What Are the Key Differences Between Resin and Filament 3D Printers?

Image source: https://induplast.es/

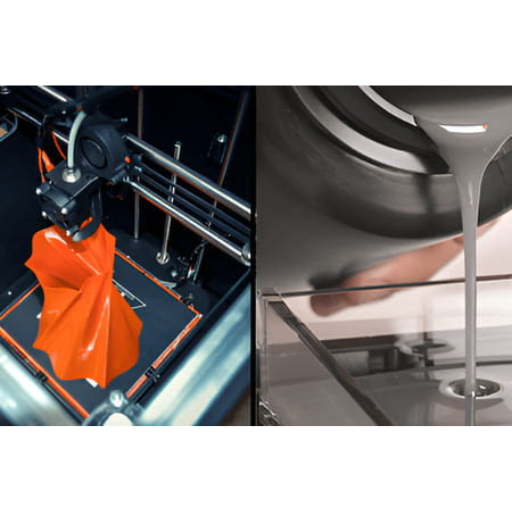

Printing technology, precision, and material properties are the main distinguishing factors for resin and filament 3D printers. In this process; termed SLA or DLP printing, Resin 3D printers employ photosensitive liquid resin cured layer by layer using a UV light source which achieves very high detail levels with smooth surfaces hence best suited for making complex miniatures. Conversely, FDM or FFF printers (which are types of filament-based 3D Printing) use melted thermoplastic materials such as PLA or ABS fed through a heated nozzle to build up an object in layers.

It should be noted that although they generally have lower accuracy than their counterparts resin machines produce rougher surface finishes than filament machines but this is compensated by being cheaper ,more user friendly and requiring less post-processing time . Further strength and durability of parts produced is higher when printed on filaments compared to resins.Printers should therefore be chosen basing on what you want achieved i.e., fine details /surface finish vis-à-vis cost/ease of use/functional strength.

Types of 3D Printers: FDM vs Resin

When I compare FDM and resin 3D printers, the most obvious difference is that FDM (Fused Deposition Modeling) printers are cheaper and easier to use. This means they’re a great starting point for beginners or anyone who wants durable functional parts quickly. In this process, an object is built layer by layer as melted thermoplastic (like PLA or ABS) is extruded through a heated nozzle. Such prints may lack fine details and smooth surface finish that can be achieved with resin printers but they will certainly be tough.

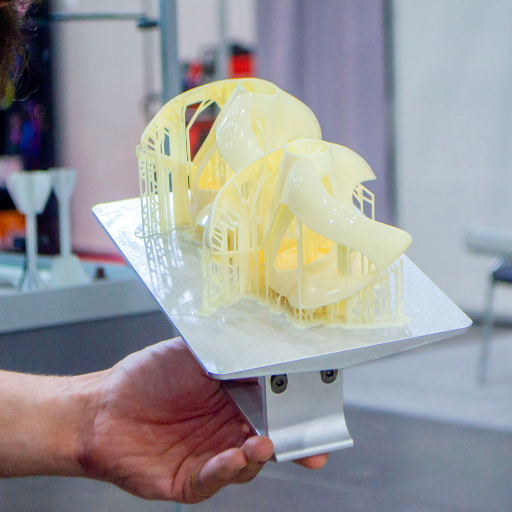

On the other hand, SLA (Stereolithography) and DLP (Digital Light Processing) are two common types of resin 3D printers which create highly detailed models with very smooth finishes – perfect for miniatures or intricate designs. However these machines tend to cost more money, require a lot more finishing work after printing is complete due to the chemicals involved in solidifying liquid resins under UV light etcetera.

In conclusion; if you need something cheap that works well then go for an FDM printer because it does what it says on the tin: It makes stuff strong. But if nice looking things matter too much such as when making figurines then go buy yourself some expensive equipment like SLA printers although there will still be additional costs associated with them so watch out.

Resin 3D Printing vs Filament 3D Printing Process

When I compared the process of resin 3D printers to filament ones, a few distinctions stood out that could affect your final choice depending on what you are looking for. Specifically, SLA or DLP technologies use UV light sources to cure layers of photosensitive resin. These kinds of prints have astounding detail and smoothness, so they are perfect for figurines, dental models, or any design with lots of intricate parts. The resins must be handled carefully; excess needs to be cleaned off during post-processing; and ventilation should be used when working since chemicals are involved.

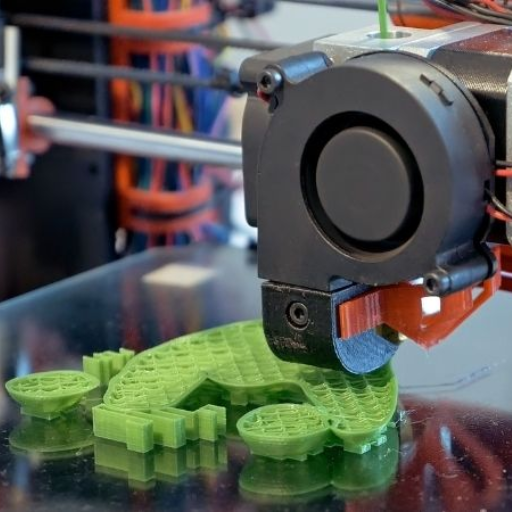

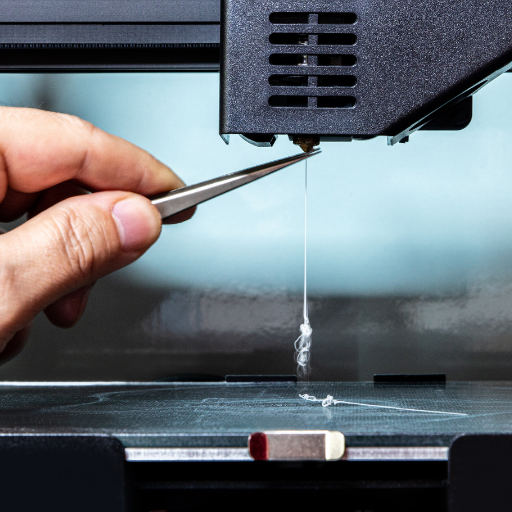

On the other hand, FDM (filament) 3D printing works by melting and extruding thermoplastic filaments like PLA or ABS through heated nozzles. This method builds things layer by layer and is known for being user-friendly as well as budget-friendly too. It is great at making large models or functional pieces that need durability without much fuss during finishing touches beyond removing supports and maybe some light sanding.

To sum it up: go with filament if you want something easy on your wallet which can produce strong parts for functional use – otherwise resin might be better suited if high levels of intricacy/detail are required along with smooth surfaces but don’t mind additional steps involved afterwards such as cleaning up excess material left behind by curing process plus greater precautions regarding safety due to chemical usage.Expectations.

Printing Technologies: UV Light vs Fused Filament Fabrication

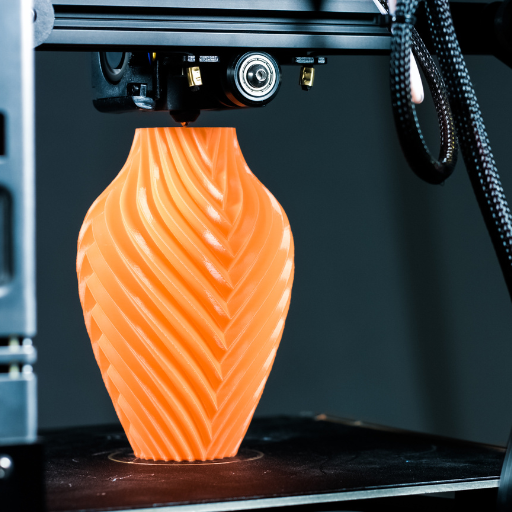

It is worth thinking about what differentiates UV light from fused filament fabrication (FFF) technologies in 3D printing. SLA and DLP are included in UV light technology, which can produce high-resolution prints with smooth surfaces. This is very useful for intricate details such as jewellery making, miniatures or dental models. The resin used in a UV light 3D printer is cured layer by layer with precise UV light, resulting in an accurate finish.

On the other hand, FFF (Fused Deposition Modelling) is known for its strength and low cost. FFF printers work by melting and extruding thermoplastic filaments like PLA or ABS from a spool through a heated nozzle to build up an object layer by layer. This method lends itself well to creating functional prototypes, durable parts and large-scale models. While it may not achieve the same level of detail as UV light technologies do, this ease of use coupled with its lower price point and material versatility make it an appealing option for many practical applications.

In conclusion: if you need something that will give you lots of detail & super smooth finishes, then go for one using UV-light printing technology; but if what matters most to you is being able to produce really strong parts at low cost – then FFF might just be your best bet.

Pros and Cons of Resin (SLA) and Filament (FDM) 3D Printing

3D Printing: Resin vs Filament

Resin (SLA) 3D Printing

Pros:

- High Resolution: SLA printers can produce highly detailed prints with smooth surfaces, making them ideal for intricate designs and fine details.

- Accuracy: The precision of UV light curing ensures a high degree of accuracy, suitable for dental models, jewellery, and miniatures.

- Smooth Finishes: The layer-by-layer curing process results in smoother surface finishes compared to FDM.

Cons:

- Cost: SLA printers and resins tend to be more expensive than FDM printers and filaments.

- Post-processing: Requires significant post-processing, including washing and curing, which adds to the time and effort needed.

- Fragility: Resin prints can be more brittle compared to filament-based prints, limiting their use for functional or load-bearing parts.

Filament (FDM) 3D Printing

Pros:

- Affordability: FDM printers and materials like PLA and ABS are generally more budget-friendly.

- Durability: Prints are often more durable and suitable for functional parts and large-scale models.

- Material Versatility: Wide range of available filaments, including flexible, composite, and high-temperature materials.

Cons:

- Lower Resolution: FDM printers may not achieve the same level of detail and smoothness as SLA printers.

- Layer Lines: Visible layer lines can be more pronounced, affecting the final surface finish.

- Less Precision: While sufficient for many applications, FDM may not meet the precision requirements for highly detailed or miniature models.

In conclusion, when choosing between resin (SLA) and filament (FDM) 3D printing technologies, consider what best fits your needs. For high-detail and smooth finishes, SLA is excellent, whereas FDM is a great choice for durable, functional parts and budget-conscious projects.

Quality of 3D Printed Parts: Detail vs Build Volume

Conversely, FDM printers are unmatched in terms of build volume. These machines can create larger models as well as functional parts which is why they are commonly used for prototyping mechanical components and other large-scale projects. But this comes with a tradeoff: FDM prints usually show more visible layer lines than their SLA counterparts since they lack some fine details achievable using stereolithography.

Resin vs Filament 3D: Printing Speed and Time

The process employed in SLA for taller objects takes much longer though accurate finishes are achieved compared to any other method. Theoretically you could reduce the print time by setting optimal values for height among other parameters but still it would never match most FDM prints speeds.

Finally if your project’s success depends on how fast it is completed and you’re willing to let go some details then FDM is recommendable over SLA. Conversely when perfection is the goal, then impeccable detail and surface finish should be given enough time hence choosing SLA as the best option even if print times may be long.

Liquid Resin vs Plastic Filament: Material Considerations

In comparing liquid resin and plastic filament, there are many things to consider about the materials. For instance, in my life, I learned that SLA printing requires liquid resin if you want to do it with good details or smooth surfaces. More brittle than filaments and prone to cracking under stress, resins can still alleviate this problem by using different kinds such as flexible or tough resins. On the other hand, FDM printing needs plastic filament which is versatile and durable too; however it has few options for material types like PLA ABS PETG where each one has different properties –– easy-to-use & eco-friendly (PLA), strong & heat resistant (ABS), well balanced between strength and flexibility (PETG).

Resin printing may be costly due to resin itself being expensive along with post-processing equipments like UV curing stations required afterwards whereas safety should also be taken into account because it could be toxic so you have to handle carefully under good ventilation while on the other side filament based 3d printer costs less money without needing many supports after print finishes thus making them safer in general but more affordable overall too; at last it all depends on what kind of project you are working with –– if need high resolution beautiful pieces then go for resins otherwise functional long lasting parts will require filaments.

Which Is Best for Printing Miniatures: Resin or Filament?

3D Printing: Resin vs Filament

In my experience with printing miniatures, I’ve come to realize that resin is the better option. This is because of its ability to hold more details and give a smoother finish which are necessary for highly detailed models. These printers can capture very fine points thus making them suitable for small statues or complex designs that need high levels of detail to be realized. The downside though is that it comes at a higher price in terms of both materials used and post processing equipment required; also safety precautions must be taken due to toxicity. On the other hand, while filament may work well enough for some people when it comes down to creating figurines, it lacks accuracy and neatness provided by resins but it’s cheaper and easier to use. All in all if you want truly beautiful intricate pieces then go with resin printing for miniatures as nothing else will do the job justice.

Detail and Precision in Miniature Printing

Cost-Effectiveness for Hobbyists and Professionals

Durability and Finish: Resin Miniatures vs Filament Miniatures

Understanding the Resin and Filament 3D Printing Workflow

3D Printing: Resin vs Filament

Resin and filament 3D printing workflows are each distinct processes, a fact that should be completely understood. In resin 3D printing, the typical workflow is to create or download a detailed 3D model which then gets sliced into layers using specialized software. The printer hardens the resin layer by layer with UV light, building up the model in a tank of liquid resin. This must be followed by post-processing; washing the prints in isopropyl alcohol and then curing them with UV light.

The process for filament 3D printing is similar; a 3D model is sliced into layers and heated plastic filament is extruded from the printer to build up the model layer by layer instead of curing resin. Filament prints usually require less post-processing such as removing supports and doing minimal sanding. These examples of work flow show us that while it may be more involved in terms of meticulousness during post processing for best results when working with resins, on other hand filaments offer an easier route which beginners can use without much interference needed after printing has completed.

Preparing for Your First 3D Print: Resin vs Filament

For the slicing software, specific settings about layer height and curing time must be entered if one wants their prints to turn out good enough. On the other hand, filament printing is easier than this. The basics include loading a spool of filament onto your machine and ensuring that its bed is leveled properly beforehand; also typical slicing softwares are more manageable since most filament prints require less demanding post-processings than others do.

Post-Processing: Cleaning and Curing vs Cooling and Removal

Post-processing for resin and filament prints is composed of different steps. It is important to clean and cure a resin print. Isopropyl alcohol should be used to wash a model made from resin after printing so as to get rid of any uncured resin. The next thing to do is curing the print entirely under UV light in order for it obtain strength and detail that are required while at the same time making the material solidify. This may take much time but this process cannot be skipped if one wants good results in the end.

On the contrary, cooling down and removing from the print bed are involved in filament prints. When printing has finished, a filament model needs to be cooled down so as not to warp. Then, sometimes using tools like scraper for help, the print can be gently detached from a print bed. In general, post-processing steps of filaments are simpler because they mainly revolve around removing support structures and doing some minor sanding works on it. From what I have found during my researches into this subject matter; post processing for filament prints is faster and easier compared with resins which require meticulous cleaning as well as curing them.

Long-Term Maintenance: Resin Printer vs Filament Printer

Compared with filament printers, resin printers are known to require more effort and attention in the long run. According to a number of different sources, keeping these types of machines working smoothly involves cleaning out the resin vat often, replacing the FEP film regularly, and making sure that the UV light source remains efficient. Furthermore, storage for this substance can be messy; it should not be contaminated or allowed to cure by any light other than ultraviolet.

On the other hand, filament printers generally need less maintenance overall. Common tasks include cleaning off the print bed every so often as well as changing out nozzles occasionally; additionally it’s recommended that filaments be stored somewhere dry where they won’t absorb moisture. These devices are easy enough to care for which makes them convenient if you’re not into too much hands-on work yourself – basically anyone who wants things done quickly without getting their hands dirty! While both kinds do require some which can’t be skipped over entirely but for most people printing with plastics is going bring about simpler and shorter periods of maintaining their machines compared against resins.

Safety and Environmental Considerations in 3D Printing

The first thing to do when working with a resin printer is to handle the resin carefully. Resin can be toxic, so it is necessary to avoid contact with the skin by wearing gloves and working in a well-ventilated room or using a fume extractor for the fumes. In addition, cured resin waste should be disposed of properly according to local regulations in order to reduce its environmental impact.

Although filament printers are generally considered safer than their counterparts, there are still some factors that need consideration too. For example, long-term exposure to fumes produced by certain filaments such as ABS may cause health problems. Therefore it is advisable either to place a printer in a ventilated area or create an enclosure which has adequate ventilation. Environmental friendliness can be achieved through use of biodegradable materials like PLA while recycling failed prints and filament scraps will help minimize environmental pollution associated with this type of printer.

To sum up, both types of printers call for careful handling and assessment of possible health effects as well as their surroundings on ecology. Users must therefore take precautions against accidents and dispose wastes responsibly not only for safety purposes but also because such steps enable them enjoy benefits brought about by three dimensional printing while at same time limiting hazards.

Handling and Disposal of Resin Material

Ventilation and Health Risks: Resin Printing vs FDM Printing

Sustainability: Biodegradable Filaments vs Toxic Resins

On the other hand, toxicity levels are high in resinous materials used for 3D printers using photopolymers made from petrochemicals therefore they need careful handling and proper disposal due to their hazardousness. Although eco-friendly resins are being worked on so as to improve them environmentally speaking this still falls short of what can be achieved by biodegradable filaments according to most reliable sources I found while researching this topic thus my recommendation would be going green with your 3d prints by using bio-films instead.

Choosing the Right 3D Printer for Your Project: Resin and Filament Compared

3D Printing: Resin vs Filament

On the flip side, when it comes to different types of PLA or ABS filament printers (which are more user-friendly and versatile in terms of application), they may be less costly both at first purchase as well as ongoing operational costs while being ideal for creating larger objects where minute details aren’t necessary – like functional parts. You should choose which one is best based on what your specific needs are considering things like budget, detail requirement and ease-of-use among others.

Budget and Cost of Ownership: Resin vs Filament 3D Printer

Larger Build Volume Needs: When to Choose FDM

Specialized Applications: When to Opt for Resin Printing

Reference sources

-

All3DP – Resin vs Filament 3D Printers: The Differences

- All3DP offers a detailed comparison between resin and filament 3D printing, covering aspects such as print quality, material properties, and typical use cases, making it an excellent resource for understanding their respective strengths and weaknesses.

- Source: All3DP

-

MatterHackers – Resin vs Filament: Which Should You Use?

- MatterHackers provides an in-depth analysis of resin versus filament 3D printing, focusing on factors like detail resolution, durability, and application suitability, which are crucial when deciding the best method for miniatures and other projects.

- Source: MatterHackers

-

3D Insider – Resin vs Filament 3D Printing: Which is Better?

- 3D Insider explores the pros and cons of resin versus filament 3D printing, discussing detailed aspects such as post-processing requirements and cost-effectiveness, which are essential considerations for making an informed choice.

- Source: 3D Insider

Frequently Asked Questions (FAQs)

Q: What is the main difference between a resin 3D printer and a filament 3D printer?

A: The main difference lies in the printing technology and material used. A resin 3D printer, also known as a stereolithography (SLA) printer, uses a liquid resin that solidifies when exposed to UV light. A filament 3D printer, known as fused filament fabrication (FFF) or fused deposition modeling (FDM), uses a solid filament of plastic that is melted and extruded through a nozzle. Each type has its own set of advantages, depending on the application.

Q: Which is cheaper to operate, filament or resin 3D printers?

A: Filament 3D printers are generally cheaper to operate than resin 3D printers. The filament material is usually less expensive than SLA resin, and FDM printers typically have lower maintenance costs. However, resin printers can produce parts with higher detail and surface finish, which may justify the higher operating costs for some applications.

Q: Can you use filament and resin in the same 3D printer?

A: Most 3D printers are designed to use either filament or resin, but not both. However, there are hybrid 3D printers on the market that can switch between filament and resin printing methods, offering a versatile solution for different types of projects. These printers can be more expensive but allow users to explore both types of 3d printing without needing to purchase two separate machines.

Q: What are the benefits of using a resin 3D printer over a filament 3D printer?

A: Using a resin 3D printer offers several benefits over its filament counterparts, including higher precision and better surface finish, which are crucial for detailed models and miniatures. Resin printers are also capable of printing complex geometries that may be difficult to print with filament. However, these advantages come with higher costs for both the printer and the materials.

Q: Are filament and resin 3D printers suitable for beginners?

A: Both types of printers have models suitable for beginners, but filament 3D printers are often recommended for those new to 3D printing due to their simplicity, affordability, and ease of use. Resin printers require handling liquid resin, which can be messy and requires safety precautions, making it a less straightforward option for beginners. However, those with a specific interest in the high detail and precision of resin printing may still find it appealing.

Q: What types of projects are best suited for filament and resin 3D printers?

A: Filament 3D printers are well-suited for larger, functional parts like household items, prototypes, and cosplay pieces due to their strength and durability. Resin 3D printers excel with projects requiring high detail and smooth surface finishes, such as jewelry, dental models, and tabletop miniatures. The choice between filament and resin ultimately depends on the specific needs of the project.

Q: How do the speeds of filament and resin 3D printers compare?

A: Generally, filament 3D printers can print faster than resin 3D printers. FDM printing speed is influenced by the movement of the extruder head and the rate of filament deposition, whereas resin printing speed depends on how quickly each layer of resin can be cured by UV light. While resin printers can produce higher detail, the layer-by-layer curing process can make them slower overall.

Q: Is it easy to switch from using a filament 3D printer to a resin 3D printer?

A: Switching from using a filament 3D printer to a resin 3D printer involves a learning curve, primarily due to the differences in printing processes and post-processing requirements. Resin printing involves handling liquid resin, using UV light for curing, and often requires washing and curing steps after printing. However, with the wealth of resources available to learn more about 3D printing, the transition can be made smoother for those willing to invest the time.

Q: Which has a wider variety of materials, filament or resin 3D printers?

A: Filament 3D printers have a wider variety of available materials, including basic plastics like PLA and ABS, specialized filaments like flexible TPU, carbon fiber-infused, and metal-filled materials. Resin 3D printers have a growing range of resins with different properties, including tough, flexible, high-detail, and castable resins, but the diversity is not as broad as filament materials. Each printing method continues to evolve with new materials being developed.

Q: What are the main differences between resin and filament 3D printers?

A: The main differences between resin (known as SLA resin in the context of 3D printing) and filament (known as FDM or fused filament fabrication) 3D printers revolve around their printing processes, material used, and the quality of the finished product. Resin 3D printers use a liquid photopolymer that solidifies when exposed to UV light, offering high resolution and smooth finishes. Filament printers, on the other hand, melt a plastic filament to create the object layer by layer, which is better for larger, more durable objects but typically has a rougher finish compared to resin prints.

Q: Is a resin 3d printer more expensive to use than filament printers?

A: Generally, initially, a resin 3D printer can be more expensive due to the cost of the SLA resin, which is typically higher than filament for FDM printers. Additionally, resin printers may require more accessories and maintenance. However, prices for both printers and materials have been decreasing, making affordable resin 3D printers more accessible. The overall cost will also depend on the volume and type of printing you plan to do.

Q: Can filament and resin 3D printers be used for professional purposes?

A: Yes, both filament and resin 3D printers are used for professional applications. The choice between using a resin 3D printer or a filament 3D printer often depends on the specific requirements of the project. For example, resin printers are favored for detailed models and prototypes, such as jewelry or dental applications, due to their high resolution. Filament printers are typically chosen for creating larger, functional parts or prototypes that require structural integrity.

Q: Are resin 3D printers faster than filament 3D printers?

A: The printing speed between resin and filament 3D printers can vary depending on the model and the specific print job. Resin 3D printers can print very detailed prints faster than filament printers due to the way the resin is cured in layers. However, for larger, less detailed items, filament printers can be faster. The complexity and volume of the object being printed play significant roles in determining the speed of printing.

Q: How do resin and filament 3D printers impact the quality of printed objects?

A: The impact on quality between using a resin 3D printer and a filament 3D printer is significant. Resin printers tend to produce objects with higher precision, finer details, and a smoother finish straight out of the printer, making them ideal for models, miniatures, and intricate parts. Filament printers might not achieve the same level of detail but are excellent for larger, functional parts that require strength over aesthetics. The choice of printing material plays a crucial role in the final object’s properties, including durability, flexibility, and detail resolution.

Q: What materials are available for filament and resin 3D printers?

A: Filament 3D printers primarily use materials known as 3D printer filament, including PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and specialized filaments like TPU (thermoplastic polyurethane) for flexibility, or PETG (polyethylene terephthalate glycol) for durability and resistance. Resin 3D printers use photopolymeric resins, which are available in standard, flexible, tough, and castable formulas designed for specific applications such as dental, jewelry, and engineering prototypes. Each type of 3D printing material offers unique characteristics tailored to different needs.

Q: What should beginners know before choosing between a filament and a resin 3D printer?

A: Beginners should consider several factors before choosing between filament and resin 3D printers. Initial cost, intended use, print quality, material costs, and post-processing requirements are crucial. Resin printers, offering high detail and precision, are excellent for small, intricate models, but require significant post-processing. Filament printers are more user-friendly, better for larger projects, and generally cheaper to maintain. Learning more about 3D printing and understanding the specific needs of your projects can help inform this decision and lead you to choose the best 3D printer for your purposes.

Q: How environmentally friendly are filament and resin 3D printers?

A: The environmental impact of filament and resin 3D printers varies depending on several factors, including the type of printing material and how waste is managed. Filament printers can use biodegradable materials like PLA, which is made from renewable resources such as cornstarch, making it more environmentally friendly. However, other filaments like ABS are petroleum-based and less eco-friendly. Resin printers use chemicals that can be harmful if not handled and disposed of properly, although there are more eco-friendly resin options becoming available. Proper ventilation and recycling or disposing of materials according to local regulations can mitigate environmental impacts.