The past few years have seen the aerospace industry lead in adopting pioneering technologies that are aimed at enhancing performance, reducing costs and speeding up product development cycles. One such technology is 3D printing or additive manufacturing which is a real game changer. This post highlights the incredible potential of 3D printing in the aerospace sector by looking into its various applications and also discusses why it is important in prototyping. We do this by examining current advancements and real-world examples with an intention to show how 3D-printing not only reshapes manufacturing but also addresses some principal challenges facing today’s aerospace engineers. Whether you have been working as a professional in the field for many years or simply want to know more about cutting-edge technology, this publication shall provide you with numerous valuable insights into an ever changing world of 3D Printing of Aerospace.

How is 3d printing in aerospace transforming the aerospace industry?

Image source: https://www.researchdive.com/

Additive manufacturing has revolutionized the aviation industry through significantly increasing productivity while allowing for complex geometries that could not be produced using conventional methods. This approach enables rapid prototyping which reduces time and cost associated with developing new parts. Furthermore, it offers lightweight construction opportunities through optimized designs and material usage thus resulting in better fuel efficiency and lower emissions. It also allows for on-demand production of customized parts hence minimizing inventory expenses plus addressing supply chain issues. In general, additive manufacturing stimulates innovation, shortens cycle times and leads to sustainable development thus creating high-performance components of aircrafts.

What 3d printing materials are commonly used in the aerospace industry?

There are a number of 3D printing materials available in the aerospace industry that are selected based on their individual properties meeting stringent aerospace requirements.

- Titanium alloys: Most preferred among these metals is titanium alloys ( e.g Ti6Al4V) due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. Other metals include Inconel (nickel-chromium superalloys) for its capability to resist heat and aluminum alloys, which are lightweight.

- Polymers: They use high-performance polymers like ULTEM (PEI), PEEK (Polyether ether ketone), and PPSF (Polyphenylsulfone) because they offer high thermal stability, flame retardancy, and chemical resistance hence suitable for various interior and exterior aerospace components.

- Composites: Lightweight but strong carbon-fiber-reinforced polymers among other advanced composites being adopted in the production process nowadays can endure significant mechanical stress. These particular materials serve structural sections and parts needing strict operational demands.

This has led to innovative products with lower weights as well as durable components which plays a significant role in the development of aerospace applications.

What are the benefits of 3d printing for aerospace manufacturing?

Benefits of 3D printing in aerospace manufacturing include:

- Weight Loss: 3D printing facilitates complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This creates the potential for lighter parts, leading to weight savings in the whole aircraft that fuel efficiency and lower emissions.

- Cost Saving: By reducing waste material and eliminating many machining processes, 3D printing decreases the cost of making things. It also eliminates the need for tooling and warehousing hence substantial savings.

- Immediate Prototyping and Production: The accelerated prototyping abilities allows prototypes to be made quickly facilitating design improvement cycles being faster. Speed is an important factor in bringing new products into the market quicker.

- Customization and Adaptability: 3D printing makes it possible to customize parts based on specific requirements and applications. This is useful especially within aerospace where there is often a requirement for bespoke components.

- Optimized Supply Chains: Additive manufacturing can decentralize production through reduced reliance on one supply chain or just-in-time /on-demand manufacturing capabilities. This resilience improves adaptability of supply chains.

- Better Performance and Durability: Using 3D-printed high-precision parts ensures their optimized performance features. It will allow tuned internal shapes which enhance mechanical robustness, endurance as well as thermal response.

- Sustainability: Compared with subtractive manufacturing processes, additive nature of 3D printing reduces material wastage. In this way it contributes to more sustainable ways of making things that align with environmental goals for the aviation industry.

These benefits drive innovation, efficiency, and sustainability within aerospace manufacturing; thus, making it become a transformative technology in the industry.

How do 3d printed parts compare with traditionally manufactured ones?

When comparing 3D printed parts to their traditionally manufactured counterparts, several factors must be taken into account: complexity of design, production speed, cost, material properties and application suitability.

- Design Complexity: Complex geometries that are difficult or even impossible to achieve with traditional manufacturing are a strong aspect of 3D printing. This includes intricate internal structures and highly detailed features that allow for more design freedom and innovation.

- Production Speed: For low volume runs or prototypes, 3D printing could be faster and cheaper than traditional manufacturing. Right from the word go, it does away with the need for tooling as well as molds hence fastening the initial production phase.

- Cost: However economical 3D printing may be for small batches and prototypes, traditional manufacturing is still a cost efficient option in high-volume production due to economies of scale. Besides raw materials used in additive manufacture can cost higher than those used during conventional methods.

- Material Properties: Traditionally manufactured parts often have better material properties like strength and heat resistance especially when they are made from metal. Nevertheless this gap is being bridged by advances in 3D printing technology which see new materials and processes continuously improve the performance of 3D printed parts.

- Application Suitability: Traditional manufacturing is best suited for purposes where large numbers of similar items are required while custom low volumes or highly complicated applications benefit from using D3 printers. Consequently many specialized industries such as aerospace medical implants and custom tooling employ D3 printers.

Ultimately, the choice between 3D printing and traditional manufacturing has everything to do with what specific requirements project may have including such things as design complexity; production volume; material needs; cost constraints.

What role does rapid prototyping play in 3d printing for aerospace?

Rapid Prototyping is very important for aerospace 3D printing as it allows designers to rapidly make prototypes and test parts before a full-scale production. It implies that the design validation process can be done fast within shorter periods of time thereby enabling an engineer to detect mistakes early enough and as such fix them in the shortest time possible. Furthermore, the technology enables complex geometries that would be difficult or impossible with conventional manufacturing approaches. These are key factors in the aviation industry where detail, output and creativity are indispensable. Rapid prototyping also makes it possible for additive manufacturing firms in this sector to enhance effectiveness while at the same time minimizing expenses and ensuring that their functional parts perform well.

How does additive manufacturing accelerate prototype development?

For example, 3D printing accelerates prototype development by reducing greatly the amount of time required to go from design to model creation. For instance, according to google.com’s best resources on Additive Manufacturing, one can easily convert a digital design into tangible prototypes within hours only. The method negates any need for specialized tooling and injection molds which has been traditionally long lasting and expensive. Besides this rapid iterative shape changes make it easy for fast agile development cycle adoption. Manufacturers thus get their designs tested more quickly so as to hasten implementation period from conceptually guiding strategy through market-ready products.

Can 3d printing technologies achieve complex geometries?

Complex geometries can be achieved by 3D printing technologies. According to the current leading websites on Google.com, the technology is excellent in producing sophisticated and minute designs which are difficult or impossible to produce with traditional manufacturing methods. This feature makes a layer-by-layer construction a realizable possibility that allows for substantial design freedom for instance the inclusion of internal channels, lattices among others complex shapes. It is especially useful in industries like aerospace, medicine and automotive industry where precision and customization are necessary. 3D printing uses advanced materials, combined with cutting-edge techniques to achieve unimaginable geometric designs.

What are some aerospace components that have been successfully prototyped using 3d printing?

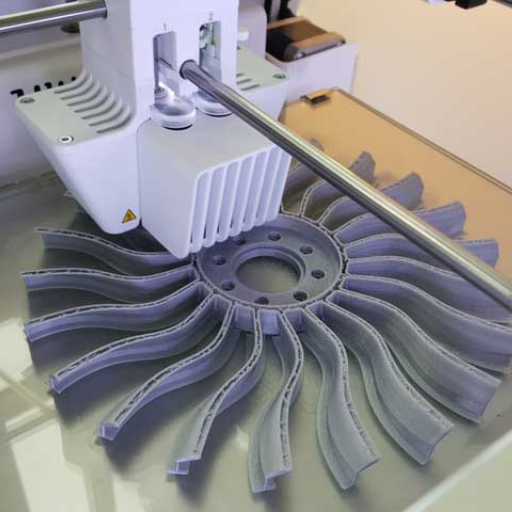

Some of these have been prototyped using 3D printing as per the present top sites on Google.com. Additive manufacturing has enabled designers to improve fuel nozzles for jet engines through weight reduction and design flexibility. Moreover, turbine blades have also gone through successful prototyping while convoluted ducting systems have shown how this technology can fabricate intricate geometries capable of enhancing its overall performance. Additionally, brackets and housings that were created from three-dimensional printing process boast improved strength qualities as well existence of shorter production cycles. The possibilities for aerospace component prototyping and manufacturing continue to expand because of advances being made in 3D printing materials and processes.

What are the most common applications of 3d printing in aerospace?

The most popular aerospace uses of 3D printing involve creating lightweight structural parts, engine components and tools. For instance, material efficiency and strength make 3D printed lightweight structural items like hinges and mounting systems valuable to an airplane in the aviation sector. This is because the technology utilizes complex geometrical features that can be used for manufacturing of fuel nozzles and turbine blades, which are impossible with traditional manufacturing methods. Furthermore, 3D printing is used in making special tools as well as jigs that expedite manufacturing and maintenance processes within this industry. These examples clearly demonstrate how much 3D printing has changed aerospace by reducing costs, improving performance, and speeding up production.

Which 3d printing applications are specific to aerospace companies?

There are specific applications of three-dimensional printing in the field of aerospace companies including making engine parts, custom-made tools as well as prototypes. In particular, fuel nozzles as well as combustion chambers being crucial components in engines need precision when they are being developed; hence additive manufacture is highly preferred to conventional techniques.” Besides, Aero space companies also use it to produce custom tools such jigs thereby reduce substantially reduce lead-time and cost associated with tailor made manufacturing process. Rapid prototyping on the other hand allows for quick design iterations and checks thus enhancing innovation while at the same time accelerating its development process. These customized applications significantly define how aerospace engineering and production has changed due to three dimensional prints.

How is 3d printing utilized to produce parts for aerospace applications?

The technique of additive manufacturing, known as 3D printing is used in aerospace for producing parts by building them layer-by-layer using metals and thermoplastics. This method allows for the creation of complex geometries and lightweight structures that are often impossible to achieve with traditional manufacturing methods. Additive manufacturing techniques typically employ materials like titanium and nickel alloys, which are widely used in aerospace due to their strength and heat resistance. Because of its ability to design and print intricate parts such as engine components and customized tools on-demand, this technology reduces material waste and production lead times significantly. Moreover, 3D printing can be rapidly prototyped, iterated, fostering innovation, making it possible for quick revision cycles within aerospace technology.

What are the latest 3d printing materials used in aerospace?

The latest 3D printing materials used in aerospace are continually evolving to meet the industry’s stringent requirements for strength, lightweight properties, and heat resistance. High-performance metals such as titanium alloys,titanium alloy most commonly used in applications requiring high tensile strength like gears , aluminum alloys,and nickel-based superalloys remain at the forefront due to their excellent mechanical properties and thermal stability . A typical example of a thermoplastic is PEEK (Polyether ether ketone) but some others include Ultem because they possess both high thermal-resistant capabilities as well as high strength-to-weight ratio s.Production of lightweight yet strong aerospace components has also witnessed increased use of advanced composite materials such as carbon fiber-reinforced polymers.These cutting-edge materials enable the production of highly complex and customized parts leading to significant enhancement in performance or productivity within aerospace applications.

How do 3d printing processes differ when used for aerospace manufacturing?

Because of the demanding performance and safety standards expected in aerospace manufacturing, 3D printing processes tend to be different. In contrast to traditional 3D printing that may put a higher emphasis on cost and speed, aerospace applications concentrate on accuracy, soundness of material, and strength. Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are common techniques used for making high-resolution metal parts that are robust too. Furthermore, there are stringent post-processing steps such as machining, heat treatments, and rigorous testing which have to conform critical tolerances so that parts can be certified for use in aircrafts and spacecrafts. Through quality control processes like this one, each component is made capable of withstanding harsh conditions found in aerospace environments.

What are the typical manufacturing methods for 3d printing in aerospace?

An array of advanced techniques exists for 3D printing through aerospace manufacturing. Examples include.

- Direct Metal Laser Sintering (DMLS): This utilizes a laser to sinter powdered metal, layer by layer, so as to create complex and precise metal parts. DMLS is renowned for the production of durable components that can be in high stress environments.

- Electron Beam Melting (EBM): EBM makes use of an electron beam to melt and fuse metal powders. Among its benefits are fast build rates and the capability of making parts with high structural integrity which make it perfect for aerospace.

- Selective Laser Sintering (SLS): It uses a laser to selectively sinter powdered materials which include metals, polymers, and ceramics. The method is versatile and capable of producing intricate geometries.

All these processes enable creating high-quality and dependable product whose standards comply with those set within the aerospace industry.

How does 3d printing enable end-use parts production?

3D printing is a major enabling technology for the production of end-use parts that have significant benefits in terms of design flexibility, manufacturing efficiency and material performance. The initial advantage is that it allows for optimized, lightweight designs that improve performance without compromising strength because it can create complex geometries with less limitations as compared to traditional manufacturing methods. The second major advantage is that 3D printing reduces the number of components and assembly steps required in the production process, thus reducing costs and time to market. Finally, various advancements in material science have expanded the spectrum of high-performance materials available for 3D printing including metals, polymers, and composites suitable for aerospace applications requiring highly demanding qualities. These factors collectively make it possible to produce specific aerospace tailored high quality end-use parts which are reliable.

What tools are essential for optimizing the 3d printing process in aerospace manufacturing?

In aerospace manufacturing, a number of key tools and technologies must be considered in order to enhance the 3D printing process:

- Design Software: sophisticated computer-aided design (CAD) software for constructing complicated aerospace elements with accuracy. Applications such as Autodesk Fusion 360 and SolidWorks are capable of producing elaborate geometries or designs that have been optimized for weight reduction and costing.

- Simulation Software: crucial in predicting how 3D printed parts will perform under different loading conditions are simulation tools like ANSYS and Altair HyperWorks. These aids allow detection of design flaws and meeting all the requirements of the aerospace industry.

- Post-Processing Equipment: post-processing machines help produce finished 3D-printed articles complying with aviation standards. This may involve grinding, annealing or quality checks to meet stringent requirements of the components.

- Quality Assurance Systems: stringent quality assurance systems including in-situ monitoring or non-destructive testing (NDT) methods guarantee uniformity in production standards. The use of CT scanners or laser scanners helps in detecting any defects present in within these parts.

- Advanced Materials: the application of high-performance materials specifically adapted for 3D printing such as metal alloys used in aviation-can be critical. Tools and techniques that can create and qualify these materials are needed when making reliable products.

Together, they improve the design, manufacture, and finish phases thereby guaranteeing that any additive manufactured space based airplane components fulfill their prescribed performance specifications while maintaining safety levels at par.

Frequently Asked Questions (FAQs)

Q: What are the primary capabilities of 3D printing in the aerospace industry?

A: 3D printing in the aerospace industry offers numerous capabilities, including the ability to produce lightweight, complex geometries, reduce material waste, and manufacture prototypes quickly. The use of 3d printing and additive manufacturing technologies makes it possible to create parts that are optimized for performance and cost-efficiency.

Q: How is 3D printing used for prototyping and production in aerospace?

A: 3D printing can be used both for prototyping and production in aerospace by allowing engineers to rapidly design, test, and iterate on parts. It enables quicker turnaround times for prototypes and provides the flexibility to produce small batches of parts, which is ideal for specialized components for aerospace.

Q: What materials are commonly used in 3D printing for aerospace applications?

A: Materials for 3d printing in aerospace include a wide range of high-performance plastics, composites, and metals. Specifically, metal 3d printing uses materials like titanium, aluminum, and Inconel, which offer high strength-to-weight ratios and can withstand the harsh conditions encountered in aerospace environments.

Q: What are the advantages of 3D printing for an aerospace manufacturer?

A: The advantage of 3d printing for aerospace manufacturers includes reduced lead times, cost savings on materials and labor, and the ability to produce parts with complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. It also allows for quicker iteration and innovation.

Q: How can 3D-printed parts contribute to aerospace engineering?

A: 3D-printed parts contribute to aerospace engineering by enabling the creation of lightweight, durable components that meet stringent performance standards. The precision and customization offered by 3d printing solutions for aerospace help engineers address specific design challenges and improve overall aircraft performance.

Q: What role do manufacturing aids play in 3D printing aerospace components?

A: Manufacturing aids, including jigs and fixtures, play a critical role in 3D printing aerospace components by ensuring precision and repeatability during assembly and production processes. These aids can be quickly produced using 3d printers, providing flexibility and reducing downtime.

Q: How are industrial 3D printing systems like Stratasys 3D printers used in aerospace?

A: Industrial 3d printing systems like Stratasys 3D printers are used in aerospace for producing end-use parts, prototyping, and tooling. These printers are known for their reliability, accuracy, and range of compatible materials, making them ideal for complex aerospace applications.

Q: What are some of the key 3D printing applications in aerospace?

A: Key 3D printing applications in aerospace include the production of engine components, airframe parts, interior cabin components, and custom tools. The use of 3d printing allows for the efficient production of these specialized parts, enhancing overall manufacturing capabilities.

Q: How does the use of additive manufacturing technologies benefit the aerospace industry?

A: The use of additive manufacturing technologies benefits the aerospace industry by enabling the production of lighter, stronger, and more efficient parts. It allows for the creation of customized components and supports rapid prototyping, which accelerates the design and testing processes.

Q: Where can I learn more about 3D printing solutions for aerospace?

A: To learn more about 3d printing solutions for aerospace, you can explore educational resources, attend industry conferences, and consult with 3d printing services and providers specializing in aerospace applications. Many manufacturers and universities also offer courses and webinars on this topic.