3D printing is an evolving technology that exhibits a fantastic turnaround in powder bed fusion. In fact, it changes manufacturing and design across multiple industries through this process, which employs metal and polymer powders. This blog will explore the complexities of the powder bed fusion 3D printer, revealing how it works, its advantages, and various applications. These advanced printers can produce prototypes and be suitable for final products, thus enhancing efficiency in production and creating innovative solutions. Let’s discover together how these developments with powdered materials have changed the world regarding manufacturing.

How Does Powder Bed Fusion Work in 3D Printers?

Image source: https://medium.com/

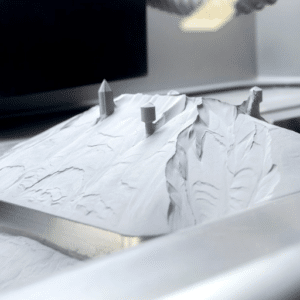

In powder bed fusion (PBF), a laser or electron beam heat source selectively fuses layers of powdered material. Initially, a thin layer of powder is spread across the build platform. The printer then scans and melts specific areas of the powder based on the 3D model. Then, another layer of powder is applied on top, and the build platform lowers one fused layer. After that, another cycle begins. This process continues until completion, when there is nothing more to grow it into shape. However, careful fabrication steps are needed as parts may still need modification by machining or surface treatment to meet the required specifications before they can be used.

What is Powder Bed Fusion 3D Printing?

Powder Bed Fusion (PBF) is an additive manufacturing category that entails the selective melting of powdered material to construct objects layer by layer. PBF uses a laser or an electron beam, for instance, SLS and EBM, respectively, as heat sources. A thin powder layer is spread across a build platform to begin the process. The heat source then targets chosen regions of the powder layer to bond particles together, thereby yielding solid parts. The succeeding layers of powder are applied and melted similarly, making it possible to produce complex shapes and designs that cannot be obtained in conventional manufacturing processes. Regarding prototyping and production parts, PBF is highly preferred in the aerospace, automotive, and medical industries due to its ability to create complicated forms with minimal wastage and high precision.

How Does Selective Laser Sintering (SLS) Operate?

Selective Laser Sintering (SLS) uses a powerful laser beam that combines tiny polymer particles into a solid structure. First, a thin layer of powder is distributed evenly on the build platform. Then, the laser selectively fuses some powder areas according to 3D model instructions. After a sintering cycle ends, another layer is deposited, molten, and sintered until an entire object takes shape. Powder that does not stick together is a support structure for complicated geometries, allowing them to be removed after the printing process terminates. Durable prototypes may be produced by SLS without requiring support material; hence, they are suitable for end-use components and prototypes used in different industries; otherwise, they would have been used by other means like injection molding.

What Are the Main Types of Powder Bed Fusion?

Some of the primary forms of Powder Bed Fusion (PBF) include Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Selective Laser Melting (SLM).

- Selective Laser Sintering (SLS): This method fuses polymer powder particles using a high-power laser. It is possible to make complex geometries without the need for support structures. It is mainly used for plastics.

- Direct Metal Laser Sintering (DMLS): This technique is similar to SLS, but it focuses on metals. In this technique, a laser sinters metal powder into solid parts. Industries requiring high strength-to-weight ratios, such as the aerospace and automotive sectors, greatly benefit from this technique.

- Selective Laser Melting (SLM): This method is also commonly confused with DMLS; however, in this case, the metal powder has to be fully melted to create denser and more substantial parts. The material’s mechanical qualities are crucial in the aerospace and medical fields, necessitating its use.

Each of these methods offers unique advantages depending on the materials employed and specific demands for final products.

What Materials are Used in Powder-Based 3D Printers?

The variety of materials used in powder-based 3D printers depends on the printing method. For example, Selective Laser Sintering (SLS) utilizes commonly applied materials like nylon (polyamide), polystyrene, or elastomers, thus creating both durable and flexible components. In most cases, Direct Metal Laser Sintering (DMLS) uses stainless steel, titanium, or aluminum powders, which are ideal for making high-performance devices. While Selective Laser Melting (SLM) employs metal powders, it frequently narrows down its focus on cobalt-chrome or Inconel, among others, where enhanced mechanical properties are required. Material choice significantly determines printed part strength, durability, and application compatibility.

Common Polymers in Powder 3D Printing

Polyamide (Nylon) is the most popular polymer used for powder-based 3D printing because of its well-known strength, flexibility, and resistance to abrasion. Polystyrene is another widespread polymer often chosen due to its ease of processing and cost-effectiveness. At the same time, elastomers are also in high demand primarily because of their rubber-like properties and elasticity. Moreover, there has been a growing reliance on polymer blends and composites such as nylon with carbon fiber or glass fiber to improve mechanical properties for specific applications. These materials come with many options based on specific needs related to diverse industry performance requirements.

Utilizing Metal Powder in 3D Printing

Metal powders are crucial in various 3D printing techniques like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). These methods employ small metal powders (usually 20 – 100 microns) to produce fine-detailed, durable components. Scanning involves melting powder layers via powerful lasers, which sinter particles without achieving the substrate material’s melting temperature. This enables intricate printout patterns that would have been difficult or impossible using traditional subtractive processes. Typical metals used in this process include titanium, aluminum, and stainless steel, among others selected based on their strong mechanical properties, lightweight, or corrosion resistance. Using metal powders for rapid prototyping and short-run manufacturing transforms industries such as aerospace, automotive, and medical sectors, resulting in lighter, more efficient designs explicitly made for narrow applications.

Optimal Material Properties for 3D Printing

Various properties are essential when considering materials for 3D printing to result in successful outcomes across different applications. To begin with, thermal stability is vital since such materials have to withstand high temperatures and be able to print without degradation. Secondly, mechanical strength is crucial in ensuring the final product can bear the intended loads and stresses. Printability is also critical; various materials should flow well when extruded or laid down, bonding correctly on preceding layers. Chemical resistance often decides whether particular materials are suitable for specific places, while flexibility or rigidity can be tuned to match requirements by different applications. Lastly, surface finish and resolution also matter, mainly if aesthetics or intricate details must be achieved within a functional part. Identifying materials exhibiting these characteristics can substantially improve the performance and functionality of 3D-printed components.

How to Optimize Workflow for Powder Bed Fusion 3D Printing?

For powder bed fusion 3D printing, these strategies can streamline workflow:

- Pre-Print Preparation: To prevent print failures, ensure the build platform is calibrated and leveled. Use software tools for optimal orientation and layout of parts to maximize build space and reduce support structures.

- Material Management: Maintain a controlled environment for powder handling to minimize contamination and moisture absorption. Consistently assess powder quality and behavior so continuity remains during printing steps.

- Process Parameters: Fine-tune parameters like laser power, scan speed, and layer thickness based on material specifications and geometry. Make test prints to help determine the right settings for desired mechanical properties.

- Post-Processing Efficiency: Implement effective cleaning and finishing processes. Consider using automated systems to remove excess powder and streamline post-print workflows.

- Data Monitoring: Use sensors and software to monitor printing conditions in real-time. Data collection helps identify issues promptly, allowing adjustments toward better print quality with less downtime.

Focusing on these areas can significantly enhance the efficiency, quality, and overall success of powder bed fusion 3D printing workflows.

Understanding the Powder Management System

For efficient powder bed fusion 3D printing, a robust powder management system is needed, directly affecting printing quality and efficiency. The principal areas to consider when designing a powder management system are as follows:

- Powder Storage: Proper sealing and storage of powders in controlled environments are necessary to avoid contamination or degradation. These environments may include vacuum-sealed containers or an inert gas atmosphere to preserve powder quality.

- Powder Recycling: Structured recycling processes allow unused powders to be reused while maintaining material integrity. Sieving, fluidizing, and other techniques can recover properties lost by recycled powders.

- Quality Control: Powder characteristics (particle size distribution, flowability, moisture content) must be regularly tested and monitored. Some advanced methods, like laser diffraction or image analysis, can help maintain consistency through real-time data collection.

Emphasizing these aspects can help manufacturers improve the reliability and efficacy of their powder bed fusion processes, ultimately resulting in enhanced print outcomes and reduced material wastage.

Navigating Post-Processing Techniques

Post-processing is essential in enhancing the mechanical properties and surface finish of printed parts during the entire powder bed fusion 3D printing workflow. The main post-processing techniques include:

- Thermal Treatment: Heat treatments such as annealing or stress relief annealing can release residual stresses, thereby improving material strength.

- Surface Finishing: Desired surface finishes are achieved through sandblasting, polishing, or chemical treatment, among other methods. This makes them more aesthetically appealing and enhances performance in particular application areas.

- Machining: There are instances when achieving tight tolerances and specific geometries that were impossible with the original print, which requires precision machining operations like milling or turning.

By introducing these post-processing approaches into their manufacturing process, manufacturers ensure that their Contact Powder Bed Fusion components meet all specification requirements and functional criteria, hence producing better end products.

Improving Print Speed and Throughput

Maximizing production efficiency in powder bed fusion 3D printing entails improving print speed and throughput. Some of the steps that can be used to achieve this include:

- Adjusting Layer Thickness: When layer thickness is optimized, printing time is significantly reduced. Though it may necessitate balancing speed with final part quality and detail, thicker layers allow faster deposition.

- Multi-Laser Systems: The use of multi-lasers increases throughput by allowing simultaneous processing in different areas of the build platform, which effectively distributes workloads and reduces printing times considerably.

- Optimized Scanning Strategies: Advanced scanning techniques can reduce the time spent on retraction moves to a minimum, enabling a continuous building process and improving overall speed.

- Material and Machine Upgrades: Manufacturers can enhance reliability and speed by investing in high-performance materials and state-of-the-art machines. New technologies usually come with upgraded cooling systems and faster processing rates.

This will enable manufacturers to improve efficiencies in their powder bed fusion processes, resulting in greater throughputs and shorter lead times.

What are the Benefits and Limitations of Powder 3D Printing?

3D printing using powders has many advantages, such as its ability to create complex geometries that are impossible through conventional manufacturing processes due to its design flexibility. Furthermore, only necessary materials are consumed; hence, little waste is produced, making it environmentally friendly. Moreover, it can be used with various types of material, including metals or plastics, making it applicable across industries like aerospace and automotive, among others.

However, there are some limitations involved. For instance, the initial setup costs for powder bed fusion systems could be substantial, while post-processing may also take a long before proper finishing is achieved. Additionally, depending on the materials selected and printing parameters chosen, the mechanical properties of printed parts might differ, causing inconsistencies within the quality output. Lastly, despite improved speeds compared to other methods in recent years, particularly for large-scale manufacturing purposes, its printing rate may remain slower than other alternatives when producing large numbers of parts.

Advantages of Using Powder Bed Fusion Technology

- High Precision and Detail: The accuracy and detail of powder bed fusion technology enables it to make highly detailed and complex geometries with high precision. This technology can be beneficial in sectors such as the aviation industry and health care, where there is a demand for intricate designs and tight tolerances.

- Choice of materials: The technology supports various types of materials, including metals, ceramics, and polymers, among others. The idea that different elements could be used in a single build enhances the produced parts’ functionality, making them suitable for certain engineering needs.

- Time-saving: When production processes are made more efficient through the powder bed fusion technique, new products can be launched quickly. Owing to rapid prototyping and iterations, manufacturers can often move quickly from concept to final product, implying that they keep up with fast-paced markets.

- Low material scrap: Powder bed fusion has low wastage as it uses only what is required for a particular part unlike traditional machining processes. This can also help save on costs by recycling unused powder for future prints, which aligns with sustainable manufacturing practices.

-

Tailored solutions: This technology offers several capabilities specific to custom designs that would be uneconomical when using conventional manufacturing techniques for addressing individual customer requirements.

Challenges in Powder-Based 3D Printing

Notwithstanding its myriad benefits, several issues must be resolved to facilitate the widespread application of powder bed fusion technology. Some of these include:

- Complexity in Process: The processes for the powder bed fusion systems are complicated, requiring expertise to handle such factors as temperature, layer thickness, and build orientation. If not controlled properly, this complexity may lead to variations in output quality.

- Limitations in Material: Although diverse materials are available, some cannot be applied in powder bed fusion, and difficulties are encountered during optimal result achievement. Additionally, their properties may change after processing, thereby affecting performance for critical applications.

- Equipment and Maintenance Costs: Powder bed fusion machines require substantial initial investments, and their maintenance costs tend to be high, discouraging small companies from adopting this technology. Due to financial impediments, this limits access by many interested users, especially in emerging markets.

These challenges underline the importance of further research and development to enhance the user-friendliness, cost-effectiveness, and flexibility of powder bed fusion processes/equipment for diverse applications.

Comparing Powder 3D Printing with Other 3D Printing Technologies

Several important differences exist between powder bed fusion and other 3D printing technologies, such as Fused Deposition Modeling (FDM) and Stereolithography (SLA).

FDM is popular due to its cost-effectiveness and ease of use, which means it can be used by hobbyists and educational institutions. Despite this, it generally has less accuracy and fewer mechanical properties compared to powder bed fusion. Because FDM relies on thermoplastic filaments, the range of materials and uses is limited compared to powder bed fusion’s metals or polymers.

On the other hand, Stereolithography (SLA) uses a light source to cure a liquid resin, resulting in high-resolution parts with smooth surfaces. However, post-processing is often needed for SLA parts, making them less durable than those produced through powder bed fusion. SLA is also limited in types of materials, predominantly using photopolymers, which might not cater to all industrial applications.

In contrast, the benefits provided by powder bed fusion technology include complex geometrical creation possibilities, intricate details, and a wide variety of constituent materials, including metals and advanced polymer processing. Despite the higher initial costs and technicality, it remains the favorite among industries requiring great precision and material performance. Thus, selecting these techniques will depend on ownership requirements like cost constraints or availability or preferred material features during production process scale-up.

What are the Most Popular Powder Bed Fusion 3D Printers?

On the one hand, some of the most famous powder bed fusion 3D printers are EOS Formiga P 110, well-known for its ability to print with a variety of polymer materials, and SLM Solutions SLM 280, widely known for its high-speed printing in metals. The 3D Systems ProX DMP 320 offers excellent precision for metal and plastic parts that serve various industrial applications. HP’s Metal Jet platform is rapidly gaining acceptance because of its efficacy in mass-producing metal parts. These printers are highly respected as they can create complicated shapes and possess highly impressive outputs, thus finding important roles in aerospace, automotive, and healthcare.

Top SLS 3D Printers Available in the Market

- EOS P 396: A large build volume and high speed are among the characteristics that make EOS P 396 capable of producing accurate functional pieces with good surface texture. This has made the device popular across industries such as automotive and aerospace, where it is used for prototyping purposes and low-volume manufacturing.

- Formlabs Fuse 1: The Formlabs Fuse is a small printer suitable for small to medium-sized businesses because of its compact size. Its user-friendly interface makes it easy to use while at the same time producing strong parts, which can be very useful in ideal scenarios like prototyping and small series production runs in consumer products or engineering sectors.

-

3D Systems SLS 350: It is tough enough to handle commercial needs, thereby making it an appropriate option when choosing between different types of equipment for selective laser sintering technology. It is also known for efficient process productivity and attracts many companies wishing to introduce SLS into their manufacturing workflow.

Evaluating Formlabs Fuse Series for SLS Printing

Formlabs Fuse Series particularly the Fuse 1 has a good balance between affordability and performance in the SLS 3D printing market. Fuse 1 takes an innovative approach to sintering; it uses a powerful laser to fuse powdered nylon and other thermoplastics, which results in solid and functional parts. They like the compact designs that make it suitable for small-sized offices, while integrated software simplifies its printing process, enabling easy management of print jobs. Post-processing accessibility is made easier through an optional Finish Kit for Fuse 1, resulting in high-quality surfaces after printing. Generally speaking, the Fuse Series is advisable for businesses seeking efficient, low-cost solutions without compromising part quality, especially in prototyping and low-volume production applications.

Best Powder Bed Fusion 3D Printer for Metal Powder

Based on current details from significant sources, three choices stand out as the best powder bed fusion 3D printers for metal powders:

- Desktop Metal Studio System: This system is well-known due to its convenient design and ability to be placed in offices. This machine’s proprietary Bound Metal Deposition (BMD) process lets complicated geometries be made of metal without requiring extensive industrial setups. Low waste with high-quality output make it an exciting choice for small or medium enterprises.

- GE Additive Arcam EBM Q20: It is favored because it can develop significant parts with excellent mechanical properties using electron beam melting technology that allows precise control over the melting procedure. Efficient handling of titanium and other advanced materials enhances its appeal to professionals. This printer proves highly reliable when industries require vital components such as aerospace and medical applications, which is why they prefer it. Its ability to effectively handle titanium, among other advanced materials, increases its attractiveness to professionals.

- SLM Solutions SLM 280: This printer’s advanced multi-laser technology can greatly increase productivity levels by speeding up print times while maintaining excellent finished part quality. It is particularly suited to the automotive and aerospace industries, which need to rapidly manufacture lightweight but strong components.

Each printer has its own strengths, addressing different requirements in metal 3D printing, such as prototyping, low-volume production, or complex part manufacturing.

Frequently Asked Questions (FAQs)

Q: What is Selective Laser Sintering (SLS) 3D Printing?

A: Selective Laser Sintering (SLS) 3D printing is a powder bed fusion process that uses a high-powered laser to sinter powdered material, typically nylon, into a solid structure. The laser selectively fuses powder, layer by layer, to build a 3D object.

Q: How does a Powder 3D Printer work?

A: In a powder 3D printer, a thin layer of powder is spread across the print bed. A laser then scans and selectively fuses the powder to create the 3D-printed parts. The process repeats layer by layer until the part is completed, with loose powder supporting the unfused regions.

Q: What are the advantages of using a Metal 3D Printer?

A: Metal 3D printers are advantageous for producing highly complex and customized metal parts, which are difficult or impossible to create using traditional methods like injection molding. They enable rapid product development and are ideal for manufacturing prototypes and end-use parts.

Q: What are the common 3D Printing Materials used in SLS 3D printing?

A: Common materials for SLS 3D printing include nylon, TPU, polypropylene, and specialized engineering-grade powders. These materials offer mechanical properties suitable for prototypes, batch production, and end-use parts.

Q: How does Laser Powder Bed Fusion differ from other types of 3D Printing?

A: Laser powder bed fusion, like in SLS and metal 3D printers, uses a laser to sinter or melt powder material, creating highly detailed and durable parts layer by layer. This contrasts with FFF 3D printing, which utilizes a thermoplastic filament extruded through a nozzle. Powder-based methods often produce parts with superior mechanical properties and complexity.

Q: What are the specific features of a 30W SLS Printer?

A: A 30W SLS printer typically features a 30-watt laser, which balances speed and detail in the sintering process. These printers can efficiently handle various powder materials to produce finely detailed, durable parts ideal for prototypes and small-batch production.

Q: Why is unsintered powder essential in the SLS 3D printing process?

A: Unsintered powder in SLS 3D printing supports the part being printed. It surrounds and supports the fused layers, eliminating the need for additional support structures and enabling the creation of complex geometries.

Q: What role does Formlabs’ Selective Laser Sintering 3D Printer play in product development?

A: Formlabs’ selective laser sintering 3D printers are widely used in product development because they rapidly produce functional prototypes and end-use parts. They provide high precision and consistent results essential for iterative design and testing in various industries.

Q: How does spreading a thin layer of powder across the print bed affect the final product?

A: Spreading a thin layer of powder across the print bed ensures uniformity and consistency in the build process. This crucial step influences the precision of the laser fusion, impacting the overall quality and dimensional accuracy of the 3d printed parts.

Q: What are the benefits of using a powder-based 3D Printing system for batch production?

A: Powder-based 3D printing systems are highly efficient for batch production because they can print many parts concurrently within a single build cycle. This is particularly useful for creating complex parts in large quantities, reducing time and costs compared to traditional manufacturing methods.