

- Model Integrity: Problems arise from broken geometries and non-manifold edges. You can correct all inconsistencies in the model by using repair tools found within your software. There are built-in repair functions that automatically detect and fix these error types in programs like Autodesk Fusion 360 or Microsoft 3D Builder.

- File Size and Complexity: Large or highly detailed models sometimes fail to correctly export due to memory limits. To facilitate a smoother export process simplify your model by reducing the number of polygons or splitting it into many parts.

- Software-Specific Issues: Different software handles differently the handling of the 3MF files. Ensure that you follow best practices specific to your software type. For instance, make sure the scale and orientation of the model are properly set before exporting in Ultimaker Cura.

- Missing Textures or Metadata: During export textures and metadata may be lost though they were included in 3MF files. Check all settings making sure that those elements have been included in the export operation itself. Re-apply missing textures on it before exporting them.

Taking care of these common issues will improve your overall experience with this type of print out process thus making an effortless start-to-finish cycle for successful 3D printing through seamless exporting from one’s application.

What are the Compatibility Considerations for STL and 3MF?

When you think about the compatibility of STL and 3MF file formats, there are several things that need to be considered:

- Software Support: Although STL is more universal in terms of its use as well as simplicity because it has been there for long, 3MF is now gaining a lot of popularity because of its additional functionalities. Most modern software for 3D modeling and slicing can handle both formats but if you intend to exploit its advanced capabilities, check whether your specific software supports 3MF.

- File Content: In addition to color and other metadata, these types contain only mesh data which is not included in any STL file. As a result, they represent a better choice when it comes to complicated models that call for immense information such as texturing and so on. If you decide on employing the above mentioned 3MF files make sure that both the hardware (e.g. 3D printer) and software support this kind of information.

- File Size and Complexity: The format based on XML called 3MF usually has a smaller file size and structure than STL making it more efficient. Therefore, they tend to have fewer errors while allowing ease in handling since they become smaller whereas STL files may grow very large resulting into some form of unmanageability especially in complex models.

- Interchangeability: In such cases, given the widespread acceptance of STL by most toolsets or frequent need to work together with different individuals who could be using diverse tools, it becomes an advantage. However, even though there are workflows with richer model data as well as better compression for which 3MF offers improved compatibility.

To sum up, even though the majority still prefers using an all-purpose format like STL one would argue that when it comes to managing large volumes of data efficiently as well as more detailed description related requirements, another type such as those designed with three-dimensional printers in mind would seem more justified. So remember what matters most is considering your needs and ensuring that your 3D printing pipeline tools are compatible with the chosen format.

3D Printer Compatibility with 3MF and STL Formats

You must consider how your devices and software handle these formats when it comes to 3D printer compatibility with 3MF and STL. Most of the 3D printers natively support STL files because they have been in use for quite a long time in the world of 3D printing. On the other hand, a number of manufacturers and software developers are increasingly incorporating 3MF in their applications so that more data can be retained like colors and textures.

If you are looking for intricacies or smart file handling then websites like All3DP and Ultimaker suggest that 3MF might be more interesting than the rest when compared to STL which is still safe for most printers. In case you need to employ advanced capabilities provided by these new format, please ensure that you crosscheck its compatibility with your specific printer settings via either user’s manual or online assistance facility at the manufacturer’s site.

Software Compatibility: Slicing Software and CAD Tools

For the software compatibility of slicing software and CAD tools, both STL and 3MF formats are widely supported with some unique advantages. The leading slicing software also known as Ultimaker Cura, PrusaSlicer, and Simplify3D can support as well as deal heavily in STL files due to their extensive use in the industry. These tools have good handling capabilities for simple geometries that come with STL files.

However, these same tools increasingly prefer the use of 3MF format because it is helpful in retaining rich model data including color, texture, material properties etc. Such a move is advantageous to individuals wishing to explore deeper functionalities of their 3D printers. For instance, Ultimaker Cura boasts about ability to store all necessary information concerning a given model within one single 3MF file that limits mistakes during printing process.

CAD applications such as Autodesk Fusion 360, SolidWorks (TM), TinkerCAD are capable of efficiently working with both STL and 3MF thereby offering design flexibility and varying options for different sorts of files. While projects based on basic modeling or those geared towards completing an item for printing in three dimensions will benefit from using an STL file, when trying out more intricate designs or creating detailed models users should opt for saving them into 3MF.

In conclusion, topmost Slicing Software’s & CAD Tools support both stl & 3mf formats but since it has more capacity to store better details regarding any work then this makes it more important in cases it involves rich model data. Therefore ensure that your software supports advanced features offered by the 3mf format if you want a complete and efficient printing exercise at all stages.

Industry Adoption and Support for 3MF

The 3MF format has become very popular in the 3D printing industry as it helps to embrace an all-inclusive model information and simplify the workflow. The leading companies and consortia such as Microsoft, Autodesk, HP or Ultimaker have adopted 3MF admitting its superiority to old STL format. This is promoted by active development and support of the 3MF Consortium that involves key industry actors.

Important 3D printing software platforms such as Ultimaker Cura, PrusaSlicer, and SolidWorks have strong support for 3MF, which is indicative of how much it is becoming important. These tools take advantages from what can be preserved by 3MF format in terms of complete details about a model like colors, textures as well as materials hence improving user’s experience and accuracy of printed models. As the industry moves towards more intricate and detailed print jobs, the capabilities of 3MF are increasingly becoming indispensable thereby making this ideal for cutting edge applications in modern information technology field.

What Does the Future Hold for 3D Printing File Formats?

3D printing file formats will continue to evolve in the future, moving towards more comprehensive and versatile standards like 3MF. As technology continues to advance, the requirements for format that can bundle detailed information such as colors, textures and material properties will increase. This change will help intricate designs and applications become possible thereby expanding the boundaries of 3D-printing possibilities. The adoption of enhanced formats like 3MF across industries will enable better innovation and increased efficiency which lead to improved quality and reliability of printed models. Ongoing commitment from major industry players as well as consortia is an indication that these formats may soon become a new standard thereby further extending the capabilities and coverage of 3D-printers.

The Evolution of Additive Manufacturing Technologies

Additive manufacturing, also called 3D printing, has changed much since its birth. In its early days, such techniques as stereolithography (SLA) and fused deposition modeling (FDM) paved way for the current 3D printing by making it possible to make prototypes and simple parts. Progressively with time, there have been more precise means resulting into sophisticated ones like selective laser sintering (SLS) and digital light processing (DLP). Consequently, these approaches offer improved resolution and stronger parts that are better functional. At present, multi-material printing or metal additive manufacturing leads to new possibilities in terms of applications across sectors like space jets to healthcare. The integration of digital design, better software and materials continues to push the field towards an exciting future for additive manufacturing technologies.

The Role of the 3MF Consortium in Future Developments

Developing and promoting the 3MF file format is a major role that the 3MF Consortium plays in shaping the future of 3D printing by developing and promoting the 3MF file format, which addresses the limitations of older formats like STL. The consortium includes tech giants such as Autodesk, HP and Microsoft. Its aim is to create a universal specification to improve sharing of 3D models among different platforms and applications. The 3MF file format gives room for richer data exchange with better precision involving color, material, and structure details applicable in advanced manufacturing processes. Through building partnerships among software vendors, hardware manufacturers as well as material scientists; this body helps foster innovation and standardization thus making additive manufacturing more accessible and effective in numerous applications.

Emerging Trends in 3D Printing File Formats

Emerging trends in 3D printing file formats are heavily influenced by the need for more sophisticated and efficient data exchange. As such, with developments in this field, there has been a rise of formats including 3MF due to their ability to contain rich information such as colors, textures or even multiple materials which could not be accommodated on earlier versions such as STL. On the other hand; new formats like AMF (Additive Manufacturing File) have emerged mostly because they support complex designs where multi-material prints can take place since these add structure complexity into CAD files. It also shows an increasing focus on universalizing software/hardware interoperability resulting from file-based workflows by creating use-case based unifying standards. In order that these formats meet current requirements of advanced three dimensional printers concerted efforts have started being made towards standardisation led by bodies like industry consortia working on them.

Frequently Asked Questions (FAQs)

Q: What is the difference between STL and 3MF file formats?

A: The STL file format is one of the oldest and most popular file formats for 3D printing, invented in 1987 by 3D Systems. It primarily represents the surface geometry of a 3D model. In contrast, the 3MF file format is more modern and supports additional information such as color, material information, and texture information, leading to potentially smaller file sizes.

Q: Why should I choose the 3MF format over STL?

A: You might prefer the 3MF format for 3D printing if you require more detailed information about your model, including color, materials, and textures. It is also better suited for handling complex models and results in smaller file sizes. This makes it ideal for more advanced 3D printing applications and multi-material printing.

Q: What are the limitations of STL files?

A: STL files have several limitations, such as the inability to store information about color, materials, or textures. They only represent the surface geometry of the 3D model but not any other metadata. Additionally, STL files can become very large and unwieldy with complex models, which can affect the efficiency of the 3D printing process.

Q: Are 3MF files compatible with most 3D printers?

A: Yes, 3MF files are increasingly becoming compatible with most 3D printers and slicer software. The 3MF Consortium, which includes many leading companies in the 3D printing world, actively works on ensuring broad compatibility and support for this advanced file format for 3D printing.

Q: What are OBJ files, and how do they compare to STL and 3MF?

A: OBJ files are another popular file format for 3D printing that stores both geometry and texture information. They are more advanced than STL files but typically larger in size. While OBJ files are good for detailed models requiring texture information, they might not offer the same level of optimization for smaller file sizes that 3MF file formats for 3D printing provide.

Q: How do I choose the right file format for my 3D printing needs?

A: Choosing the right file format depends on the complexity of your model and the requirements of your 3D printing project. If you need detailed color, material, and texture information, 3MF is a superior choice. For simpler models, STL may suffice, but if texture and advanced detail are important, OBJ might be the best.

Q: What role does a slicer play in 3D printing file formats?

A: A slicer converts your 3D model file into instructions that a 3D printer can understand. It slices the model into layers and generates the necessary code for printing. The choice of file format can affect how well the slicer interprets your model, with formats like 3MF offering more detailed information that can improve the slicing process and result in more successful printing.

Q: Is the AMF file format a good alternative to STL and 3MF?

A: Yes, the AMF file format is another alternative that supports color, material, and texture information. Like 3MF, it uses XML encoding to store comprehensive model details. While not as widely adopted as 3MF, it is still a viable option for those requiring more than what STL files offer.

Q: What is the future of 3D printing file formats?

A: The future of 3D printing file formats leans towards more comprehensive and efficient formats like 3MF and AMF that can handle complex models and detailed information. These formats are likely to become more standard, enabling better optimization, smaller file sizes, and more successful printing outcomes. The print industry continues to innovate, seeking ways to address the limitations of older formats like STL.