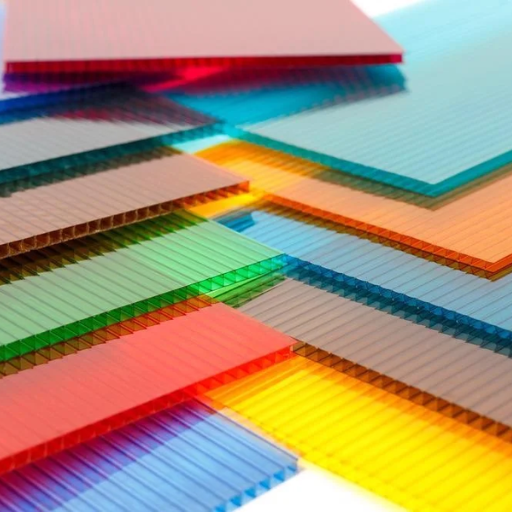

Comparing Polycarbonate vs. Polyethylene: Which Plastic Reigns Supreme?

The universe of plastics is dominated by these two materials, polycarbonate and polyethylene. These two types of plastic are different from each other in a number of ways including their properties which make them versatile enough for use in many applications that range from household objects to industrial parts. The objective of this blog post […]

Comparing Polycarbonate vs. Polyethylene: Which Plastic Reigns Supreme? Read More »