This paper will discuss how the 3D printing has transformed different industries by enabling production of complex objects with a level of accuracy and efficiency that was unattainable before. The gantry system is an essential part of most 3D printers and it guides the movement of their tool heads or robotic arms. This mechanism, which is often made up of rails, belts, and motors, ensures accurate positioning and stable functioning, parameters that are indispensable in producing high-quality printouts.

In this blog post we shall be going into detail about the gantry system, its components like mechanics and how it contributes to various applications in 3D printing. From compact desktop printers to expansive industrial setups, understanding the gantry system provides valuable insights into the capabilities and limitations of various 3D printing technologies. We shall look at how this mechanism amplifies precision as well as speed plus flexibility therefore allowing for additive manufacturing on a large scale resulting to innovation across many sectors. Let us share some few details of engineering wonders behind gantry systems that defines future of three Dimensional Printing through explaining its significance on next generation products.

What is a Gantry System and How Does it Work in 3D Printing?

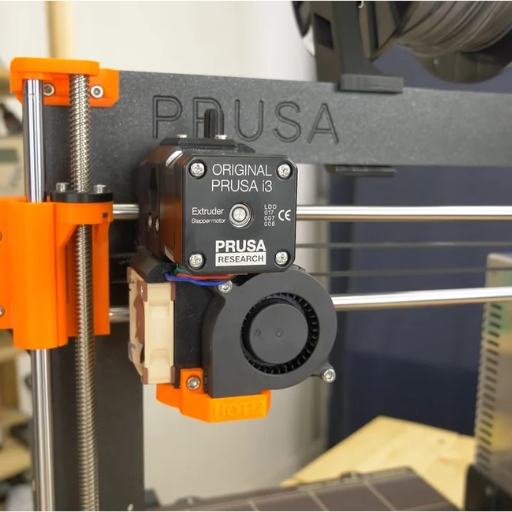

Image source: https://all3dp.com/

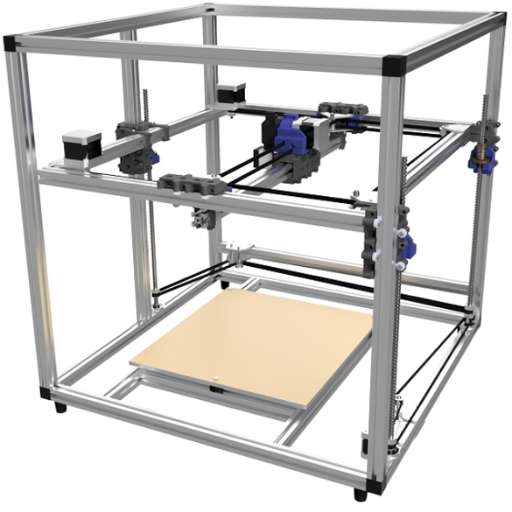

A system of overhead beams in 3D printing is a mechanical structure that prescribes the motion of either the printer’s tool head or a robotic arm along the print area. Most often it will have rails, straps, and motors that work together to control the position of the tool head on X, Y and sometimes Z axes. The rails provide a stable path for movement; belts carry force from motors to the tool head, while precision drives all this assembly by motors. This unified device allows depositing or solidifying material layer by layer with extreme accuracy which makes it possible to manufacture intricate and accurate 3D objects. The gantry system takes charge of smooth and precise movements thereby influencing the quality and dependability of three dimensional printed parts.

Basics of Gantry Systems

It is important to note that gantry systems in 3D printing play a crucial role in ensuring accuracy and repeatability during the manufacturing process. Such systems are basically made up of a set of linear rails and several motors that determine the movement of the print head along the X, Y and sometimes Z axes. This is what allows them to offer great precision on the parts produced, thus making it easy for them to design complex designs and produce small details with ease. The performance of gantry systems can also be enhanced through integration of advanced control software as well as feedback mechanisms, which allow printers to compensate for slight deviations thereby maintaining consistent quality over long print jobs. Furthermore, the choice between aluminum or steel materials for constructing these rails and support structures boosts their overall rigidity and stability hence preventing vibrations or other mechanical stresses from distorting the final prints. Gantry systems optimize motion while preserving structural integrity; they are thus central to modern 3D printers’ functionality and efficiency.

Role of Gantry Systems in 3D Printers

The significance of the gantry system on 3D printers lies in the fact that it determines the accuracy, speed and dependability of the printing process. These systems operate by moving print heads along multiple axes, thus ensuring precision in layer deposition. It is possible to move a print head very precisely and repeatedly using high quality linear rails with powerful stepper or servo motors that contribute to overall print accuracy. Advanced control software supplements these systems and helps them to adapt to minor changes during printing so as to maintain uniformity in outputs. The materials used for constructing the gantry system like aluminum or steel are very strong and help minimize vibrations which can affect the quality of prints. Therefore, this makes gantry system an important aspect of modern 3D printers efficiency and effectiveness.

Gantry vs. Cartesian Systems

In 3D printers, both gantry and Cartesian systems are used to control the print head’s movement. However, they are different in their design and how they operate. In this case, the Cartesian system is based on three linear axes (X, Y and Z) each equipped with own motor and rail. This arrangement is typically less complex and more cost-effective hence widely utilized for many 3D printers.

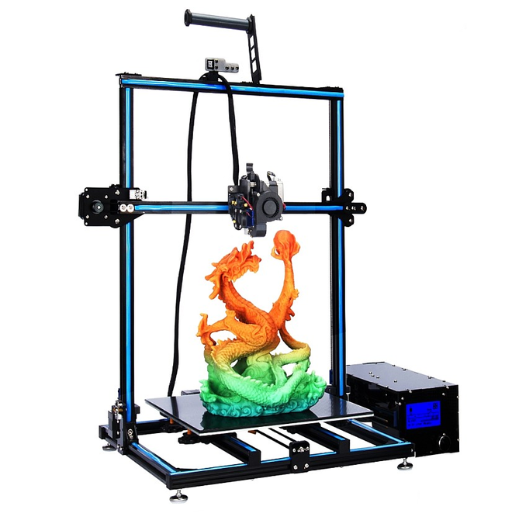

On the contrary, gantry systems offer improved stability and higher precision resulting from its stiff configuration. Gantry system has a suspended print head that moves along beams parallel to the print bed. Such design reduces the deflection and vibrations affecting print quality thus it suits high-precision applications. Moreover, in most cases gantry systems have large printing volumes as well as capability to bear heavier loads enhancing their versatility.

To sum up, while Cartesian systems tend to be less complicated than other kinds of set ups in most 3D prints, gantry models yield better results for accuracy as well as stability making them relevant for more demanding or industrialized printing jobs.

Why are Gantry Systems Essential for Large Scale 3D Printing?

The main reasons why gantry systems are important for larger-scale 3D printing are that they are more rigid and capable of controlling a larger volume. By the way, gantry systems have stronger structures that can resist bending and vibrations during large prints. They have greater weight-bearing capabilities, which allow them to yield large components with more intricate features hence making them indispensable within the industrial sphere where precision, stability, and expansion must come together.

Advantages in Build Volume

Gantry systems possess considerable advantages in build volume due to their inflexible and fixed design that allows for bigger prints with high accuracy. As shown by some of the top sources, gantry systems reduce deflection and vibration in order to accommodate larger print sizes. Therefore, large-scale projects tend to rely on stability of this kind because it brings about higher print quality as well as dimensional accuracy. Furthermore, wider underpinning frameworks in printers using gantries support heavier loads and provide access to complex geometries rendering them more suitable for industrial scale operations.

Precision and Stability

Gantry systems, which are known for their strong architectural design, are the best at ensuring accuracy and stability in 3D printing. Gantry systems have a rigid structure that eliminates any deflections and vibrations thereby undermining print accuracy as stated by leading sources. As such, even complicated geometries can keep the required dimensions and details. In addition, gantry positioning system guarantees that each layer is stacked uniformly throughout the build process to ensure structural integrity of a printed object. The use of gantries in motion control means that they have excellent stability compared to other types of printers, making them very reliable for industrial applications requiring high precision and large-scale products printing.

Applications in Large Scale Manufacturing

The incorporation of precise yet intricate designs in huge build volumes has made gantry systems gain popularity as the heart of many large scale manufacturing activities. According to major industry sources, these machines have found prominence in aerospace because they create light structural parts through complex structures with minimal wastage of materials. The automotive sector benefits from gantries’ use in 3D printers for rapid prototyping and production of vehicle parts hence reducing time taken to develop new products as well as costs involved. Furthermore, the construction industry is using on-site building component 3D printing provided by gantrysystems which boosts productivity while minimizing labor expenses. Therefore, this flexibility and accuracy are what make it necessary for developing large scale manufacturing using gantry systems.

What Are the Key Components of a 3D Printer Gantry System?

3D printer gantry system’s core building blocks include:

- Rails and Carriages: They provide the paths for linear motion and guarantee smoothness and accuracy of movements made by the print head.

- Stepper Motors: Responsible for ensuring precise movement along Z, Y, and X axes.

- Belts and Pulleys: These components take up motional energy from the motors to the rails and carriages that allows for accurate positioning.

- Control Board: This is the mind of the whole system; it interprets commands from software to run motors and all other elements.

- Print Head (Extruder): This prints layer by layer of matrix material under control of gantry system.

- Frame: The moving parts’ support is maintained by this rigid structure necessary to keep everything intact.

Parts of the Gantry: Rails, Motors, and Carriages

Rails

Stepper motors are fundamental to the functionality of a 3D printer gantry system, as they control the movement along the X, Y, and Z axes. These motors convert electrical pulses into precise mechanical movements, allowing for accurate positioning and smooth transitions. By adjusting the frequency of the pulses, the speed and acceleration of the motors can be finely tuned, enabling intricate and detailed prints. The reliability and precision of stepper motors make them ideally suited for gantry systems in 3D printing.

Motors

Stepper motors are vital components in a 3D printer gantry system since they direct movement along X, Y and Z axes. By converting electrical pulses into precise mechanical movements, these motors ensure accurate positioning and smooth transitions. Fine-tuning speeds and accelerations of motors can be done through varying pulse frequencies which allows for intricate prints with details on them. Accordingly, stepper motors are suitable for use in 3D printing gantry systems due to their dependability and high precision levels.

Carriages

The print head is kept on track by carriages fixed to the rails. When printing, carriages must smoothly move and hold onto the print head tightly thereby avoiding any interruptions. Carriages are commonly equipped with low friction bearings or wheels to enable them easily roll along the tracks. Moreover, carriage designs help in reducing vibrational effects that may interfere with the printer’s quality of printing by ensuring that the print head remains accurately aligned with respect to its bed.

A gantry system for 3D printers has such key components as rails, motors and carriages which results in a high level of precision as well as efficiency necessary for complex manufacturing tasks.

How the Extruder and Filament System Work Together

The extruder and filament system in a 3D printer are crucial for the actual production of the printed object. While it stands to be a substance needed for printing (usually plastics), the material is put into the extruder. The extruder comprises gear that pushes filament in a heated nozzle. When passing through this nozzle, filament gets melted due to its high temperature. The molten material is then deposited onto the print bed very precisely, layer upon another one. The motion of the extruder is carefully managed so that each layer sticks properly to the preceding ones. This process goes on until finally three-dimensional objects are completely formed as desired. Coordinating between the filament feed and how well does it match with movements of an extruder leads to high quality and accurate prints.

Importance of the Z-Axis in Gantry Systems

In gantry systems, Z-axis plays an important role in defining vertical positioning and layer resolution for a 3D printout.A print head or bed can move up or down along this axis thereby allowing addition of materials in numerous layers which is necessary for making three-dimentional objects. An accurate movement along Z-axis ensures that every next layer deposits at correct height thus maintaining completeness and accuracy of printing work. Moreover, a well-calibrated Z-axis assists to make printed object’s surface smoother and reduces chances for defecting structures; which could affect significantly on quality of resultant product.

What Are the Challenges and Limitations of Gantry 3D Printing?

Gantry 3D printing is useful because it is precise and available to many people, but it has some challenges and limitations. One of the major difficulties is the size of build volume which depends on gantry system’s dimensions. Besides, keeping axes precisely calibrated is important because slight deviations may result into printing defects or failures. Also speed of printing is a limitation since it takes long times producing large or complex objects due to layer-by-layer approach. Moreover, material constraints restrict certain materials from being used in gantry 3D printers. Lastly, the printer’s reliability can be affected by mechanical wear and hardware malfunctions over time resulting in increased maintenance costs.

Structural Limitations and Rigidity

In gantry 3D printing, there are structural limitations and rigidity concerns. Accuracy and precision in printed objects require a stable and rigid frame. Frame stiffness variations make vibrations and oscillations during print process that can negatively affect print quality. In addition, sagging or misalignment due to weight of print head as well as moving components over time results to cumulative errors for layer deposition. Thus, such issues are minimized by having a rigidly designed gantry system which helps enhance the overall reliability plus performance of the printer as a whole. However, achieving such rigidity often involves high manufacturing costs and complex assembly processes limiting both makers and manufacturers by this factor too.

Precision and Tolerance Issues

Gantry 3D printing relies heavily on precision and tolerance, which determine the quality and accuracy of the final product. One common source of inaccurate prints is poor resolutions that are related with stepper motors as well as control systems in this type of printers. Errors as small as slight deviations from a straight line can accumulate over large heights resulting in significant errors from the intended dimension. Besides, gantry 3D printer’s tolerance also depends on its components such as rails, belts and bearings. High accuracy parts can reduce these deviations but they increase the cost of the machine overall. Additionally, thermal expansion during printing due to material properties or uneven calibration worsens print tolerances resulting into warping or layer misalignment. For that reason maintenance must be routine so that such problems cannot happen leading to consistent quality prints.

Common Mechanical Failures and Solutions

Typical mechanical issues seen in gantry 3D printers are belt slippages, layer shifting and nozzle clogs . Quite often belt slippage occurs due to worn-out or under tensioned belts which may be fixed by inspecting them regularly tightening them when necessary or replacing totally . Layer shifting usually emanates from loose components like pulleys or motor mounts being not aligned properly . This problem can be avoided simply by securing all parts firmly and periodic verification of proper alignment . In most instances nozzle clogs arise because of debris accumulating inside the hotend or filament blockage caused by excessive heat applied on it. Such incidences can be greatly curtailed through cleaning nozzles frequently and using high-quality filaments only The useof a filament filter will go a long way in keeping impurities out ofthe nozzle itself . Regular service routines coupled with proper care for components like these however will improve significantly the overall efficiency and dependability of gantry 3D printers.

How Can You Optimize Your Gantry System for Better 3D Prints?

To enhance your 3D prints, you can optimize the gantry system by first checking if the frame is rigid and stable enough to reduce vibrations. The moving parts should be lubricated on a regular basis to ensure that they are not worn out and also check for wear on belts and bearings. Precisely calibrate your printer, including bed leveling and nozzle alignment, to avoid misprints. For improved reliability, upgrade to high-quality components like precision belts and stepper motors. Moreover, fine-tune your print settings while maximizing the use of advanced slicing software so as to improve the layer height, print speed and extrusion rates among others. These practices will make your 3D prints more accurate and effective.

Parameter Tuning for High Precision

To enhance your 3D prints, you can optimize the gantry system by first checking if the frame is rigid and stable enough to reduce vibrations. The moving parts should be lubricated on a regular basis to ensure that they are not worn out and also check for wear on belts and bearings. Precisely calibrate your printer, including bed leveling and nozzle alignment, to avoid misprints. For improved reliability, upgrade to high-quality components like precision belts and stepper motors. Moreover, fine-tune your print settings while maximizing the use of advanced slicing software so as to improve the layer height, print speed and extrusion rates among others. These practices will make your 3D prints more accurate and effective.

Maintenance Tips for Longevity

These crucial maintenance tips will help ensure your 3D printer lasts as long as possible. Start by trying to remove any excess filament and keep the print bed clean so that future prints can adhere well. Sometimes, you may need to use cleaning tools to inspect or clean the nozzle and hotend for clogs, perform a cold pull if necessary. For instance, you can apply lubricants suitable for friction reduction and wear on any moving components such as rods and bearings. Plus, don’t fail to check for loose screws which should be tightened to prevent the printer’s frame from being degraded. The latest s/w just makes it more advanced with enhanced features and improvements; hence it becomes another point of attraction for buyers.. Finally, ensure that filament is stored properly in a moisture free environment.

Software and Firmware Upgrades

A little attention paid to regular software and firmware updates ensures optimum functionality of your 3D printer. Ensure that your slicer software is updated since these modifications are regularly linked with enhancements on printing speed or quality or compatibility with new types of filaments. Consult the manufacturer’s website for firmware upgrades pertaining to your model as these might add some functionalities, solve some bugs or even increase the stability of this device. Be careful following their installation instructions ensuring that there are no interruptions in the operation of Your Printer’. Having both software and firmware up-to-date helps maximize the potential of a 3D printer thereby maintaining its ability to produce high-quality prints at all times.

Frequently Asked Questions (FAQs)

Q: What is a gantry system in 3D printing?

A: A gantry system in 3D printing is a motion system that uses rails and stepper motors to move a print head or extruder along the X, Y, and Z axes to fabricate 3D printed parts. This allows for precise control over the position and movement of the hot end and print bed.

Q: How does a gantry system differ from a robotic arm in 3D printers?

A: A gantry system uses a fixed frame and moves the extruder along linear paths, whereas a robotic arm has multiple degrees of freedom and can move in various planes. Gantry systems for 3D printing are typically more rigid and precise, suitable for standard extrusion methods, whereas robotic arms are often used for more complex, multi-axis fabrication tasks.

Q: What are the key components of a gantry system?

A: Key components of a gantry system include stepper motors, linear rails, pulleys, and belts. It also comprises the hot end, print bed, and the extruder assembly that moves along the X, Y, and Z axes to create the model from the STL files.

Q: Can gantry systems achieve the same level of precision as CNC machines?

A: While both gantry systems and CNC machines use stepper motors and linear motion to achieve precision, CNC machines typically have a robustness and build quality designed for cutting and milling, allowing for extremely precise outcomes. Gantry printers are more focused on additive manufacturing and might not always match the precision of high-end CNC machines.

Q: What kinds of materials can be used with gantry-based 3D printers?

A: Gantry-based 3D printers can use a variety of materials, including PLA, ABS, PETG, and more specialized filaments. The choice of material depends on the specific application and the specification of the print bed and hot end to handle different extrusion temperatures and speeds.

Q: How does a gantry system maintain precision during the printing process?

A: Precision in a gantry system is maintained through the use of stepper motors, which provide exact positioning, and rigid linear rails that prevent flexing. The combined motion system ensures that the extruder head moves along the X, Y, and Z axes accurately, producing precise 3D printed parts.

Q: Are gantry systems suitable for large-scale additive manufacturing?

A: Yes, gantry systems are quite adaptable and are used in large-scale additive manufacturing. Their modular design and scalability make it easy to construct bigger machines, suitable for large parts or numerous smaller parts in the same build volume.

Q: What is the role of the z-axis in a gantry system?

A: The z-axis in a gantry system allows for vertical motion, raising and lowering the print bed or the extruder. This is crucial for building up layers in additive manufacturing, enabling the system to fabricate taller objects by depositing material layer by layer.

Q: What advantages do gantry systems for 3D printing offer over other systems?

A: Gantry systems for 3D printing offer several advantages including ease of assembly, scalability, and excellent precision. The simple yet effective design supports a wide range of 3D printing methods and materials, making it suitable for hobbyists and professionals alike.